3D printing, printing everything?”

Author | Guo Renxian

Produced by | Lei Feng Network Industry Group

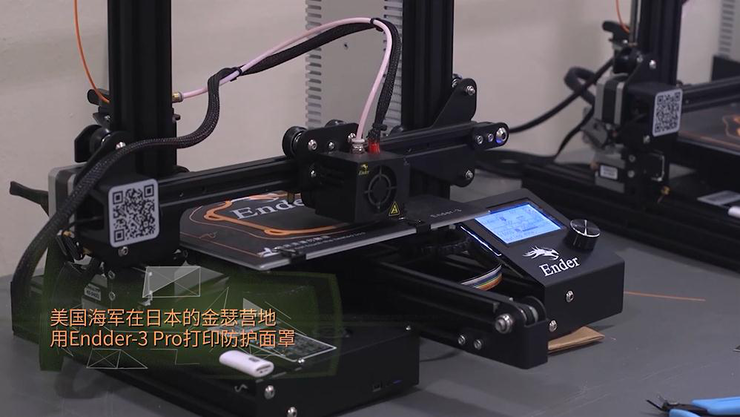

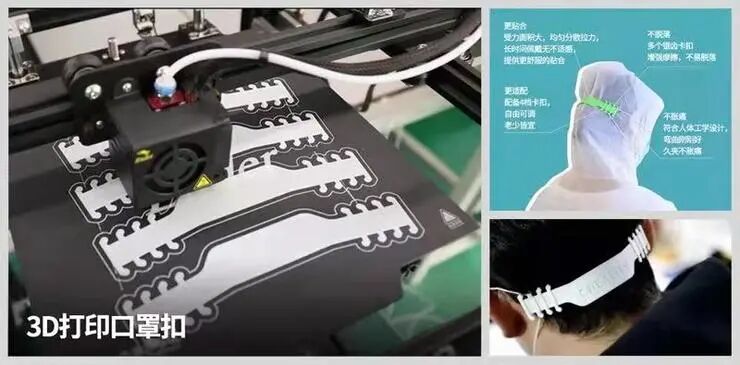

Due to the shortage of overseas medical protective materials, masks, medical face shields, goggles, and other items produced using 3D printing equipment have become “saviors” in a time of need.

According to data from the domestic B2C cross-border e-commerce platform AliExpress, sales of 3D printers on the platform have doubled compared to last year since the pandemic began. Despite a significant increase in stock at overseas warehouses for 3D printers this year, these stocks have been quickly depleted under the pandemic. In April, China’s 3D printing equipment production increased by 344.7% year-on-year.

So, why have 3D printer sales surged due to the pandemic?

Lei Feng Network learned that in Europe and the United States, where basic manufacturing is limited, they have chosen to use 3D printing technology to produce scarce medical supplies such as face shields, breathing valves, and mask clips. Compared to traditional manufacturing models, this manufacturing approach has the advantage of being unconstrained by space, shortening supply chain processes, increasing production efficiency, and lowering manufacturing thresholds.

Domestic consumer-grade 3D printer manufacturer Creality is both a beneficiary of this wave of 3D printing and a major player in the domestic 3D printing industry. They stated:

“3D printing only requires prior design, and the production process can be completely automated, reducing labor costs. Additionally, 3D printing requires fewer processes; traditional methods involve prototyping, molding, and polishing, while 3D printing does not require machining tools and molds, significantly reducing complexity. Although individual print times are longer, mass production can shorten the process.”

“Moreover, the precision of 3D printing is far superior to traditional methods, allowing for early detection of product issues, avoiding unnecessary rework, shortening product design cycles, responding to the market more quickly, reducing development costs, and improving efficiency.”

To provide a deeper understanding of the 3D printing industry, Lei Feng Network recently engaged in discussions with key players in the domestic 3D printing industry, such as Creality and Dashi Wisdom, covering topics like 3D printers, 3D modeling, and future industry trends.

1

How to Print the “World”?

3D printing, also known as Additive Manufacturing, has revolutionized people’s understanding of traditional manufacturing.

Compared to regular printers, the working principle of 3D printers is fundamentally similar, but the printing materials differ. Regular printers use ink and paper, while 3D printers are equipped with powdery metals, ceramics, sand, and other adhesive printing materials. When connected to a computer, the 3D printer can layer the printing materials to transform the computer model into a physical object.

Initially, 3D printing was primarily used in mold manufacturing and industrial design to create models, but it gradually expanded to direct production of certain products or components, with applications in vertical fields such as aerospace, construction, medical, education, and geographic information systems.

- In 2015, NASA printed the head of a rocket engine using 3D printing technology, significantly reducing the number of parts and welds, thereby lowering the probability of engine failure while shortening iteration cycles and costs.

- In Dubai, the government chose to use 3D printing to construct government buildings. 3D printed buildings are primarily completed by machines, allowing for rapid construction with minimal human labor required for operation and inspection of the 3D printers.

- In 2019, the University of California, San Diego, used 3D printing technology to create a spinal cord scaffold that mimics the structure of the central nervous system, successfully helping rats regain motor function.

- Scientists at the University of Leeds and the University of Edinburgh successfully developed a bionic tongue. Researchers created silicone molds of 15 adult volunteers’ tongues and then used 3D scanning to design hundreds of taste bud-like structures…

Additionally, the Long March 5B rocket, which successfully launched in May this year, carried China’s new generation crewed spacecraft test vehicle, which included a “3D printer.” This marks China’s first 3D printing experiment in space and the first international experiment of continuous fiber-reinforced composite 3D printing in space.

All of these applications, from large-scale engineering and rocket engines to small spinal scaffolds, utilize 3D printing technology. So how does it print all of this?

Lei Feng Network learned that the upstream of the 3D printing industry chain includes modeling tools such as 3D modeling software, 3D modeling scanners, and 3D model data platforms, as well as various 3D printing materials. The midstream mainly consists of desktop and industrial-grade printers, along with downstream applications focused on aerospace, shipbuilding, automotive, rail transportation, and medical fields.

According to public information, the mainstream technologies currently used in 3D printing include: FDM (Fused Deposition Modeling), SLS (Selective Laser Sintering), DLP (Digital Light Processing), and SLA (Stereolithography).

Creality, a domestic manufacturer focusing on FDM and photopolymerization technology research and manufacturing, discussed why they chose these two technological directions:

“These two directions are currently the most widely used and have the highest penetration rates. Since its establishment six years ago, Creality has combined its technology and resources to focus on FDM and photopolymerization for functional development, truly facilitating the industrialization of 3D printing.”

“Many people view 3D printers as large, expensive, and with significant usage barriers, making it a game for a select few. Therefore, Creality aims to optimize the underlying technology of 3D printing to promote the global popularization of 3D printers, insisting on focusing on consumer-grade 3D printers to make them accessible to households, allowing people to enjoy the convenience brought by technology.”

Furthermore, for foreign markets where 3D printing enthusiasts possess strong hands-on skills and creativity, some domestic 3D printer manufacturers are meeting this demand with DIY series products, allowing users to assemble a 3D printer they need at a lower cost. For example, the DIY product CR-6 SE, which was crowdfunded on the overseas Kickstarter platform this June, is a product based on this concept.

2

From 3D Printers to 3D Modeling

The popularity of 3D printing technology is partly due to its lack of mold constraints, which can shorten R&D cycles, especially suitable for flexible manufacturing scenarios with strong demands for complex shapes, customization, and lightweight.

At the same time, we also find that current 3D printers have relatively slow printing speeds and are time-consuming. While large 3D printers may appear very advanced, they are not suitable for home use, whereas desktop 3D printing devices can help transition 3D printing from a “niche” to a “mainstream” technology.

In recent years, Creality’s sales of 3D printers in overseas markets have been significantly increasing. According to official information from Creality, their Ender-3 and CR-10 series printers are hot sellers globally, consistently ranking at the top of Google’s global search rankings for 3D printers.

Their upcoming promotion of new photopolymerization products aims to meet users’ demands for precision, producing faster, higher-precision, better-performing, and more reliable photopolymerization 3D printers, starting from the consumer market to expand the application range of photopolymerization 3D printers.

As for how 3D printers accurately print specific physical objects, we must mention 3D modeling.

For example, in the application of 3D printing in geographic information systems, Dashi Wisdom, a three-dimensional data manufacturing and application service provider, is making significant strides from small-scale 3D modeling to large-scale 3D modeling, making it a representative enterprise in China.

Currently, their targeted vertical fields have expanded from food, cultural heritage display, and gaming to smart city firefighting, emergency management, and engineering construction.

Lei Feng Network learned that when digitizing and 3D modeling the real world with high precision, the main focus includes data collection and algorithm processing. In the former, data collection methods like SLAM (Simultaneous Localization and Mapping) using laser radar are relatively expensive and limited by conditions such as laser energy and reception time.

Therefore, when performing high-precision digitization of cities, the data collection for 3D modeling generally adopts photogrammetry, which is a cost-effective and high-performance method. Additionally, industrial cameras used for photogrammetry are equipped with GPS and other modules, allowing the camera to have posture and position, and the modeling results can be synthesized based on a series of photos.

In mid-October this year, Dashi Wisdom launched G-Engine 2.0, based on its real-scene three-dimensional reconstruction engine G-Engine 1.0, with enhanced three-dimensional semantic results. It can achieve “on-demand individualization,” allowing for classification of buildings, terrain, and roads during the modeling process, further identifying building floors and road vegetation, achieving semantic information extraction, and truly realizing three-dimensional data from being “visible” to “usable.”

Regarding the challenges in the 3D modeling process, Dashi Wisdom’s CEO Huang Xianfeng highlighted two key points: the fault tolerance of large-scale image processing and the matching and file processing in weak texture areas.

First, regarding fault tolerance, Huang Xianfeng stated:

“It’s like a jigsaw puzzle; if we have only 100 images to piece together, even manual operation is unlikely to make mistakes. However, when we have 1 million images, the complexity of operations like retrieval and matching increases significantly, and with some images being similar or even damaged, various errors must be automatically identified by the system during processing to ensure the accuracy of the computer’s calculations.”

In terms of matching and file processing in weak texture areas, Huang Xianfeng mentioned that many urban areas have weak texture regions, making it difficult for computers to distinguish during image matching. Therefore, Dashi Wisdom has introduced artificial intelligence into the processing of these details.

“For example, they extract many feature points from the same image and use the parameters of the connecting images to determine if they can match. During this process, many mismatches occur, but a portion of correct matches remains, which is then used as training samples for the computer to learn these rules. The artificial intelligence technology then uses the original numerical matching results for further training.”

In practical applications, Dashi Wisdom is empowering industries with real-scene three-dimensional data services, widely applying three-dimensional data services across various industry fields.

3

From “Niche” to “Mainstream”

Tracing its origins, we find that 3D printing technology has gradually entered people’s production and life since its invention in the 1980s, and people are progressively pushing the idea that everything can be printed towards reality.

What will the future of 3D printing look like?

Experts believe that precision and miniature instruments will be the focus of future 3D printing, while the industry also faces some constraints. On one hand, production speed remains a challenge; micro-nano 3D printing has yet to surpass traditional injection molding in terms of printing time, making it more suitable for early product development stages.

On the other hand, regarding printing materials, the mainstream micro-nano 3D printing still primarily uses photopolymerization (DLP) methods, with many materials not meeting industrialization requirements.

Creality stated:

“Factors constraining the development of the 3D industry include the high usage threshold of 3D printers. Since 3D printing involves specialized modeling technology, there are certain technical barriers to its use. Creality is working to establish the Creality Cloud APP platform, which gathers over ten thousand exquisite and practical models, aiming for one-click printing.”

“Additionally, 3D printing is still a relatively new industry, currently in the functional development and application stage. Creality is continuously striving for breakthroughs in 3D printing technology.”

Besides the aforementioned issues, Lei Feng Network has learned that the 3D printing industry still faces a lack of user awareness. Many people believe that 3D printing is far from their lives and are unaware of what 3D printing can do and how it can bring convenience to their lives…

This series of common situations indicates that we need more influential manufacturers to drive industry progress, helping the general public understand 3D printing and enjoy the benefits brought by technology. Only in this way can 3D printing better transition from “niche” to “mainstream.”

Previous Recommendations

▎Huawei’s Self-Rescue, Honor’s Difficult Survival▎Pinduoduo Subsidizes Apple, Shareholders “Subsidize” Pinduoduo▎Alibaba Cloud Struggles to ‘Touch the Ceiling’▎Honor Officially Sold! Huawei No Longer Holds Any Shares, 40 Companies Jointly Take Over; iPhone 12 Faces Large-Scale Green Screen Issues; Baidu Acquires YY’s Domestic Business