Click the blue text to follow us

Introduction

There are various types of wireless Bluetooth headsets on the market, which offer excellent sound quality and convenient control features. Wireless Bluetooth headsets not only free our hands but also allow us to enjoy calls and music more freely. The sales of wired headsets are gradually declining, with more people opting for wireless Bluetooth headsets. This type of headset no longer requires insertion into the ear; it simply connects to the phone via Bluetooth, providing a brand new audio experience. The portability and comfort of wireless Bluetooth headsets make them an indispensable companion in people’s daily lives.

Customer Requirements

1. Testing needs to withstand contact discharge of ±6KV and air discharge of 10KV.

2. PCB layout and shell structure cannot be modified.

3. Implement rectification at the lowest cost.

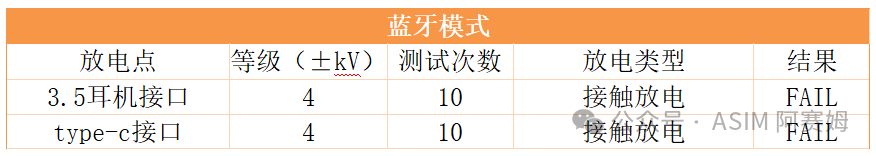

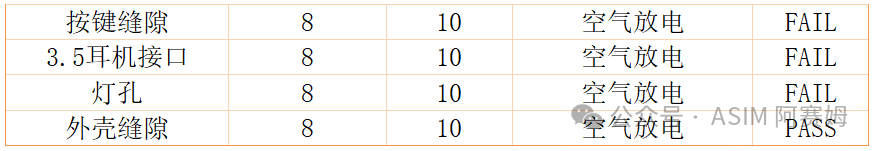

Pre-rectification Testing

Testing anomaly: The prototype shuts down during testing and requires manual pressing of the power button to restart.

Fault Diagnosis and Phenomenon Analysis

1. Power on with only the mainboard and battery connected, and perform contact discharge testing at the TYPE-C and 3.5mm headphone jack. Both test points experienced shutdown during testing. Adjusting the test points away from the TYPE-C and 3.5mm headphone jack to the GND on the mainboard (noting the electrostatic discharge path) increased the electrostatic level. Based on the observed anomalies, when the detection pin of the 3.5mm headphone jack detects a low potential, the prototype switches from Bluetooth mode to AUX mode. After processing the detection pin, the bare board test passed.

2. After the bare board test passed, each functional module was restored one by one, conducting electrostatic tests after each restoration. When restoring the connection to the MIC module, testing at ±6KV caused Bluetooth disconnection and reconnection, and playback pause. After restoring all functions, disconnecting only the MIC module allowed the 3.5mm headphone and TYPE-C interface contact discharge at ±6KV to pass the test. It was determined that when the MIC circuit is connected, electrostatic interference couples into the MIC circuit, affecting the main control chip.

Rectification Measures

1. Added ESD (ESD5D150TA) to the detection pin of the 3.5mm headphone jack to ground, as shown in the yellow box in the figure below.

2. Added common mode inductors (ASIM model: CMF1210UD900MFR) to the D+/D- communication circuit on both ends of the USB interface connecting the PC module and algorithm module.

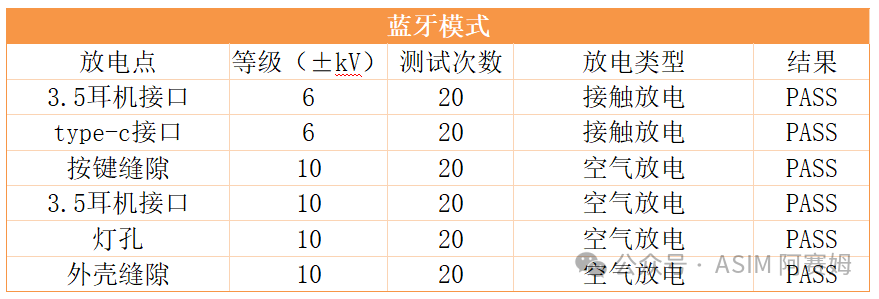

3. The above measures were replicated across multiple prototypes and passed testing.

Post-rectification Data

Conclusion

1. The company involved in the headset PCB layout design had our engineers participate, greatly improving the PCB layout itself and reserving pads for solutions when encountering problems. This led to the use of a total of 4 ESD components in the project, significantly reducing costs.

2. Based on the phenomena, interference functions were identified.

3. When troubleshooting, it is advisable to simplify the prototype functions progressively to eliminate fault points.

4. Adjusting test points helps to lock down problem areas.

About ASIM

Dedicated to providing one-stop EMC solutions

● Technical services ● Component sales ● Corporate training

● EMC testing ● EMC rectification ● EMC design

Scan to get specifications and samples for free

Email | [email protected]

Website | https://www.asim.com.cn