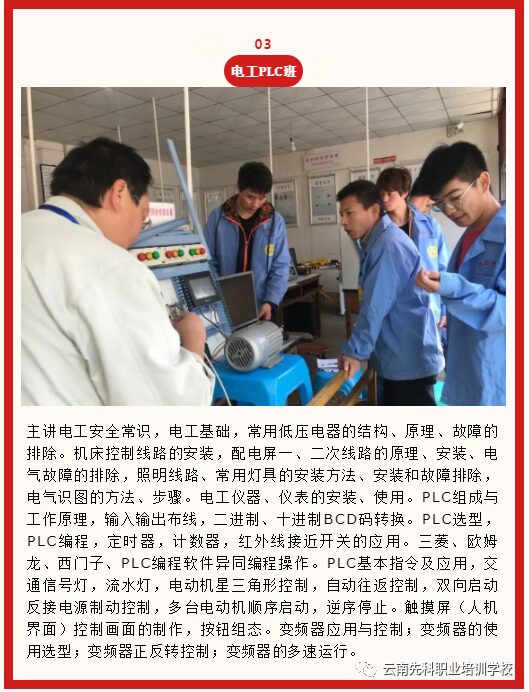

In modern industrial production equipment, there are a large number of digital and analog control devices, such as the start and stop of motors, the opening and closing of solenoid valves, product counting, and the setting and control of temperature, pressure, and flow. For these automatic control issues in industrial sites, Programmable Logic Controllers (PLCs) have become one of the most effective tools for solutions.

When designing a PLC control system, the following points should be noted.

1. Selection of Programmable Logic Controllers (PLC) and Programmers

Currently, there are many PLC products on the market. In addition to domestic brands, foreign brands include: Japan’s OMRON, MITSUBISHI, FUJI, IDEC, HITACHI, Panasonic, Germany’s Siemens, and Korea’s LG. How to select PLC products?

1. System

First, determine whether the system uses a single PLC for control or forms a network with multiple PLCs. This will allow you to calculate the number of input and output (I/O) points, and when purchasing a PLC, it is necessary to reserve an additional 10% capacity based on the actual required points.

2. Determine Load Type

Based on whether the load connected to the PLC output is DC or AC, whether it is high current or low current, and the frequency of the PLC output points, determine whether to use relay output, transistor output, or thyristor output. Choosing the correct output method based on different loads is crucial for the stable operation of the system.

3. Execution Speed

The storage capacity and execution speed of instructions are important indicators for selecting a PLC. Generally, the larger the storage capacity and the faster the speed, the higher the price of the PLC. Although the products from foreign manufacturers are generally similar, there are still some differences.

4. Selection of “COM” Points

The number of “COM” points varies among different PLC products. Some have one “COM” point with 8 output points, while others have 4 output points, and some have 1 or 2 output points. When the types of loads are numerous and the current is high, use a product with one “COM” point and 1-2 output points; when the types of loads are few but the quantity is large, use a product with one “COM” point and 4-8 output points.

5. Reasonable Selection of PLC Products

Due to the different development software from various manufacturers, system compatibility is also a key point during selection. Currently, no completely compatible products have been found, so PLC products should be selected reasonably based on the system.

6. Selection of Programmers

PLC programming can be done in three ways:

First, using a general handheld programmer, which can only program using the statements specified in the manufacturer’s statement table. This method is easy for on-site debugging, compact, and low-cost, but its efficiency is low, and it adapts to fewer models, making it more suitable for small systems with low usage.

Second, graphical programming, which uses graphical methods for programming, is convenient and intuitive, and generally, electrical personnel can use it proficiently in a short time, but the programmer is relatively expensive.

Third, programming with an IBM-compatible personal computer + PLC software package, which is the most efficient method and the most commonly used, but most software packages are expensive.

7. Prefer Products from Large Companies

Because their product quality is guaranteed, and they provide good technical support, generally offering better after-sales service, which is beneficial for future product expansion and software and hardware upgrades.

2. Design of Input and Output Circuits

1. Power Supply Circuit

PLC power supply is generally AC85-240V (there are also DC24V), which has a wide range of adaptable power supply, but to resist interference, power purification components (such as power filters, 1:1 isolation transformers, etc.) should be added.

2. Use of DC24V Power Supply on PLC

Most PLC products from various companies have a DC24V power supply, but the capacity of this power supply is small, ranging from tens of milliamps to several hundred milliamps. When using it for loads, attention should be paid to its capacity, and measures against short circuits should be implemented (as overload or short circuit of this power supply will affect the operation of the PLC).

3. External DC24V Power Supply

If the input circuit has proximity switches, photoelectric switches, etc., powered by DC24V, and the capacity of the DC24V power supply on the PLC is insufficient, an external DC24V power supply should be provided; however, the “one” end of this power supply should not be connected to the “one” and “COM” ends of the PLC’s DC24V power supply, otherwise it will affect the operation of the PLC.

4. Input Sensitivity

Each manufacturer has specifications for the input voltage and current of the PLC. When the input current of the input element exceeds the maximum input current of the PLC or has leakage current, erroneous actions will occur, reducing sensitivity. Therefore, weak current inputs should be used, and protective measures against leakage current should be taken, and PLCs with leakage-type inputs should be selected.

5. Handling of Inductive Loads

When connecting inductive loads at the input and output ends, a surge suppressor or diode should be connected in parallel across the load, with the cathode of the diode connected to the positive voltage side.

6. External Interlocking and Grounding

When using the PLC to control the forward and reverse rotation of motors and other actions, to avoid abnormal actions of the PLC causing accidents and mechanical damage, an external interlock circuit should be formed.

Grounding: The GR terminal is the ground terminal. Use a dedicated grounding wire (with a cross-sectional area of more than 2mm2) to adopt the third grounding method (grounding resistance below 100Ω).

The LG terminal is a neutral terminal in the noise filter. If erroneous actions occur due to high noise, or to prevent electric shock, short-circuit the LG with GR, using the third grounding method. The length of the grounding wire should preferably be within 20m.

Using the grounding wire with other equipment or connecting it to the metal structure of the building will have adverse effects and be negatively impacted.

7. External Driving Circuit for PLC

If the PLC output cannot directly drive the load, an external driving circuit must be used, which can use solid-state relays or thyristor circuits for driving, and protective circuits and surge absorption circuits should also be used.

Additionally, the wiring of the PLC’s input and output also has certain requirements; please refer to the user manuals of various companies.

3. Selection of Expansion Modules

For small systems, such as those with fewer than 80 points, generally, there is no need for expansion; when the system is larger, expansion is necessary. Different manufacturers’ products have limitations on the total number of points and the number of expansion modules. When expansion still cannot meet the needs, a network structure can be adopted.

At the same time, some manufacturers’ products do not support certain instructions for expansion modules, so attention should be paid during software programming. When using temperature or other analog modules, various manufacturers also have some specifications; please refer to the relevant technical manuals.

4. PLC Network Design

When designing a network using PLCs, the difficulty is much greater than that of single PLC control. First, select a model you are familiar with, and have a deeper understanding of its basic instructions and functional instructions, as well as the execution speed of instructions and user program storage capacity. Otherwise, it may not meet real-time requirements, leading to system crashes. Additionally, consider communication interfaces, communication protocols, data transmission speeds, etc.

Finally, seek network design and software support, as well as detailed technical materials from the PLC manufacturer. The number of working stations to be selected depends on the size of the system.

5. Software Programming

Before programming, first familiarize yourself with the PLC product manual you have selected, and once familiar, proceed with programming.If using graphical programmers or software package programming, you can program directly; if using a handheld programmer, you should first draw the ladder diagram, then program, which can reduce errors and speed up the process. After programming is completed, first run it empty, and once all actions are normal, proceed to debugging on the equipment.

The images and text are sourced from the internet; if there is any infringement, please contact us for deletion!

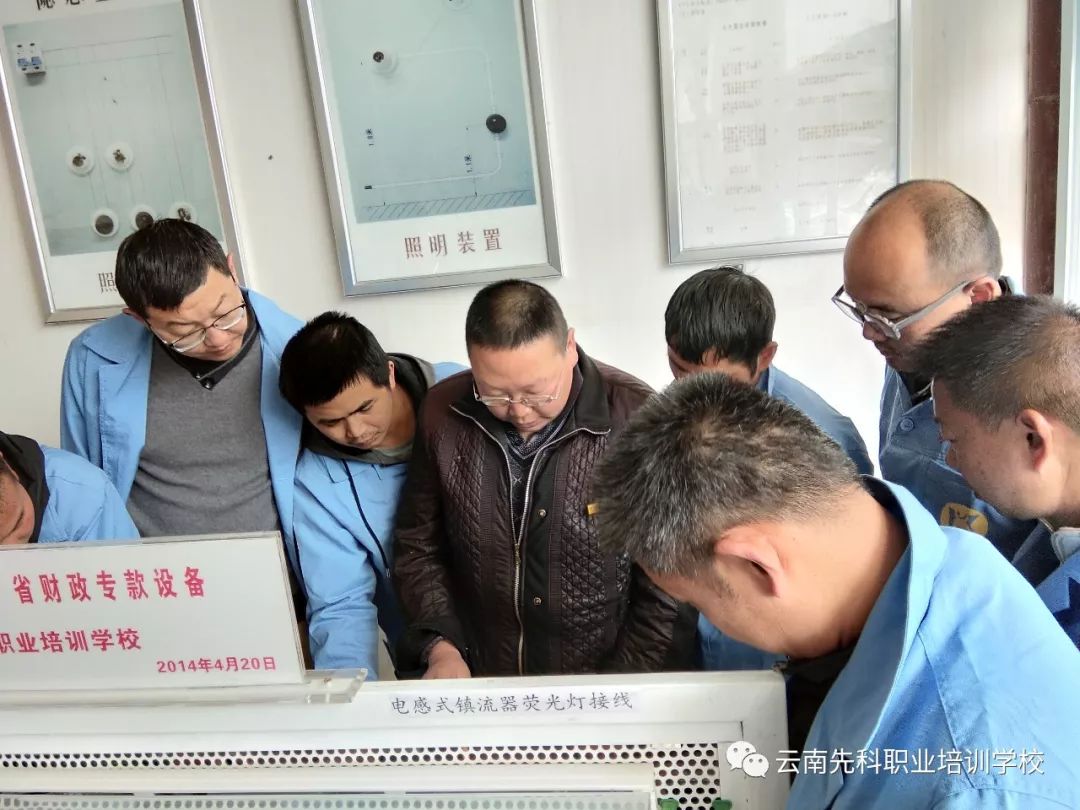

Professional electrician PLC training at Xianke, learn anytime, theory in the morning, practical in the afternoon.

Enrollment is open all year round, classes start every month; cyclical teaching, learn anytime, uniform accommodation; job placement recommended!1. Registration Method:

Registration at any time, on-site registration, WeChat registration, QQ registration are all acceptable.2. Registration Conditions:

(Zero-Basic Training Class)1. No age, gender, or regional restrictions; 2. No educational restrictions; 3. Must meet corresponding physical conditions.

3. Registration Hotline:

Contact Number: 0871—65131138Address: 485 Tanhua Road, Kunming (next to the back gate of Tanhua Temple Park)Website: www.ynxk.com.cn