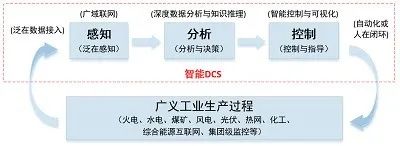

The modern industrial production process is rapidly developing towards large-scale, integrated, complex, and refined directions. Major equipment and significant projects increasingly rely on control systems for operational control.Control systems have become the brain and nervous system of modern industrial production processes, and their development level directly reflects the level of industrial production.Among them, Distributed Control Systems (referred to as “DCS”) are the main force in control systems.