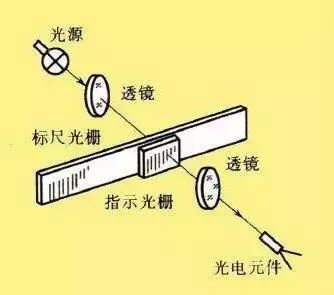

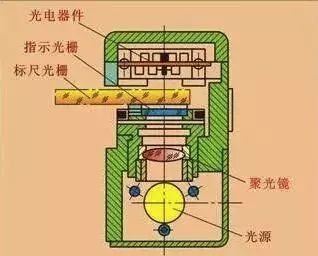

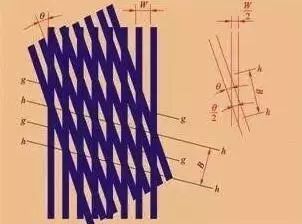

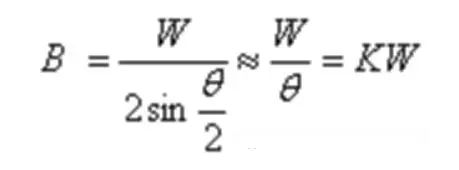

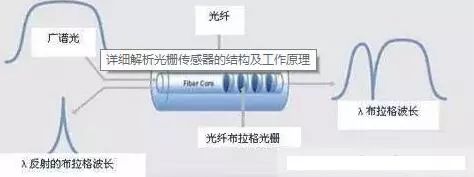

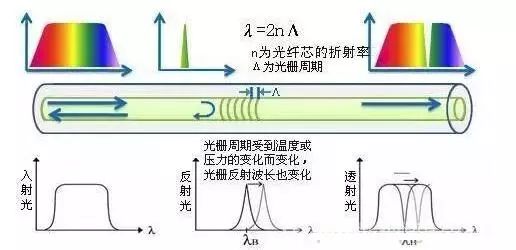

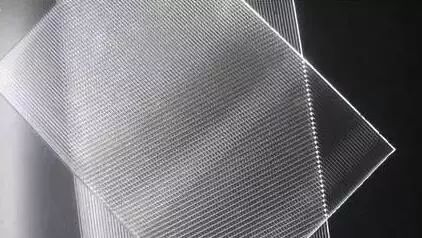

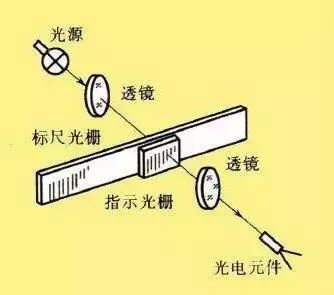

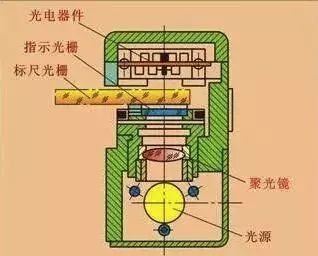

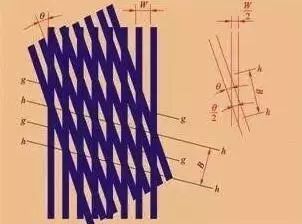

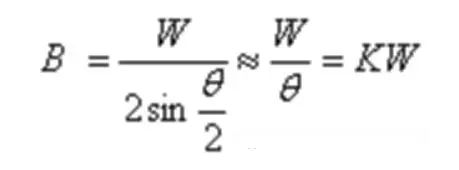

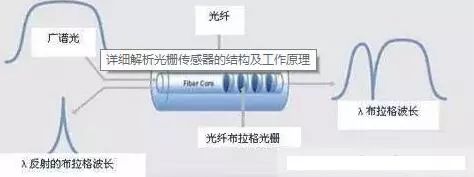

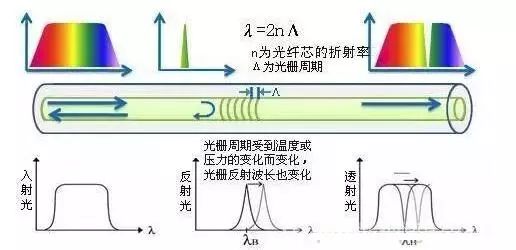

Grating Sensors

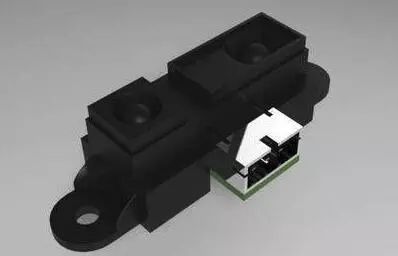

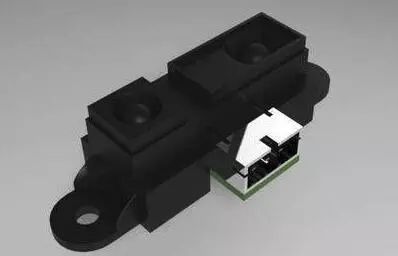

Infrared Sensors

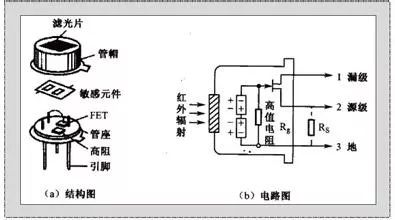

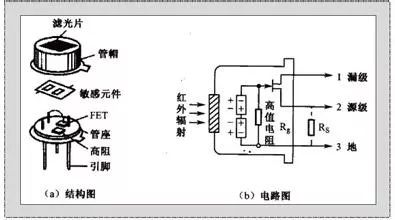

Pyroelectric Infrared Sensors

Fiber Optic Gyroscope Sensors

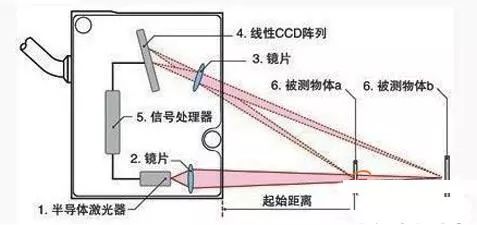

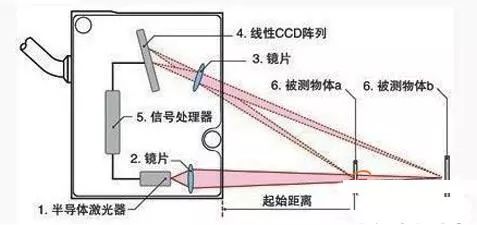

Laser Displacement Sensors

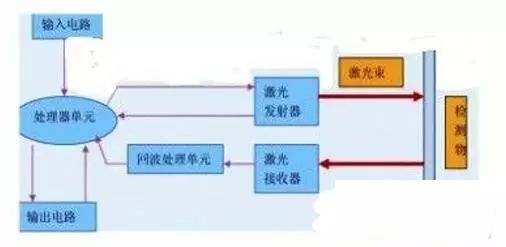

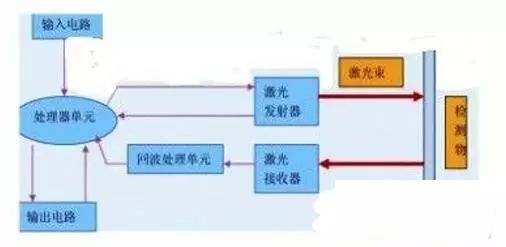

Laser Ranging Sensors

0.001m(3X10^8m/s)=3ps

Grating Sensors

Infrared Sensors

Pyroelectric Infrared Sensors

Fiber Optic Gyroscope Sensors

Laser Displacement Sensors

Laser Ranging Sensors

0.001m(3X10^8m/s)=3ps