Antarctic Bear Guide: As engineers continuously seek to improve process reliability and reduce defects, simulation has become an important tool for controlling the complex physical processes of metal additive manufacturing.

Garrett Clyma from FlowScience. Photo: Michael Petch.

Antarctic Bear learned that at the 2025 AMUG conference, Garrett Clyma, a computational fluid dynamics (CFD) engineer at FlowScience, Inc., outlined how melt pool modeling provides new capabilities to optimize laser processes without incurring the high costs of physical experiments.

The core challenge lies in the highly localized heating and rapid cooling of metals during the additive manufacturing process. Overheating or excessive heating can lead to melt pool instability, resulting in defects such as porosity, lack of fusion, and surface irregularities. Clyma explained, “Controlling material behavior in additive manufacturing is highly challenging due to the complexity of interactions among various physical fields.”

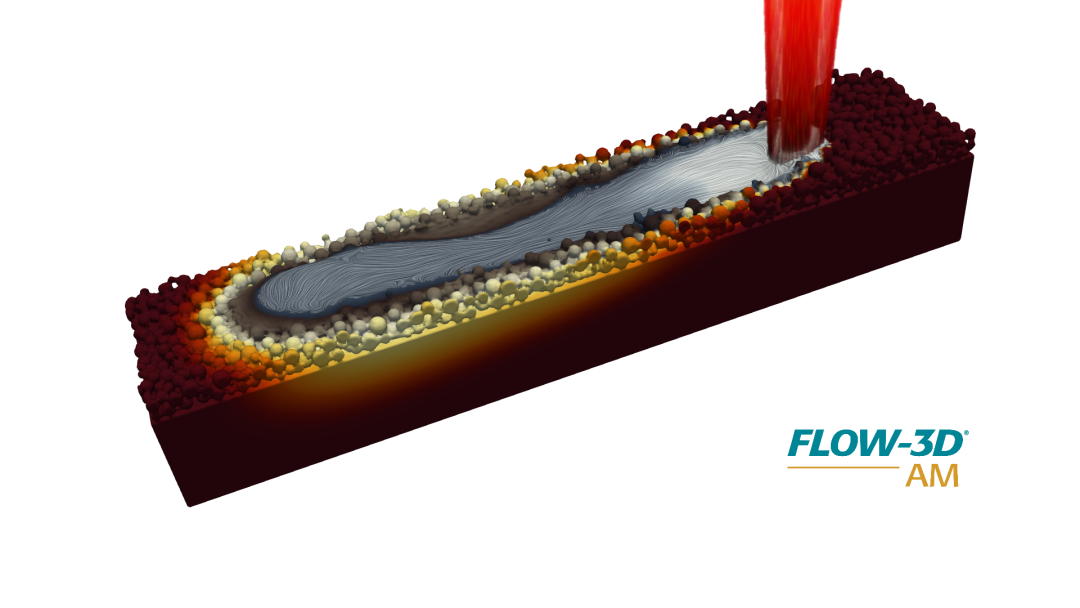

FLOW-3D AM is a multiphysics CFD platform designed to capture these phenomena with high fidelity, allowing engineers to visualize changes in melt pool instability and prevent defects before conducting expensive build experiments.

Beam Shaping: A Tool for Process Stability

Laser beam shaping is a mature method in the welding field, and it is gradually gaining popularity in additive manufacturing (AM) as a way to adjust the spatial energy distribution of the beam. Unlike traditional Gaussian distributions, beam shaping can distribute energy more uniformly or selectively across the entire beam, thereby affecting melt pool behavior and solidification characteristics.

Clyma introduced research conducted by Dr. Mohamed Bayat’s team at the Technical University of Denmark, which utilized FLOW-3D AM technology to study the application of annular beam profiles in single-pass titanium alloy manufacturing. Through cross-sectional cuts and in-situ X-ray monitoring verification, the simulation results were highly consistent with experimental results, with melt pool size errors well below 10%.

When the team varied the core ring power ratio while keeping the total laser energy constant, the simulation results showed a clear trend. The melt pool produced by the annular beam was wider and shallower, avoiding the deep keyhole characteristic of Gaussian beams. Clyma stated, “The annular depression area produced by the annular beam is significantly smaller and shallower, resulting in a more stable melt pool.”

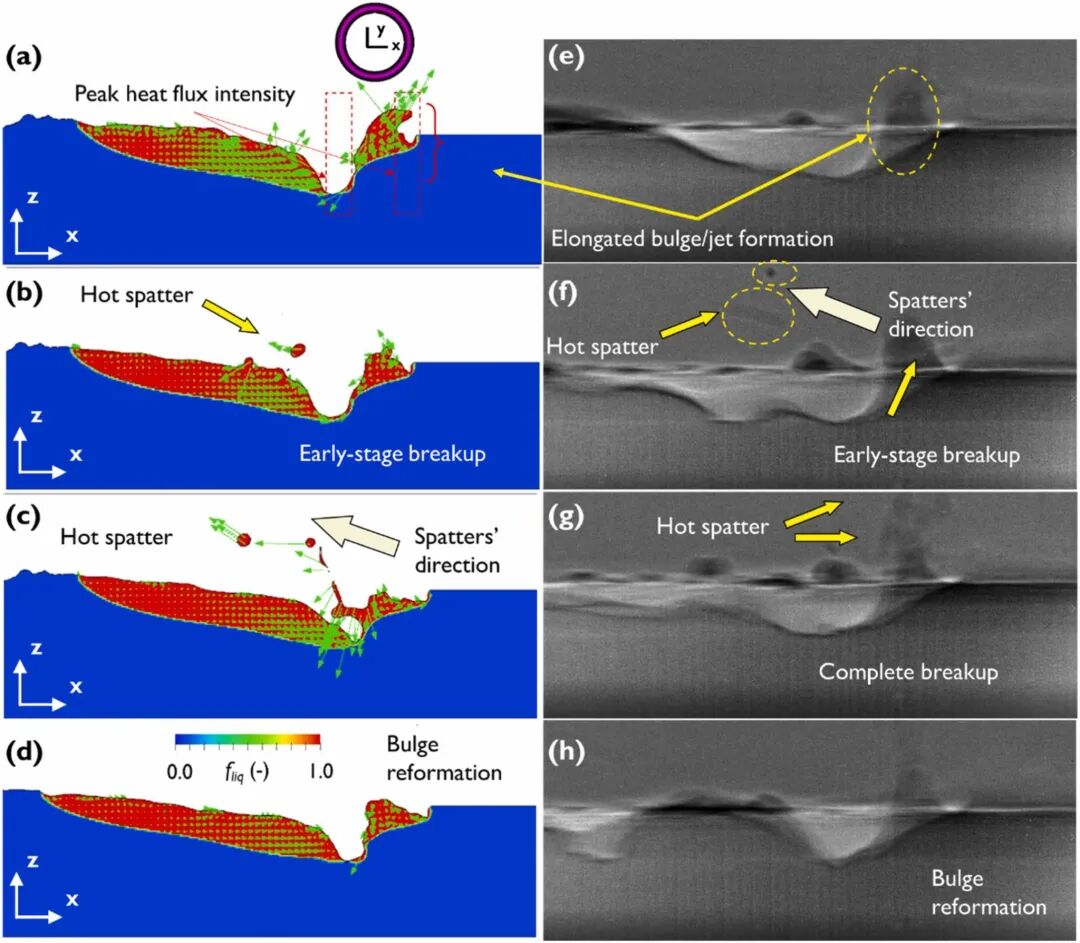

However, at higher laser power, instability re-emerged. The simulation predicted the formation of elongated melt jets and splattering in the melt pool—behaviors that were subsequently confirmed by high-speed X-ray imaging.

Spatial beam shaping in laser powder bed fusion: high-fidelity simulation and in-situ monitoring, simulation and experimental melt pool profiles. Image from Elsevier.

Extending to Arbitrary Beam Shapes

Based on these results, Flow Science conducted an internal study exploring static and dynamic shapes of laser beams, including complex profiles such as infinite patterns, spirals, and five-point arrays. On a 10-core desktop, individual simulations typically completed within 6 hours, and recent parallelization developments have made larger-scale parameter scanning possible.

For example, the five-point structure concentrates energy at discrete points, achieving higher penetration depth in small hole mode but limited efficiency in conduction mode. “We are not effectively heating the melt pool; we are just heating these single points,” Clyma explained, emphasizing that beam selection must align with the intended working mode.

Lower maximum melt pool velocities and more uniform temperature distributions were observed in spiral and infinite far patterns, indicating that these shapes can provide better process stability than concentrated beams. In all cases, metrics such as intensity, temperature, melt pool velocity, and processing rate provide a consistent framework for evaluating trade-offs before conducting physical experiments.

“Simulation is a very useful tool to help make these decisions,” Clyma said, noting the increasing degrees of freedom in laser control and the need for systematic approaches to identify promising beam strategies.

Visualization of laser powder bed fusion simulation. Image from Flow Science.

Surface Tension, Optical Effects, and Material Dependence

Attendees at the AMUG conference raised detailed questions about the depth of physical models in FLOW-3D AM. Clyma confirmed that key factors such as surface tension varying with temperature, contact angle, and laser absorption rate have been incorporated into the simulations. Absorption rates are often missing from published material datasets but can be adjusted as needed.

Thermophysical properties are typically sourced from databases like JMatPro, allowing simulations to reflect the specific behavior of alloys under melting conditions. Additionally, it supports precise modeling of laser reflection and multiple reflection phenomena.

One participant praised the high consistency between simulation predictions and experimental observations, particularly regarding melt pool shape, splatter formation, and transitions between conduction and keyhole modes.

Practical Trade-offs: Stability vs. Penetration

The conference concluded with discussions on how different beam profiles affect defect formation and material properties. While Gaussian beams can achieve deeper penetration due to larger thermal gradients and potentially form finer grain structures, they also pose higher risks of splatter and porosity. In contrast, annular beams offer greater stability and lower peak temperatures but may alter solidification patterns.

Clyma stated, “It really depends on your intended goals; if you can explore effects in simulation rather than in experiments, the advantages become much greater.”

FLOW-3D AM provides output data such as temperature gradients and cooling rates, which are primary drivers of microstructural evolution. Although the software currently cannot directly predict mechanical properties, these output data can help users infer possible outcomes, such as grain size, elongation, and impact resistance.

Another engineer further pointed out that finer, more directional grains (resulting from high gradients and rapid cooling) are often associated with improved mechanical performance. The unit-level resolution of FLOW-3D AM typically reaches five million elements or finer, allowing for detailed local analysis of these solidification dynamics.

As simulation capabilities continue to expand, additive manufacturing engineers now have a powerful toolkit to optimize laser processing strategies, reduce defects, and enhance the performance of printed metal parts—all accomplished before hitting the “print” button on the machine.

Recent Hot Articles from Antarctic Bear:

“AI-Driven Advances in 3D Printing: Tencent Cloud Collaborates with Antarctic Bear for an Exchange Event”

“I Dreamed of Raising 20 Billion Yuan to Acquire All Foreign Listed 3D Printing Companies and Achieve 290 Billion in A-Share”

“China’s 100-Meter Metal 3D Printer to be Built in Tianjin, Developed by Beijing Institute of Technology, with Ultra-Large Scale Metal Lattice Structure Multi-Arc Parallel 3D Printing Technology and Equipment”

“CCTV Reports: Under Tariff Bullying, Delayed US 3D Printing Toy Orders are Gradually Returning”

Notice for 3D Printing Professionals:

△Scan to open the Antarctic Bear website, set WeChat to Star Mark ☆, or open it in your mobile browser and set it to your phone’s desktop