Earthquakes, as one of the sudden and highly destructive natural disasters, can cause significant casualties and property damage in a short time. A large number of building structures are damaged or even collapse, seriously threatening people’s lives and property safety. Therefore, it is essential to conduct seismic design and reinforcement of buildings.

The traditional seismic system is based on ductile design, which involves increasing the cross-section size of components and delaying the appearance of plastic hinges for seismic design. However, many issues have been found in traditional seismic design at the sites of major earthquakes. For example, allowing structural damage in the early design phase can provide some level of seismic resistance, but after an earthquake, the structural damage is severe and difficult to repair. At the same time, many facilities lose functionality during earthquakes, leading to urban paralysis, with hospitals, schools, command centers, and networks unable to operate, severely affecting urban operations. Modern urban construction has new requirements for vibration reduction and disaster prevention technologies, demanding that buildings remain intact during minor earthquakes, repairable after major ones, and not collapse during severe ones, forming a dual protection requirement to meet resilient urban planning.

Currently, significant changes have occurred in the technology for earthquake prevention and disaster reduction, transitioning from the hard “anti” seismic traditional systems to the soft “reduce” seismic control systems developed over the past 40 years. Among them, buckling-restrained braces (BRB) are one of the most widely used seismic products in China, featuring equal tension and compression forces, high bearing capacity, good ductility, and excellent energy dissipation capabilities. This article reviews BRB structures, BRB frame structures, and design methods applicable to BRB structures from three aspects.

1. Research on BRB Forms

1.1 Structure of BRB

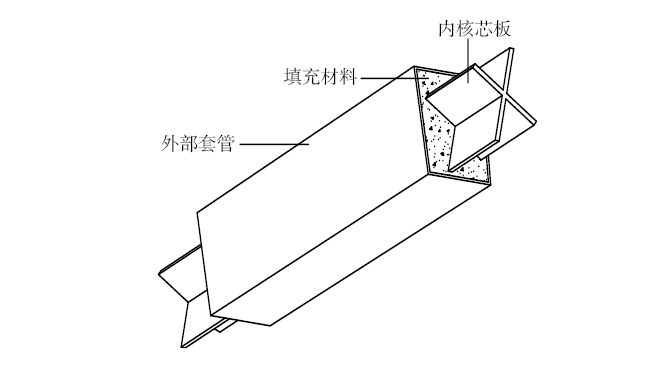

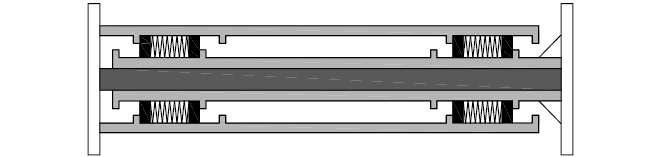

Buckling-restrained braces are a new type of steel brace consisting of three parts: the inner core plate, the outer casing, and the intermediate filling material, as shown in Figure 1. The inner core plate can take various forms, such as straight, cross, H-shaped, and prefabricated; the outer casing also comes in many styles, including square and round. The constraint effect of the outer casing prevents the inner core plate from buckling under compression, allowing full cross-section yielding and thus fully utilizing material performance. This is the essential difference between buckling-restrained braces and ordinary braces. The traditional filling materials are concrete or mortar, but they are difficult to eliminate due to the significant weight of concrete. Currently, commonly used materials are rubber or silicone layers, which ensure the relative movement between the inner core plate and the outer casing.

Figure 1. Schematic of Buckling-Restrained Brace Structure

The joint action of the three parts—the inner core plate, the outer casing, and the filling material—allows buckling-restrained braces to not only enhance the lateral stiffness of the structure but also exhibit good hysteretic energy dissipation capabilities, providing excellent energy dissipation and vibration reduction effects under seismic action. Depending on the function of the BRB, they can be divided into two categories: load-bearing BRB, which mainly improves the bearing capacity of the structure and provides lateral stiffness; and energy-dissipating BRB, which can still provide sufficient stiffness and bearing capacity under repeated loads.

1.2 Research on Inner Core Plates

The inner core plate is the main energy-dissipating component. Traditional buckling-restrained braces often use straight or cross-shaped inner core plates. The straight structure is simple but prone to multi-wave buckling under compression, increasing friction with the outer casing; the cross-shaped core plate has a double-axis symmetry characteristic, reducing the occurrence of multi-wave buckling and resulting in relatively lower friction. Research by Nakamura et al. indicates that the cross-shaped core plate exhibits lower low-cycle fatigue performance compared to the straight core plate and is more susceptible to torsional effects. Experimental findings by Jia Mingming et al. conclude that the straight core section shows better hysteretic performance than the cross section. Meanwhile, Wang Yonggui et al. found that the core material section shape (cross, T-shaped, and straight) did not affect the hysteretic performance and failure mode of the BRB when anti-torsion devices were installed during experiments.

Due to the welding method used for the cross core, residual stresses can occur at the welded joints, reducing the low-cycle fatigue performance of specimens. Zhang Wenxin’s study on discontinuous welding of the cross core and quasi-static tests found that the welding method significantly influences the failure mode and bending deformation mode of the core unit. To mitigate the impact of residual stress and strain caused by welding, Guo Lixing employed four angle steels to form a welded-free cross-section, achieving better low-cycle fatigue performance and effectively avoiding residual stresses and strains. During the loading cycles, the spliced angle steels do not fracture simultaneously but break in segments, displaying good staged ductility characteristics.

The material properties of the inner core plate can significantly affect the failure performance of the BRB. The yield point of the steel plate directly influences the low-cycle fatigue performance and hysteretic energy dissipation capacity of the specimens. Yan Hong compared two different inner core materials, LY 225 and SN 490, used in a full steel BRB with a straight section, concluding that the inner core material made of LY 225 exhibits better low-cycle fatigue performance and plastic deformation capacity than SN 490. The failure modes of the two materials differ, with LY 225 exhibiting ductile failure due to mid-section fatigue fracture, while SN 490 shows brittle failure at the end reinforcement ribs. Chen Hongjian et al. conducted numerical simulations on a double yield point straight full steel BRB, which is made of two low yield point steels LY 100 and one high yield point steel SN 490. The study indicates that the hysteretic curve of the component is full and stable, with LY 100 yielding energy dissipation under design intensity, while SN 490 maintains elasticity to provide lateral support. Under rare earthquake conditions, both types of steel yield energy dissipation, adapting to different levels of horizontal seismic action.

Shi Qingxuan et al. performed numerical simulations on full steel prefabricated buckling-restrained braces, using low yield point steel in a straight configuration. The research demonstrated that the width-to-thickness ratio and spacing ratio of the core material significantly affect the hysteretic performance of the specimens, with smaller slenderness ratios in the weak axis direction leading to quicker plasticity onset. Yang Lu et al. conducted axial compression cyclic tests on full steel prefabricated BRBs with cross low yield point LY 315 steel as the inner core, finding that LY 315 effectively prevents premature buckling, maintains stable mechanical properties, and exhibits good hysteretic curves and energy dissipation capabilities.

By creating holes in the inner core plate, weak points can be artificially introduced to control the yielding position. Zhou Yun et al. and Huo Linsheng et al. treated the straight inner core materials and double aluminum tube BRBs with perforation, resulting in the core unit yielding first at the perforation location, achieving point yielding energy dissipation in the BRB inner core plate. Li Guochang et al. further studied the perforation methods of the inner core plate, discovering that the energy dissipation capacity increases with the decrease of transverse perforation rate and increases with the increase of longitudinal perforation rate, with double-row perforation slightly improving energy dissipation performance compared to single-row perforation.

1.3 Research on Filling Materials

The filling between the inner core plate and the outer casing significantly affects the performance of the BRB, with the key influencing factors being the size of the gap and the magnitude of the friction force. When the BRB is under pressure, the inner core plate undergoes buckling deformation and contacts the outer casing at amplitude points, generating friction between the inner core plate and the outer casing under external forces, causing the constraint components to also bear some axial force.

Some scholars have found that the size of the gap affects the magnitude of the friction force, with increasing gap size resulting in increased friction force. However, if the gap is too large, the brace cannot undergo higher-order buckling modes, leading to significant amplitude changes in the core, which affects yielding performance and fatigue performance; conversely, if the gap is too small, the core expansion is restricted, causing a sharp increase in internal forces in the filling concrete.

Chen Yu investigated the impact of friction on the hysteretic performance of BRBs using finite element analysis software ANSYS. Without friction, the component’s hysteretic curve is full, but as friction increases, the hysteretic curve area decreases, and energy dissipation capacity declines, concluding that friction undermines the energy dissipation capacity of the brace. When using non-bonded materials as filling gaps, BRB components can achieve good hysteretic performance and fatigue resistance, effectively reducing friction between the core and the outer casing.

1.4 Research on Outer Casings

The outer casing effectively restricts the deformation of the inner core plate, enabling it to exhibit higher-order buckling modes, which is beneficial for the inner core plate to undergo buckling and avoid instability failure. By altering the material composition, cross-section shape, assembly method, and layout position of the outer casing, the axial compression performance and hysteretic performance of the components can be enhanced. Traditionally, outer casings are often made of concrete-filled steel tubes or reinforced concrete, which are heavy and not conducive to processing. Currently, more lightweight and easily assembled forms are being used, gradually transitioning from integrated forms to pure steel structures.

Guo Yanlin et al. connected four peripheral constraint angle steels into a whole using high-strength bolts, forming a four-corner rigid combination constraint mechanism, and conducted axial compression cyclic tests, discovering that the component’s bearing capacity mainly depends on the constraint ratio of the BRB.

Ding Ting et al. enhanced the lateral stiffness of the braces by setting different forms of stiffening pipes on the inner wall of the outer casing, effectively constraining the lateral deformation of the inner core plate. Experimental results indicated that longitudinal stiffening methods performed better than transverse stiffening methods in terms of load-bearing performance.

Lv Lei et al. compared the seismic performance of outer casings positioned differently, placing circular steel tube constraint mechanisms around the outer and inner core materials, forming external and internal constraints. Quasi-static tests revealed that the hysteretic performance of external constraints significantly surpassed that of internal constraints, with internal constraints more prone to overall instability.

Mohamad et al. studied the impact of discontinuously arranged external constraint casings on square and cross inner cores, determining suitable distances between the constraints while also reducing material weight. Their research found that cross-core components could reduce the amount of mortar used by up to 64%.

Guo Yanlin et al. proposed a prestressed cable brace type buckling-restrained brace component, which increases the bending stiffness of the peripheral constraint components through the introduction of a cable brace system. The results indicated that the prestressed cable brace type buckling-restrained brace can effectively enhance the constraining ability of peripheral constraint components.

1.5 Research on Self-resetting Buckling-Restrained Braces

Buckling-restrained braces have strong energy dissipation capabilities, effectively reducing earthquake damage to buildings. However, after yielding, their stiffness is relatively low, and they lack resetting capability. Once residual deformations occur after an earthquake, the structure is difficult to return to its initial state, necessitating the replacement of the BRB to ensure the safety and reliability of the structure. The complexity and high cost of replacing BRBs make achieving self-resetting functionality a current research hotspot.

Currently, there are three main methods to achieve the self-resetting capability of BRBs. The first is shape memory alloys, which have a memory function for shapes. By controlling temperature conditions, the structure can return to its original shape while absorbing some energy, exhibiting good damping capabilities. Moreover, as the diameter of the shape memory alloy increases, its energy dissipation capacity also increases. Zhu et al. applied shape memory alloys in friction-type energy-dissipating devices, achieving good self-resetting capabilities. Miller et al. used large-diameter shape memory alloys to provide self-recovery forces, combining them with BRBs to form self-resetting BRB devices that satisfy large deformation self-recovery while also providing certain energy dissipation capabilities. Liu Weihua studied a new type of SMA strand-buckling-restrained brace, finding that it possesses good energy dissipation and self-resetting capabilities. Applying this BRB to frame structures can reduce the top-level displacement response and interlayer displacement angles, demonstrating significant vibration reduction effects.

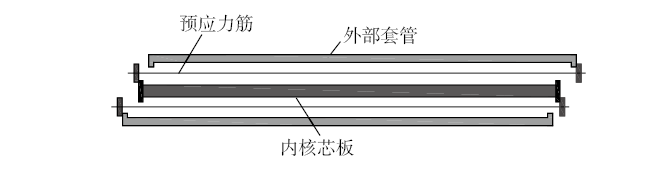

The second method involves prestressed tendons. Prestressed tendons serve as excellent resetting materials, remaining in an extended state whether the brace is under tension or compression. Some scholars have incorporated prestressed cables into H-shaped steel BRBs, using high-strength bolts for assembly, resulting in a simple structure with good energy dissipation and self-resetting capabilities. Wang Haishen et al. designed a three-tube self-resetting buckling-restrained brace device, placing prestressed steel bars between the inner and outer tubes, which performs well within a deformation range not exceeding 1/200 of the brace length.

Liu Lu et al. employed prestressed steel strands as resetting materials in BRBs, with results showing that self-resetting buckling-restrained braces essentially eliminate the residual deformations of buckling-restrained braces. When the restoring force of the prestressing equals that of the energy-dissipating core, optimal configuration is achieved; however, the axial deformation capability of self-resetting BRBs is limited by the elastic deformation limit of the prestressed steel strands. To overcome these limitations, Zeng Peng designed a system with two strands of prestressed tendons in series as resetting materials, significantly increasing the axial deformation capability of the components, with axial deformation being twice that of a single strand of prestressed steel. The double-strand series prestressed tendon self-resetting system is illustrated in Figure 2.

Figure 2. Schematic of Double-Strand Series Prestressed Tendon Self-Resetting System

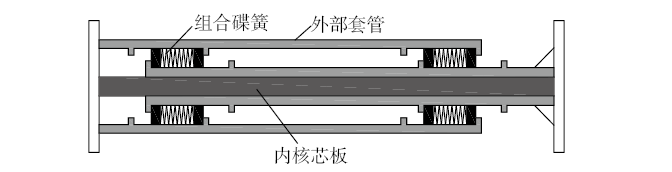

The third self-resetting material is the disc spring, which is formed by stamping thin plate springs into a disc shape, referred to as disc springs. Disc springs are compact, have high load-bearing capacity, strong cushioning and vibration reduction capabilities, and are easy to replace.

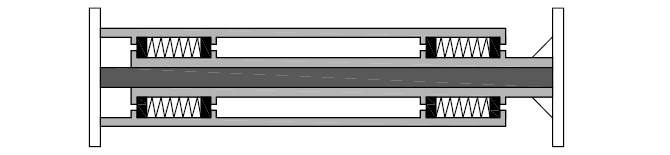

Researchers have installed disc springs as self-resetting devices at both ends of the braces, providing self-recovery capabilities regardless of whether the brace is under tension or compression. The working principle of the structure is illustrated in Figure 3. In the initial state, the disc spring is relaxed with no force acting on it; when the component is under tension or compression, the slots on the inner core plate and outer casing compress the disc spring, causing it to deform under pressure. When the external force is released, the disc spring pushes the inner core plate and outer casing to move back to the original state. However, the friction coefficient between the disc springs can affect their load-bearing capacity, and friction may lead to slight residual deformation, limiting the number of disc springs used and consequently affecting the overall resetting capability of the brace.

(a)

(b)

(c)

Figure 3. Working Principle of Disc Spring Support

(a) Tension State; (b) Initial State; (c) Compression State

Some scholars have assembled various self-resetting devices within BRB components to form a combined application. Zhang Chaozhong et al. applied two sets of prestressed steel strands and combined disc springs in series within prefabricated buckling-restrained braces, utilizing the elongation deformation of the steel strands and the compression deformation of the combined disc springs to provide restoring forces. Results indicated that after compressing the combined disc springs, the stiffness of the brace significantly increased, reducing the concentrated deformation effects between layers and slowing down the interlayer deformation speed under strong earthquakes.

Currently, the three self-resetting materials studied for buckling-restrained braces each have their advantages and disadvantages. Shape memory alloys provide excellent self-resetting capabilities but are expensive, and their performance can be affected by temperature. Prestressed steel strands are difficult to anchor and inevitably require welding during processing, with temperature changes potentially reducing or even eliminating prestressing. Disc springs exhibit good self-resetting capabilities, but the friction between them can affect their self-resetting ability.

2. Application of BRB in Frame Structures

2.1 Research on BRB Frame Structures

Buckling-restrained braces can improve the lateral stiffness of frame structures while enhancing their seismic performance. Under seismic action, buckling-restrained braces act as a “fuse,” providing the first line of defense for the structure. After yielding, the internal forces of the structure redistribute, making the frame structure the second line of defense, still retaining seismic resistance. Therefore, BRB frame structures are energy-dissipating structures with dual lateral force systems. When arranging BRBs, it is essential to ensure that the dynamic characteristics in both principal axes of the structure are similar, and to align the mass center with the stiffness center as much as possible, minimizing torsional seismic effects. Additionally, efforts should be made to avoid local stiffness weakening or abrupt changes that create weak points, leading to excessive stress concentration or concentrated plastic deformation.

Researchers have installed BRBs in frame structures, effectively improving the lateral stiffness and seismic performance of the frame structures. Qiao Jinli et al. studied the force mechanism and transmission mechanism of concrete frame structures with and without installed buckling-restrained braces, finding that the hysteretic performance and energy dissipation capacity of concrete frames with buckling-restrained braces significantly improved compared to ordinary concrete frames. Miao Jie applied spring-type self-resetting buckling-restrained braces in frame structures, conducting finite element analysis using OpenSees, and found that this type of BRB could effectively reduce the residual displacement of the frame structure to negligible levels. Li Guochang et al. applied BRBs in high-rise concrete structures, establishing a buckling-restrained brace frame-core tube hybrid structure model. Research results indicate that reasonable arrangement of BRB devices can increase the torsional stiffness of the structure and reduce the seismic response.

Different forms of BRBs can affect the seismic reinforcement performance of frame structures. Gu Luzhong et al. studied the seismic performance of three forms of BRB frame structures: ordinary beam single diagonal brace, wide flat beam single diagonal brace, and ordinary beam herringbone brace. Analysis of crack development conditions showed that the frame beams and columns exhibit good yielding mechanisms, with the wide flat beam single diagonal brace and ordinary beam herringbone brace having more reasonable force mechanisms. Wang Yonggui et al. studied the seismic performance of frame structures under inverted V and single diagonal brace arrangements, finding that the seismic performance of the inverted V arrangement outperformed that of the single diagonal arrangement.

Wu Hui et al. investigated the seismic performance of frame structures under two reinforcement methods—reinforcement by bonding bars and shear key reinforcement. Through quasi-static seismic tests and nonlinear simulations using Perform-3D software, they analyzed the deformation performance, bearing capacity, and energy dissipation capacity of the structure. Results indicated that both reinforcement methods could enhance the seismic performance of reinforced concrete frame structures, with the bonding method showing better stability.

2.2 Research on BRB Frame Structure Joints

Under seismic action, the column ends and beam-column joints of frame structures are prone to failure, leading to loss of bearing capacity and potential collapse of the structure. Reinforcing the structure with shear walls can help, but it may affect the building’s lighting performance. Applying BRBs in concrete frame structures can avoid lighting issues caused by shear walls. In multiple earthquakes in China, a significant portion of seismic damage to concrete frame structures occurred in the core area of column-beam joints, contradicting the design principle of strong joints and strong anchoring. Therefore, in BRB frame structures, the design and reinforcement of joints have become an unavoidable research direction.

Wu Kechuan et al. studied the seismic performance of reinforced concrete frames with buckling-restrained braces under different stiffness ratios, finding that the greater the stiffness ratio, the more severe the damage to component joints.

Some scholars analyzed ordinary beam-column joints and beam-column joints with braces. Finite element software was used to analyze the trends of vertex displacement and rotation angles. Due to the design considering the rotational capacity of the joints, the seismic performance of beam-column joints with braces was lower than that of ordinary beam-column joints but closer to reality.

Wang Jingfeng et al. studied two types of beam-column joints: integral and concealed steel seat types, finding that the overall performance of concealed steel seat beam-column joints outperformed that of integral beam-column joints. Other scholars designed a T-shaped connection node connecting buckling-restrained braces and concrete. Results indicated that the new T-shaped steel anchoring node transfers the plastic hinge to the beam-column area outside, ensuring stable and reliable connections with clear force transmission.

Zhu Jiang et al. researched the development of cracks and deformations in edge nodes of BRB concrete frame structures under different stress states, clarifying the limit states and failure states of the nodes. Results showed that the reinforcement ratio of longitudinal steel bars in beams and the stiffness ratio of beam-column lines significantly affect the elastic-plastic performance of the nodes, while the axial compression ratio has minimal impact on node performance.

Ma Chuanzheng et al. studied high-strength concrete columns with BRBs and H-shaped steel weakened nodes. Results indicated that the weakened nodes caused the plastic hinge at the beam end to occur at the weakened area, helping to shift the plastic hinge outward, reducing stress concentration in the node area, thereby facilitating the achievement of the seismic design goal of “strong columns, weak beams, strong nodes.”

Bai et al. proposed a new connection method between BRBs and frame structures, connecting angle braces and RC components entirely through shear connectors to achieve more reliable BRB-to-RC connections in new frame structures. This connection method exhibits good seismic performance and stable energy dissipation capabilities.

3. Research on Design Methods

The preliminary design defense objectives: under frequent earthquake actions, the main structure and reinforced frame remain in an elastic state; under design intensity earthquake actions, buckling-restrained braces consume seismic energy, allowing the main structure to crack without yielding, and under rare earthquake actions, the structure does not collapse.

Two-stage design and three-level defense objectives are currently common seismic design methods. However, traditional seismic design often fails to economically and effectively utilize resources due to its inability to predict and judge the timing and energy levels of earthquakes. Therefore, further refinement of existing seismic theories is required to explore new methods for seismic resistance or energy absorption.

Zhang Jiaguang et al. proposed a simplified calculation method for interlayer deformation capacity of reinforced concrete frames based on the weakest plastic hinge. This design method can implement the addition of BRBs while avoiding the need for local seismic reinforcement of structural components that do not meet requirements.

Li Xiaolong et al. proposed a simplified design method for buckling-restrained braces based on stiffness compensation concepts, demonstrating that buckling-restrained braces effectively eliminate weak layers, with the best effects achieved when the braces are centered, meeting the requirements of not yielding under frequent earthquakes and yielding energy dissipation under rare earthquakes.

Wang Hongwei et al. conducted a comparative study of buckling-restrained steel structures designed with fixed and variable lateral stiffness ratios, exploring the optimal arrangement of braces in buckling-restrained steel structure design. Results indicated that designs using variable K values are superior to those with fixed K values, requiring smaller brace cross-sections to achieve similar performance goals.

Pan Yi et al. proposed a BRB frame structure seismic design method based on shear ratios, designing multiple structures with different shear ratios and modeling using SAP2000. Through nonlinear analysis under strong earthquakes, they studied the seismic performance of the structures. Results indicated that the reasonable range of values for establishing buckling-restrained braces is determined by the maximum interlayer displacement angle and the energy dissipation ratio of the BRB.

4. Conclusion

Currently, the research field of buckling-restrained braces is continuously innovating and breaking through, but many issues remain unresolved. In theoretical analysis, considerations for localized buckling of core materials are relatively simplistic, and mechanisms to prevent localized buckling have not been systematically proposed; in support testing, most tests have certain drawbacks in handling the support ends, and in model analysis, most models idealize the connection between buckling-restrained braces and structures, which may not accurately reflect the braces’ roles and performance. Research on BRBs can be conducted from the following aspects.

(1) Study the performance of different forms of BRBs. Changes can be made to the core form, peripheral constraint forms, etc., to enhance the hysteretic performance and energy dissipation capacity of the BRBs.

(2) Incorporate self-resetting systems into BRBs, enabling self-resetting BRBs to provide lateral resistance while also resetting themselves, ensuring that structures can continue to operate normally after seismic actions.

(3) Use different forms to integrate BRBs into frame structures and study the cooperative working mechanisms of BRB frame structures. Damage to BRB and frame structure joints is common, and well-constructed connection nodes can provide stable seismic performance for the structure.

(4) Research the design methods for BRB frame structures. This can be achieved through the control of different parameters to study suitable design methods.

Excerpt from Building Technology2023March, Ding Lei

◎ All original articles published in this WeChat account are owned by the Building Technology Magazine. Any media reprints or excerpts must indicate the original source.