Today’s Highlights

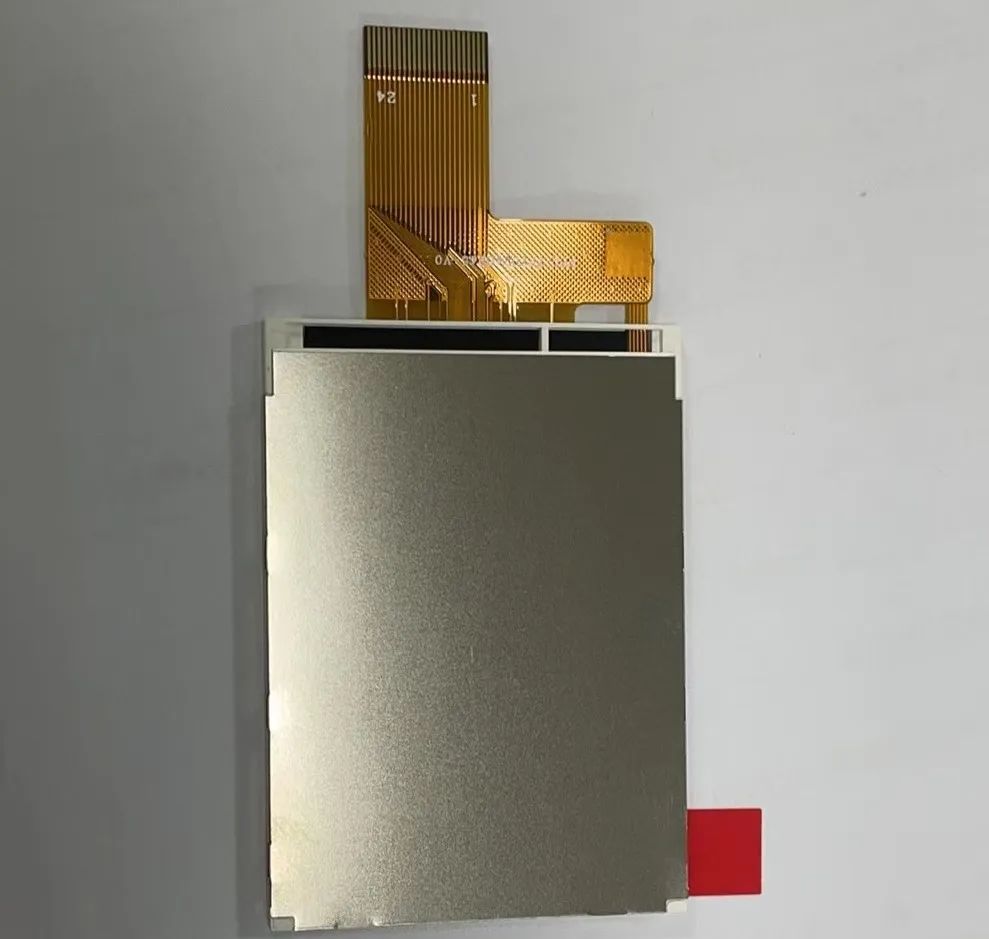

Quality testing of LCD displays is a critical step in ensuring product performance, reliability, and user experience, covering multi-dimensional testing from raw materials to finished products. Below is a detailed testing process and key items: 1. Appearance Inspection

Surface Defects: Use a high-power microscope or AOI (Automated Optical Inspection) equipment to check for scratches, bubbles, stains, uneven coating, and other issues.

Structural Integrity: Confirm the fit of the frame, ensuring no deformation or gaps, and that the backlight module has no light leakage.

Pixel Inspection: Test with solid colors (red/green/blue/white/black) to identify dead pixels, stuck pixels, or dark pixels, determining compliance with industry standards (e.g., ISO 9241-307) based on an acceptable range (typically ≤3 dead pixels).

2. Optical Performance Testing

Luminance: Measure the luminance values at the center and corners using a Luminance Meter, ensuring compliance with nominal values (e.g., 250 cd/m²) and calculating uniformity (e.g., >85%).

Contrast: The luminance ratio between full white and full black screens (e.g., 1000:1) must be tested in a darkroom environment.

Color Gamut and Accuracy: Use a colorimeter to detect sRGB/Adobe RGB coverage, with a ΔE value (color difference) typically ≤3.

Viewing Angle: Test luminance decay and color shift at different angles (horizontal ±85°, vertical ±85°) to ensure no significant distortion within the viewing angle.

Response Time: Measure gray-scale response time (e.g., 5ms) using a high-speed camera or dedicated instruments to avoid motion blur in dynamic images.

3. Electrical Performance Testing

Power Consumption Testing: Record current and voltage at different brightness levels to verify compliance with energy efficiency standards (e.g., Energy Star).

Signal Compatibility: Input various resolution/refresh rate signals (e.g., 4K@60Hz) through HDMI, DP, VGA, etc., to test display stability.

Electromagnetic Compatibility (EMC): Test radiation and anti-interference capabilities according to IEC 61000 standards.

4. Functionality and Interaction Testing

Touch Screen (if applicable): Use a touch testing device to check multi-touch accuracy, response speed, and edge touch sensitivity.

Backlight Adjustment: Verify that the automatic brightness adjustment (ALS) function is smooth, with no flicker or delay.

OSD Menu: Test menu navigation, language switching, and function settings for normal operation.

5. Environmental Adaptability Testing

High and Low-Temperature Testing: Operate in environments from -20°C to 70°C to verify that the display shows no ghosting, delay, or backlight failure.

Humidity Testing: Operate continuously for 48 hours at 85% humidity to check for condensation or corrosion.

Mechanical Strength: Ensure normal functionality after simulating transport vibrations (ISTA standards) and drops (1m height, multi-angle drops).

6. Lifespan and Reliability Testing

Backlight Lifespan: Continuously illuminate the screen to the nominal lifespan (e.g., 50,000 hours), monitoring brightness decay (≤30% is acceptable).

Pixel Aging Testing: Check for burn-in phenomena after displaying static images for extended periods.

Power Cycle Testing: Repeat power on/off cycles 10,000 times to test the durability of interfaces and circuits.

7. Packaging and Transport Inspection

Compression Testing: Simulate stacking pressure (e.g., 200kg/24 hours) and check for screen damage.

Dust and Water Resistance: Test the IP rating (e.g., IP65) for industrial screens.

Common Equipment for Optical Testing: Konica Minolta CS-2000 colorimeter, Photo Research spectrometer.

Signal Sources: Tektronix signal generator, MVTools testing suite. Environmental Simulation: Constant temperature and humidity chamber, vibration test table.

Industry Standards Reference

International Standards: ISO 9241 (Ergonomics), IEC 62341 (OLED/LCD Reliability)

Domestic Standards: GB/T 18910 (Testing Methods for LCD Devices)

Enterprise Standards: Such as Apple’s Display P3 color gamut specification or Samsung’s QLED quality standards.

Typical Issues and Solutions

Stuck/Dead Pixels: Replace the driver IC or repair the TFT layer (some can be repaired). Uneven Backlight: Adjust the light guide plate or diffusion film process. Touch Failure: Calibrate the sensor or replace the ITO film. Through this systematic testing, the yield rate of LCD displays can be effectively controlled, ensuring that products meet market requirements in terms of color, durability, and user experience. During production, it is necessary to combine SPC (Statistical Process Control) to monitor key parameters in real-time and continuously optimize processes.