The popularity of personal computers has laid the foundation for the Internet, and the development of smartphones has ushered us into the era of mobile Internet. Now, we are entering the era of perception and witnessing the surge of the Internet of Things (IoT).

One of the key technologies in the IoT is sensor technology. The four major application areas of the sensor market in China are industrial, automotive electronics, communication electronics, and consumer electronics. Wireless Sensor Networks (WSN) play a pivotal role in the application of industrial IoT, connecting independent sensor units through wireless networks and aggregating the data collected by various sensors for collaborative monitoring of physical or environmental conditions across spatially dispersed areas, enabling corresponding analysis and processing based on this information. Thus, the arrival of the perception era and the rise of Industry 4.0 have created favorable development opportunities for industrial sensors and industrial wireless sensor network products.

1. Current Status and Development Factors of Industrial IoT

The IoT is an important component of China’s strategic emerging industries, containing enormous economic value, and endowing the “integration of informatization and industrialization” with more intelligent connotations. Transforming traditional industries with the IoT will undoubtedly enhance the economic added value of traditional industries, effectively promoting the shift of China’s economic development model from production-driven to innovation-driven, and facilitating the adjustment of China’s industrial structure. At the same time, the innovation of new technologies, products, applications, and service models in the IoT will inevitably give rise to a batch of emerging business formats, becoming a new economic growth point for China.

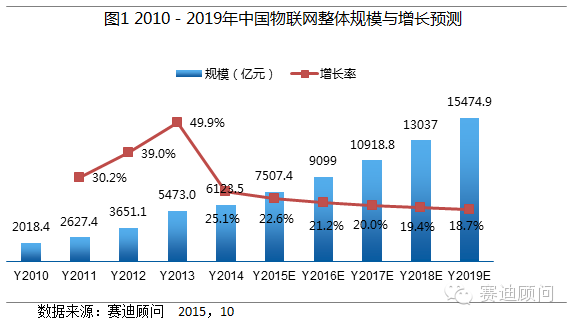

Currently, the development of the IoT in China is at a nascent stage, having initially established a certain technological, industrial, and application foundation, showing a good development trend. According to data from the Ministry of Industry and Information Technology, the total sales revenue of China’s IoT industry reached over 600 billion yuan in 2014. In recent years, the comprehensive growth rate of China’s IoT industry has exceeded 30%, fully reflecting its strong development momentum.

The IoT consists of sensing terminals, information transmission, processing centers, and application users, and its technology has entered the practical application stage in various fields such as smart industry, smart agriculture, smart logistics, and smart transportation. Industry is a crucial area for IoT applications. The industrial IoT integrates sensors into various industrial equipment such as power grids, railways, bridges, tunnels, highways, buildings, water supply systems, and oil and gas pipelines, achieving an organic fusion of the IoT with industrial processes, significantly improving manufacturing efficiency, enhancing product quality, and reducing product costs and resource consumption, thus elevating traditional industries to smart industries.

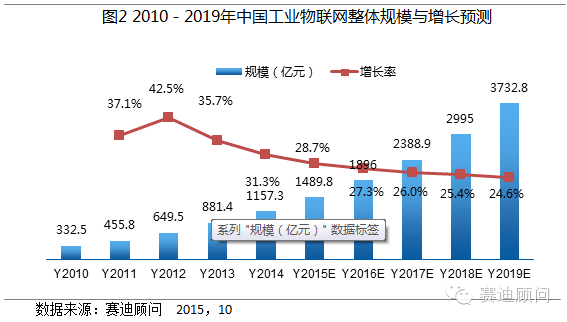

In 2014, the scale of China’s industrial IoT reached 115.73 billion yuan, accounting for about 18% of the overall IoT industry. With policy support, it is expected that by 2020, the industrial IoT will account for 25% of the overall IoT industry, with a scale exceeding 450 billion yuan.

As shown in the figure above, the overall scale of China’s industrial IoT is expected to maintain a growth momentum of over 25% in the coming years. The enhancement of manufacturing enterprises’ competitiveness is the main driving force behind the development of industrial IoT. Currently, many Chinese enterprises are on the edge of Industry 2.0 and 3.0, with low levels in cost control, production efficiency, and process management, indicating significant room for improvement. IoT technology creates a convergence point for the integration of informatization and industrialization, allowing the informatization process and industrialization process to no longer proceed independently, but rather to interweave at various levels of technology, products, and management, driving industrialization with informatization and promoting informatization with industrialization, helping enterprises transform their production processes, organizational management, and service upgrades, thereby enhancing their competitiveness in the market.

At the same time, policy factors have strongly promoted the development of industrial IoT. With the global advancement of the Industry 4.0 strategy, smart industry has gradually become the focus of various countries. Against the backdrop of encouraging energy conservation and emission reduction and green environmental protection, from the proposal of the IoT-based “Perception China” initiative in 2009, to the release of the “12th Five-Year Plan for IoT Development” by the Ministry of Industry and Information Technology in 2012, and to the approval of the Chinese version of the “Industry 4.0” plan “Made in China 2025” by Premier Li Keqiang in 2015, the development of industrial IoT in China has a favorable policy environment.

2. Current Status and Future Trends of Industrial Sensors

Sensors play a crucial role in industrial automation, providing important information connectivity between the physical world and control systems. In industrial process control, computer technology has matured, and the amount of information to be collected is continuously increasing. The production process requires a large number of various sensors, such as pressure sensors, temperature sensors, light sensors, gas sensors, humidity sensors, and magnetic sensors, converting a large number of non-electric physical parameters into electrical signal control information to meet the automation and intelligence development needs in various industrial processes. Currently, the most commonly used sensors include pressure, displacement, acceleration, angular velocity, temperature, humidity, and gas sensors.

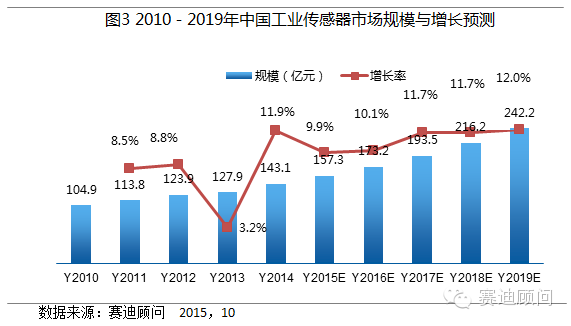

The overall quality of China’s sensor industry is uneven, with insufficient self-sufficiency in high-end products. In 2014, there were over 2,000 enterprises and institutions engaged in sensor research, production, and application in China, with more than 50 companies involved in micro-system research and production, offering over 6,000 product types, with an annual total output of over 4 billion units and a market sales volume close to 100 billion yuan. Among them, the application scale of sensors in the industrial field reached 14.31 billion yuan in 2014, accounting for about 15% of the sensor market scale.

In the coming years, the comprehensive application of information technology in the industrial field will promote rapid growth in the industrial sensor market scale. The proposal of “Made in China 2025” will facilitate the comprehensive intelligent transformation of enterprises, accelerate product updates, and improve product technological content, gradually narrowing the gap between domestic and international advanced levels. By integrating modern information technologies such as sensors, microprocessors, PLCs, and digital communication interfaces into production equipment, industrial environments, and process management, the degree of digitization, intelligence, and networking of products will be enhanced, ultimately improving the competitiveness of China’s manufacturing enterprises and the overall industrial level. Thus, sensors will have broad application prospects in the industrial field.

However, traditional sensors still face some limitations in the industrial field: sensors connected to buses are expensive, the cost of sensor networking is high; wiring in hazardous areas that are difficult for personnel to access is challenging; and there is incompatibility between protocols of different types of sensors and control systems.

In this context, with the development and maturity of wireless sensor network technology, wireless sensor network products are gradually replacing traditional wired sensor products due to their unique advantages, penetrating various aspects of the industrial field and becoming a new market hotspot. Compared to traditional wired sensors, wireless sensors have several advantages:

1. Wireless sensors offer high flexibility. They are suitable for situations where mobility is required but wiring is inconvenient, such as cranes, mobile bottling equipment, the transportation industry, automated guided vehicle systems, and monorail conveyors.

2. Wireless sensors provide high reliability. Wireless sensors can avoid damage caused by movement, such as wire bending from long drag chains and cable twisting or breaking due to rotational movement. Additionally, they eliminate failure factors caused by connectors in wired networks.

3. Wireless sensors ensure high safety. With the development of technology and the emergence of new threats, the ability to upgrade security maintenance is essential. New encryption strategies and covert data transmission indicate that wireless security levels will surpass those of wired systems. Moreover, in some hazardous extreme environments, such as blasting sites where wiring is inconvenient, wireless sensors can ensure personnel safety.

4. Wireless sensors can significantly reduce labor workload. In areas where cable construction is not feasible due to terrain influences such as bridges, rivers, and mountains, wireless sensors can reduce labor costs and project cycles. When faults occur, wireless sensor repair points are relatively centralized, eliminating the cumbersome tasks of traditional line patrols.

5. Wireless sensors are cost-effective. Compared to wired sensors, wireless sensors have significant cost advantages in installation, maintenance, fault diagnosis, and upgrade wiring expenses.

Today, modern industrial production is moving towards large-scale, rapid, efficient, low-consumption, and environmentally friendly directions. With the development of information technology, the intelligence of production and business processes is a prerequisite for overall intelligence. Enterprises are increasingly implementing production line transformations and IT equipment upgrades to achieve internal internetization, ultimately realizing a deep integration of new-generation information technology with manufacturing, forming new production methods, industrial forms, and business models. Wireless sensors, due to their flexibility, safety, reliability, convenience, and low cost, will play a special role in the future of intelligent production in enterprises.

3. Current Status and Trends of Industrial Wireless Sensor Network Products

Industrial wireless sensor network products are system-level products, including field wireless sensors, data forwarding gateways, and monitoring hosts, among other comprehensive solutions. Due to their low cost, wide range, flexible deployment, and mobility support, industrial wireless sensor network products have been widely recognized in industries such as mechanical parameter detection, industrial monitoring, smart power, mine safety, medical health, and environmental monitoring. At the same time, industrial wireless sensor network products also face technical challenges such as extending node working time, increasing communication distance, miniaturization, standardization, and finding application scenarios.

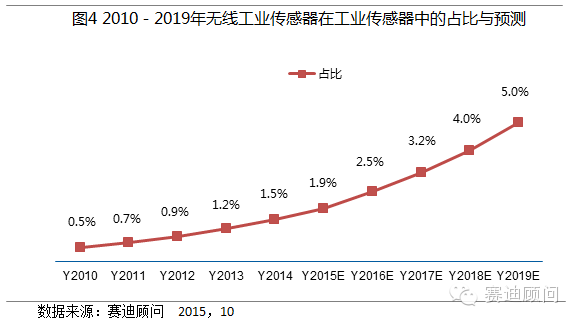

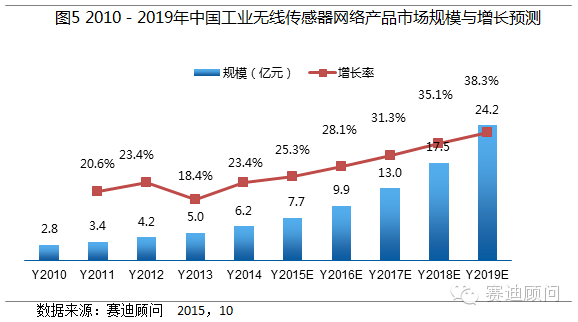

With the continuous maturity of industrial wireless sensor network technology and the increasing market demand, the replacement effect of industrial wireless sensor network products on traditional industrial sensors is continuously improving. In 2014, industrial wireless sensor network products accounted for about 4.3% of the industrial sensor market in China, with a scale of 620 million yuan. By 2019, the share of industrial wireless sensor network products in the industrial sensor market is expected to reach 10.0%, with a market scale projected to reach 2.42 billion yuan, achieving a compound annual growth rate of 27.1%, indicating a broad market prospect.

The transition from wired networks to wireless networks will accelerate the growth of wireless sensor networks, allowing access to a wider, more flexible, and scalable range of applications than wired networks. With the rapid development of wireless sensor network technology in recent years, more and more wireless sensor network products are being put into use. Currently, wireless sensor network products are mainly used in the detection and monitoring markets.

Wireless sensor network products are primarily applied in the detection market in fields such as defense research, universities, professional research and testing institutions, and large equipment manufacturing. In these detection fields, wireless sensor network products have significant advantages over wired products, including lower costs, higher flexibility, and a wide range of application scenarios, indicating a future trend of wireless replacing wired.

Defense products require extensive testing to ensure precision and stability, thus imposing high reliability requirements on sensors used for testing defense products. In recent years, the country has begun to implement more major defense projects and is committed to self-control, coupled with a high replacement frequency, leading to a gradual expansion of demand for testing sensors. Currently, China has a certain scale of universities and a relatively complete talent training system, but there is still a gap in teaching equipment compared to foreign countries.

Similarly, China’s research institutions also face the issue of relatively outdated experimental equipment. In the future, with the development of China’s education industry, the demand for purchasing related teaching and experimental equipment will rapidly expand, indicating a broad market prospect for testing sensors. China is also increasing its efforts to develop the testing industry, with the demand for testing infrastructure construction such as roads, railways, and bridges continuing to grow, leading to increased demand for testing sensors from professional research and testing institutions. With the development of smart manufacturing, the demand for high-end large equipment is also increasing. Testing devices can effectively reduce product development cycles, improve product quality, and lower product costs. Testing sensors have gradually become a necessity for large equipment manufacturing enterprises in the product development process, indicating an upward trend in the market scale of testing sensors in the large equipment manufacturing sector.

Wireless sensor network products are mainly applied in the monitoring market in the following areas:

1Industrial Environmental Monitoring

The monitoring scope of industrial environments has covered various aspects of the entire ecological environment, including daily environmental monitoring such as air, water, electromagnetic radiation, and radioactive monitoring; as well as monitoring in special areas such as deserts, high mountains, and areas with radiation sources. These environments impose high requirements on the flexibility, reliability, and safety of sensor products.

Wireless sensor network products can break through traditional monitoring methods, reducing costs while meeting flexibility, reliability, and safety requirements for industrial environmental monitoring, significantly streamlining the cumbersome processes of traditional monitoring and facilitating the acquisition of random research data. As public concern for industrial environments increases, the demand for environmental data collection is also growing, leading to a gradual expansion of demand for wireless sensor network products.

2Smart Grid

Currently, global issues such as energy, environment, and climate change are becoming increasingly prominent, prompting countries worldwide to focus on the development and utilization of clean energy as a key aspect of energy development and transformation. The smart grid has now become one of the important applications of IoT technology and an inevitable trend in grid development. The smart grid ensures the safety, reliability, and economy of power supply through the application of advanced sensing measurement technology, communication technology, advanced control methods, and decision support system technology. To ensure the continuous operation of the smart grid, equipment safety assurance has become a critical issue. Since grid equipment operates under high voltage and high current for extended periods and faces threats from extreme natural environments such as thunderstorms, implementing intelligent monitoring of equipment is particularly important. Wireless sensor network products can remotely monitor grid equipment, understand the operational status of the equipment, and transmit data to the control center for unified management, while real-time monitoring also improves maintenance efficiency. As the smart grid plan progresses, the demand for intelligent monitoring of grid equipment is creating a huge market for wireless sensor network products.

3Digital Oilfield

The continuous expansion of economic development and social demand is accelerating the rapid increase in the number of oil wells, and the overall scope of oilfield development is also expanding. Therefore, the intelligentization of oilfield production, management, and operation has become a development trend, giving rise to the digital oilfield.

In the digitalization process of oilfields, wireless sensor network products can achieve real-time monitoring of oil well environments and wellhead equipment, transmitting important information such as equipment status and environmental parameters from the work site to the control center, issuing alarms and arranging dispatch when necessary. With the in-depth promotion and widespread demonstration of wireless sensor network products in oilfields, the number of digital oilfields will gradually increase, and the market demand for wireless sensor network products will show rapid growth.

4Smart Industry

China’s manufacturing industry is facing a new round of industrial revolution opportunities, and the demand for manufacturing enterprises to utilize IoT technology for transformation and upgrading is urgent. Information technology companies are also actively leveraging IoT technology as a breakthrough to penetrate the industrial field rapidly. The proposal of Industry 4.0, centered on intelligence, aligns with the trend of integrating IoT technology into the industrial field, indicating significant market development potential in the future. One of the cores of smart manufacturing is the intelligent monitoring of industrial processes.

Applying wireless sensor network technology to intelligent monitoring will help optimize industrial production processes, while also enhancing the capabilities and levels of process detection, real-time parameter collection, production equipment monitoring, and material consumption monitoring, continuously improving the levels of intelligent monitoring, intelligent control, intelligent diagnosis, intelligent decision-making, and intelligent maintenance in production processes. With the rapid development of the IoT and the further advancement of Industry 4.0, the market demand for industrial process monitoring system solutions based on wireless sensor network technology will grow rapidly.

The rapid growth of industrial wireless sensor network products is primarily due to the maturation of the entire IoT ecosystem, with industrial IoT gradually developing from government-led initiatives. The number of industrial sensing terminals in China has been growing rapidly, with approximately 700 million industrial sensing terminals in 2014, and it is expected that with the implementation of Made in China 2025, the number of industrial sensing terminals in China will exceed 2 billion by 2020.

At the same time, developments in wireless communication, power consumption, extreme miniaturization (one of the driving forces being MEMS sensors), and embedded computing have also contributed to the rise of wireless sensor networks designed for harsh industrial environments. Industrial wireless sensor network products will continue to grow rapidly due to the enterprise production line transformations and IT equipment upgrades driven by the proposal of Made in China 2025, maintaining an upward trend.

Author: Li Long

— Analyst at the Semiconductor Industry Research Center of CCID Consulting—

China’s Largest Industry Decision-Making Support O2O Platform

China’s Largest Industry Decision-Making Support O2O Platform

Click to read the original text and download the CCID Consulting “Industry Tong” APP.