> At seven in the morning, the city awakens from its slumber. The traffic at the intersection flows like blood, and the traffic lights act as the “heart valves” controlling the flow. Have you ever wondered: why does the green light always turn red just after the vehicles pass? Why is there a continuous green light when an ambulance goes through? Behind all this lies an industrial computer hidden in the traffic light control box—PLC (Programmable Logic Controller), which is precisely directing the pulse of urban traffic with millisecond accuracy!

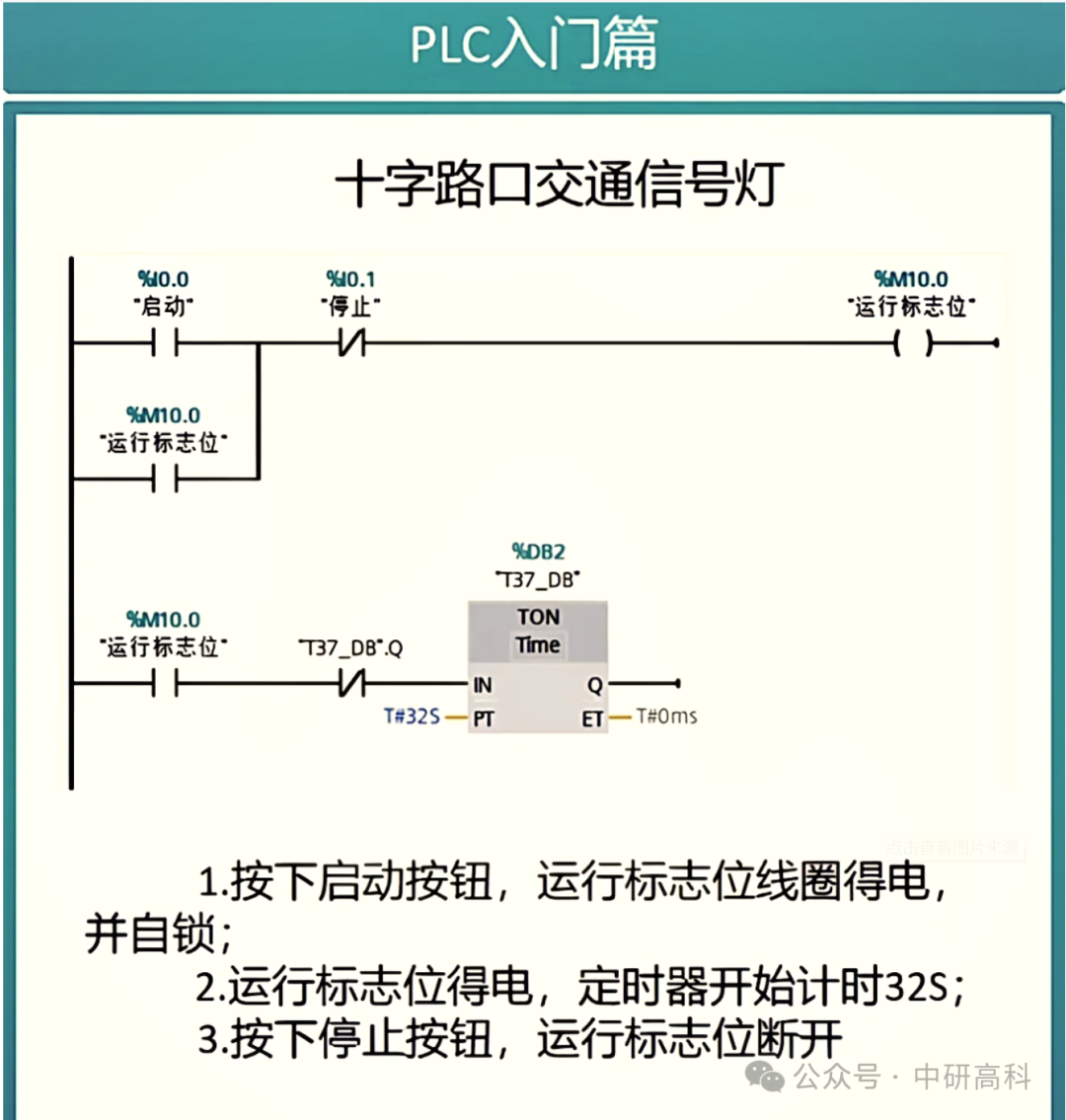

1. Basic Rhythm: The “Timer Magic” of PLC

Principle of Time Control:

PLC has a built-in high-precision timer, strictly timing like a stopwatch:

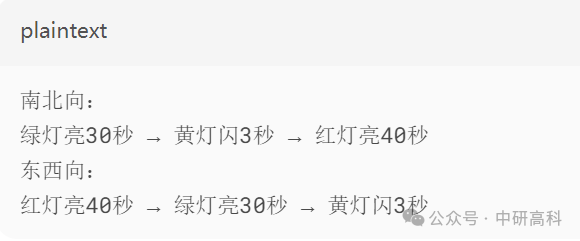

– `T1=30s`: Triggers the green light to turn yellow

– `T2=3s`: Triggers the yellow light to turn red

– Key Detail: Duration of the red light = the green light duration of the other direction+ yellow light time (to avoid conflicts!)

> Why not block completely? By calculating the traffic flow in each direction, dynamically allocating green light duration—during the morning rush hour, the green light for the inbound direction is extended by10 seconds, while the evening peak optimizes in the opposite direction!

2. Intelligent Upgrade: The “Eagle Eye” of Sensing Control

1. Geometric Sensors:

Installed behind the stop line, vehicles compress and generate an electrical signal→ PLC immediately counts

`IF the queue of vehicles>5 vehicles THEN extend the green light by 10 seconds`

2. Camera AI Recognition:

Identifies special vehicles like buses and ambulances→ PLC initiates green wave priority

`Emergency Mode: Forces the current direction’s green light to switch+ extends by 15 seconds!`

> Anti-traffic Jam Logic: PLC analyzes data in real-time, if there are no vehicles in the east-west direction, it immediately shortens its green light time, “borrowing” it for the north-south traffic!

3. Regional Coordination: The “Symphony” of Green Waves

[Road Network Coordination Diagram]

Scenario: Continuous main road5 intersections

PLC group control strategy:

– Intersection 1 PLC turns on the green light → calculates vehicle speed50km/h → notifies intersection 2 PLC

– Intersection 2 lights the green light after precise delay (ensuring the convoy arrives just as it turns green)

– Effect: Traffic flows smoothly, reducing30% waiting time!

Technical Core:

Multiple PLCs are interconnected via fiber optics, with a time synchronization error of <1 millisecond!

4. Emergency Handling: The “Safety Guardian” during Failures

PLC triple protection design:

1. Yellow Light Flashing:

Detects traffic light failure→ automatically switches all directions to yellow flashing (reminding cautious passage)

2. Countdown Protection:

3 seconds before switching the red and green lights, a digital screen displays the countdown (preventing sudden stops and rear-end collisions)

3. Manual Intervention:

Traffic police insert a key and turn to “manual mode,” directly taking over control

> Lessons Learned: In a certain city, the PLC lacked failure protection, and a short circuit caused all lights to go out during heavy rain, resulting in multiple vehicle collisions—now all PLCs are mandated to be equipped with a power outage auto-start yellow flashing function!

Conclusion: The Silent Conductor of the City

When you gently press the accelerator to pass through the intersection at a green light, it is the invisible PLC that, with precise rhythms of 0 and 1, paves an efficient and safe passage for you. It does not have the whistle of a traffic officer, but it transmits commands through fiber optics; it does not wear white gloves, yet it schedules the steel torrents in milliseconds. The next time you wait for a red light, remember: that “industrial brain” hidden in the gray iron box is tirelessly guarding every pulse of the city’s lifeblood with precise calculations.