When people talk about the industrial Internet, they often discuss PLCs in the industrial field. However, most people seem to have an understanding of PLCs that dates back 20 years—Is PLC just logic control? In fact, it hasn’t been like that for 20 years.

Yes, today’s automation industry, both in hardware and software, is no longer like the era of the MCS-51 microcontroller, which had only 128 bytes of registers. Even the 16-bit 8096-level CPU’s addressing space could only support a 512kB storage card. It was unimaginable to handle tasks like encapsulating and unpacking Ethernet data frames on such CPUs. Therefore, PLCs with Ethernet interfaces were quite impressive in the early 21st century. If high-speed tasks needed to be processed, DSPs and CPLDs were extremely expensive. Looking back, even in the 1980s, a single logic point in a PLC could cost up to 1000 yuan.

These issues have been resolved. A mobile phone’s processor can handle all the computational power of the computers used in the lunar landing mission, and a chip costs only a few hundred yuan. A 128GB USB drive costs less than 100 yuan. The advancement of technology has allowed automation to enjoy these resources; hardware is no longer a problem.

Of course, on the other hand, the control tasks of machines have become more complex than before. Early PLCs were primarily used to replace inconvenient relay control cabinets, thus their tasks mainly involved relay switching, delays, and sequential control actions, distinguishing them from DCS’s continuous automation. However, today our machines include more complex tasks such as motion control, vision, robotics, safety, complex process algorithms, hydraulics, and production data, recipes, users, alarms, trends, and documents. Therefore, the demands on controllers have also become more complex—specifically, the requirements for controllers have long surpassed what the term PLC, or Programmable Logic Controller, implies.

(Image source: Internet)

Although people still habitually call machine controllers PLCs, in reality, the forms of PLCs are diverse. For example, PLCs can be combined with HMIs to form a controller, which eliminates the instability caused by communication connections. Additionally, PLC control tasks can also be incorporated into industrial PLCs. Today’s multi-core processing CPUs can fully support two different operating systems running different tasks, such as RTOS and Windows/Linux simultaneously.

You could probably ask this question over 20 years ago; back then, PLCs could already do this. Beckhoff launched a black series PLC in 1993 that ran an operating system called pSOS+, which supported BASIC programming. This pSOS+ is a qualitative time-sharing multitasking operating system that can support complex algorithm design.

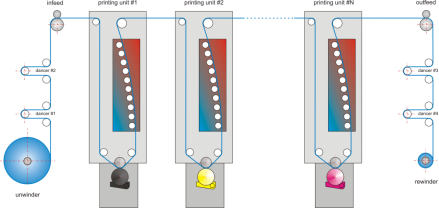

Later PLCs don’t even need to be mentioned; traditional tasks that required specialized control systems for color registration have been integrated into a single PLC by Beckhoff because algorithms for decoupling multi-variable systems can be entirely written in C/C++ and run on a PLC.

In Beckhoff’s integrated color registration flexographic printing system, logic, color mark detection, registration, and electronic shaft drive are all controlled by a single controller.

There are countless application cases, and PLCs have long been able to handle complex process algorithms.

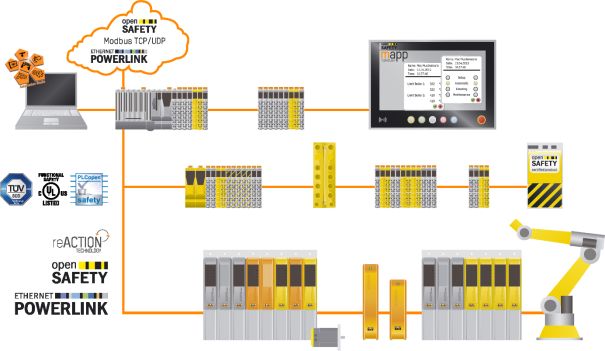

In fact, when IT discusses the need for low latency, it started when they wanted to enter OT with existing high bandwidth needs. In 2001, POWERLINK based on 100M Ethernet could already achieve relatively high responsiveness. Initially, refreshing 90 nodes (2000 I/O, 50 servo axes) took 2.4ms, and now with OPC UA over TSN, the refresh time for these nodes is only 100μs.

What about other communications?

2 USB ports

1 standard Ethernet port

1 POWERLINK real-time Ethernet interface

1 RS232 interface

Profibus-DP master/slave

Profinet master/slave

DeviceNet/ControlNet

Ethernet/IP

CAN/CANopen

RS485

Typically, each inserted card can have two different interfaces, meaning that an X20 PLC can support up to 11 interfaces.

What!Can motion control be fun?——Yes, of course.

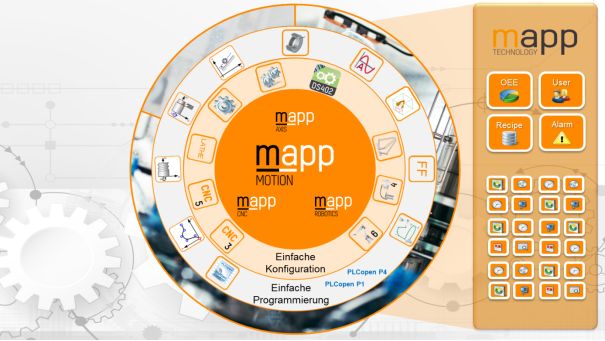

PLCopen is the standard for ladder diagrams and structured text programming that we usually use, and in PLCopen Motion Part IV’s coordinated motion control, robots, CNC, positioning, and synchronization control have long been incorporated into a unified architecture.

A single PLC can handle it.

In traditional PLCs, because the CPU could only handle relatively simple logic tasks, a dedicated Motion Control module was often needed. Early implementations used pulse or analog signals, which required extensive wiring. Now, real-time Ethernet technology is used for connections, and on the other hand, using a motion control module can lead to lower response speeds, especially when PLC logic and motion control need to collaborate. For example, during an electronic cam cutting process, an external encoder is needed, and in the original PLC + motion control module architecture, the slow response would prevent achieving high-speed cutting. However, in the ACOPOS system, this issue can be solved through direct encoder input.

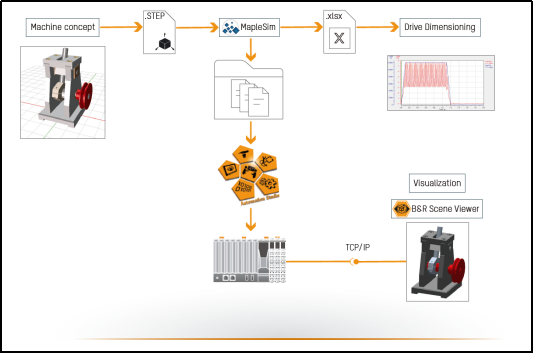

Beckhoff adopted bus-based control when it launched the ACOPOS series servo drives in 1997, using CAN bus to communicate with PLC controllers to coordinate complex electronic gear synchronization tasks, including electronic cams. Later, the NC module was added to handle non-linear calculations for CNC, and in 2010, the GMC (Generic Motion Control) was introduced, incorporating robots and hydraulics into a unified control architecture, using standardized PLCopen Motion Part IV for programming, and then packaging reusable mappMotion modules.

Complex motion curves require high-order function support, and the order of the function determines the smoothness of the curve. The smoothness of the curve significantly impacts mechanical shocks, affecting precision and machine lifespan. By using high-order curves (up to six orders), drive control becomes smoother. It’s like riding an elevator; some elevators are more comfortable because the frequency converter’s curve is smoother, which is due to the higher order.

Edge computing typically addresses strategic and optimization issues. Edge computing is an extension of the computing boundary, from local control to distributed computing, and controllers play a crucial role in this. The edge focus first addresses connectivity issues, such as connecting edge nodes through Profibus, POWERLINK, CAN, etc. Embedded nodes can perform some local computing tasks like OEE, energy status display, asset management, etc. At the workshop and factory level, edge controllers can handle collaborative, optimization, and planning issues.

Such edge-side tasks can be handled by an edge connection module of a PLC or by a PLC or an industrial PC with Windows + RTOS.

Please refer to “Easy Introduction – What Is Edge Computing”.

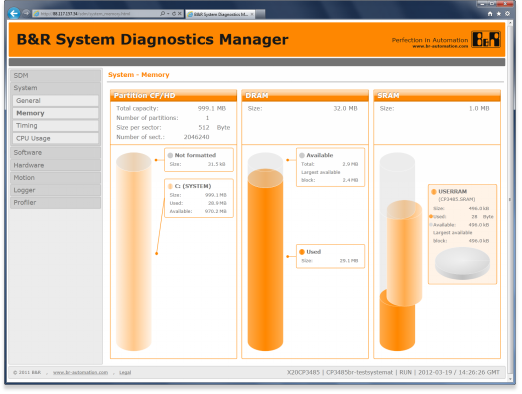

This has been discussed over a decade ago; PLCs can already integrate a Web Server or a VNC Server, allowing access via remote IE browsers.

Early PLCs often used RISC architecture CPUs without real-time operating systems, only having processing similar to computer BIOS. Their hardware execution speed for logic tasks was extremely fast, but this limited their ability to handle complex algorithms, high-speed signal processing, Ethernet tasks, etc. However, CPUs based on Intel’s complex instruction set can run powerful operating systems and handle large data tasks like running a Web Server. Therefore, the X20 series CPUs can integrate Web Servers, VNC Servers, and FTP Servers.

Web technology enables remote diagnostics and maintenance, and supports data publishing via Web methods. Any terminal supporting IE browsers can access remote device maintenance data, including uploading and downloading programs via FTP service.

Simulation modeling has probably been around for a long time; it was already possible before 2008 when Mathworks launched SimulinkPLC, and Beckhoff was one of the first to accept this interface. By importing C code, modeling and simulation can be done using MATLAB/Simulink, and the automatically generated program can be downloaded to the PLC for Hardware In the Loop testing.

In fact, security includes three aspects: program security, information security, and functional safety;

(1) Program Security: Regular PLCs use an interpreted execution method, which is not hard to crack. However, with systems like X20, which use a compiled system that directly compiles to binary code downloaded to the PLC, you can read the program, but what you see is all binary code. Do you understand binary code?

(2) Information Security (Security): PLCs typically control using non-commercial operating systems like Windows/Linux, and the networks are industrial real-time networks like POWERLINK and Profinet, thus isolating them from general systems. Even when using OPC UA to connect to higher-level systems, there are authorization and verification processes, and usually, a dedicated channel like SiteManager is provided to establish a VPN connection to ensure encrypted data transmission.

(3) Functional Safety: Meets safety specifications such as IEC61508, IEC62061, IEC62784 with SafeLOGIC and software SafeDesigner, and the bus’s openSAFETY.

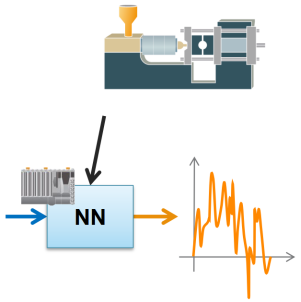

Can machine learning do anything?——No problem!

In fact, if we recognize that machine learning is a “mathematical problem”, i.e., selecting feature values, establishing loss functions (or cost functions) or penalty functions, choosing models, and testing evaluations, then you can see that all these can be implemented with software.

For example, Beckhoff’s X20 series PLC supports qualitative time-sharing multitasking operating systems and advanced language programming. Therefore, the problem is simplified; machine learning programs are equivalent to a thread developed in a high-level language and can observe existing control tasks of the controller, such as PID control during the injection molding process, and obtain the relationship between quality and process parameters (which can use genetic algorithms or supervised learning), thus achieving optimal process learning.

Yes, PLC is no longer just a “Programmable Logic Controller”.

Source: Internet, please delete if infringed.