In recent years, with the advancement of intelligent factory construction in the cement industry, many experts and scholars have dedicated themselves to the research of electric control systems for vertical mills to meet the needs of intelligent factory construction. Among them, the research on electric control systems for vertical mills based on bus control technology is a relatively hot topic. This paper takes the electric control system of the cement final grinding vertical mill as the optimization research object and introduces a modular design scheme for the remote I/O station based on the Profibus-DP bus, further optimizing and improving the electric control system of the cement final grinding vertical mill. Practical application results show that the electric control system of the cement final grinding vertical mill based on Profibus-DP bus control technology has the characteristics of easy installation, quick debugging, and simple maintenance, providing certain reference for the optimization and improvement of the electric control system of the cement final grinding vertical mill.

In the traditional electric control system of the cement final grinding vertical mill, the main control cabinet of the vertical mill is connected to various oil station control cabinets, frequency converter cabinets, field instruments, button boxes, and other equipment through cables, achieving centralized control of the vertical mill and auxiliary equipment. At the same time, the sensors of each lubrication oil station are connected to the wiring terminal box inside the oil station, and then the oil station wiring terminal box is connected to each oil station control cabinet via cables to achieve independent control of each oil station by the oil station control cabinet. This leads to a situation where signals such as pressure, temperature, and flow need to be connected not only to the oil station control cabinet but also to the main control cabinet, resulting in multiple wiring situations. Additionally, the number of detection sensors for pressure, temperature, flow, and vibration installed on-site is large and the distance to the control cabinet is relatively far. Therefore, many long connection cables are needed, and there are many associated cable trays, brackets, etc., which increases the engineering workload of laying cable supports, trays, and connections, and it is also prone to common cable wiring issues such as misconnection and missing connections. Therefore, designing a simple and reliable structure with fewer field connections, easy construction, simple debugging, and easy maintenance for the electric control system of the vertical mill is an inevitable trend.

The cement final grinding vertical mill consists of a transmission system (main motor, reducer, and slow drive motor), hydraulic lubrication system (grinding roller hydraulic station, main motor lubrication station, grinding roller lubrication station, reducer lubrication station, and grease lubrication station), spraying system (water pump, water valve, flow meter), grinding system (grinding roller, retaining ring, and grinding plate), air separator system (classifier), and electric control system (button box, junction box, and control cabinet).

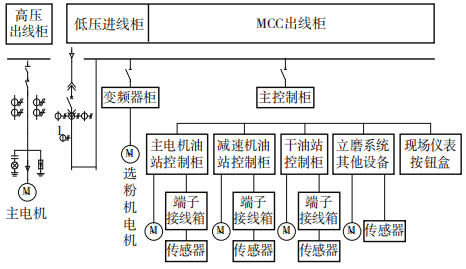

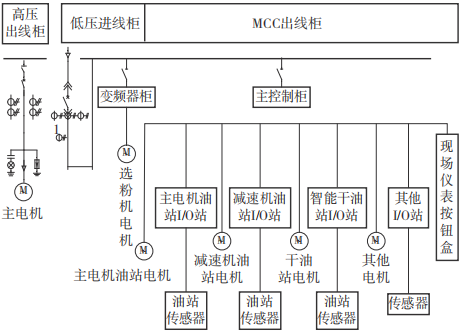

The traditional electric control system of the cement final grinding vertical mill mainly consists of a high-voltage cabinet, control cabinet, frequency converter cabinet, field instruments, and operation button box (see Figure 1). Among them: the high-voltage section, the high-voltage outgoing cabinet supplies power to the main motor and interlocks with the vertical mill control cabinet for safety, generally controlled directly by the DCS for starting and stopping the main motor; the low-voltage section is powered by the factory’s MCC outgoing cabinet to supply power to the main control cabinet and frequency converter cabinet, where the control cabinet is responsible for the power supply and control of electrical equipment, and processes the sensor signals sent from the field, displaying them on the touch screen and controlling the operation of on-site equipment, including the main control cabinet, main motor oil station control cabinet, reducer oil station control cabinet, and intelligent grease station control cabinet. The sensors connected to various hydraulic and lubrication stations are gathered in their respective terminal junction boxes, and then connected to their respective control cabinets through the oil station terminal junction boxes; the frequency converter cabinet is mainly used for speed regulation of the classifier motor; field instruments mainly display the sensor signal values and send the values into the PLC inside the control cabinet; the field instrument button box is used for operating equipment beside the machine.

Figure 1 Traditional Electric Distribution System of Cement Final Grinding Vertical Mill

4.1 Power Supply and Distribution System Design

The electric control system of the cement final grinding vertical mill based on Profibus-DP bus has two main differences from the traditional electric control system: first, the lubrication oil station no longer requires an independent oil station electric control cabinet; second, the distributed I/O stations are embedded in the oil station terminal junction box or other field instrument boxes, both powered and controlled by the main control cabinet, as shown in Figure 2.

Figure 2 Power Distribution System of Cement Final Grinding Vertical Mill Based on Profibus-DP Bus

4.2 Control System Architecture Design

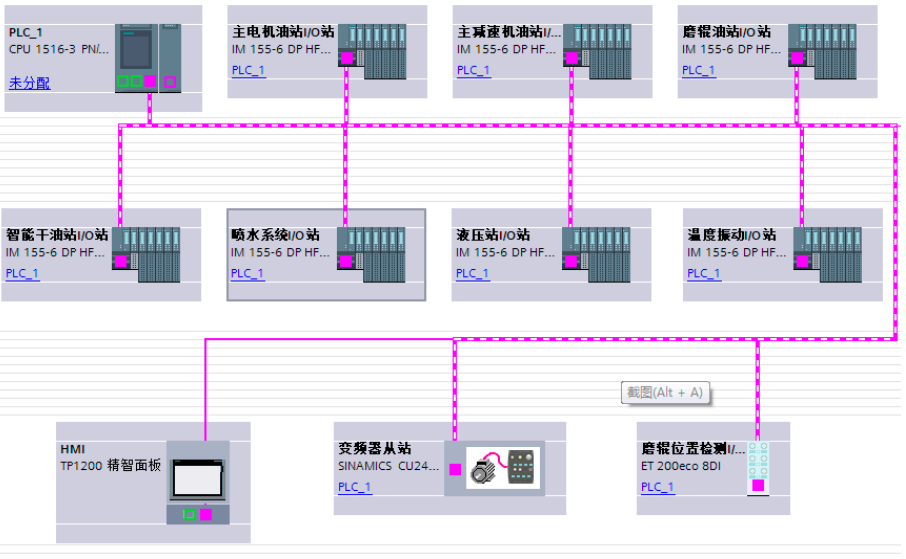

The entire control system is based on the Profibus-DP fieldbus and adopts a remote distributed I/O control method, using the PLC central processing unit structure to construct the Profibus-DP control network. The overall system architecture is shown in Figure 3.

Figure 3 Profibus-DP Bus System Architecture

The system controller is based on Siemens S7-1500 series, consisting of distributed I/O stations, DP slaves, HMI touch screens, etc. There are 8 distributed I/O stations: main motor oil station I/O station, main reducer oil station I/O station, grinding roller oil station I/O station, hydraulic station I/O station, intelligent grease station I/O station, temperature vibration I/O station, spraying system I/O station, and grinding roller position detection I/O station; there are 2 DP slaves: frequency converter slave and HMI slave.

(1) The PLC uses Siemens S7-1500 series DP interface PLC (CPU 1516-3 PN/DP) as the master station to communicate with each device in the Profibus-DP control network; the CM 1542-5 communication module is configured as the DP slave for communication between the PLC and the DCS system.

(2) The grinding roller position detection I/O slave is installed close to the mill, where vibration and dust are significant, and the environment is harsh. Therefore, it uses the ET 200eco distributed I/O with a high protection level (IP68) that can be used in harsh environments, placed inside an I/O slave control box with a protection level of IP65 for double protection. At the same time, the ET 200eco uses a quick plug-in form without wiring, allowing for rapid connections between the ET 200eco and sensors through dedicated connection cables with prefabricated cable lengths.

(3) Each lubrication oil station, hydraulic station, spraying station, and intelligent grease station uses ET 200SP distributed I/O. ET 200SP is a new generation of distributed I/O system launched by Siemens, characterized by compact structure and quick wiring technology without the need for wiring tools. ET 200SP distributed I/O modules are installed in the terminal junction boxes of each hydraulic or lubrication oil station, and signals from sensors such as temperature, pressure, liquid level, and flow are directly connected to the corresponding module terminals in the I/O station, with wiring and debugging completed before leaving the factory.

(4) The frequency converter is optionally equipped with a DP bus communication module, integrating the frequency converter as a DP slave into the DP bus system.

5.1 Advantages Analysis

Through the installation and debugging of a 5.4 m diameter cement final grinding vertical mill project under a subsidiary of Jidong Cement Group, the Profibus-DP bus control system has the following advantages:

(1) Short debugging time. The modular design greatly shortens the debugging time of the electrical system, completing the debugging work of one electric control system for a vertical mill in just 3 days.

(2) Cost savings. By adopting DP bus communication, each I/O station only requires one power line and one DP dedicated communication line, significantly reducing the number of cables used, while also correspondingly reducing the workload of cable laying, wiring, and calibration, allowing for considerable savings in cable procurement and installation costs.

(3) Space savings. The traditional electric control scheme uses four control cabinets, namely the main control cabinet, reducer oil station control cabinet, main motor oil station control cabinet, and intelligent grease station control cabinet, while the bus control scheme uses only one control cabinet, saving a lot of installation space.

(4) Strong maintainability. The distributed I/O bus of Profibus-DP has powerful diagnostic functions, supporting three-level diagnostics: station level, module level, and channel level. Each input and output channel supports short circuit and disconnection diagnostics and protection functions, providing timely fault warnings, helping maintenance engineers quickly identify, analyze, and eliminate faults.

5.2 Disadvantages Analysis

(1) During the design phase, since the I/O stations are embedded in the oil station junction boxes or other field instrument boxes, deep cooperation with the relevant equipment suppliers is required to assist in modifying the original electrical schematic design and module configuration selection, making communication and coordination quite challenging.

(2) During the factory testing phase, it is necessary to cooperate with the PLC of the master station to thoroughly test whether the wiring of each I/O station is correct, and whether signal input and output are normal. This requires individuals with certain PLC programming experience to complete the testing work.

The electric control system for the cement final grinding vertical mill based on the Profibus-DP bus adopts a modular design concept. The distributed I/O system uses standard interfaces, allowing for quick connections of I/O stations to the PLC control system. The system architecture is simple, with fewer connections, fast installation, easy configuration, and quick debugging. Currently, common industrial communication protocols include Profinet, Profibus-DP, Modbus, DeviceNet, EtherCAT, etc. This paper only introduces the application of the Profibus-DP bus, while similar research can be conducted on the others.