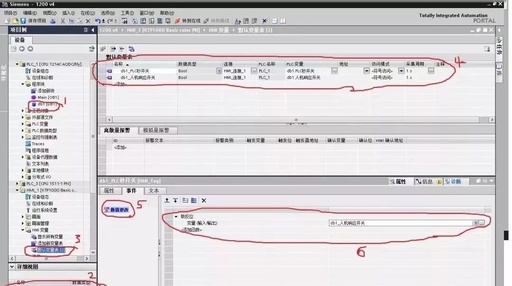

SuperCAT: Software-Defined EtherCAT Motion Controller

The motion controller is one of the core control devices in the industrial control field, essential for high-speed and high-precision motor control. Traditionally, motion controllers have relied on dedicated hardware and embedded motion control algorithms. However, with the advancement of control technology and the demand for decoupling hardware and software, software-defined control is gradually becoming … Read more