Sensors are devices designed based on the physical, chemical, and biological properties and laws of materials. There are various types, and in the measurement and control field, a sensor designed based on a certain principle can simultaneously measure multiple non-electrical quantities. Sometimes, a single non-electrical quantity can be measured by various sensors based on different principles. Therefore, there are many classification methods for sensors, which can generally be categorized as follows.

1. Classification by Input Quantity

Sensors can be classified into pressure, displacement, speed, temperature, humidity, etc., based on input quantities. This classification method clearly expresses the purpose of the sensor, making it easier to choose. However, this classification method groups sensors with different principles into one category, making it difficult to identify the commonalities and differences in the conversion principles of each type of sensor.

2. Classification by Measurement Principle

This classification method is based on principles, laws, and effects from physics and chemistry, such as voltage type, thermoelectric type, resistive type, photoelectric type, inductive type, etc. The advantage of this classification method is that it provides a clear understanding of the working principles of sensors, with fewer categories, facilitating in-depth analysis and research on sensors.

3. Classification by Energy Relationship

From the perspective of energy, sensors can be divided into active sensors and passive sensors. The former converts non-electrical energy into electrical energy, known as energy conversion sensors. These typically work with voltage measurement circuits and amplifiers, such as piezoelectric, thermoelectric, and electromagnetic sensors. Passive sensors, also known as energy control sensors, do not function as transducers themselves; the measured non-electrical quantity only controls or adjusts the energy within the sensor. Therefore, they require an auxiliary power supply, and this type of sensor includes resistive, capacitive, and inductive sensors.

4. Classification Based on Semiconductor Theory

These include semiconductor force-sensitive, temperature-sensitive, light-sensitive, and gas-sensitive solid-state sensors.

5. Classification by Output Quantity

Based on output quantity, sensors can be classified into analog and digital types. Analog sensors output analog signals, while digital sensors output digital signals, making them easier to use with computers and more resistant to interference, such as disc-type angular pressure digital sensors and grating sensors.

6. Other Classifications

Sensors can also be classified based on structural types and physical property types.

(1) Structural Type

This mainly involves converting the external measured quantity into corresponding changes in physical quantities such as resistance, inductance, and capacitance through changes in the geometric shape or size of the mechanical structure, thereby detecting the measured signal. This type of sensor is currently the most widely used.

(2) Physical Property Type

This type utilizes changes in the physical properties of certain materials to achieve measurement. It includes solid-state devices with sensitive materials such as semiconductors, dielectrics, and ferroelectrics.

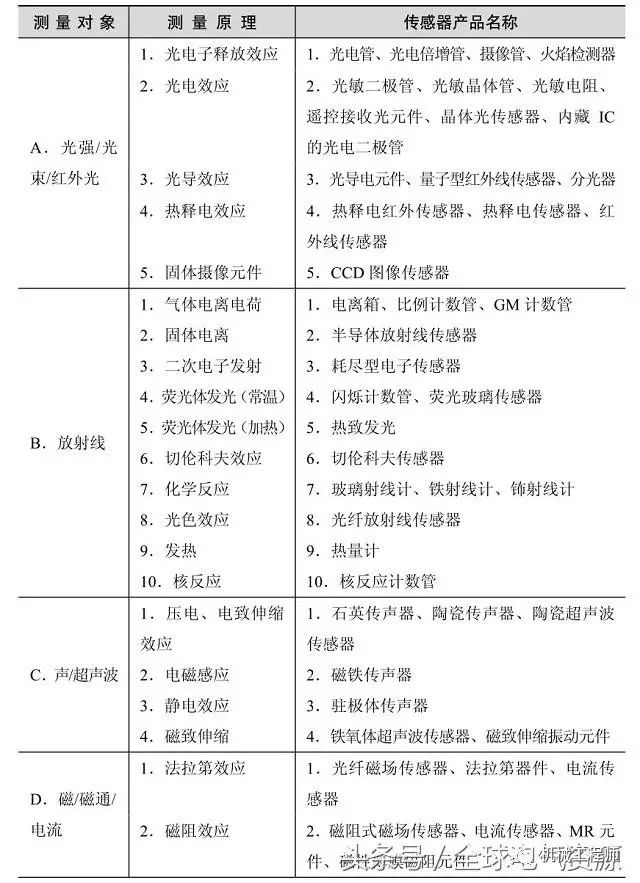

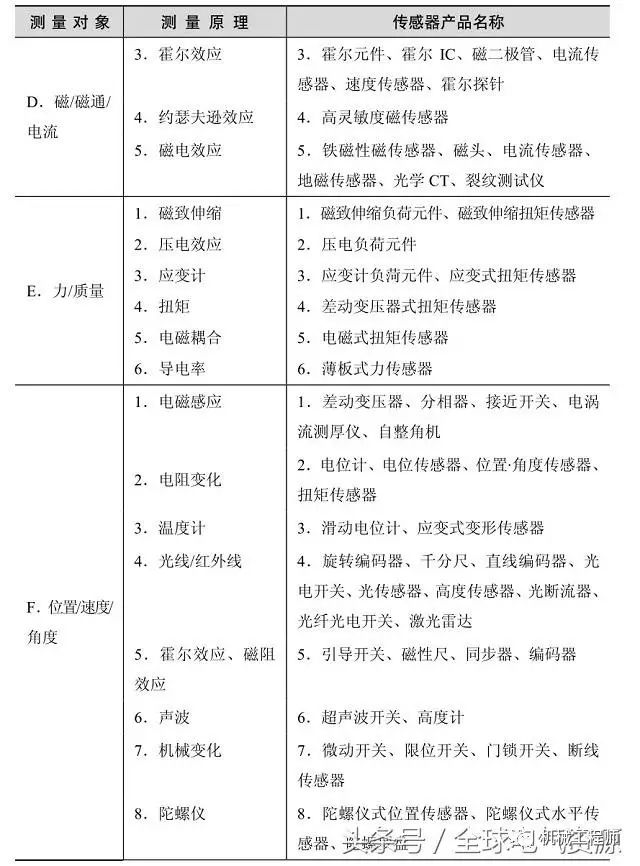

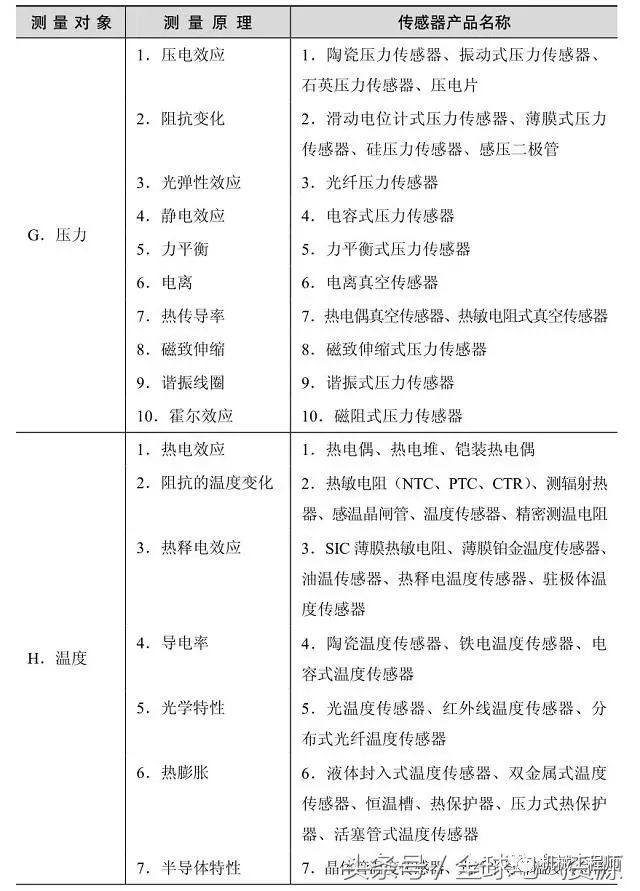

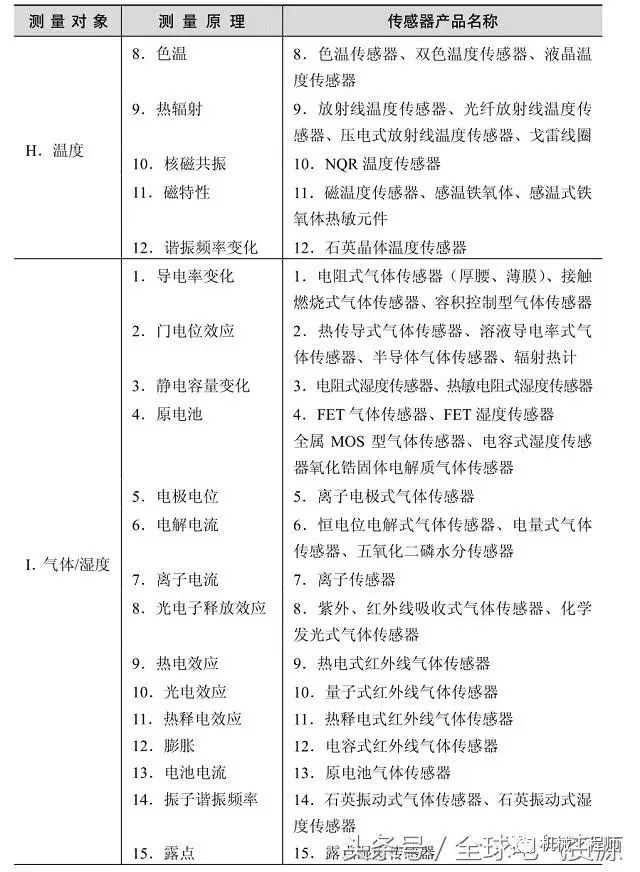

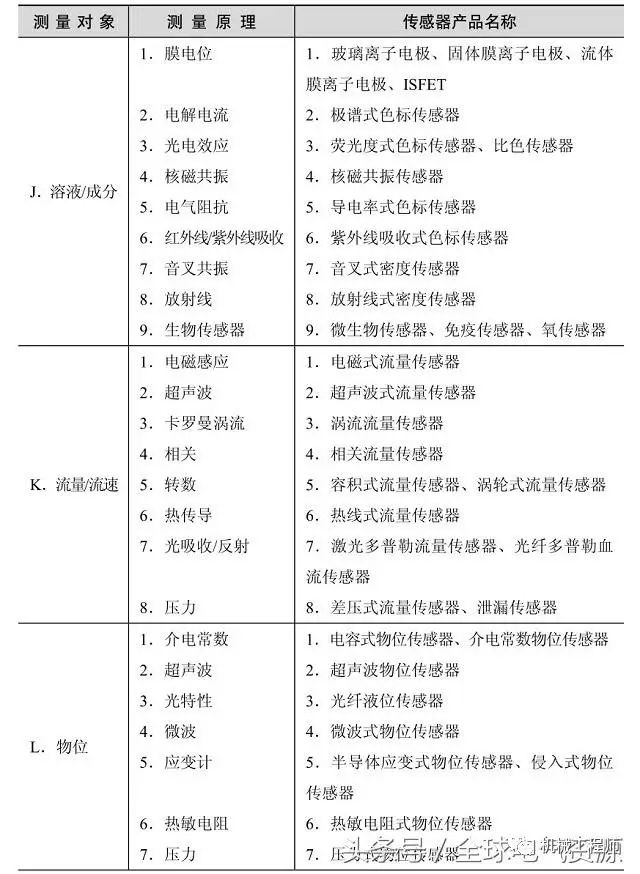

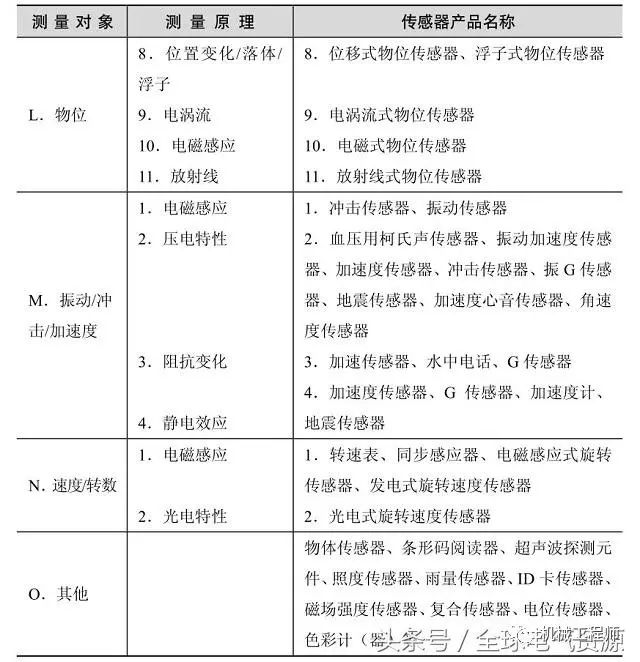

The sensors are further subdivided based on measurement principles and applications, as shown in the table below.

Precautions for Using Sensors

(1) Installation and Circuit Debugging

① Familiarize yourself with the principles, characteristics, and requirements of the sensor and the subsequent circuit.

② The installation position and method of the sensor must be correct, and it should be securely fixed. The output signal wire of the sensor must meet the requirements of the manual.

③ The power supply for the sensor must comply with the manual’s requirements. The polarity and current direction of the output signal must match the input requirements of the subsequent circuit.

④ After the installation of the sensor and the subsequent circuit is complete, turn on the power and repeatedly adjust until the best state is achieved.

(2) Operational Points

① The sensor must maintain close contact with the measured object; some must be directly installed on the object being measured. The accuracy of the sensor’s installation position has a significant impact on the detection results.

② The accuracy of the input circuit of the sensor’s receiving device depends on the sensor’s accuracy, the correctness of the installation position and method, and the accuracy of the receiving device.

Source: Mechanical Engineer, General Machinery Compilation