Today’s post is a highly technical article discussing the issues of phone screen lamination and screen materials. Those engaged in this field of English translation can pay more attention to the relevant terms and basic principles involved. The technology in the internet and technology industry is constantly evolving, and as language service professionals, it is essential to maintain a keen awareness of new technologies and to have a proper understanding of the principles behind them.

For more English translation content related to technology and the internet, you can reply with “Internet Translation” to the Yijiang public account dialog box. You are also welcome to participate in our interpretation training course themed on technology and the internet (click to learn more), which is packed with useful information.

The competition among smartphone manufacturers has become increasingly fierce, and many companies hope to highlight their products through hardware differentiation. New terms such as IPS, SLCD, Retina, and ClearBlack keep emerging, and often new technical terms are born before we fully understand the previous technologies. In the past two years, several smartphone manufacturers have begun to use the technology of “full lamination” (also known as non-airgap) to enhance the selling points of their phones.

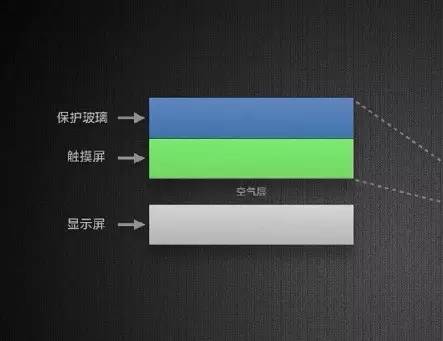

Structure of the Screen

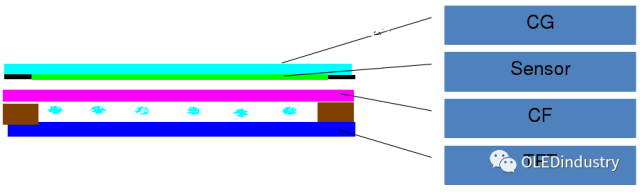

From the structure of the screen, we can roughly divide it into three parts: from top to bottom, they are the protective glass, touch screen, and display screen. These three parts need to be laminated together, generally requiring two lamination processes: one between the protective glass and the touch screen, and another between the display screen and the touch screen.

The familiar screen protector is the lamination between the protective glass and the protective film, done by the screen protector technician, but in principle, it also emphasizes the technique of lamination, hahaha.

Screen lamination can be divided into two types based on the lamination method: full lamination and frame lamination.

Frame Lamination

Frame lamination, also known as edge tape lamination, is a simple method that uses double-sided tape to fix the edges of the touch screen and the display screen. This is the lamination method used by most displays today. Its advantages are a simple process and low cost, but the presence of an air layer between the display screen and the touch screen leads to significant degradation of the display effect, which is the biggest drawback of frame lamination.

Full Lamination

Full lamination means that the panel and touch screen are completely bonded together without any gaps using water glue or optical glue. Compared to frame lamination, it provides a better display effect. Currently, the common full lamination screens in the market are mainly the OGS solutions led by the original touch screen manufacturers, as well as the On Cell and In Cell technology solutions led by panel manufacturers.

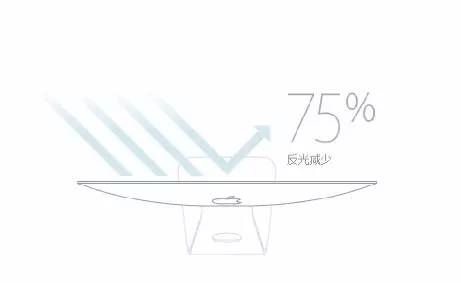

The advantages of full lamination: this technology eliminates the air gap between the screen, which helps reduce reflections between the display panel and glass, making the screen look more transparent and enhancing the display effect.

Using full lamination technology, the iMac can reduce reflections by 75%.

Another benefit of full lamination technology is that screens will no longer accumulate dust. The touch module, due to its close bonding with the panel, also experiences an increase in strength. Additionally, full lamination can more effectively reduce the interference of noise from the display panel on the touch signal. Although the advantages of full lamination are significant, the yield rate (the ratio of sellable products to produced products) is relatively low. The waste of surface glass and even panels during the lamination process due to poor yield will inevitably lead to increased costs. Therefore, controlling the defoaming and lamination yield becomes a more important factor than material costs.

Full Lamination InCell, OnCell, and OGS Screen Technologies

During the production process of a phone screen, it is necessary to perform two lamination processes on the protective glass, touch screen, and display screen. If frame lamination is used, the display effect will be significantly reduced, while adopting full lamination presents another challenge in yield rates.

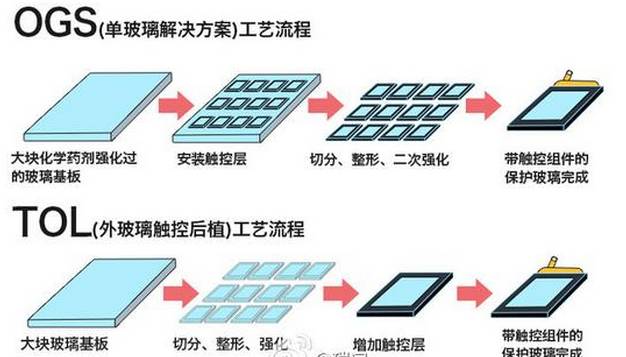

Each lamination process the protective glass, touch screen, and display screen go through reduces the yield rate. If the number of lamination processes can be reduced, it will undoubtedly improve the yield rate of full lamination. Currently, several development directions have emerged: the OGS/TOL solutions led by the original touch screen manufacturers, as well as the On Cell and In Cell technology solutions led by panel manufacturers.

Currently, more capable display panel manufacturers tend to promote On-Cell or In-Cell solutions, mainly because they have the production capacity for display screens and prefer to create the touch layer on the display screen. On the other hand, touch module manufacturers or upstream material manufacturers tend to favor OGS, which creates the touch layer on the protective glass, mainly due to their strong manufacturing capabilities and technology.

Both approaches can reduce the number of lamination processes, thus saving costs and improving the yield rate of lamination. Additionally, with one less touch layer, material costs can also be saved, achieving a thinner design.

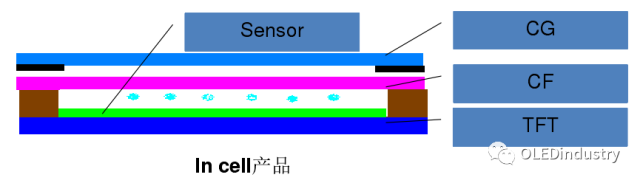

This refers to the technology that integrates the touch panel function into the liquid crystal pixels, meaning that the touch sensor function is embedded within the display screen. Therefore, the original three layers of protective glass, touch screen, and display screen are reduced to two layers: protective glass and display screen with touch functionality, making the screen thinner. This technology is primarily developed by panel manufacturers and has a relatively high barrier to entry.

In Cell Technology Screen Layers: The In-Cell screen consists of a top layer of glass bonded to the LCD layer (the touch screen is on the LCD layer), totaling 2 layers.

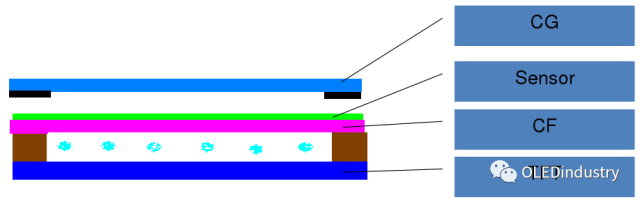

On-Cell Technology

On-Cell refers to the method of embedding the touch screen between the color filter substrate and the polarizer of the display screen, meaning that the touch sensor is integrated onto the liquid crystal panel. Compared to In-Cell technology, it is less complex.

On Cell is commonly used in Samsung AMOLED panel products, but it has yet to overcome issues related to thinness and color uniformity during touch.

On Cell Technology Screen Layers: consists of a top layer of glass bonded to the touch screen and LCD layer, totaling 3 layers.

OGS technology integrates the touch screen with the protective glass, coating the inner side of the protective glass with a conductive layer, allowing for direct coating and photolithography on the protective glass. This saves a piece of glass and one lamination process, allowing the touch screen to be thinner and cheaper.

TOL refers to the small piece process of OGS, meaning that after toughening the white glass, it undergoes the border BM and functional electrode processes. Products made through this method generally have higher strength than those made through large piece processes of OGS, but due to lower process efficiency, the cost is higher. Many domestic mobile brands have adopted OGS technology. However, OGS still faces challenges regarding strength and processing costs, which need to be enhanced through secondary strengthening.

OGS Technology Screen Layers: consists of an OGS layer bonded to the LCD layer, totaling 2 layers.

GG, PG, GF, G1F, GF2, GFF, etc. all require two lamination processes, are relatively thick, and have low yield rates.

Screen Transparency: OGS is the best, followed by In-Cell and On-Cell, with GFF being the worst.

Thinness: In-Cell is the lightest and thinnest, which is one reason why phones like the iPhone and P7 can be relatively light and thin. OGS and On-Cell follow, with GFF being the worst.

Screen Strength: GFF > On-Cell > OGS > In-Cell.

Touch Sensitivity: Strictly speaking, OGS has better touch sensitivity than On-Cell/In-Cell, but touch sensitivity also relates to the optimization of the phone’s system, such as the iPhone using In-Cell technology, which has a much better touch experience than many Android phones.

Cost and Technical Difficulty: In-Cell/On-Cell technologies are more complex and costly, followed by OGS/TOL, while GFF has the lowest cost and technical difficulty, so it is mostly used in budget phones.

Fundamentals of Screen Imaging

If previous mobile phones had various elements and combinations of buttons, today’s smartphones seem to have only a screen at first glance. We operate through this screen and view information on it. As the overall performance of smartphones improves, they are no longer just devices for calls; therefore, the importance of the screen is increasingly highlighted. Videos, images, games—the screen bears a lot of content, which is why when purchasing a smartphone, we consider the screen as one of the factors.

However, how much do we really know about screens? When a phone is released, we mainly care about the screen size and resolution, but do you really think that screen size and resolution can determine everything? In terms of screens, among those letters that make our heads spin, which represent screen materials and which represent panel technologies? In fact, our misunderstandings about screens run deeper than we might imagine.

Analysis of Phone Screen Materials/Technologies

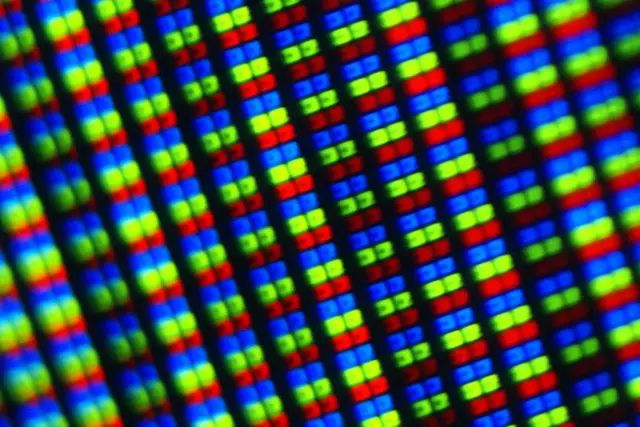

For a phone screen to display the text and images we see, it requires the three primary colors: R (red), G (green), and B (blue). Each pixel on the screen consists of a complete arrangement of three RGB sub-pixels, and every color on the screen can be recorded and expressed by a set of RGB values, with each RGB component’s intensity ranging from 0 to 255. By mixing these three colors in different proportions, we can present all the colors we see.

Pixels display everything we see (image source: orlandobarrozo)

As mentioned earlier, RGB has 256 levels of brightness, represented by numbers ranging from 0 to 255, with 0 being one of the brightness values. Therefore, the total brightness value sums up to 256 levels. The 256 levels of RGB colors can combine to produce approximately 16.78 million colors, which is why we often see parameters such as 16 million colors written in phone screen specifications. These sub-pixels are at their weakest brightness at level 0 and at their brightest at level 255. When the RGB values are the same, the result is a colorless grayscale; when all RGB values are 255, it becomes the brightest white, and when all are 0, it becomes black.

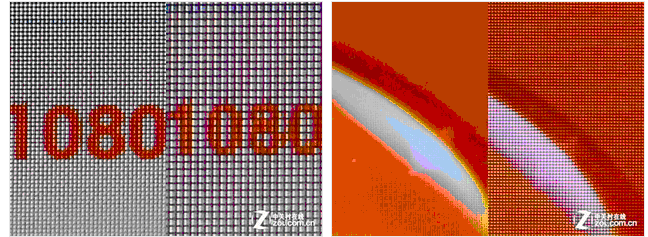

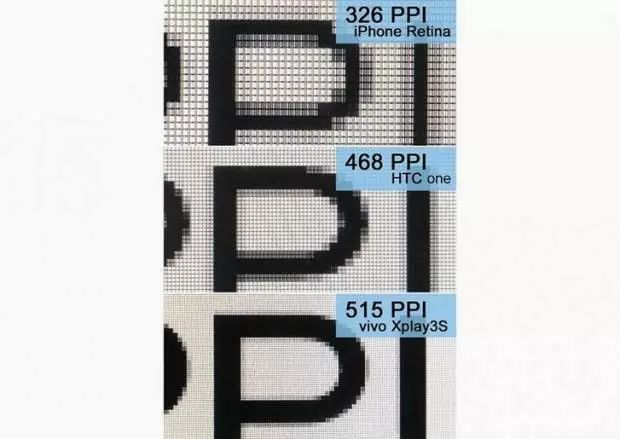

Comparison images of 441ppi and 326ppi, where the left side shows that 441ppi is noticeably finer and smoother

As we have experienced a rise in screen resolution, this also means that with the development of technology and the passage of time, screens of the same size can have more pixel counts. We use ppi to represent pixel density, which indicates how many pixels are contained in one inch.

When smartphones first entered the 1080p era, we compared the world’s first 1080p model, the HTC Butterfly, with the iPhone 5. By photographing the screens with a macro lens and zooming in, we could clearly see that the 441ppi HTC Butterfly appeared finer than the 326ppi iPhone 5. From a visual perspective, this means that there is no graininess when viewing the screen, and the overall visual effect is smoother. Of course, as today’s phone screens upgrade to 2K levels, the fineness of the screens has further improved, but whether our eyes can truly perceive the difference is hard to say.

Of course, at this point, you will realize how one-sided it is to judge a phone’s screen quality based solely on screen size and resolution. These little RGB dots are fundamental, but they are just part of the screen; screen materials and technologies also determine the final display effect you see.

Currently, mainstream smartphone screens can be divided into two categories: LCD (Liquid Crystal Display) and OLED (Organic Light Emitting Diode). First, let’s look at LCD.

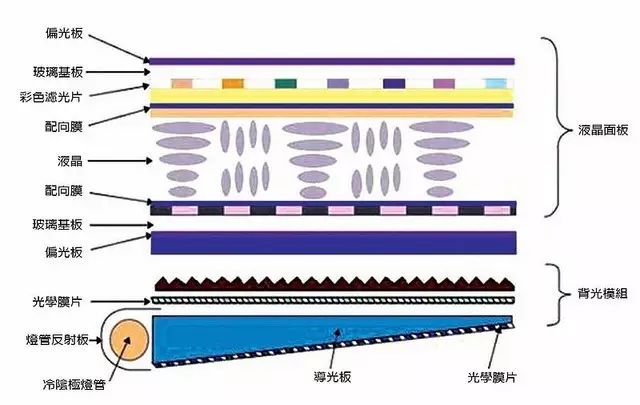

Basic structure of LCD (image source: wiki)

LCD requires backlighting for display, and the light must pass through two layers of glass, substrates, and various optical films, alignment films, and color filters, inevitably causing some loss in brightness and color. The term TFT stands for Thin-Film Transistor, which is widely used in electronic devices. In LCDs, a thin film is deposited on the glass substrate to act as a channel area, improving image quality through thin-film transistor technology.

The upper glass substrate of a TFT-LCD is adjacent to the color filter, while the lower glass substrate is embedded with transistors. When an electric current passes through the transistors, it creates changes in the electric field, causing the liquid crystal molecules to tilt, thereby altering the polarization of light. The polarizers then determine the brightness of the pixels. The color filter bonded to the upper glass forms the RGB colors contained in each pixel, which constitutes the colors and images displayed on our screens.

After briefly discussing LCD, let’s look at the types of liquid crystal panels or panel technologies. LCDs can be divided into passive matrix drive and active matrix drive. The passive matrix drive includes TN and STN, while the active matrix drive includes TN, IPS, VA, and OCB. In today’s smartphone market, TN and IPS are considered the mainstream technologies, while VA is more commonly used in television products.

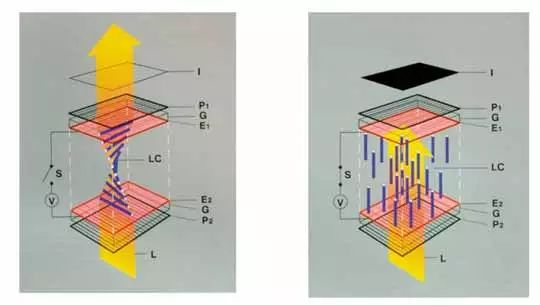

TN screen diagram (image source: wiki)

TN stands for Twisted Nematic, which has been widely used since the invention of liquid crystal technology and occupies a dominant position in electronic devices. Many users now equate TN screens with TFT screens, which is a conceptual misunderstanding. Due to the mature production technology and low cost of TN screens, they are still favored by some low-cost smartphones. In addition, TN screens have a higher opening rate and consume less power at the same brightness, with a response time of 8-15ms, which is quite fast. Therefore, despite the drawbacks of narrow viewing angles and color distortion, TN screens have not faded from the smartphone market.

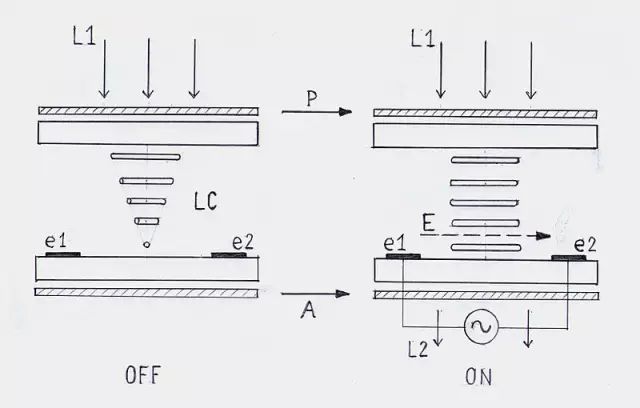

IPS screen diagram (image source: wiki)

IPS screen diagram (image source: wiki)

IPS stands for In-Plane Switching, a wide viewing angle technology launched in 1996 that effectively improves the color difference issues and narrow viewing angles seen in TN screens. In IPS liquid crystals, the electrodes and liquid crystals are in the same plane, allowing for a 178-degree viewing angle from above, below, and both sides, greatly improving the issues present in TN screens. However, IPS screens are not without their drawbacks. They consume more power and do not show significant improvements in other aspects besides viewing angles, and their response time is slower, so they also have their pros and cons.

In 1998, Hitachi launched S-IPS, which improved response times in addition to the original IPS technology. In 1999, LG-Philips joined the IPS camp as a joint venture, and after declaring bankruptcy in 2006, the IPS business was mainly managed by LG Display.

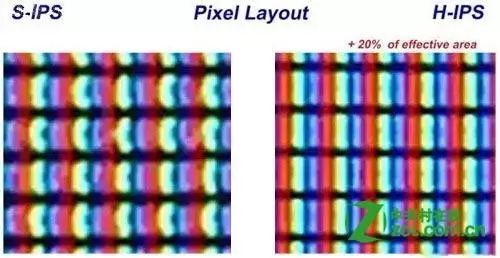

H-IPS improved upon S-IPS

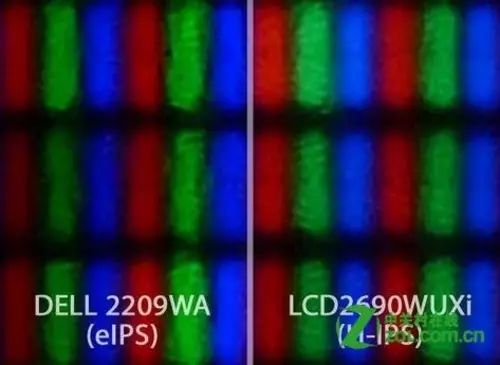

E-IPS is the economical version of H-IPS

During this period, Hitachi launched the AS-IPS screen in 2002, making significant improvements in brightness and darkness ratios. In the same year, Hitachi also introduced the IPS-POR screen and specifically categorized it into H-IPS, S-IPS, and E-IPS. H-IPS (Horizontal IPS) is distinguished by its straight pixel arrangement, with each pixel forming a straight line from top to bottom, and smaller electrode widths than before. H-IPS slightly improves contrast and color performance compared to S-IPS, making it a relatively high-end product at a higher price, while S-IPS offers good cost-performance at a lower price. E-IPS is considered the economical version of H-IPS, with slightly inferior contrast and color performance compared to H-IPS, achieving a color gamut of 72%, reduced opening rate, and improved viewing angles, making wide viewing angles one of the few advantages of E-IPS.

Later, LG Display, which took on the responsibility of IPS, launched AH-IPS in 2012, which significantly improved color, contrast, and energy consumption, further enhancing the user’s visual experience.

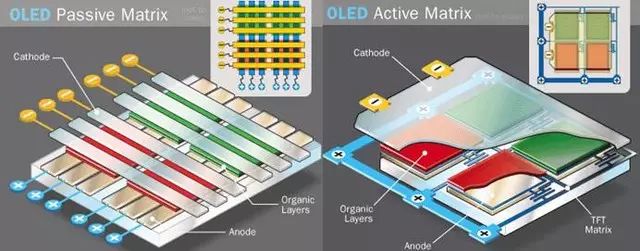

Having briefly covered LCD, let’s now talk about OLED. OLED stands for Organic Light-Emitting Diode, and unlike the previously mentioned TFT-LCD, OLED does not require backlighting and has self-luminous properties, along with advantages such as wide viewing angles, high contrast, low power consumption, high response rates, and simple processing. OLED can be divided into passive OLED (PMOLED) and active OLED (AMOLED) based on the driving method.

PMOLED and AMOLED (image source: vankaizer)

If OLED can be equated with LCD, PMOLED is like the STN LCD that has faded from the market. PMOLED is not suitable for displaying dynamic images, has a slower response time, and while it is more power-efficient, it has limitations in size. For today’s smartphone users, being confined to a 5-inch low-resolution PMOLED is clearly not appealing and cannot meet user needs. If PMOLED is made larger, it will require increasing the brightness of each pixel to maintain overall panel brightness, which in turn raises the operating current and reduces lifespan.

Thus, the OLED screens we generally encounter are mostly AMOLED screens, which are a type of OLED. Just as we say IPS is a type of TFT-LCD, AMOLED is not limited to smartphones; it is also used in television products from Samsung and LG, so there is no distinction between OLED used in televisions and AMOLED used in small and medium-sized screens.

AMOLED stands for Active-matrix organic light-emitting diode, which refers to the pixel addressing technology behind it.

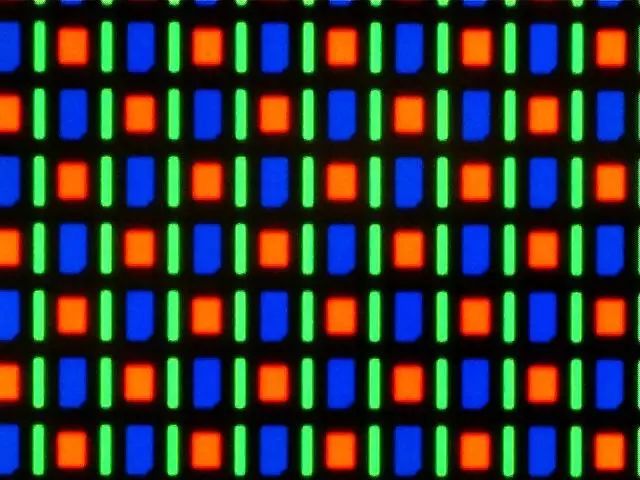

Pentile arrangement used in Nexus One (image source: wiki)

AMOLED displays emit light from OLED matrix molecules that have been electrically excited, storing or integrating light in TFTs to control the flow of current to each pixel, with at least two TFTs controlling the continuous current for each pixel. TFT backplane technology is crucial for AMOLED; both polysilicon and amorphous silicon have been applied to AMOLED.

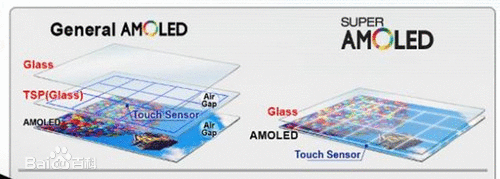

In terms of advantages, AMOLED has self-luminous properties, wide viewing angles, high contrast, and high response rates. It also has a higher refresh rate than PMOLED, significantly reducing energy consumption. However, under direct sunlight, the readability of AMOLED is not very good. Therefore, Samsung’s Super AMOLED reduces the gap between the screen layers to achieve better visibility in bright sunlight.

Comparison of traditional MOLED and Super AMOLED (image source: Baidu)

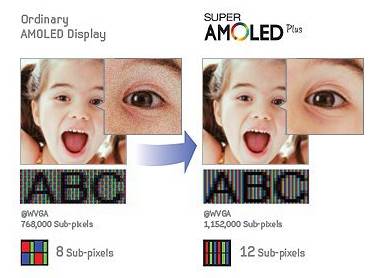

Comparison of traditional AMOLED display effects and Super AMOLED Plus (image source: CNET)

Super AMOLED touch is operated directly on the panel without the need for an air layer. Compared to traditional AMOLED, Super AMOLED has a brighter screen that reduces sunlight reflection and lowers power consumption, marking a significant improvement over traditional AMOLED. Subsequently, Samsung has launched Super AMOLED PLUS, HD Super AMOLED, HD Super AMOLED PLUS, Full HD Super AMOLED, and Quarter HD Super AMOLED, each with improved resolution and enhanced display effects.

Edited by Yijiang, with materials from: Electronic Materials Circle, OLEDindustry, etc.

Translation Study Society (click or reply with the keywords below to the Yijiang public account to access the topic)

Technology and Internet Translation (click to register for the live course)

Interpretation Skills

North American Interpretation Study Tour

Fashion Translation

Automotive Translation

Medical Translation

Court Translation

Financial Translation

Translation Technology