PLC Communication Protocol

In modern industrial control systems, PLC is widely used. Programs can be easily modified and managed, thereby improving production efficiency, saving time and costs.

The communication protocol of PLC is the communication support protocol for connecting different operating systems and hardware architectures.

In simple terms, PLC usually controls the underlying layer, collects sensor signals, and controls field actuators through configuration logic. If you want to understand its operating status (remote human-machine interface), or if the process is too complex with too many conditions that require other PLCs, DCS, and other systems to jointly control, you need to connect the PLC with other systems. The PLC communication protocol tells you what methods I can use to connect with third-party software; commonly used communication protocols include Ethernet protocol, Modbus protocol, etc.

Next, we will discuss several common types of PLC communication protocols and their applications in industrial environments.

1. Modbus Protocol

Modbus is a serial communication protocol used to connect electronic devices in industrial environments. This protocol uses a simple and understandable communication method, based on open standards, and is widely used in various automation and control applications. Communication between different devices is usually achieved using the Modbus protocol. Modbus is often used for data transmission between industrial control devices.

There are several versions of the Modbus protocol: standard Modbus protocol, Modbus TCP/IP protocol, Modbus RTU protocol, and Modbus ASCII protocol. When initializing the starting device, we generally use the Modbus TCP/IP protocol, which is a standard Modbus protocol based on TCP/IP communication, allowing high-speed data exchange over Ethernet. Modbus RTU protocol and Modbus ASCII protocol are usually used for serial communication and RS485 bus communication.

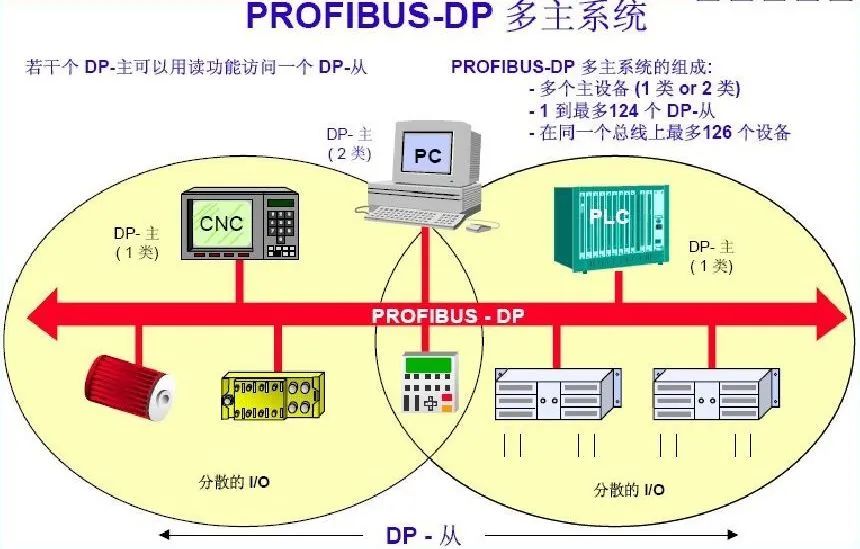

2. Profibus Protocol

Profibus (Process Field Bus) is a communication protocol with strong anti-interference, mainly used in automated industrial control systems. It is an industrial fieldbus system that enables real-time data transmission with a data communication speed of 12 MBps. The Profibus protocol is commonly used for communication between various industrial control devices and for communication with sensors, actuators, or other field devices.

There are two versions of the Profibus protocol: DP and PA. The PA version is mainly used for communication between field devices (such as valves, instruments, etc.), while the DP version can connect various types of devices, modules, and automation components.

3. Ethernet/IP Protocol

Ethernet/IP protocol is an industrial protocol based on Ethernet, allowing plug-and-play for industrial automation devices, with data transmission speeds higher than TCP/IP protocol. The Ethernet/IP protocol is commonly used in various industrial control applications, such as automation control, factory automation, and power plant automation. This protocol can transmit data using standard Ethernet protocol and has high compatibility.

Although the Ethernet/IP protocol can work at transmission speeds exceeding 60MBps, it requires reliable high-speed network hardware and optimized device control strategies. The advantages of the Ethernet/IP protocol include fast data transmission speed, high network compatibility, and easy device configuration.

4. CANopen Protocol

CANopen protocol is a high-level protocol based on CAN (Controller Area Network) communication, usually used in industrial automation, machinery, and vehicle control. The CANopen protocol provides the basic rules for networking, communication, and data transmission, as well as standards for data exchange. It is a flexible communication protocol that can adapt to various industrial control applications. The standard specification of the CANopen protocol stipulates elements such as data types, data transmission formats, network topology, and error detection.

Source: Internet, Copyright belongs to the original author. If there are copyright issues, please contact us in time to delete, thank you!

ZHINANCHE

Click ‘Read the Original’ to sign up for robot courses