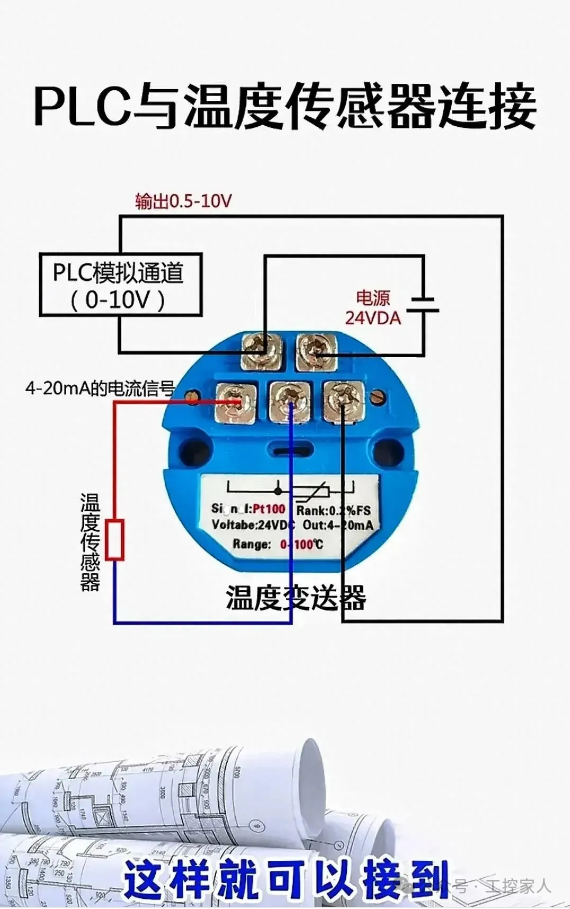

On the grand stage of modern industrial production, various automation devices resemble precision instruments, collectively playing a symphony of efficiency, accuracy, and safety. Core devices such as PLCs, sensors, encoders, inverters, and relays not only perform unique roles but also collaborate closely to ensure the smooth operation of the entire production process. Next, let us delve into the mysteries and charms behind these key devices through a series of vivid practical cases.First: Physical Wiring of PLC and Temperature Sensor Second: Understanding the Basic Parameters of Encoders

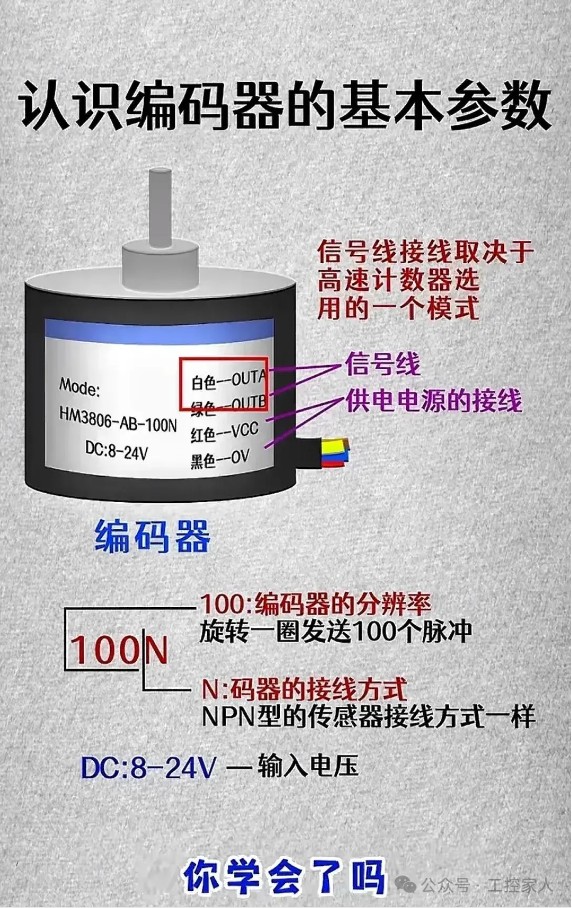

Second: Understanding the Basic Parameters of Encoders Third: Meaning of Terminal Letter Symbols on Inverter Control

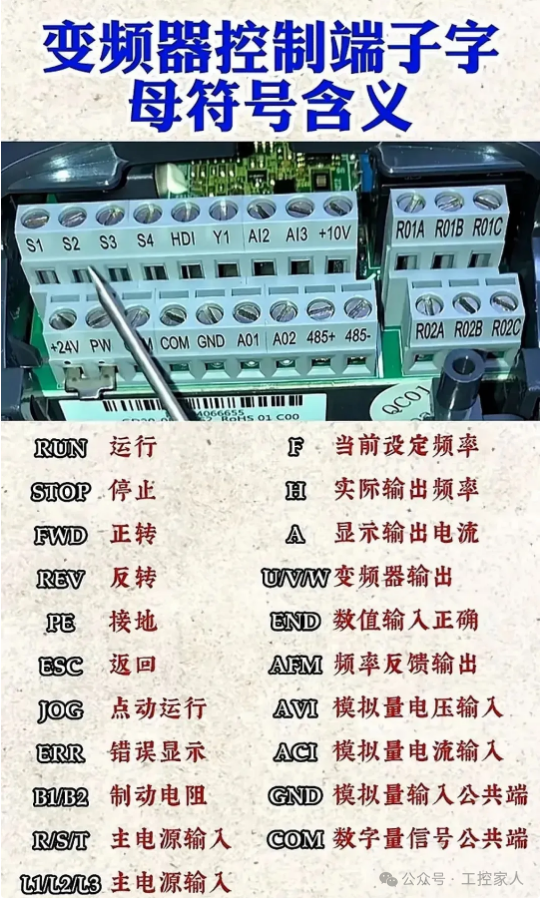

Third: Meaning of Terminal Letter Symbols on Inverter Control Fourth: Wiring of PLC and Servo Drive

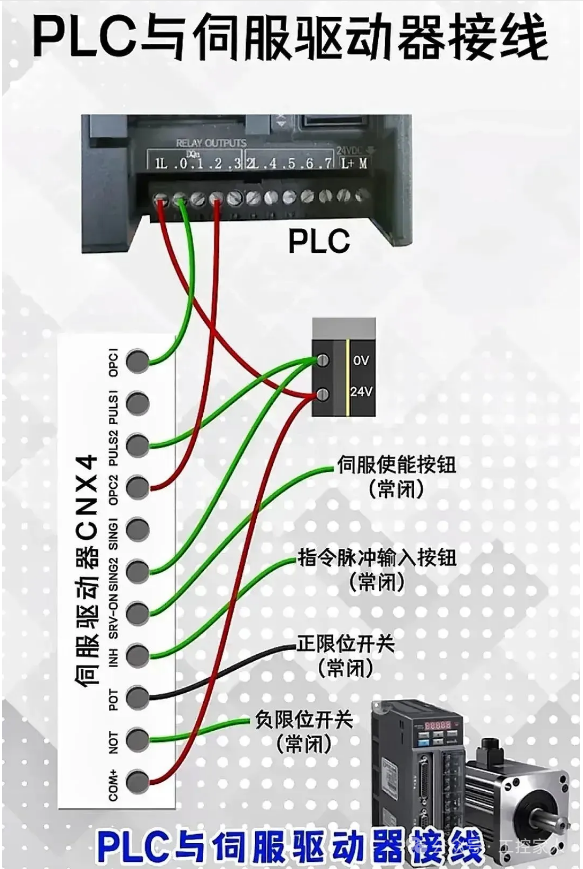

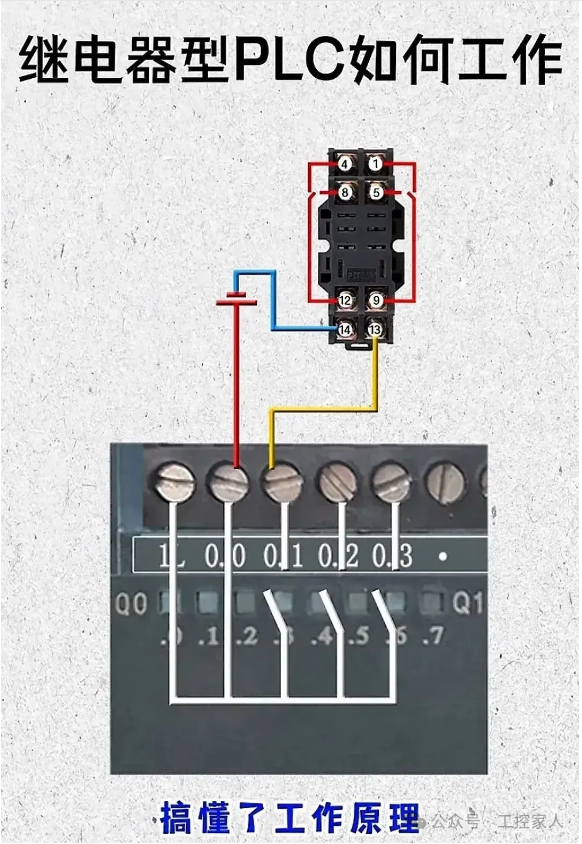

Fourth: Wiring of PLC and Servo Drive Fifth: Wiring Diagram of Relay Type PLC Operation

Fifth: Wiring Diagram of Relay Type PLC Operation Sixth: Common Special Auxiliary Relays in Siemens PLC Programming

Sixth: Common Special Auxiliary Relays in Siemens PLC Programming Seventh: Differences Between RS232 and RS485

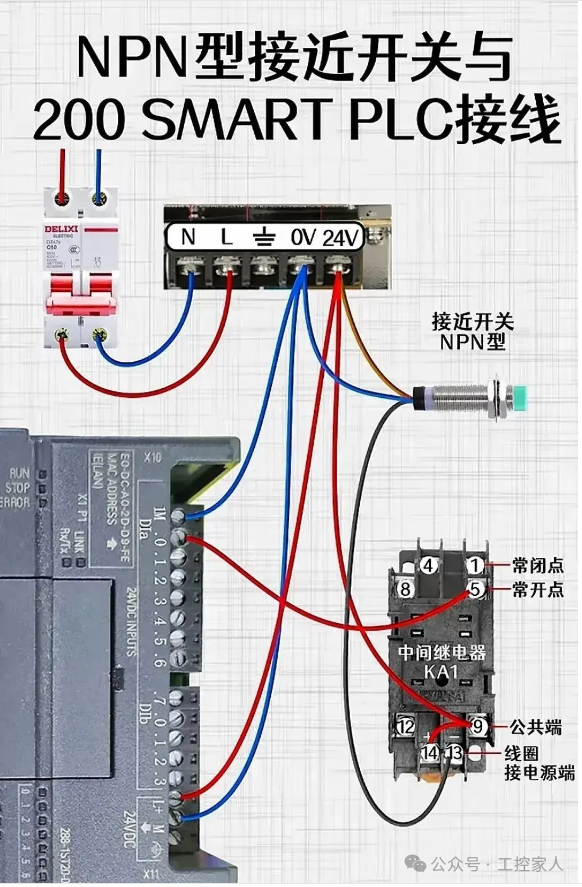

Seventh: Differences Between RS232 and RS485 Eighth: Wiring of NPN Proximity Switch and 200SMART PLV

Eighth: Wiring of NPN Proximity Switch and 200SMART PLV Ninth: Differences Between Servo Motors and Stepper Motors

Ninth: Differences Between Servo Motors and Stepper Motors Tenth: One-Button Start-Stop Circuit Diagram and PLC Program

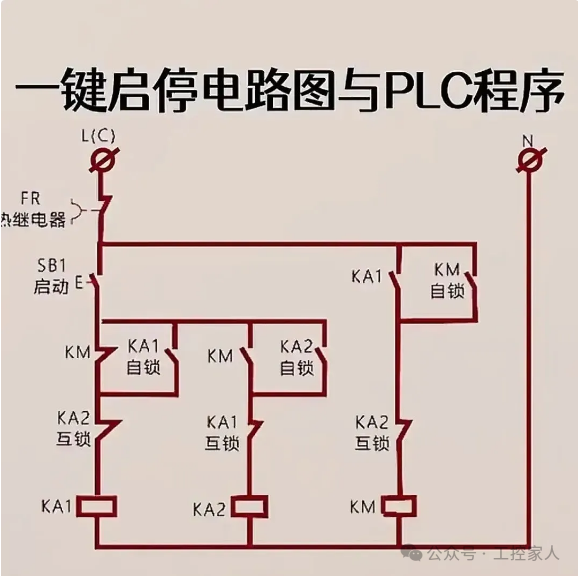

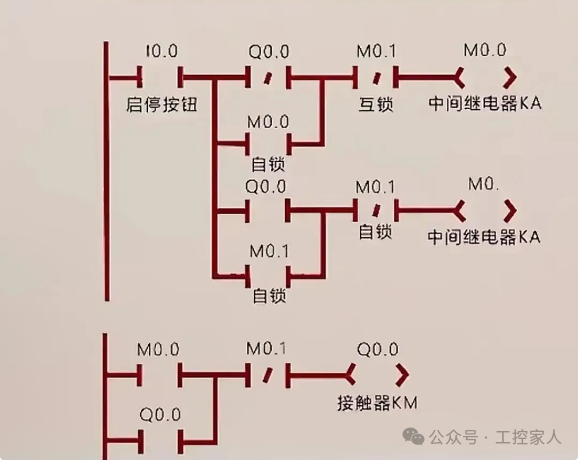

Tenth: One-Button Start-Stop Circuit Diagram and PLC Program

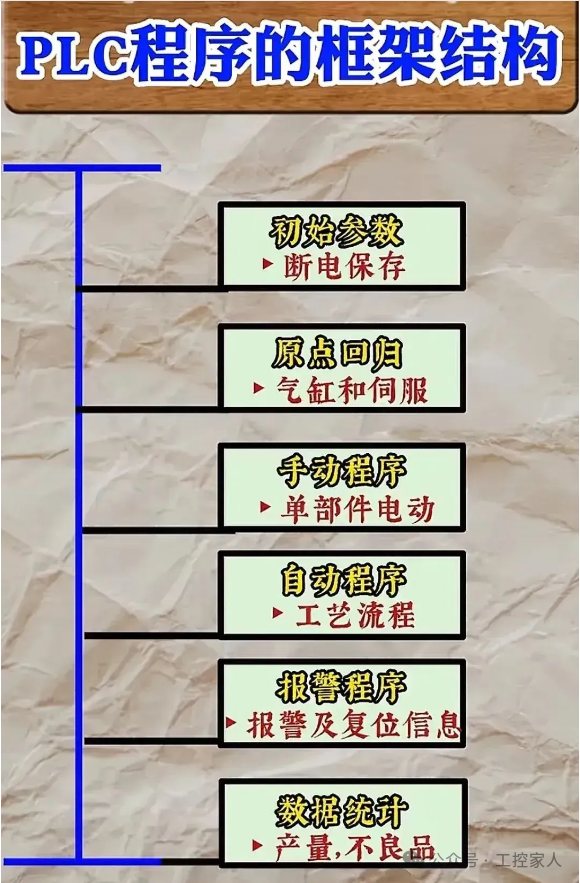

Eleventh: Framework Structure of PLC Programs

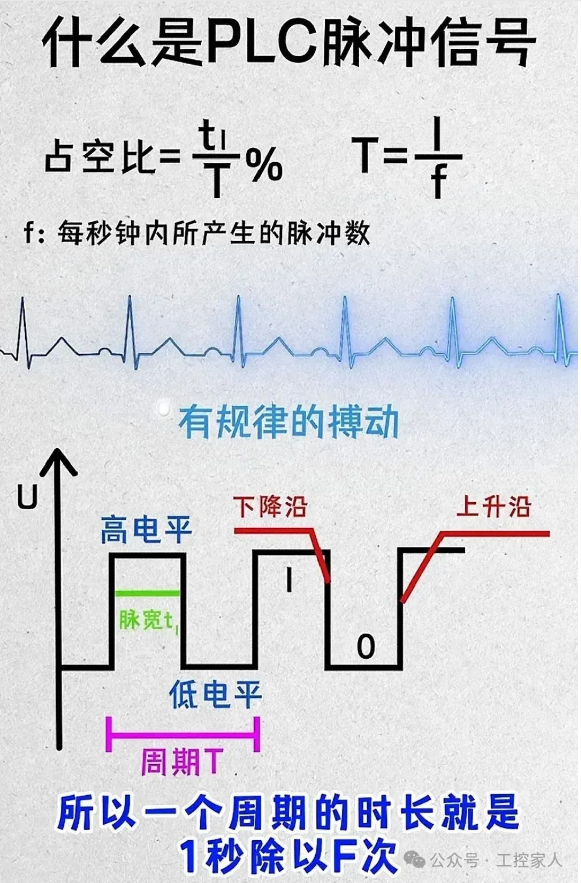

Eleventh: Framework Structure of PLC Programs Twelfth: What is a PLC Pulse Signal

Twelfth: What is a PLC Pulse Signal Thirteenth: Differences Between RS232, RS422, and RS485

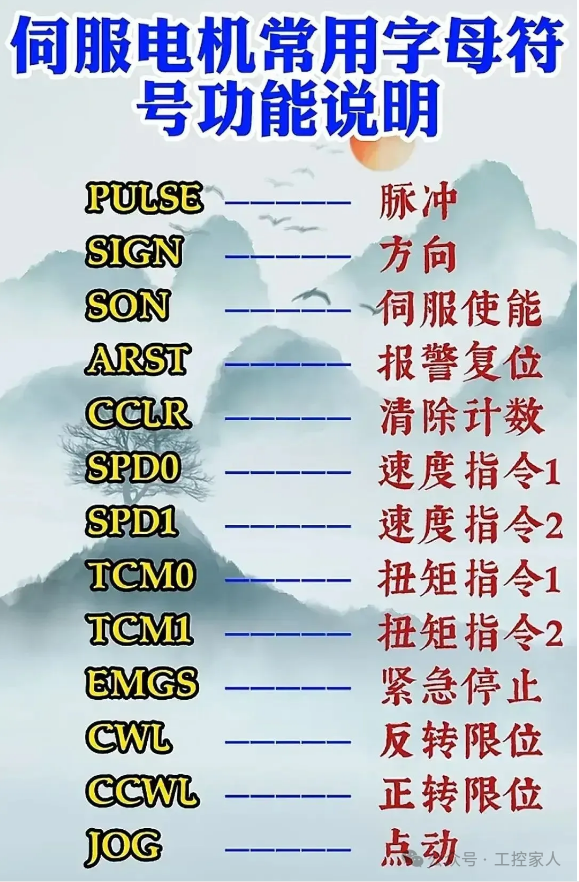

Thirteenth: Differences Between RS232, RS422, and RS485 Fourteenth: Function Description of Common Letter Symbols for Servo Motors

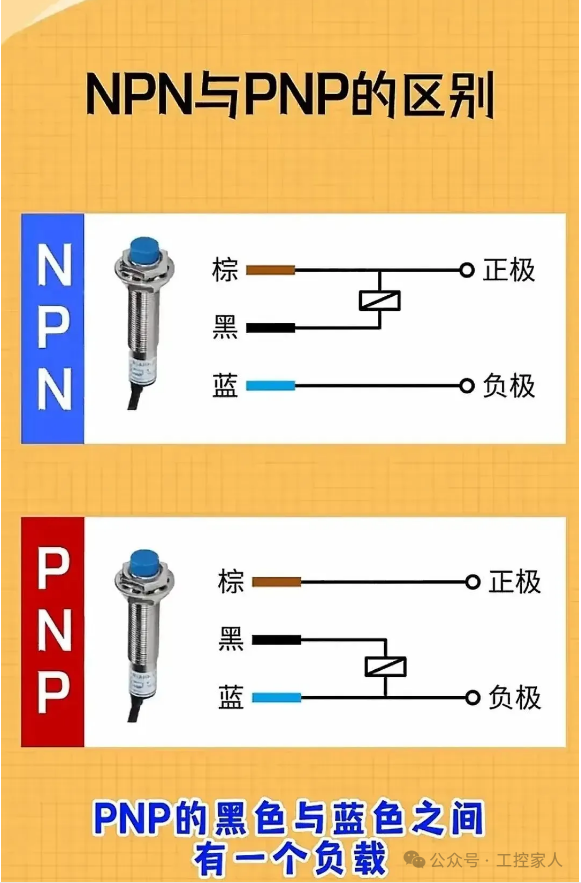

Fourteenth: Function Description of Common Letter Symbols for Servo Motors Fifteenth: Differences Between NPN and PNP

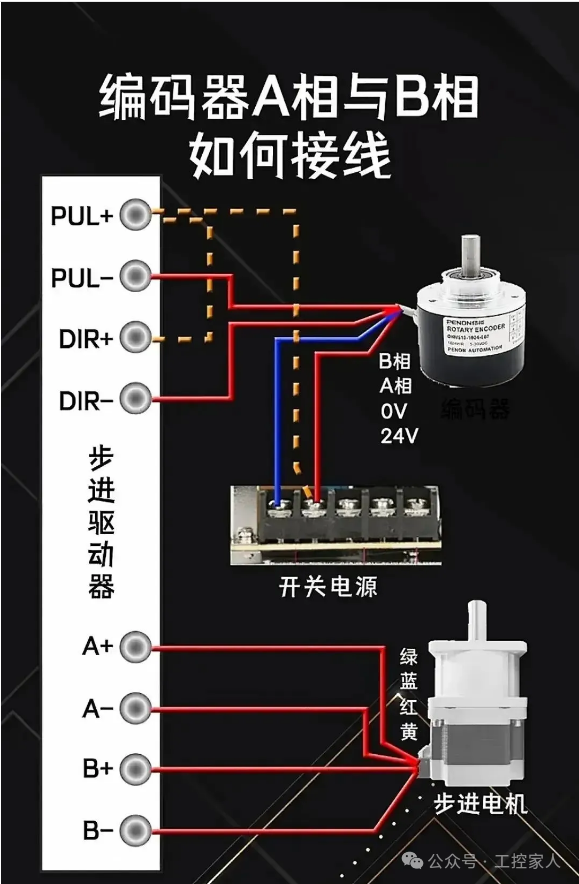

Fifteenth: Differences Between NPN and PNP Sixteenth: How to Wire Encoder A Phase and B Phase

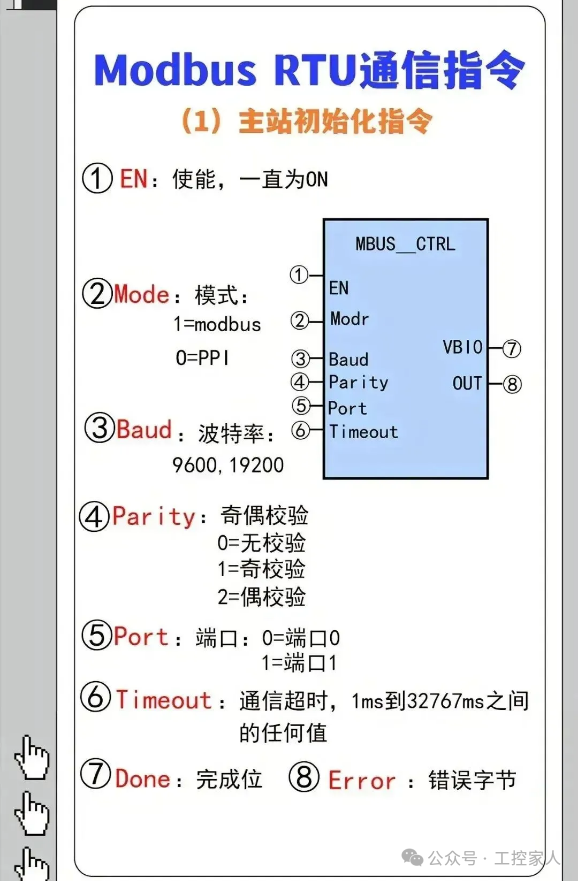

Sixteenth: How to Wire Encoder A Phase and B Phase Seventeenth: Modbus RTU Communication Commands

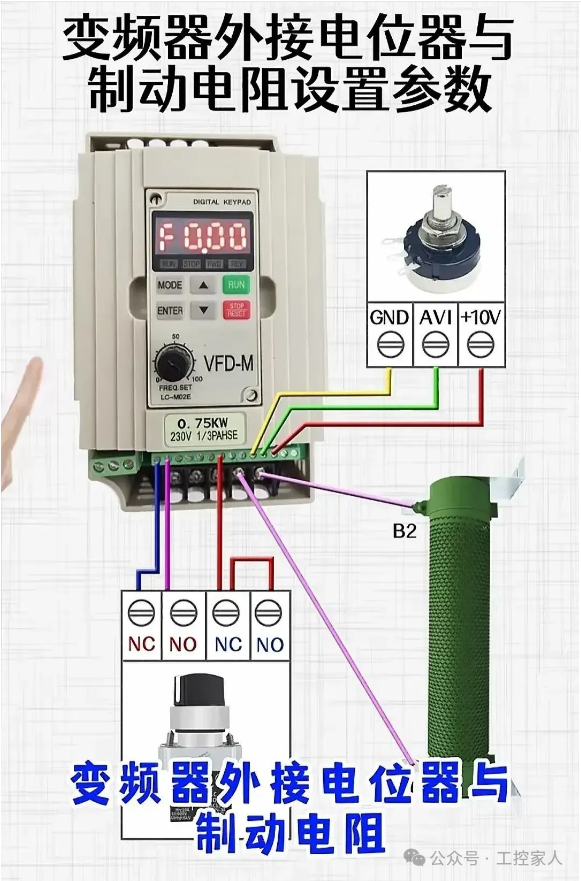

Seventeenth: Modbus RTU Communication Commands Eighteenth: External Potentiometer and Braking Resistor Parameter Settings for Inverters

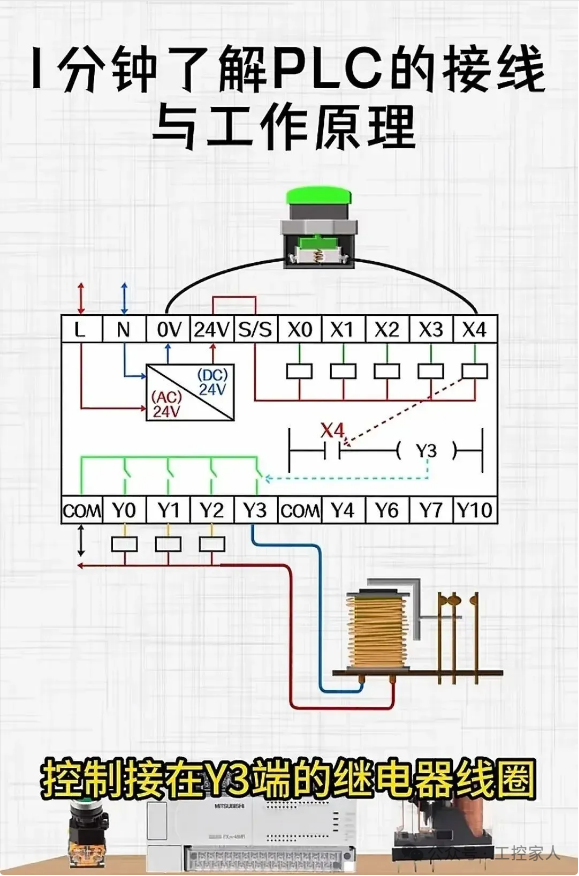

Eighteenth: External Potentiometer and Braking Resistor Parameter Settings for Inverters Nineteenth: Understand PLC Wiring and Working Principles in 1 Minute

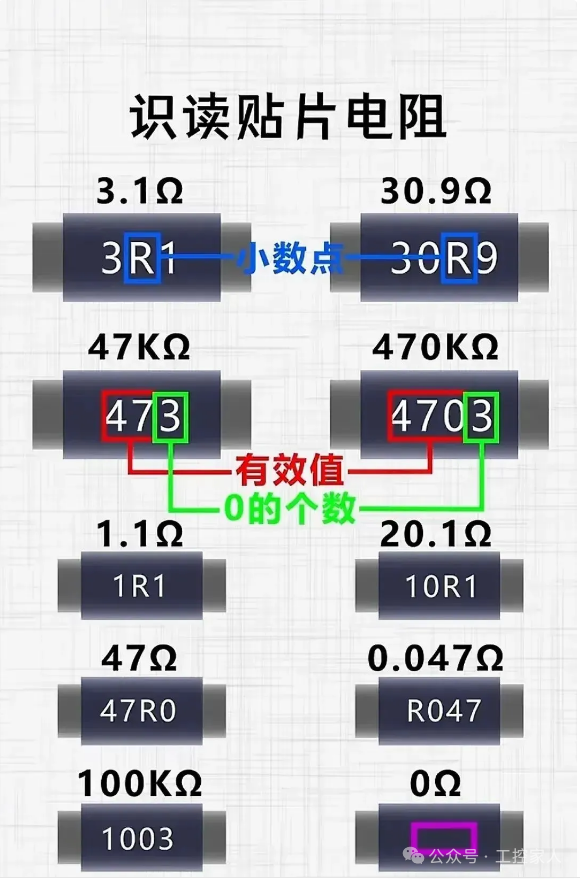

Nineteenth: Understand PLC Wiring and Working Principles in 1 Minute Twentieth: Reading Surface-Mounted Resistors

Twentieth: Reading Surface-Mounted Resistors Everyone, please like and share!

Everyone, please like and share!