The report from Electronic Enthusiasts Network (by Wu Zipeng) states that robot controllers are the core components of robotic systems, responsible for coordinating sensor perception, decision-making, and actuator control, enabling motion control, task execution, and environmental interaction. When designing and selecting controllers, it is essential to balance performance, cost, and application requirements. With the development of AI and edge computing technologies, future controllers will evolve towards intelligence and flexibility, becoming the core driving force behind the evolution of robots from “automated tools” to “autonomous intelligent agents.”

At the electronica China 2025 exhibition in Shanghai, Texas Instruments (TI) and KUKA jointly launched the next generation of robot controllers based on the TDA4 chip — the KR C5 micro-2.

The KR C5 micro-2 controller features a compact and sophisticated design, with rich expansion capabilities, capable of driving 4-axis or 6-axis small desktop robots, efficiently empowering smart manufacturing upgrades in industries such as 3C, home appliances, and automotive electronics. Compared to the previous generation, its volume has been reduced by 25% and its weight by approximately 13%. The compact structure combined with a stackable design not only significantly improves space utilization but also provides more possibilities for flexible production line transformations.

Zhang Guozhu, Head of Controller Development at KUKA China, stated that there are currently very few chip solutions based on the Arm architecture that meet KR technology requirements in the market. During the development of the KR C5 micro-2 project, KUKA conducted a comprehensive evaluation of various architectures, including x86 and FPGA, ultimately selecting Texas Instruments’ Arm architecture chip as the core solution. Currently, this controller has passed TOE safety certification and has received recognition for its leading technological achievements.

It is reported that the KUKA KR C5 micro-2 controller is built on Texas Instruments’ TDA4 chip, which provides robust performance support for the controller. The TDA4 chip features an innovative combination of high-performance computing, deep learning engines, and dedicated signal image processing accelerators, making it highly suitable for various applications such as robotics, mobile machinery, off-road vehicle controllers, machine vision, AI boxes, gateways, retail automation, and medical imaging. Its key cores include: next-generation DSP with scalar and vector cores, dedicated deep learning and traditional algorithm accelerators, the latest Arm and GPU processors (supporting general computing), integrated next-generation imaging subsystems (ISP), video codecs, Ethernet hubs, and isolated MCU islands.

The TDA4 chip, configured with an independent octa-core Arm Cortex-A72 cluster, efficiently supports multi-operating system applications while having a very low dependency on software management programs. The eight Arm® Cortex®-R5F subsystems can independently manage low-level timing-critical processing tasks, allowing the Arm® Cortex®-A72 core to focus on core application logic. The “C7x” next-generation DSP integrates TI’s industry-leading DSP with EVE cores into a single high-performance core and adds floating-point vector computing capabilities, simplifying software programming complexity while maintaining backward compatibility with legacy code.

Zhao Xiangyuan, Director of Technical Support for Texas Instruments China, pointed out that the TDA4 chip has extensive applications in the automotive field, and its empowering value is equally significant in the industrial robotics sector. The chip has three core advantages in supporting the development of modern industrial robots:

-

Cross-domain application adaptation and intelligent empowerment: By integrating DSP, hardware accelerators, and AI functions, the TDA4 chip can achieve human-robot interaction scenarios such as obstacle avoidance and object recognition, as well as perform fine motion control like gesture recognition.

-

Multi-core heterogeneous architecture and energy efficiency optimization: The chip adopts a multi-core heterogeneous design, including high-performance A cores (Cortex-A72) and real-time processing R cores (Cortex-R5F), balancing performance and power consumption based on advanced 16nm technology while ensuring high performance and real-time capabilities.

-

Industrial-grade interfaces and functional safety certification: In collaboration with KUKA, the TDA4 chip provides complete technical documentation and system-level solutions, offering critical support for KUKA’s new generation of controllers to meet the latest functional safety standards by 2025. For demanding scenarios such as industrial robots, the chip integrates an 8-port network switch, multiple PCIe, and CAN-FD high-speed interfaces, supporting real-time data fusion transmission from multiple sensors, and has achieved ASIL-D/SIL-3 functional safety certification, establishing a complete safety system from physical interfaces to system levels — these features are fully utilized in the new generation of industrial robot controllers.

Zhao Xiangyuan emphasized that for industrial robot applications, Texas Instruments will rely on a complete portfolio of analog and embedded products to continuously build full-stack robotic system solutions.

Disclaimer: This article is original from Electronic Enthusiasts Network, please indicate the source above when reprinting. For group discussions, please add WeChat elecfans999,for submission of interview requests, please send an email to [email protected].

More Hot Articles to Read

-

Humanoid Robot “Dexterous Hand” Approaching 27 Degrees of Freedom of Human Hand

-

2 hours 40 minutes! The world’s first humanoid robot half-marathon champion is born, revealing two major pain points behind the surprise

-

150,000 models can also have automotive-grade SiC! Highlights of six manufacturers’ new products at the 2025 Munich Exhibition

-

18 analog companies will soar in 2024! Highest net profit surges by 400%, shipments exceed 6 billion units

-

Humanoid robots explode at the 2025 Munich Exhibition! Domestic and foreign semiconductor manufacturers showcase their strengths

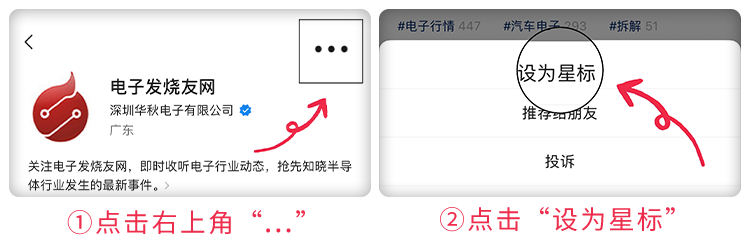

Click to Follow and Star Us

Don’t miss any updates by marking us as a star!