CoolPlayExperimentLabWorksOriginally published on WeChat account Cool Play LabWeChat ID: coollabsRecently, NASA announced that it has collaborated with scientists from Ohio State University to create the most elastic superalloy to date, GRX-810.How impressive is this alloy? In harsh working environments of 1,093°C and 20 MPa (197 times atmospheric pressure),the current top nickel-based alloy material, AM718, typically experiences slow material plastic deformation and fracture after just 10 hours. Other alloys last only a few dozen hours at most.

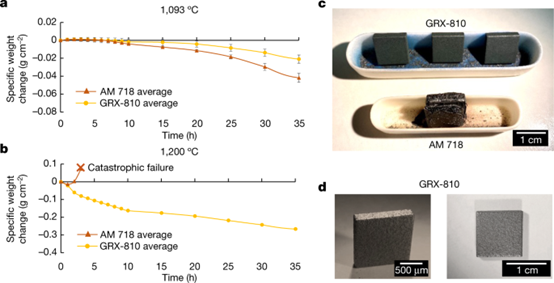

CoolPlayExperimentLabWorksOriginally published on WeChat account Cool Play LabWeChat ID: coollabsRecently, NASA announced that it has collaborated with scientists from Ohio State University to create the most elastic superalloy to date, GRX-810.How impressive is this alloy? In harsh working environments of 1,093°C and 20 MPa (197 times atmospheric pressure),the current top nickel-based alloy material, AM718, typically experiences slow material plastic deformation and fracture after just 10 hours. Other alloys last only a few dozen hours at most. However, GRX-810 is completely different; it takes2,800 hours just to bend it by 1%, and it takes6,500 hours to cause it to fracture, highlighting itsdurability.Additionally, the superalloy GRX-810, due to the doping of Y2O3, has doubled its strength compared to other alloys and increased its ductility by twofold. Under1,093°C high-temperature conditions, its oxidation resistance is twice that of superalloy 718, and it can withstand temperatures of1,200°C.

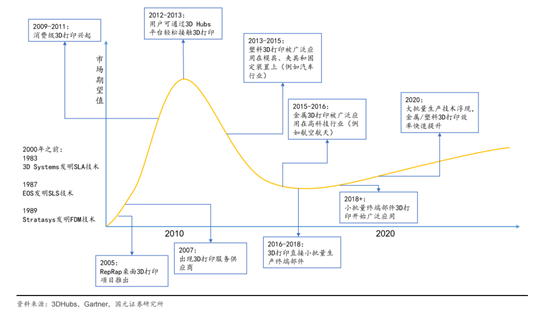

However, GRX-810 is completely different; it takes2,800 hours just to bend it by 1%, and it takes6,500 hours to cause it to fracture, highlighting itsdurability.Additionally, the superalloy GRX-810, due to the doping of Y2O3, has doubled its strength compared to other alloys and increased its ductility by twofold. Under1,093°C high-temperature conditions, its oxidation resistance is twice that of superalloy 718, and it can withstand temperatures of1,200°C. What does this mean? Are we one step closer to creating Iron Man’s suit?Of course, we certainly won’t use such high-end materials to make toys like Iron Man’s suit. Just like its sponsor NASA’s main business, this superalloy will primarily be applied in the aerospace field, especially in high-temperature and high-pressure components.The manufacturing process of this superalloy is not through other methods, but through 3D printing, which is often seen on Bilibili.However, unlike other common types of 3D printing based on resin and other materials, this belongs to a relatively unfamiliar type of 3D printing—metal powder bed 3D printing.Today, let’s talk about 3D printing and its high-end, yet lesser-known aspects.01Many people have dreamed of 3D printing technology since childhood. We pile up a bunch of sand and use magic to shape it into an extraordinary weapon, becoming the best in the world. This kind of childish fantasy isn’t just mine, right? Hahaha.Now science has realized this magic, but the hands that shape the sand are not human hands, but machines. And this technology is the3D printing technology that can print everything in the future.Many people have a very vague understanding of 3D printing, thinking that it is just about printing resin figurines or various toys. Manufacturing alloys for spacecraft is beyond 3D printing.But you underestimate 3D printing; today’s 3D printing is not comparable to the 3D printing of the past. Since 1984, after two patent abandonments, 3D printing technology has officially become a patent and has undergone 40 years of development.If 3D printing had only this level of development, you would be underestimating the creativity of the world’s strongest minds.3D printing technology is now also known as additive manufacturing technology because every point it produces adds material, rather than reducing material like subtractive machining.Last year, the gun used to assassinate Abe was 3D printed by the assassin at home.If this were in ancient times, according to Japanese tradition, it would have to be given a name like “XX Cut”.

What does this mean? Are we one step closer to creating Iron Man’s suit?Of course, we certainly won’t use such high-end materials to make toys like Iron Man’s suit. Just like its sponsor NASA’s main business, this superalloy will primarily be applied in the aerospace field, especially in high-temperature and high-pressure components.The manufacturing process of this superalloy is not through other methods, but through 3D printing, which is often seen on Bilibili.However, unlike other common types of 3D printing based on resin and other materials, this belongs to a relatively unfamiliar type of 3D printing—metal powder bed 3D printing.Today, let’s talk about 3D printing and its high-end, yet lesser-known aspects.01Many people have dreamed of 3D printing technology since childhood. We pile up a bunch of sand and use magic to shape it into an extraordinary weapon, becoming the best in the world. This kind of childish fantasy isn’t just mine, right? Hahaha.Now science has realized this magic, but the hands that shape the sand are not human hands, but machines. And this technology is the3D printing technology that can print everything in the future.Many people have a very vague understanding of 3D printing, thinking that it is just about printing resin figurines or various toys. Manufacturing alloys for spacecraft is beyond 3D printing.But you underestimate 3D printing; today’s 3D printing is not comparable to the 3D printing of the past. Since 1984, after two patent abandonments, 3D printing technology has officially become a patent and has undergone 40 years of development.If 3D printing had only this level of development, you would be underestimating the creativity of the world’s strongest minds.3D printing technology is now also known as additive manufacturing technology because every point it produces adds material, rather than reducing material like subtractive machining.Last year, the gun used to assassinate Abe was 3D printed by the assassin at home.If this were in ancient times, according to Japanese tradition, it would have to be given a name like “XX Cut”. Has this already subverted your understanding?Let’s talk about a “Russian joke”; there have long been rumors that due to a broken production line, some small parts of the MiG-31 fighter jet had no manufacturers, and the military couldn’t set up a production line. To solve this, Russia held some competitions to see how to repair and improve the supply chain for related parts.How was it finally solved?Alexey, the chief designer at the Nizhny Novgorod “Eagle” aircraft manufacturing plant,spent 2,000 yuan to buy a 3D printer from China to quickly solve the 3D printing problem for the MiG-31 fighter jet.Note!!! This channel does not guarantee the authenticity of this joke!!!So as a crystallization of 40 years of human wisdom, I want to tell you a secret: according to the website of the Chinese Society of Mechanical Engineering,3D printing can be divided into seven different types of additive manufacturing technologies based on the forming method.First, there are two types of 3D printing technologies that you often see in various entertainment videos:1. Additive manufacturing based on photopolymerization technology: The main material is photosensitive resin. Its manufacturing method is simple; it focuses light on specific parts of the photosensitive resin and other materials, allowing the resin to cure and form. After that, the area of light curing is changed, and the next layer of material is cured. The classic photopolymerization technology is SLA stereolithography technology.

Has this already subverted your understanding?Let’s talk about a “Russian joke”; there have long been rumors that due to a broken production line, some small parts of the MiG-31 fighter jet had no manufacturers, and the military couldn’t set up a production line. To solve this, Russia held some competitions to see how to repair and improve the supply chain for related parts.How was it finally solved?Alexey, the chief designer at the Nizhny Novgorod “Eagle” aircraft manufacturing plant,spent 2,000 yuan to buy a 3D printer from China to quickly solve the 3D printing problem for the MiG-31 fighter jet.Note!!! This channel does not guarantee the authenticity of this joke!!!So as a crystallization of 40 years of human wisdom, I want to tell you a secret: according to the website of the Chinese Society of Mechanical Engineering,3D printing can be divided into seven different types of additive manufacturing technologies based on the forming method.First, there are two types of 3D printing technologies that you often see in various entertainment videos:1. Additive manufacturing based on photopolymerization technology: The main material is photosensitive resin. Its manufacturing method is simple; it focuses light on specific parts of the photosensitive resin and other materials, allowing the resin to cure and form. After that, the area of light curing is changed, and the next layer of material is cured. The classic photopolymerization technology is SLA stereolithography technology. 2. FDM, Fused Deposition Modeling: This type of 3D printing is even more common than SLA,which uses melted resin, plastic, and other materials to layer and stack the required items, then waits for them to cure. I believe many of you have seen various creators using this type of 3D printer to make their own little gadgets.

2. FDM, Fused Deposition Modeling: This type of 3D printing is even more common than SLA,which uses melted resin, plastic, and other materials to layer and stack the required items, then waits for them to cure. I believe many of you have seen various creators using this type of 3D printer to make their own little gadgets. Next, the following five types of 3D printing are likely unfamiliar to most people:1. Powder bed fusion additive manufacturing technology based on sintering and melting powders:This technology is also known as powder bed fusion (PBF) process, which is the manufacturing process for the superalloy mentioned at the beginning of this article. The core is to use melted powder that cools to form a 3D printed solid shape.There are three main technical paths: SLS: Selective Laser Sintering, SLM: Selective Laser Melting, and EBM: Electron Beam Melting.

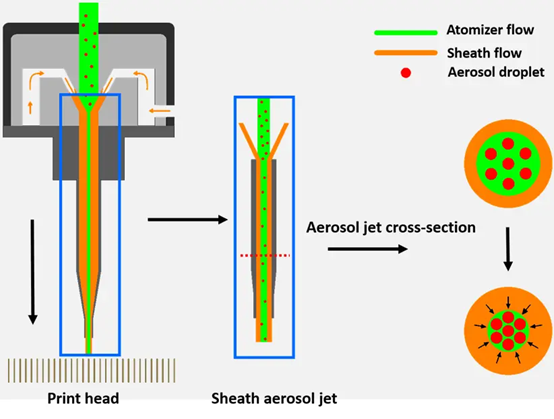

Next, the following five types of 3D printing are likely unfamiliar to most people:1. Powder bed fusion additive manufacturing technology based on sintering and melting powders:This technology is also known as powder bed fusion (PBF) process, which is the manufacturing process for the superalloy mentioned at the beginning of this article. The core is to use melted powder that cools to form a 3D printed solid shape.There are three main technical paths: SLS: Selective Laser Sintering, SLM: Selective Laser Melting, and EBM: Electron Beam Melting. 2. Additive manufacturing technology based on powder-binder principles:This manufacturing principle is similar to the previously mentioned powder bed fusion 3D printing, but it chooses to use a binder to bond the powder instead of melting it.If the bonded powder is metal, the entire material will undergo a sintering process to form.3. Additive manufacturing based on aerosol printing technology: This is a type of 3D printing material generally used for new material films and high-performance electronic and biological devices. It mainly uses a narrow aerosol jet carrying metal nanoparticle ink, achieving micro-manufacturing of precision devices at a micro-scale.

2. Additive manufacturing technology based on powder-binder principles:This manufacturing principle is similar to the previously mentioned powder bed fusion 3D printing, but it chooses to use a binder to bond the powder instead of melting it.If the bonded powder is metal, the entire material will undergo a sintering process to form.3. Additive manufacturing based on aerosol printing technology: This is a type of 3D printing material generally used for new material films and high-performance electronic and biological devices. It mainly uses a narrow aerosol jet carrying metal nanoparticle ink, achieving micro-manufacturing of precision devices at a micro-scale. 4. Layered manufacturing based on sheet fusion: This is quite simple; it uses sheets of paper, plastic films, etc., which are ultrasonically welded, brazed, bonded, or chemically stacked and laminated together to form a three-dimensional shape.5. Cell 3D printing based on rapid prototyping technology and biological manufacturing technology: These mainly use cells as raw materials, referencing the tissue morphology of biological organisms, and install cells bit by bit to form simple living tissue structures, such as skin, muscle, and blood vessels.These five technical paths each have their own characteristics, but which one can revolutionize current and future industrial production?It must be the ability to print metals, manufacturingJ-20 and Long March 5 national treasures, and creating the superalloy mentioned earlier through powder bed fusion additive manufacturing technology. 02In many real manufacturing scenarios, there are many parts that may encounter difficulties in demolding and cutting due to the complexity of their internal structures, such as hollow blades of an engine with an integrated structure. In such cases, the best choice for manufacturers is to usemetal 3D printing technology.

4. Layered manufacturing based on sheet fusion: This is quite simple; it uses sheets of paper, plastic films, etc., which are ultrasonically welded, brazed, bonded, or chemically stacked and laminated together to form a three-dimensional shape.5. Cell 3D printing based on rapid prototyping technology and biological manufacturing technology: These mainly use cells as raw materials, referencing the tissue morphology of biological organisms, and install cells bit by bit to form simple living tissue structures, such as skin, muscle, and blood vessels.These five technical paths each have their own characteristics, but which one can revolutionize current and future industrial production?It must be the ability to print metals, manufacturingJ-20 and Long March 5 national treasures, and creating the superalloy mentioned earlier through powder bed fusion additive manufacturing technology. 02In many real manufacturing scenarios, there are many parts that may encounter difficulties in demolding and cutting due to the complexity of their internal structures, such as hollow blades of an engine with an integrated structure. In such cases, the best choice for manufacturers is to usemetal 3D printing technology. The initial form of metal 3D printing technology is SLS, or Selective Laser Sintering. This technology is quite interesting. Its core is simple: it uses a high-power laser source to selectively melt the powder and bond it into a finished product:First, a thin layer of powder material, usually thermoplastic or metal powder mixed with other thermoplastic powders, is evenly spread on the platform.Then, a high-power laser scans the surface of the powder bed, selectively outlining various patterns based on the 3D model, melting low-melting-point materials like plastic. The melted binder naturally bonds with the other unmelted powder, forming a specific pattern.In the third step, after melting each layer of the part, the build platform will lower slightly based on calculations, and a new layer of powder material will be spread on top of the previous layer.After that, the printer will repeat this process, scanning layer by layer until the object is completed.The final step is to remove the finished product from the powder bed, and then polish, grind, or dye the object to bring it to life.

The initial form of metal 3D printing technology is SLS, or Selective Laser Sintering. This technology is quite interesting. Its core is simple: it uses a high-power laser source to selectively melt the powder and bond it into a finished product:First, a thin layer of powder material, usually thermoplastic or metal powder mixed with other thermoplastic powders, is evenly spread on the platform.Then, a high-power laser scans the surface of the powder bed, selectively outlining various patterns based on the 3D model, melting low-melting-point materials like plastic. The melted binder naturally bonds with the other unmelted powder, forming a specific pattern.In the third step, after melting each layer of the part, the build platform will lower slightly based on calculations, and a new layer of powder material will be spread on top of the previous layer.After that, the printer will repeat this process, scanning layer by layer until the object is completed.The final step is to remove the finished product from the powder bed, and then polish, grind, or dye the object to bring it to life. Doesn’t this have a beautiful feeling of gathering sand into a tower?This powder-based laser 3D printing equipment generally has a printing speed of only a few to dozens of millimeters per hour, but the entire process is very precise, with typical SLS printing accuracy reaching 0.2 millimeters.However, it has a problem,its internal connections rely on melted binders, and the strength cannot be compared to forged metals.So what to do?There is a Russian saying: A steel rod sweeps away all obstacles; if it meets resistance, it thickens the rod.Since lasers cannot currently melt metals, we can increase the power to allow the laser to melt metals.This is the most important technology in industrial 3D metal additive manufacturing today,SLM.

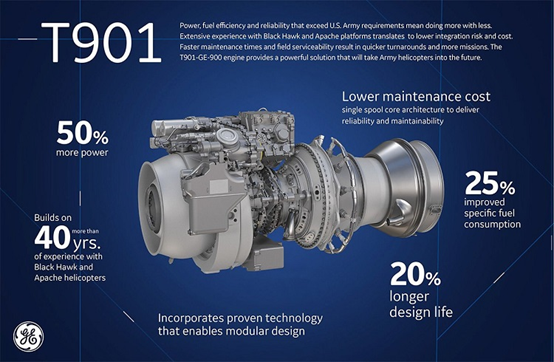

Doesn’t this have a beautiful feeling of gathering sand into a tower?This powder-based laser 3D printing equipment generally has a printing speed of only a few to dozens of millimeters per hour, but the entire process is very precise, with typical SLS printing accuracy reaching 0.2 millimeters.However, it has a problem,its internal connections rely on melted binders, and the strength cannot be compared to forged metals.So what to do?There is a Russian saying: A steel rod sweeps away all obstacles; if it meets resistance, it thickens the rod.Since lasers cannot currently melt metals, we can increase the power to allow the laser to melt metals.This is the most important technology in industrial 3D metal additive manufacturing today,SLM. SLM stands for Selective Laser Melting, which directly melts specific areas of metal, allowing for the free manufacturing of various uniquely shaped parts, such as hollow turbofan blades essential for some advanced engine models.But more importantly, its ability to form integrated parts brings potential disruptive capabilities to many advanced industries.How disruptive is this capability? For example, in October 2017, GE conducted prototype testing of its fifth-generation turboshaft engine, the T901-GE-900. This engine uses a large number of 3D printed components, and compared to traditional designs, the overall weight of the engine was reduced by about20%. This means that the thrust-to-weight ratio of the engine was increased by25%, which is almost equivalent to enhancing the engine’s performance by a generation.

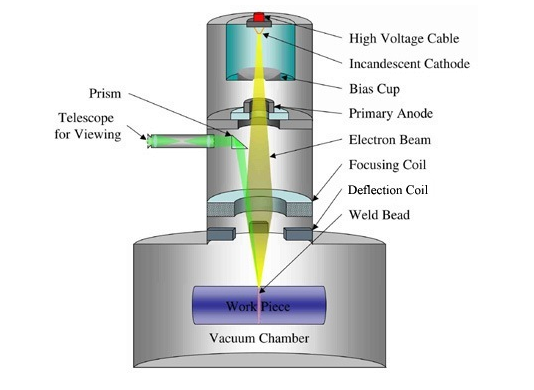

SLM stands for Selective Laser Melting, which directly melts specific areas of metal, allowing for the free manufacturing of various uniquely shaped parts, such as hollow turbofan blades essential for some advanced engine models.But more importantly, its ability to form integrated parts brings potential disruptive capabilities to many advanced industries.How disruptive is this capability? For example, in October 2017, GE conducted prototype testing of its fifth-generation turboshaft engine, the T901-GE-900. This engine uses a large number of 3D printed components, and compared to traditional designs, the overall weight of the engine was reduced by about20%. This means that the thrust-to-weight ratio of the engine was increased by25%, which is almost equivalent to enhancing the engine’s performance by a generation. Not only that, among the series of 3D printed parts, one part, if manufactured using traditional methods, would requiremore than 50 subcomponents to be assembled through welding and bolting. However, using 3D printing, this part can be formed integrally, completely eliminating the complex supply chain of traditional manufacturing methods.This is also significant because the 3D printed parts not only reduce costs but also lower the inventory and delivery cycles for enterprises. Moreover, direct forming also reduces the performance losses that may occur during forging, welding, and other manufacturing processes, improving the yield and mechanical properties of the final structural components.This means that when humans travel through space, we can only bring a pile of powder and a few printers, rather than a whole production line for colonization. At that time, if something is missing or something breaks, we can directly print it on the spot. We won’t have to wait for support from Earth, right?The last form of PBF isElectron Beam Melting technology,EBM.This technology is even more powerful; its core uses a high-energy electron beam focused to produce high-density energy, causing the scanned metal powder layer to reach high temperatures, resulting in the melting of metal particles. After the metal solidifies, it connects to form linear and planar metal layers.

Not only that, among the series of 3D printed parts, one part, if manufactured using traditional methods, would requiremore than 50 subcomponents to be assembled through welding and bolting. However, using 3D printing, this part can be formed integrally, completely eliminating the complex supply chain of traditional manufacturing methods.This is also significant because the 3D printed parts not only reduce costs but also lower the inventory and delivery cycles for enterprises. Moreover, direct forming also reduces the performance losses that may occur during forging, welding, and other manufacturing processes, improving the yield and mechanical properties of the final structural components.This means that when humans travel through space, we can only bring a pile of powder and a few printers, rather than a whole production line for colonization. At that time, if something is missing or something breaks, we can directly print it on the spot. We won’t have to wait for support from Earth, right?The last form of PBF isElectron Beam Melting technology,EBM.This technology is even more powerful; its core uses a high-energy electron beam focused to produce high-density energy, causing the scanned metal powder layer to reach high temperatures, resulting in the melting of metal particles. After the metal solidifies, it connects to form linear and planar metal layers. Wow, this is like amini particle accelerator.However, EBM is not easy to use; first, it needs to be in a vacuum to operate, and the usage and maintenance costs are high; secondly, the printing process generates X-rays, so for most people, EBM is a radiation hazard.Although the United States has already used EBM to manufacture engine blades, includingLeap and GE9X.

Wow, this is like amini particle accelerator.However, EBM is not easy to use; first, it needs to be in a vacuum to operate, and the usage and maintenance costs are high; secondly, the printing process generates X-rays, so for most people, EBM is a radiation hazard.Although the United States has already used EBM to manufacture engine blades, includingLeap and GE9X. In most cases, the most widely used powder bed forming technologies in industrial applications are still laser-based 3D printing technologies SLS and SLM.03So, does laser 3D printing have any weaknesses?Of course, there are some,first, the strength of an alloy produced using laser 3D printing technology can exceed the strength of that alloy when cast, but it still falls short compared to the same alloy that has been forged.I believe many of you have seen knife forging competitions. In those competitions, whether stacking large horses or three blades, mechanical stamping and hand hammering are crucial for the strength of forged knives.This is because forging is a processing method that applies pressure to metal blanks to induce plastic deformation, obtaining forged parts with certain mechanical properties, shapes, and dimensions. The core purpose is to change the microstructure of the metal using external force to eliminate defects such as porosity that occur during smelting and optimize the microstructure.3D printing itself does not involve such microstructure modifications; it merely involves the crystallization process after melting the metal. This means that 3D printing cannot replace forged parts in many critical areas, such as the main load-bearing components of the Y-20.Moreover, 3D printed parts are generally integrated structures, such as a complete engine combustion chamber or a complete hollow blade. If you want to add a round of forging for strength at this point, it will ruin the entire formed part, causing it to deform or flatten.Secondly, the batch manufacturing capability of 3D printing is still relatively low.In traditional industries, whether for forged or cast parts, each method can form a scale effect through assembly lines. As additive manufacturing, after investing fixed costs, the scale effect of 3D printing is not strong because each part is printed point by point.

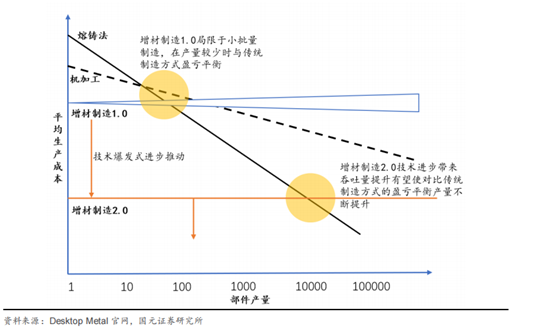

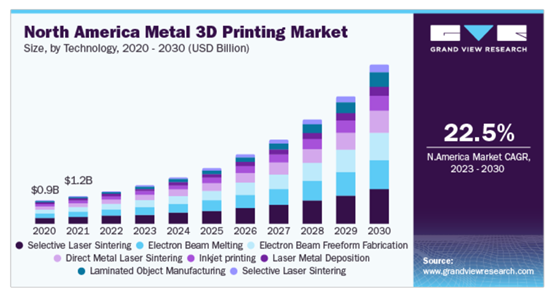

In most cases, the most widely used powder bed forming technologies in industrial applications are still laser-based 3D printing technologies SLS and SLM.03So, does laser 3D printing have any weaknesses?Of course, there are some,first, the strength of an alloy produced using laser 3D printing technology can exceed the strength of that alloy when cast, but it still falls short compared to the same alloy that has been forged.I believe many of you have seen knife forging competitions. In those competitions, whether stacking large horses or three blades, mechanical stamping and hand hammering are crucial for the strength of forged knives.This is because forging is a processing method that applies pressure to metal blanks to induce plastic deformation, obtaining forged parts with certain mechanical properties, shapes, and dimensions. The core purpose is to change the microstructure of the metal using external force to eliminate defects such as porosity that occur during smelting and optimize the microstructure.3D printing itself does not involve such microstructure modifications; it merely involves the crystallization process after melting the metal. This means that 3D printing cannot replace forged parts in many critical areas, such as the main load-bearing components of the Y-20.Moreover, 3D printed parts are generally integrated structures, such as a complete engine combustion chamber or a complete hollow blade. If you want to add a round of forging for strength at this point, it will ruin the entire formed part, causing it to deform or flatten.Secondly, the batch manufacturing capability of 3D printing is still relatively low.In traditional industries, whether for forged or cast parts, each method can form a scale effect through assembly lines. As additive manufacturing, after investing fixed costs, the scale effect of 3D printing is not strong because each part is printed point by point. According to relevant industry reports in China, after entering the additive manufacturing 2.0 era, the cost advantage of 3D printing has increased from double digits to less than ten thousand. This means that although costs have decreased,if the demand exceeds ten thousand, 3D printing no longer has a significant cost advantage compared to traditional casting of metal parts..The third disadvantage is that the difficulty of large-scale 3D printing remains high.This issue is mainly limited by the size of current 3D printers. Friends who have seen 3D printing should have some impression of the printer’s shape, which is generally square and not very large. In fact, manufacturing a super-large 3D printer, especially for powder printing, poses a series of global challenges regarding safety, product quality control, and production efficiency.The last disadvantage is that the precision of laser 3D printing is still slightly low.Not only do the finished products require further processing, but for example, the repeat positioning accuracy of the S500 and S600 laser 3D printers from our country, Plater, is only ±5μm. This precision is still slightly inferior compared to the precision of traditional precision machining, which is 10 to 0.1μm.The defects exhibited now are a good thing for an emerging industry.After all, the upper limit of an industry is determined by its physical laws, while its engineering capabilities only determine its lower limit.From a certain perspective, the problems currently exhibited by 3D printing are all engineering issues. However, the upper limit of its physical manufacturing capabilities is fascinating.04Currently, the world of 3D printing technology is rapidly expanding in the manufacturing sector.According to a report released by Grand View Research, the annual compound growth rate of the 3D metal printing market in North America is expected to reach22.5% between 2023 and 2030, which is almost equivalent to doubling in just over three years.Globally, the value of the metal 3D printing market in 2022 was6.36 billion USD. Moreover, the metal 3D printing market in North America is relatively more mature, so the growth rate of the global metal 3D printing market is expected to be higher than that of North America, with a projected compound annual growth rate (CAGR) of24.2% from 2023 to 2030.

According to relevant industry reports in China, after entering the additive manufacturing 2.0 era, the cost advantage of 3D printing has increased from double digits to less than ten thousand. This means that although costs have decreased,if the demand exceeds ten thousand, 3D printing no longer has a significant cost advantage compared to traditional casting of metal parts..The third disadvantage is that the difficulty of large-scale 3D printing remains high.This issue is mainly limited by the size of current 3D printers. Friends who have seen 3D printing should have some impression of the printer’s shape, which is generally square and not very large. In fact, manufacturing a super-large 3D printer, especially for powder printing, poses a series of global challenges regarding safety, product quality control, and production efficiency.The last disadvantage is that the precision of laser 3D printing is still slightly low.Not only do the finished products require further processing, but for example, the repeat positioning accuracy of the S500 and S600 laser 3D printers from our country, Plater, is only ±5μm. This precision is still slightly inferior compared to the precision of traditional precision machining, which is 10 to 0.1μm.The defects exhibited now are a good thing for an emerging industry.After all, the upper limit of an industry is determined by its physical laws, while its engineering capabilities only determine its lower limit.From a certain perspective, the problems currently exhibited by 3D printing are all engineering issues. However, the upper limit of its physical manufacturing capabilities is fascinating.04Currently, the world of 3D printing technology is rapidly expanding in the manufacturing sector.According to a report released by Grand View Research, the annual compound growth rate of the 3D metal printing market in North America is expected to reach22.5% between 2023 and 2030, which is almost equivalent to doubling in just over three years.Globally, the value of the metal 3D printing market in 2022 was6.36 billion USD. Moreover, the metal 3D printing market in North America is relatively more mature, so the growth rate of the global metal 3D printing market is expected to be higher than that of North America, with a projected compound annual growth rate (CAGR) of24.2% from 2023 to 2030. Although this growth rate is not as high as the previously mentioned smart robotics industry, which has an annual growth rate of

Although this growth rate is not as high as the previously mentioned smart robotics industry, which has an annual growth rate of

38.6%

6%

the growth rate is still compelling. Moreover, the future growth rate of metal 3D printing in our country will undoubtedly exceed the global average.

Compared to the United States, while our country lags behind in traditional aerospace manufacturing capabilities, we are not so far behind in advanced applications of 3D printing.

The leading domestic SLM equipment manufacturers are Plater and Huashu High-Tech.

Among them, Plater has the highest market share in the country, with over a hundred self-developed equipment sold from 2016 to 2019, making it a leading supplier of comprehensive metal 3D printing technology solutions in China. Huashu High-Tech is also continuously developing metal printing equipment represented by SLM technology.According to disclosures from Plater, the leading metal 3D printing company in China:“As of July 2019, Plater’s 3D printed parts have been applied in batch installations or support for multiple national key model projects, including 7 aircraft models, 4 drone models, 7 aircraft engine models, 2 rocket models, 3 satellite models, 5 missile models, 2 gas turbine models, and 1 space station model.The projects involve military and civilian large aircraft such as C919, advanced fighter jets, drones, high-thrust-to-weight ratio aircraft engines, new missiles, space stations, and satellites.”In fact, China’s attempts at metal 3D printing have gone further than most countries, with greater ambitions. As early as 2012, the “Laser Forming Technology for Large Complex Titanium Alloy Components for Aircraft” led by Academician Wang Huaming won the first prize of the National Technology Invention Award. This clearly established that China would adopt laser 3D printing technology for the manufacturing process of titanium alloy structural components.According to the public materials of Academician Wang Huaming, who was elected as an academician of the Chinese Academy of Engineering in 2015, we can see:“The metal component laser melting deposition additive manufacturing technology developed by him has been applied in engineering applications for the development of key models such as J-15, Y-20, J-11B, J-31, C919, and others since 2005, playing a key role.”Even in the development of the Y-20, laser additive manufacturing technology completed the rapid manufacturing of six large main load-bearing components of the fuselage/main landing gear joints within seven days, ensuring the aircraft’s timely first flight.Although the Y-20 ultimately used more forged parts as the main load-bearing structure, this shows China’s ambition in related fields.Years later, almost all known and unknown advanced aerospace model components in our country can find integrated parts produced using metal 3D printing. In the field of engine blade manufacturing, national key research enterprises such as Steel Research High-Tech are following in the footsteps of international giants like GE, transitioning from traditional subtractive manufacturing to powder forging and 3D laser and even electron beam melting printing additive manufacturing.

As early as 2012, the “Laser Forming Technology for Large Complex Titanium Alloy Components for Aircraft” led by Academician Wang Huaming won the first prize of the National Technology Invention Award. This clearly established that China would adopt laser 3D printing technology for the manufacturing process of titanium alloy structural components.According to the public materials of Academician Wang Huaming, who was elected as an academician of the Chinese Academy of Engineering in 2015, we can see:“The metal component laser melting deposition additive manufacturing technology developed by him has been applied in engineering applications for the development of key models such as J-15, Y-20, J-11B, J-31, C919, and others since 2005, playing a key role.”Even in the development of the Y-20, laser additive manufacturing technology completed the rapid manufacturing of six large main load-bearing components of the fuselage/main landing gear joints within seven days, ensuring the aircraft’s timely first flight.Although the Y-20 ultimately used more forged parts as the main load-bearing structure, this shows China’s ambition in related fields.Years later, almost all known and unknown advanced aerospace model components in our country can find integrated parts produced using metal 3D printing. In the field of engine blade manufacturing, national key research enterprises such as Steel Research High-Tech are following in the footsteps of international giants like GE, transitioning from traditional subtractive manufacturing to powder forging and 3D laser and even electron beam melting printing additive manufacturing. It can be said that China’s defense and military industries have already led the trend of national 3D printing industrialization, and the remaining challenge is how to further reduce costs and expand production.The National Standardization Management Committee launched the “Additive Manufacturing Standard Navigation Action Plan (2020-2022)” in 2020.According to the “Plan”, by 2022, the number of “leading” standards in the fields of additive manufacturing materials, processes, equipment, software, testing methods, and services in China will reach 80-100, forming a batch of competitive and leading group standards. (China will) promote 2-3 of its advantageous additive manufacturing technologies and standards to be established as international standards, with an international standard conversion rate reaching90%.In January 2023, the National Development and Reform Commission and other departments issued the “Guiding Opinions on Coordinating Energy Conservation, Carbon Reduction, and Recycling to Accelerate the Update and Transformation of Key Product Equipment”, listing the promotion of additive manufacturing as a key direction for forging new industrial competitive advantages in achieving carbon peak and carbon neutrality goals.In February, the National Standardization Management Committee officially launched the “2023 National Standard Project Guide”, establishing key foundational material standards, including additive manufacturing materials, high-purity rare metal materials, and high-quality special steel materials.

It can be said that China’s defense and military industries have already led the trend of national 3D printing industrialization, and the remaining challenge is how to further reduce costs and expand production.The National Standardization Management Committee launched the “Additive Manufacturing Standard Navigation Action Plan (2020-2022)” in 2020.According to the “Plan”, by 2022, the number of “leading” standards in the fields of additive manufacturing materials, processes, equipment, software, testing methods, and services in China will reach 80-100, forming a batch of competitive and leading group standards. (China will) promote 2-3 of its advantageous additive manufacturing technologies and standards to be established as international standards, with an international standard conversion rate reaching90%.In January 2023, the National Development and Reform Commission and other departments issued the “Guiding Opinions on Coordinating Energy Conservation, Carbon Reduction, and Recycling to Accelerate the Update and Transformation of Key Product Equipment”, listing the promotion of additive manufacturing as a key direction for forging new industrial competitive advantages in achieving carbon peak and carbon neutrality goals.In February, the National Standardization Management Committee officially launched the “2023 National Standard Project Guide”, establishing key foundational material standards, including additive manufacturing materials, high-purity rare metal materials, and high-quality special steel materials. With the future standardization and normalization of 3D printing industry at the official level in our country, 3D printing will supplement and even replace traditional lathes in maintenance and other aspects, becoming one of the most important manufacturing means in many fields.ConclusionTurning stone into gold and gathering sand into towers is humanity’s eternal dream, and 3D printing is physically realizing this dream. Our country is racing down this path and continuously overtaking on the curve. So what can we do?I don’t know.But whether it’s the development of AI, the advancement of robotics, the popularity of smartphones, or the leap in 3D printing, all mean that the threshold for everyone to create has never been lower.We no longer need a team, a production line, a pile of printers, or countless cameras and satellite antennas to realize our creativity. We can even find relevant stores on Taobao to send our ideas to them, allowing their 3D printers or other interfaces to help us realize our ideas.This brings unprecedented convenience for realizing personal creative ideas.So, why not take advantage of this unprecedented convenience and invest in even grander future endeavors?Comrades, cherish the dividends brought by technological development in this era and create new stars and seas for our future.CoolPlayExperimentLabEditor整理编辑Originally publishedonWeChatPublicAccount:CoolPlayExperimentLab(ID:coollabs)ForreprintpleaseleaveyourcommentstosharewithfriendsorfriendcirclesFeel freeto share

With the future standardization and normalization of 3D printing industry at the official level in our country, 3D printing will supplement and even replace traditional lathes in maintenance and other aspects, becoming one of the most important manufacturing means in many fields.ConclusionTurning stone into gold and gathering sand into towers is humanity’s eternal dream, and 3D printing is physically realizing this dream. Our country is racing down this path and continuously overtaking on the curve. So what can we do?I don’t know.But whether it’s the development of AI, the advancement of robotics, the popularity of smartphones, or the leap in 3D printing, all mean that the threshold for everyone to create has never been lower.We no longer need a team, a production line, a pile of printers, or countless cameras and satellite antennas to realize our creativity. We can even find relevant stores on Taobao to send our ideas to them, allowing their 3D printers or other interfaces to help us realize our ideas.This brings unprecedented convenience for realizing personal creative ideas.So, why not take advantage of this unprecedented convenience and invest in even grander future endeavors?Comrades, cherish the dividends brought by technological development in this era and create new stars and seas for our future.CoolPlayExperimentLabEditor整理编辑Originally publishedonWeChatPublicAccount:CoolPlayExperimentLab(ID:coollabs)ForreprintpleaseleaveyourcommentstosharewithfriendsorfriendcirclesFeel freeto share Cool Play Lab Video AccountHot Video Recommendations↓↓↓

Cool Play Lab Video AccountHot Video Recommendations↓↓↓

For victory!

For victory!