Click the blue text to follow us

“

Research on Matching Layer Materials and Performance of 200kHz Ultrasonic Distance Sensors

”

01

#

Research Summary

#

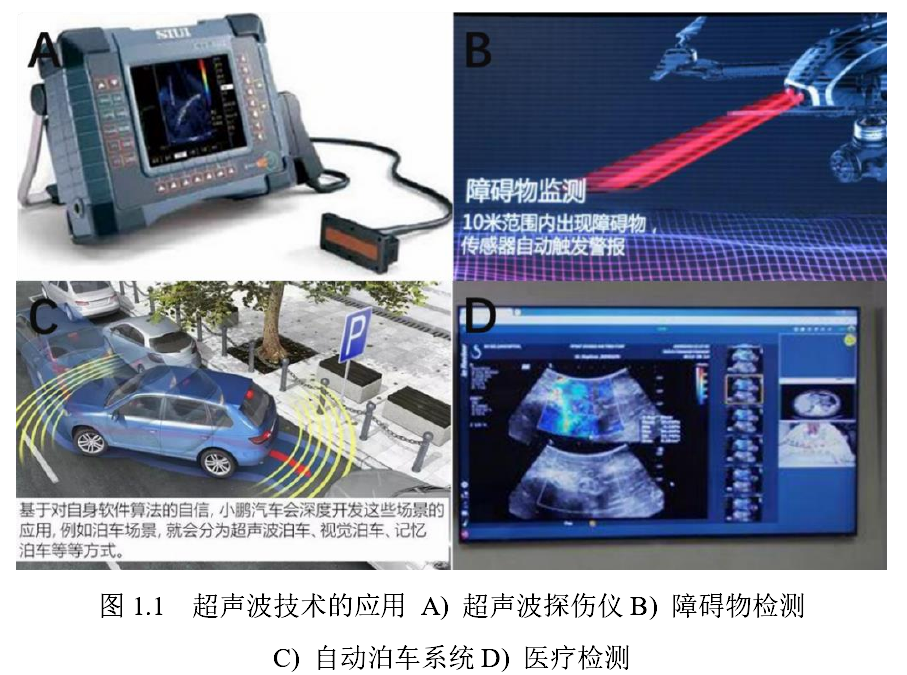

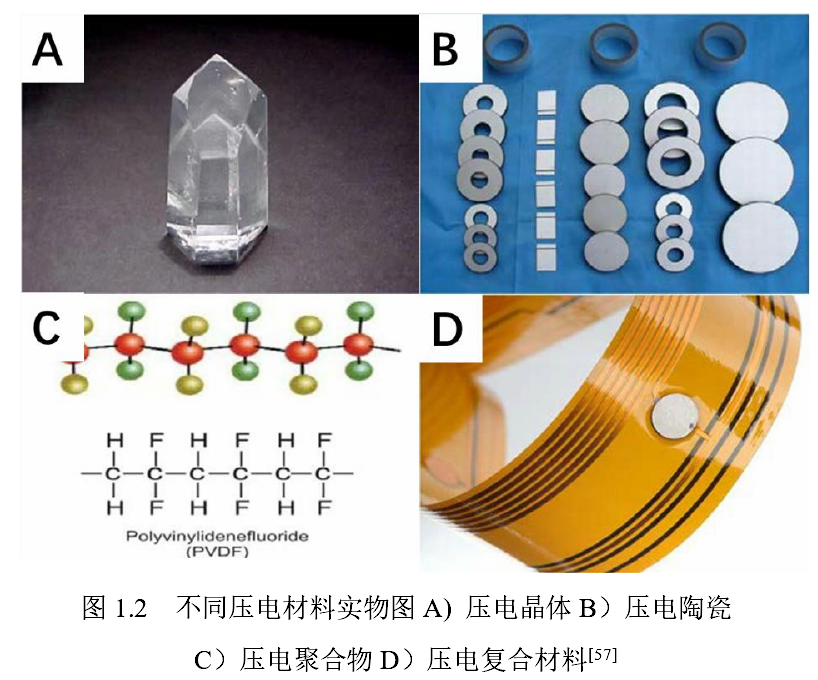

In today’s rapidly advancing technology, ultrasonic waves have gained widespread attention from researchers due to their good directionality, penetration, and anti-interference capabilities. The key to the application of ultrasonic technology lies in ultrasonic sensors, which are devices that emit and receive ultrasonic waves using the piezoelectric properties of piezoelectric elements. There exists a certain acoustic impedance mismatch between the sensor’s piezoelectric element and the detection target, which can lead to phenomena such as reverberation, self-heating, low signal-to-noise ratio, and signal distortion within the sensor. Therefore, to improve the performance of ultrasonic sensors, it is necessary to add a matching layer to the device to reduce acoustic mismatch, thereby enhancing the coupling between the sensor and the medium through effective acoustic impedance transition. Addressing the issue of domestic ultrasonic distance sensors performing significantly below comparable imported products, Wang Qiang from Hubei University of Arts and Science conducted research on the industrial preparation scheme of matching layers for domestic piezoelectric elements used in sensors, as well as the assembly and performance optimization of ultrasonic sensors.

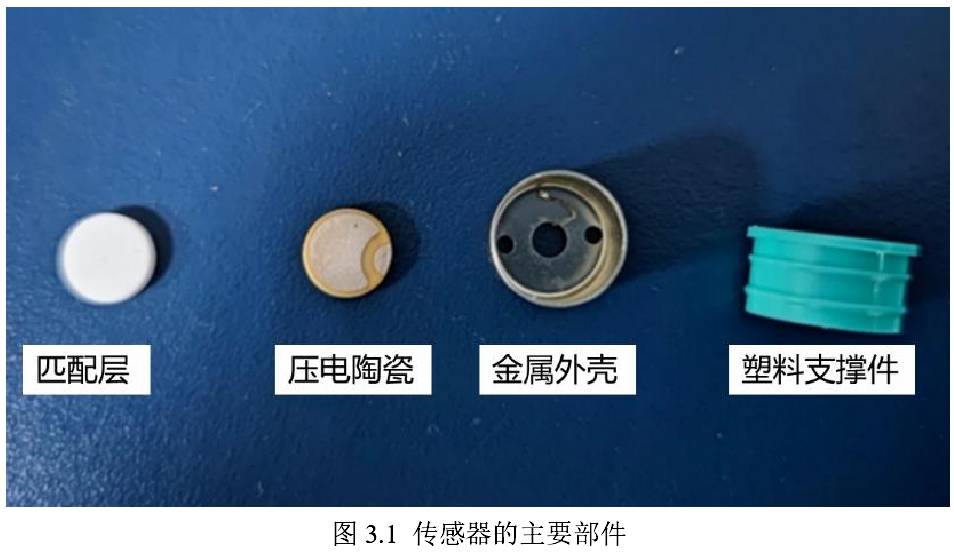

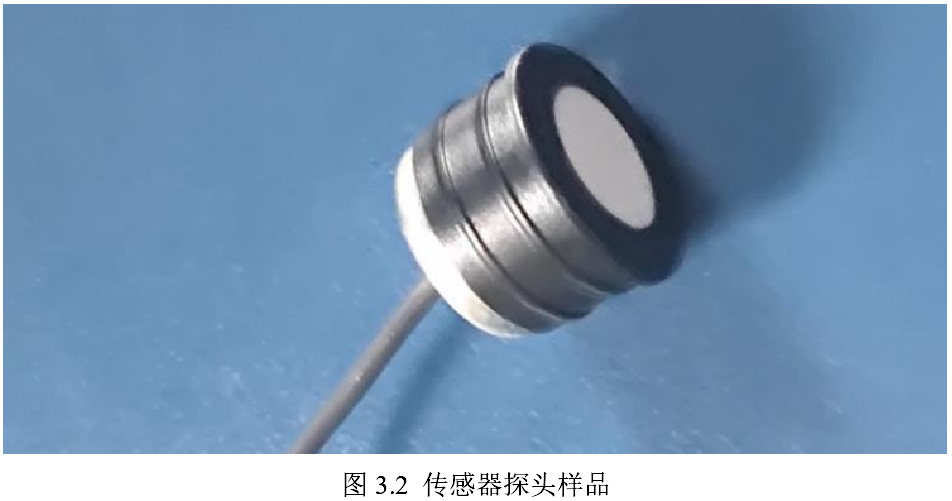

To meet the needs of industrial production and ultrasonic distance sensing, the author Wang Qiang selected the commonly used 200kHz PZT-5 lead zirconate titanate piezoelectric ceramic, which closely matches the frequency range of imported products, as the piezoelectric transducer for the ultrasonic sensor. He chose four models of hollow glass microspheres (k1, k20, k25, s32) produced by 3M and commercial epoxy resin as bonding materials to prepare the matching layer. Based on the selection of epoxy resins with suitable viscosity and curing properties, the impact of the preparation process on the performance of the matching layer was explored. By comparing the impedance characteristic curves of the piezoelectric ceramic before and after the matching layer was applied using an impedance analyzer, the effects of matching layer thickness and filler concentration on the impedance performance of the ultrasonic sensor probe were tested and analyzed. The study found that due to the influence of the bonding process, the matching layer thickness does not strictly adhere to the quarter-wavelength principle in practical applications, and must be rigorously selected based on actual processes to achieve optimal matching results. The concentration of the matching layer filler has little effect on the sensor’s resonant frequency and anti-resonant frequency, but it can cause significant changes in the difference between the forward and reverse resonant frequencies, with optimal matching layer performance occurring when the difference is around 60kHz.

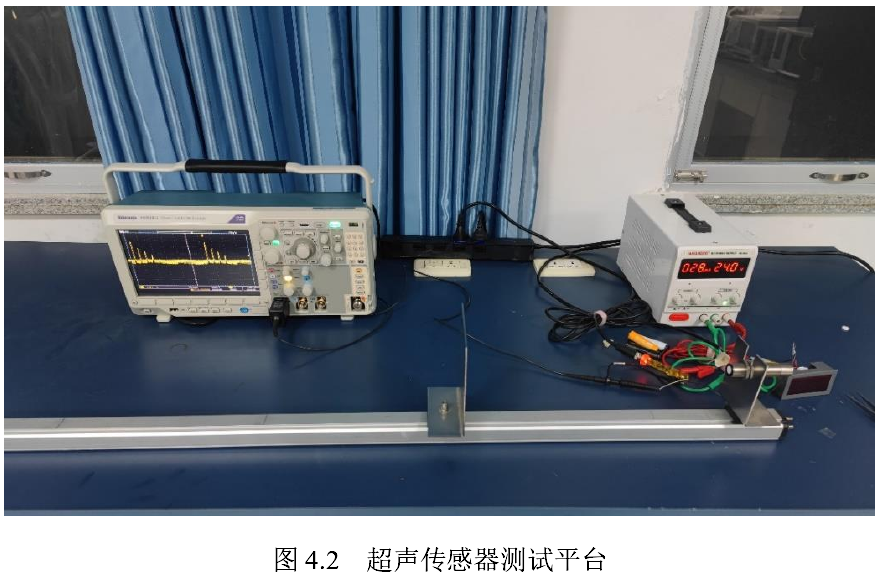

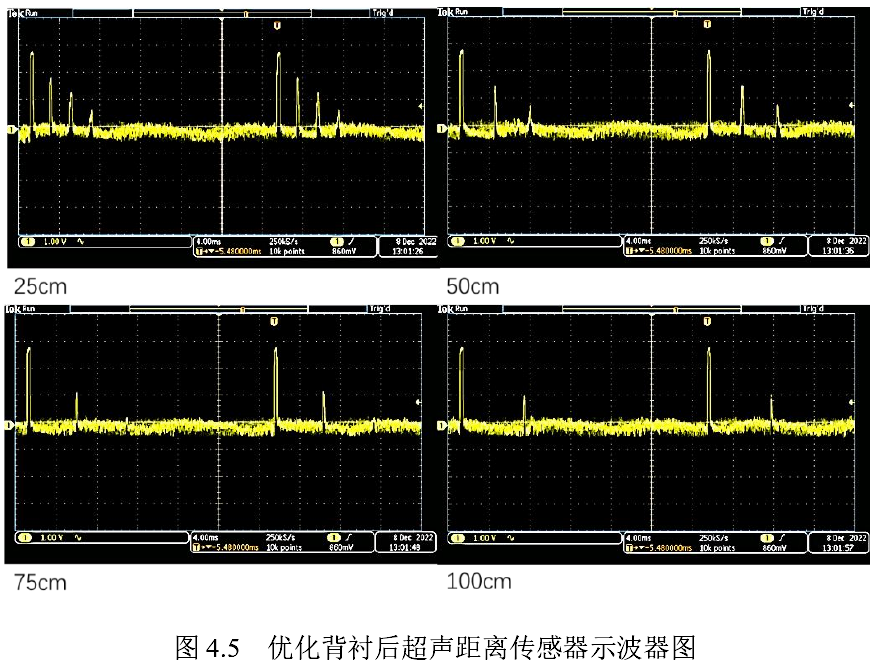

Some ultrasonic sensor circuits were designed, and a performance testing platform for ultrasonic sensors was built. The ultrasonic sensor probes that met performance standards were tested on the ultrasonic sensor testing platform, resulting in echo signal graphs from the ultrasonic sensors. The distance between the metal reflector and the ultrasonic sensor probe was directly read using an external ammeter. Through multiple process controls, the ultrasonic sensing distance of the sensor developed using the optimal piezoelectric element from this paper can reach 1.8 meters, which is 1.5 times that of similar domestic products and approaches the performance of imported counterparts. Subsequent optimizations of backing materials, bonding processes, and packaging processes are expected to enable this sensor to meet or even exceed the performance of imported counterparts, achieving domestic substitution for such sensor products. The author’s research provides significant guidance for the preparation of matching layers and the production of similar sensors.

02

#

Research Process

#

References:

[1] Wang Qiang. Research on Matching Layer Materials and Performance of 200kHz Ultrasonic Distance Sensors [D]. Hubei University of Arts and Science, 2023.

Disclaimer: The images and text used in this article are reproduced. If there are any copyright issues, please inform us immediately, and we will confirm and delete the content based on the proof materials you provide.The content of this article represents the author’s personal views and does not reflect the views or positions of Ultrasonic Intelligent Measurement Island.

Special Reminder: To enhance scientific research innovation and various services, we have opened a professional communication group for ultrasonic science and technology cooperation QQ Group 115997706. We provide free services for companies and research institutions, including: 1. Company introductions; 2. Recruitment; 3. Product promotion; 4. Technical exchanges, etc. Interested friends can contact us through QQ group or public account. Please note your name, organization, and research direction when joining the group (without notes, we regret that we cannot approve), and you will be invited to join the group after the editor’s review.

END