Source: EETOP.

3D printing can turn 3D modeling files from a computer into physical objects, with a printing process that requires no intervention and precision that far exceeds manual production. It sounds and feels quite cool. Although it has been popular for a long time, it remains mysterious to the general public. Considering that many people might not actually need it but still have the impulse to buy, here’s a science popularization piece.

This article will briefly explain 3D printing and 3D scanning from aspects such as principles, classifications, software and core components, printing processes, precision, and usability.

Principles and Technical Advantages

3D printing is a technology that creates three-dimensional objects by stacking thin layers. Its key term is thin layer stacking, using different principles to shape and stack materials layer by layer.

While it sounds sophisticated, the basic principle is simply a nozzle that can move on the XY plane, precisely controlling the position of the material. After completing one layer, the platform moves down (generally by 0.1mm) before printing the next layer, until the entire product is printed.

Compared to traditional processing methods like milling (cutting material from outside to inside using a milling cutter) and casting (melting and pouring into molds), the greatest advantage of 3D printing is its ability to manufacture products with complex internal spaces, and the material utilization rate is close to 100%.

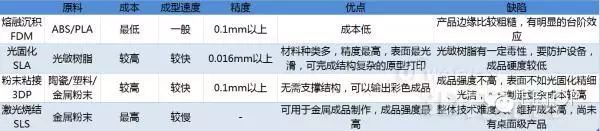

Classification of 3D Printing Principles and Their Advantages and Disadvantages

Classification of 3D Printing Principles and Their Advantages and Disadvantages

Comparison of Printing Precision

Comparison of Printing Precision

According to the different principles of material shaping, costs are arranged from low to high, including four types: Fused Deposition Modeling (FDM), Stereolithography Apparatus (SLA), Three Dimensional Printing and Gluing (3DP), and Selective Laser Sintering (SLS). Their working principles are as follows:

˙Fused Deposition Modeling (FDM) involves a nozzle heating and extruding filament thermoplastic material, which solidifies upon contact with the cooler printing platform, forming the final product through layer stacking.

˙Stereolithography Apparatus (SLA) uses UV light or other light sources to cure photosensitive resin material layer by layer, forming the final product through stacking. It is the earliest developed, most mature, and widely used rapid prototyping technology.

˙Three Dimensional Printing and Gluing (3DP) sprays an adhesive onto materials such as ceramic/metal/plastic powder, continuously repeating the processes of layering powder, spraying, and gluing to achieve the final product.

˙Selective Laser Sintering (SLS) is a hybrid of the previous two technologies, using high-power lasers to sinter or melt metal powder and other materials. It continuously repeats the processes of layering powder and sintering until the entire model is formed. This is the type of 3D printing commonly mentioned in industrial contexts.

The most expensive technologies, laser sintering and powder binding, have very few desktop models available, and no desktop-level products have emerged for the latter. Models using SLA technology generally start at around 20,000 yuan, so currently, consumer-grade 3D printing technology primarily uses the cost-effective FDM technology, with many manufacturers managing to control prices around 2,000 yuan. Thus, it is these machines that are the focus of this popular science piece.

In addition to the core mechanical components, a 3D printer needs a 3D modeling file to control the movement of the print head. While most printers come with displays and control buttons, the 3D modeling files required for printing still need to be handled by a computer. Mid-to-high-end products can generally connect to a computer and have dedicated clients, while low-end products usually skip the connection feature and can only print by reading files from an SD card.

3D printers can only read sliced 3D modeling files (approximately equivalent to creating N layers from a 3D digital model) and can directly convert .stl or .3w format files output from modeling software like 3Dmax, CAD, or MAYA.

Many manufacturers’ websites and modeling sites have ready-made 3D modeling files, and users with software skills can create models themselves. For beginners, popular items include figurines, phone cases, and other small gadgets.

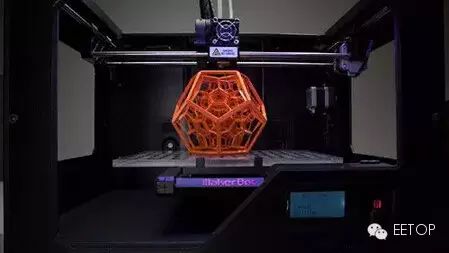

The key term for 3D printing is thin layer stacking. For FDM 3D printers, the print head that can move in a two-dimensional plane is responsible for the “thin layer,” while the vertically moving platform is responsible for the “stacking.” There are not many core components, exemplified by the recently reviewed XYZ da Vinci 1.0 AiO.

The print head is a heating device that can move precisely along the XY axis, capable of heating and melting ABS/PLA materials. It has gears to feed the filament and a cooling fan at the back. The machine uses belt drive, allowing the print head to move left and right on the X-axis, while the print head and the entire X-axis are mounted on the Y-axis.

The printing platform is a glass plate with heating capabilities, allowing precise control of vertical movement, with a maximum heating temperature of 90 degrees (to prevent ABS material from failing to adhere due to low temperatures). Its power source is a motor located at the bottom. The platform usually has calibration points for positioning and screws for adjusting its level (tilting forward or backward).

Regarding materials, the mainstream options are ABS resin and PLA (biodegradable polylactic acid), made into filaments of fixed diameter (1.75mm) and wound onto spools, generally priced around 200 yuan/kg. Some manufacturers use boxed packaging with chips at the bottom to record material type and remaining quantity, making it slightly more convenient, albeit at a higher cost.

Both materials can be dyed in different colors, with differences in their melting points: ABS melts at around 220 degrees, has an opaque matte finish, is stronger, requires the platform to be heated to 90 degrees for proper forming, but is toxic and emits a burning plastic smell during use, and has significant thermal contraction, leading to lower precision in the final product.

PLA melts at around 200 degrees, has lower energy consumption and faster processing, has a semi-transparent shiny finish, can form at platform temperatures of 45 degrees, is non-toxic and environmentally friendly with almost no odor, and is gradually replacing ABS as the primary printing material.

Before printing, a solid glue layer should be applied to the platform, serving as a barrier to facilitate the removal of the final product. The first step in printing is heating the print head and platform, with time varying based on machine power. Machines under 500W typically complete print head heating in 1-2 minutes, but the platform takes about 5-6 minutes to heat from room temperature to 90 degrees.

Once the printing platform reaches its highest point, printing can begin. The process involves the filament being heated and melted in the print head, flowing out in a fluid state, and hardening upon contact with the printing platform. The movement path of the print head is “recorded” by these materials, and after completing one layer, the platform moves down, and the machine prints the second layer until the entire object is printed.

Materials can be dyed, but FDM printers can only achieve pure color or horizontal color variation by changing materials midway. Therefore, typically, different colored parts of the final product are printed separately and then assembled like models.

During operation, only the sounds of the three XYZ axis motors and the print head cooling fan can be heard, which is not very loud. However, if using ABS resin, additional ventilation measures are required.

Desktop printers are generally ready to use right out of the box, but if used for extended periods, or if the product and platform are too tightly bonded requiring forceful removal, users need to level the printing platform themselves. Otherwise, it may affect forming quality, and in severe cases, the print head and platform may collide, causing deformation. Additionally, the print head can become quite dirty over time, requiring occasional cleaning of the material outlet with wire.

Some high-end entry-level models now feature 3D scanning capabilities, allowing physical objects to be scanned and generating 3D modeling files for duplicating the same product.

3D scanning can be categorized as contact and non-contact methods. The former uses traditional measurement points to contact the object and collect spatial information, which is both costly and slow; the latter mainly uses lasers and low-frequency sound waves for indirect scanning, which is fast but generally less precise, requiring multiple scans for data correction.

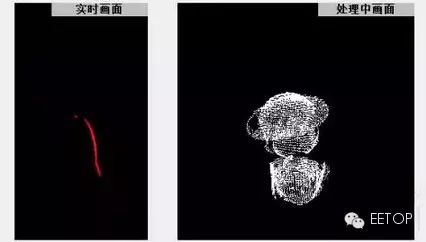

3D scanning process

Scanning File

Scanning File

Currently, most printers come with built-in laser scanning devices. The scanned object is placed on a rotating platform, and the scanner emits a laser plane onto the object, with the receiver calculating the spatial point data based on the reflected light.

Unfortunately, even the scanning function of printers priced in the tens of thousands is generally inoperable. There are many limitations to the scanning function, which can significantly affect the scanning effect, especially for materials with abnormal light scattering properties, such as objects that are too low, too dark, too colorful, too smooth, too complex, or with deep interiors.

Using it to scan simple geometric shapes is certainly not an issue, but attempting to scan complex figurines or high-end models is almost impossible…

Moreover, models with added 3D scanning functions generally cost 3,000 to 4,000 yuan more than the base models, making the cost of this feature too high, so it is not recommended to purchase models with 3D scanning capabilities.

Finally, we arrive at the core aspect of 3D printers. The speed of 3D printing is much slower than most people imagine, but this is understandable: the thickness of each layer printed ranges from 0.1 to 0.4 mm (the filament extruded is 0.1 mm wide), meaning printing a product 1 cm high requires over 25-100 layers to be printed…

The printing time is proportional to precision (layer thickness), and due to the fixed filament extrusion speed, the printing time can be easily calculated. As a reference, at a precision (layer thickness) of 0.3 mm, printing a 4-gram hollow case takes about 30 minutes. If printing a hand-sized figurine weighing over 100 grams, the printing time can exceed 12 hours.

Actual Printed Samples

Regarding printing precision, many people believe that the products from 3D printers can serve as final products, but this only applies to SLA printers; the other three types produce items more akin to rough casts. If high precision and appearance are required, the final product must still undergo additional polishing.

Sadly, the cost-effective FDM printers show clear joining marks between each layer, commonly known as the “stair step effect,” resulting in a rather rough surface. After seeing the works of entry-level FDM printers, many users may feel a psychological gap.

Although the thin layer stacking principle of 3D printing can handle many complex internal structures, it also brings corresponding limitations:

Insufficient lateral strength: Regardless of the printing method, they are all vertical thin layer stackings, resulting in much lower lateral strength;

Objects that are smaller at the bottom and larger at the top require additional support structures: Due to gravity, 3D printing cannot create suspended objects, hence requiring additional supports or frames to be printed beneath suspended objects;

To print products in multiple colors, materials can only be changed midway or printed separately;

FDM printers can only produce plastic products, and the hardness of the final products is limited, with only powder binding and laser sintering able to print ceramics, metals, and other truly industrial-use items;

The contradiction between precision and speed: The thinner the layers in thin layer stacking, the more layers and time required, necessitating methods like multi-nozzle operation to increase speed.

3D printers are still emerging products; although the principles of FDM printers are relatively simple, the differences between brands and product lines can be significant, so it’s essential to have a basic understanding of commonly used parameters before purchasing. For FDM printers, there are not many options; those under 10,000 yuan are generally single nozzle designs, supporting both ABS and PLA materials.

The larger the printing size, the higher the price, with 10,000 yuan printers typically having printing sizes below 20*20*20 cm; regarding precision, 3D printers under 10,000 yuan can generally achieve a layer thickness of 0.1 mm, and printing speeds (filament extrusion speeds) range from 0.2 to 0.5 mm/s.

In conclusion, it is still advisable to approach the purchase of 3D printers under 10,000 yuan with a “big heart” and not to have overly high expectations. Although their entry-level price has dropped below 2,000 yuan, they still retain a toy-like nature, primarily helping enterprises and geeks test samples and save on high mold costs. Regular users should be cautious when making purchases.