Multi-Photon 3D Laser Printing Technology has been widely used but still faces challenges such as printing speed and resolution. Increasing the printing rate can be achieved by enhancing focusing speed or the number of laser foci, but due to power budget constraints, prioritizing the increase in focusing speed is more beneficial.

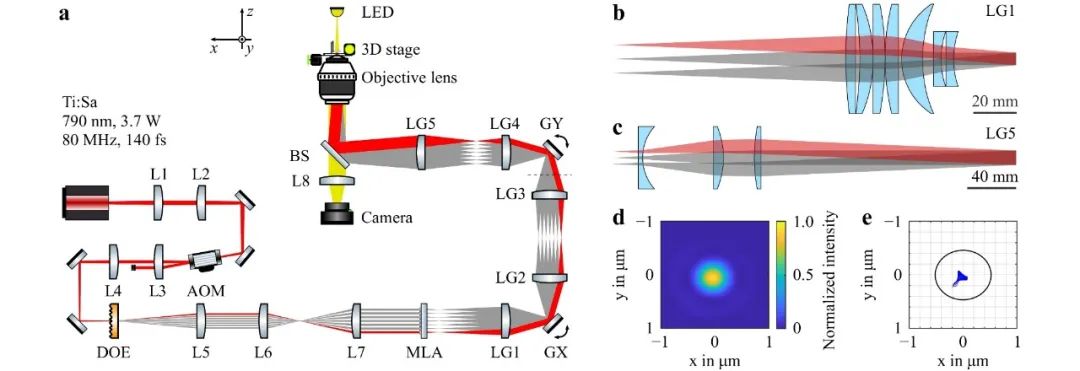

The team led by Pascal Kiefer at the Karlsruhe Institute of Technology in Germany has developed a new high-throughput multi-focus 3D laser printing system that combines diffractive optical elements (DOE) and multi-lens arrays (MLA) to overcome the dispersion problems in the splitting of femtosecond pulse beams, achieving large field of view, high speed, and high-resolution printing.

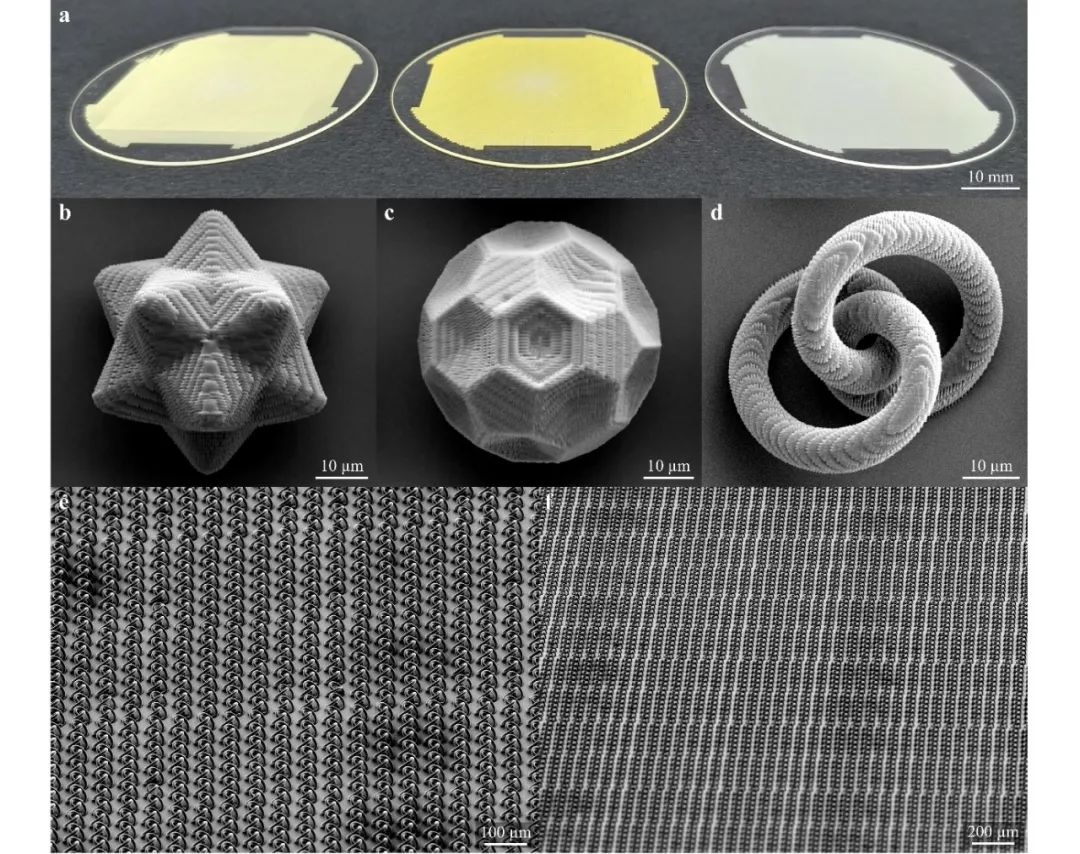

Researchers utilized two-photon grayscale lithography technology to fabricate high-precision 7×7 DOE and MLA, optimizing the optical design to achieve a low aberration and high uniformity 49-focus array. Based on this, they constructed a complete printing system with a focusing speed of up to 1 meter/second and a printing rate of 100 million voxels per second, while maintaining sub-micron spatial resolution.

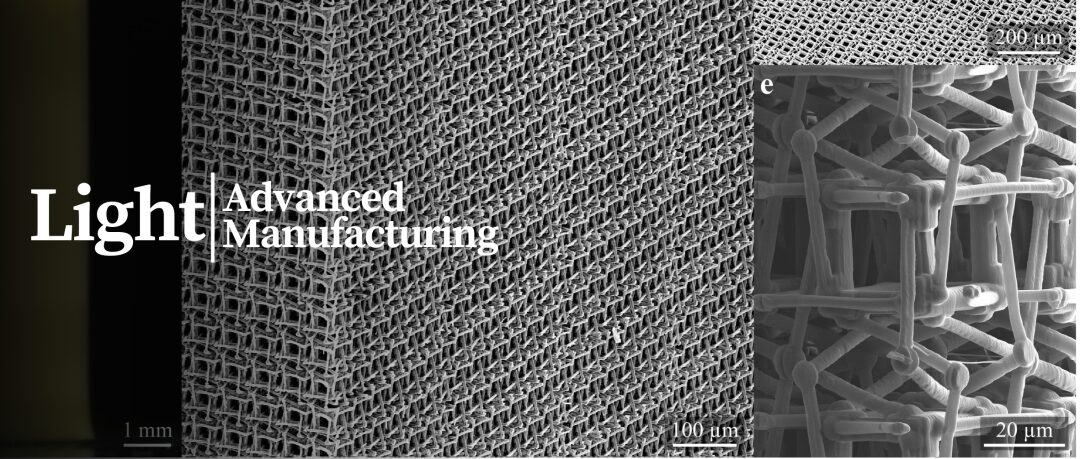

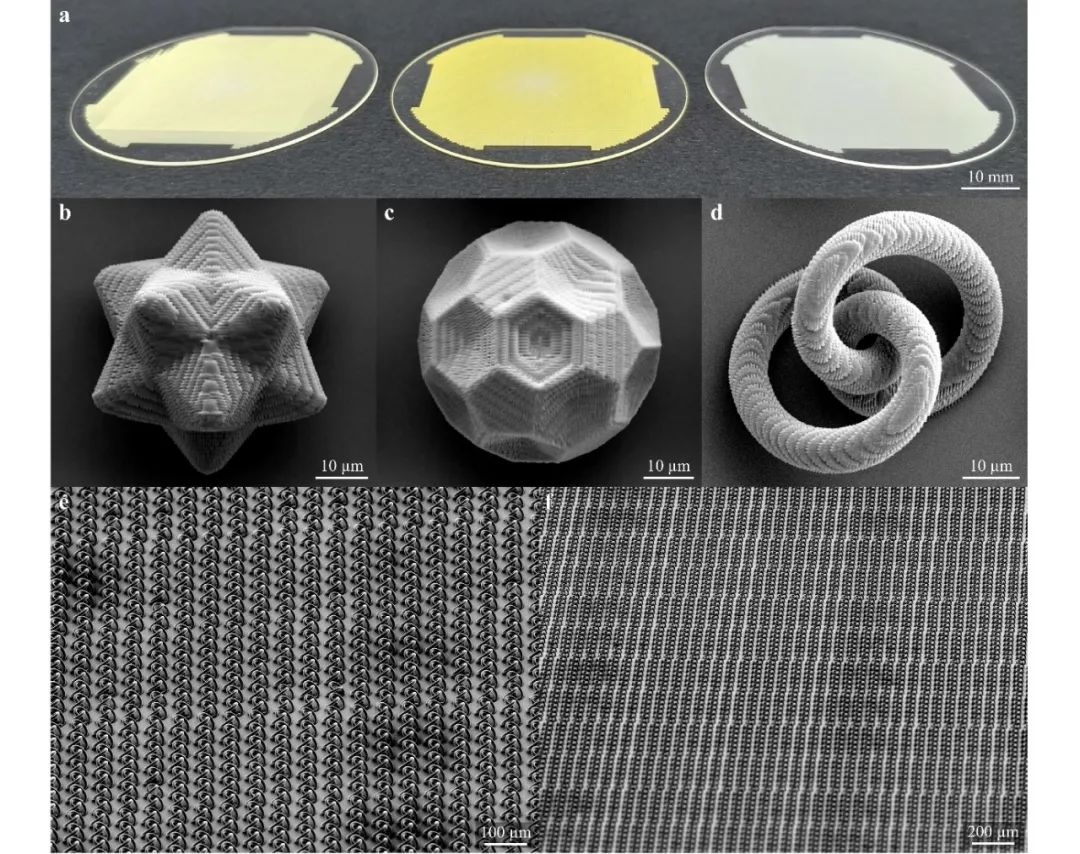

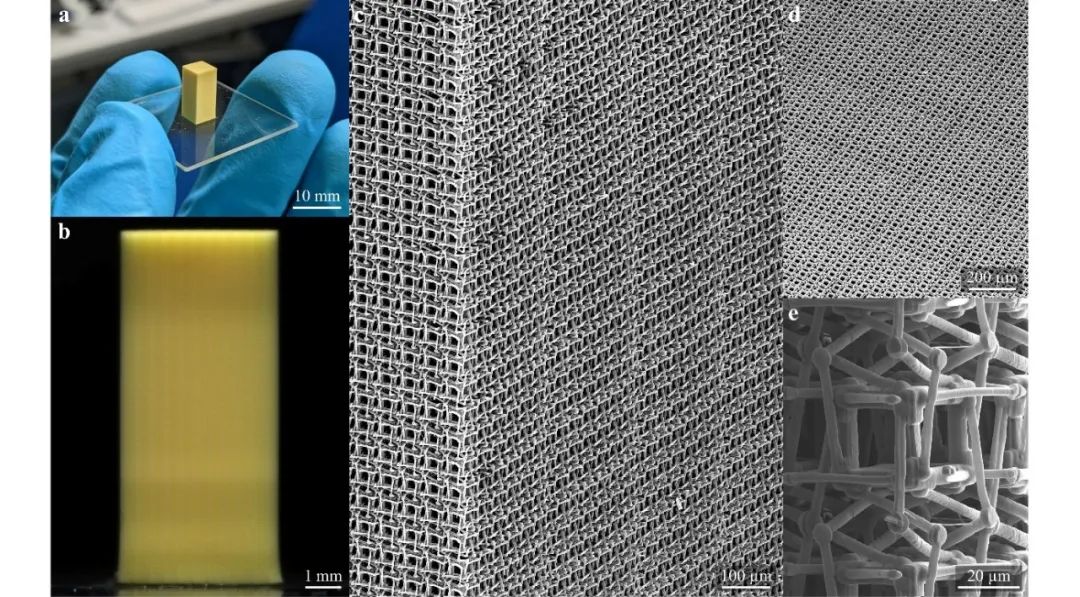

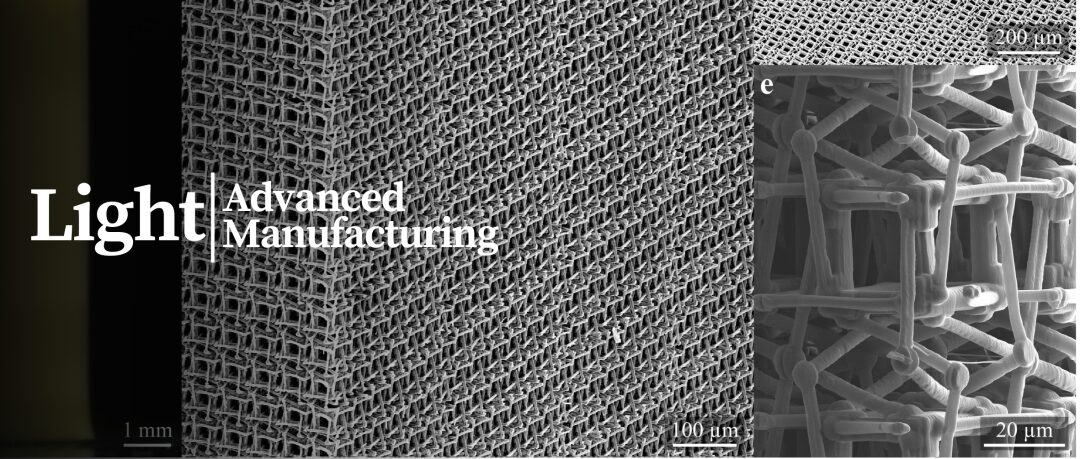

To demonstrate the application potential of this technology, researchers rapidly produced millions of high-resolution drug carrier particles in the pharmaceutical field; on the other hand, they successfully printed large-scale chiral metamaterials containing over 1.7 trillion voxels.

The related results were published in Light: Advanced Manufacturing. This breakthrough will accelerate the application of multi-photon 3D printing in fields such as biomedicine and micro-optical devices.

The related research results were published under the title “A multi-photon (7 × 7)-focus 3D laser printer based on a 3D-printed diffractive optical element and a 3D-printed multi-lens array” in Light: Advanced Manufacturing.

Encyclopedia 1: What is “Multi-Photon 3D Laser Printing”?

Multi-Photon 3D Laser Printing is an advanced additive manufacturing technology. It utilizes femtosecond pulsed lasers to simultaneously excite multiple photons in photosensitive materials, triggering localized photopolymerization reactions, thereby forming ultra-fine 3D structures in resin. Compared to single-photon absorption, multi-photon absorption requires a higher photon density, thus occurring only in a minuscule area near the laser focus, enabling this technology to break the diffraction limit and achieve nanoscale spatial resolution. In the multi-photon process, materials simultaneously absorb two or more long-wavelength photons and transition to a higher excited state, equivalent to absorbing one short-wavelength photon. This nonlinear optical effect confines the photopolymerization reaction to specific locations in three-dimensional space. By precisely controlling the three-dimensional scanning of the laser focus and adjusting material formulations and process parameters, multi-photon 3D printing can fabricate arbitrarily complex micro-nano structures, compatible with various polymers and composite materials, holding vast application prospects in micro-optics, microfluidics, and biomedicine.

Encyclopedia 2: What is a “Voxel”?

Voxels are the basic volume units in three-dimensional space, analogous to pixels in two-dimensional images. In fields such as 3D printing, medical imaging, and computer graphics, voxels are widely used to represent and process three-dimensional data.

Each voxel has specific spatial coordinates (x, y, z) and a certain size, which can be viewed as a small cube in a three-dimensional grid. The size of the voxel determines the resolution of the three-dimensional model; the smaller the voxel, the richer the details of the model. By assigning different property values (such as density, color, transparency, etc.) to each voxel, the spatial distribution and changes within the object can be described.

Three-dimensional models represented by voxels can be processed and analyzed through various algorithms, such as three-dimensional reconstruction, volume rendering, boolean operations, etc. In 3D printing, printers deposit or solidify materials point by point according to the position and property values of the voxels, ultimately constructing solid models.

Voxels are the cornerstone of constructing the digital three-dimensional world, and with the development of high-resolution 3D printing, tomography, virtual reality, and other technologies, voxels will play an increasingly important role in characterizing complex three-dimensional structures.

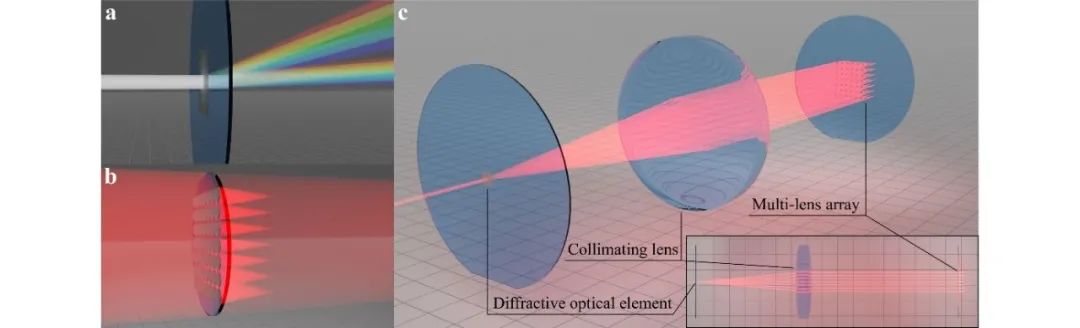

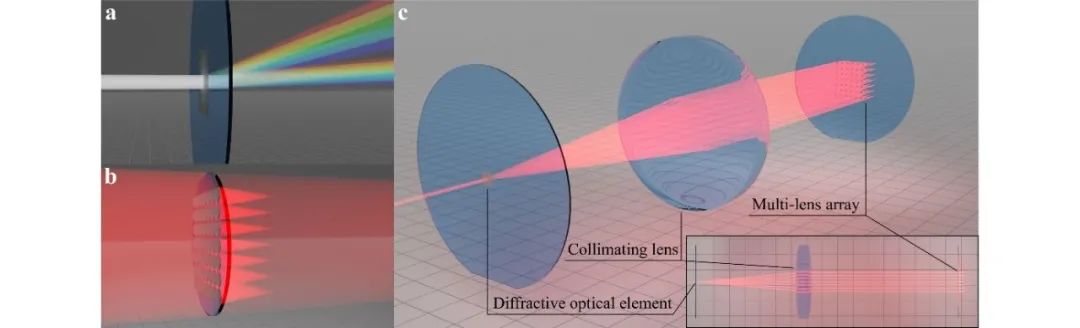

Combining Diffractive Elements and Multi-Lens Arrays

Diffractive elements can provide high resolution and power efficiency, which is crucial in applications where multi-focus printing is highly power-constrained. However, due to their diffractive nature, they bring a limited bandwidth of the incident light, with each mode having different diffraction angles, a phenomenon referred to as chromatic dispersion. When using picosecond or femtosecond pulse beams for multi-photon printing, this aspect can become problematic. Although splitting based on multi-lens arrays is not affected by dispersion effects, when using Gaussian beams, the focusing array will exhibit an uneven power distribution. Furthermore, even with a flat-top profile, the tightly packed MLA lenses can only focus 50% of the incident beam’s power into the focus array, and this power loss can be unacceptable.

The problems described for the two splitting methods can be overcome by combining both; the incident laser beam is initially split by the diffractive optical element, ensuring lower chromatic dispersion, but also results in the near-focus distance being far below our target nearest neighbor focus displacement. Thus, by utilizing a multi-lens array to adjust the focus spacing, a uniform focal array can be created without sacrificing additional laser power.

Figure 1: Comparison of different splitting methods in multi-focus printing technology

Figure 2: Principle of multi-photon multi-focus 3D laser printer.

Multi-Photon Multi-Focus Processing in Material and Pharmaceutical Science Applications

By combining the rapid scanning speed of a large array of laser foci of up to 1m/s, using high 3D printing rates to mass-produce very large or small samples while maintaining sub-micron resolution. This opens up possibilities for new research into sample requirements that were previously unattainable. The authors demonstrate the functionality of multi-photon multi-focus 3D printing through applications in respiratory drug delivery and another application in 3D mechanical metamaterials.

Figure 3: Using multi-photon multi-focus 3D printing to manufacture carrier particles for respiratory drug delivery.

The second application example lies in the field of materials science, meeting the growing demand for larger and more complex 3D mechanical metamaterial samples with sub-micron resolution. Here, instead of printing a large number of individual small structures, large samples composed of individual metamaterial units assembled together are printed.

Figure 4: Multi-photon multi-focus 3D printing of large chiral rotating metamaterials containing millions of unit cells.

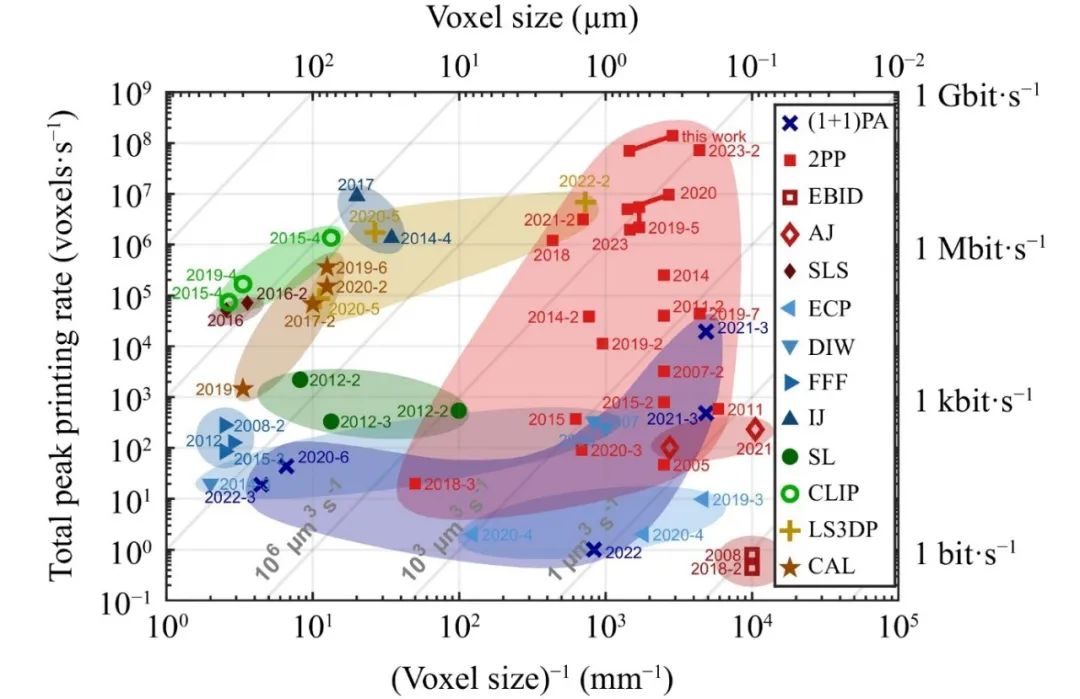

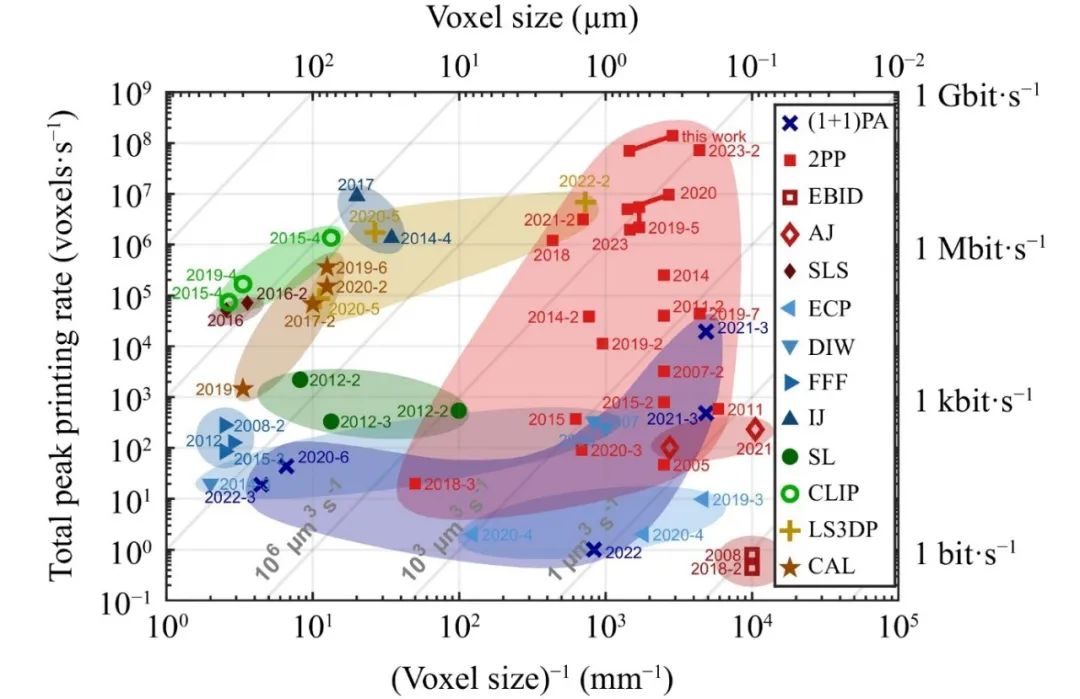

Comparison of High-Speed 3D Printing

To better assess the manufacturing speed of the new device, various 3D printing technologies were compared. The vertical axis ranks different methods based on the total peak printing rate (on a logarithmic scale), while the horizontal axis ranks them based on their inverse voxel size or loosely speaking, their fineness or resolution. The device is represented by using two data points: one assumes a diffraction-limited voxel size of approximately 350 nm, and the other uses the average measured voxel size within the 7 × 7 focus array to obtain the same result, which is at the same level as the recently published advances using acousto-optic deflectors combined with digital mirror devices (DMD) labeled “2023-2” for rapid 3D printing based on two-photon polymerization. Compared to their work, this article demonstrates a printed structure with a larger total number of voxels within a structure, due to the larger field of view accessible by the device.

Figure 5: Comparison of insertion loss models of S-bends with and without composite waveguide technology.

This groundbreaking research marks a new height for multi-photon 3D printing technology in high-throughput manufacturing. By ingeniously combining diffractive optical elements and multi-lens arrays, the researchers achieved an ultra-high printing rate of 100 million voxels per second while maintaining excellent spatial resolution, opening up new possibilities for micro-nano manufacturing. Looking ahead, high-speed, high-precision, and multi-material compatible 3D printing platforms are expected to further develop and find wide applications in biomedicine, micro-robotics, micro-optical devices, and many other fields. At the same time, the deep integration of multi-photon 3D printing technology with emerging technologies such as artificial intelligence and online monitoring will also be a promising research direction. As multi-photon 3D printing continues to advance towards higher speeds, better performance, and broader applications, it is expected to become an important force in driving technological progress and industrial transformation.

Pascal Kiefer, Vincent Hahn, Sebastian Kalt, Qing Sun, Yolita M. Eggeler, Martin Wegener. A multi-photon (7 × 7)-focus 3D laser printer based on a 3D-printed diffractive optical element and a 3D-printed multi-lens array[J]. Light: Advanced Manufacturing 4, 3(2024).

https://doi.org/10.37188/lam.2024.003

Welcome to Submit Press Releases

Please scan the code to contact the duty editor