Industrial Automation Maintenance Manual: Modbus TCP Communication Troubleshooting and Optimization Guide

▲ 90% of Engineers Overlook Modbus TCP Communication Risks: Timeout Settings and Message Boundary Handling

Dear friends, I am Wang, and I have been working in industrial control for over ten years. Today, let’s talk about the Modbus TCP protocol, which seems simple but actually hides many secrets. I have found that most engineers focus only on superficial parameters like station numbers and register addresses, while neglecting two core issues: timeout settings and message boundary handling, which are precisely the culprits behind system instability.

On the front lines, I often see devices disconnecting inexplicably and data loss occurring. After investigation, 90% of the time it is due to improper TCP connection management and message parsing errors. Especially in multi-slave systems, if the polling cycle is not set reasonably, communication efficiency will drop sharply. A project with 5 slaves may only require a 20ms polling cycle, but with 20 slaves, it could become 80ms, leading to severe system response delays.

# ● Common Fault Phenomena and Troubleshooting Mnemonics

Fault Phenomenon 1: Frequent Communication Disconnections

-

Manifestation: PLC and slave device connections repeatedly disconnect

-

Root Cause: Improper TCP keep-alive parameter settings or unreasonable network topology

Fault Phenomenon 2: Data Reading Errors

-

Manifestation: Read data is abnormal or all zeros

-

Root Cause: Incorrect register address offset or data type conversion issues

Fault Phenomenon 3: Communication Timeout

-

Manifestation: No response to operations, system reports communication timeout

-

Root Cause: Network congestion or insufficient slave response capability

# ※ Troubleshooting Mnemonics (Effective in Field Testing):

Check Modbus, first look at the message, protocol format must be clear;

Station address must be verified, function codes must correspond carefully;

Timeout settings should not be too short, prevent network congestion;

In multi-slave situations, check in groups, eliminate one by one for good positioning.

■ Modbus TCP Fault Troubleshooting Flowchart and Tool Selection

Fault Occurs → Confirm Physical Connection → Check IP/Port Configuration → Packet Capture and Analyze Messages

↓ ↓

Confirm Slave is Online ← Test PING Connectivity ← Check Firewall Settings

↓

Analyze Error Codes → Refer to Error Code Manual → Targeted Solutions

↓

Verify Data Types → Check Byte Order → Confirm Register Mapping

↓

System Restores to Normal

# ● Essential Tools Checklist:

-

Wireshark – Packet capture analysis tool for capturing and analyzing Modbus TCP messages

-

NetAssist – Network debugging assistant for simulating Modbus TCP master-slave communication

-

Modpoll – Command-line Modbus testing tool for quickly verifying slave responses

-

Multimeter – Measure RS485/Ethernet physical connections (must “short the resistance value” for resistance measurement)

-

Protocol Analyzer – Professional equipment for fault localization in complex network environments

◆ Performance Comparison Table of Modbus TCP on Different PLC Platforms

| Parameter Item | Beckhoff X20CP | Siemens S7-1200 | Mitsubishi FX5U | Omron NJ Series |

|———|————|————–|———|————|

| Max Slave Count | 64 | 16 | 32 | 32 |

| Max Bytes per Read | 250 bytes | 125 bytes | 125 bytes | 125 bytes |

| Refresh Cycle for 16 Slaves | 3ms | 12ms | 8ms | 10ms |

| Multiplexing Support | Yes | No | Partial | Yes |

| Max TCP Connections | Unlimited (Software) | 16 | 8 | 32 |

| Exception Code Handling Capability | Comprehensive | Basic | Good | Good |

Note: The above data is based on actual project testing; different firmware versions may vary.

▲ Hard-Earned Experience: A Case Study of Modbus TCP Communication Failure in a Chemical Plant

Last year, I encountered a tricky problem at a chemical plant: the entire DCS system communicated with over 20 frequency converters via Modbus TCP. After running for a while, some frequency converters would randomly drop offline, causing frequent production line shutdowns.

Fault Phenomenon:

-

Frequency converters drop offline randomly, with no discernible pattern

-

Temporary recovery after reboot, but the problem reappears

-

System logs show a large number of “connection timeout” errors

Troubleshooting Process:

-

First, check the network cable for insulation issues to rule out physical connection problems

-

Use Wireshark for packet analysis and find a large number of TCP RST packets

-

Check switch configuration and find that port storm control is too strict

-

Analyze the DCS master program and find that TCP connections are not being closed properly

Root Cause:

The DCS system did not correctly release TCP resources during communication anomalies, leading to connection accumulation, which eventually triggered switch storm control and cut off communication.

Solution:

-

Modify the DCS program to add TCP connection management mechanisms

-

Adjust switch storm control parameters

-

Divide the 20 devices into 4 groups, each with independent communication channels

-

Add communication status monitoring and automatic recovery mechanisms

After implementation, the system has been running stably for over 18 months without a single communication failure. This made me deeply realize that: In industrial settings, TCP connection management is more important than the protocol itself!

● Maintenance Notes: Quick Reference Points for Modbus TCP Communication Failures

▲ Important: Modbus TCP error code 01 (Illegal Function) usually indicates that the slave does not support that function code; check the slave manual to confirm the list of supported function codes.

● Note: The address space for reading and writing coils (function codes 01, 05) and reading and writing registers (function codes 03, 06) is separate; do not confuse them.

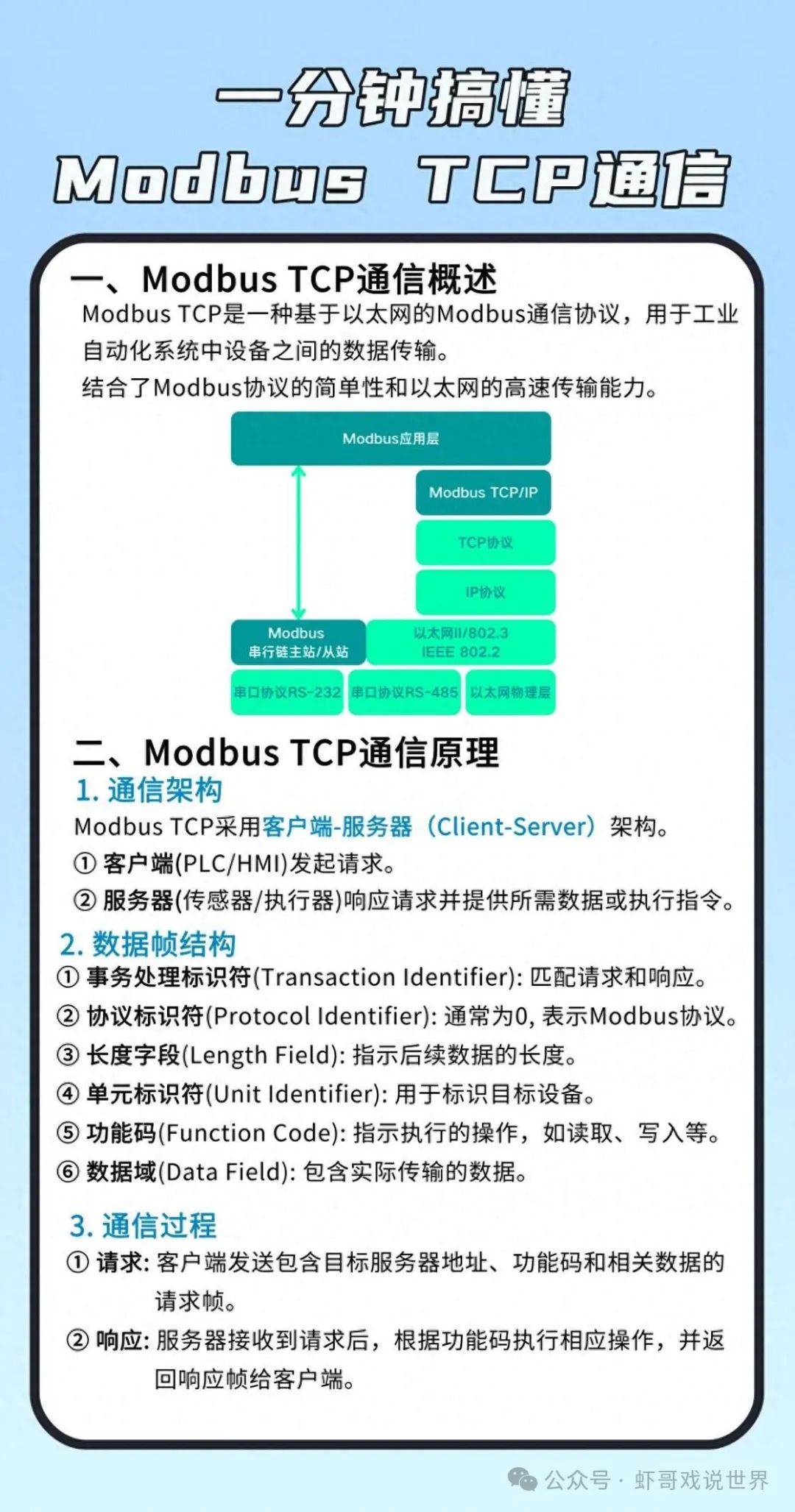

※ Key: The MBAP header of Modbus TCP messages contains transaction identifier, protocol identifier, length, and unit identifier, totaling 7 bytes, followed by the PDU part.

▲ Must Check: When error code 0x0A (Gateway Path Unavailable) occurs, it is usually due to gateway device configuration errors or the target device being offline.

● Tip: Use network debugging software like NetAssist to analyze specific messages, which can quickly locate communication errors.

※ Experience: In multi-slave systems, using multiplexing can significantly improve communication efficiency; Beckhoff controllers have been tested to control the refresh cycle of 16 slaves to around 3ms.

▲ Warning: The default port for Modbus TCP is 502; some systems may list this port as a security risk, requiring special allowance in the firewall.

■ Essential for Engineers: Modbus TCP Performance Optimization Solutions

In actual projects, the efficiency of Modbus TCP communication directly affects system response speed. Here are some optimization experiences I have summarized:

-

Grouped Communication Strategy: Group slave devices by function or location, using independent Modbus master instances for each group, which can significantly increase refresh rates

-

Multiplexing Technology: On supported controllers (like Beckhoff), achieve concurrent communication, reducing refresh time to one-sixteenth of the original

-

Data Packaging Optimization: Reasonably plan register addresses, concentrating frequently accessed data to reduce communication frequency

-

Timeout Parameter Tuning: Adjust timeout parameters based on actual network conditions to avoid long waits or premature retries

-

Network Topology Optimization: Use industrial switches and reasonably plan network topology to reduce the risk of broadcast storms

※ Download Practical Tool Kit

To help engineers quickly resolve Modbus TCP communication issues, I have compiled the following toolkit:

-

Modbus TCP Error Code Quick Reference Table: Contains all standard error codes and handling suggestions

-

Communication Parameter Configuration Template: Parameter configuration table suitable for mainstream PLC platforms

-

Fault Diagnosis Flowchart: Printable version, essential for field troubleshooting

-

Message Format Parsing Tool: Automatically parses Modbus TCP message structures

-

Multi-Slave Communication Optimization Example Code: Sample program based on the Beckhoff platform

These resources can be found on my technical blog: https://industrial-automation.tech/modbus-tools

Remember, when encountering errors like ORA-12170 (TNS connection timeout), first check network connectivity and server status, then confirm if the client configuration is correct. In industrial settings, network issues are often more common than protocol issues.

Conclusion: As the “universal language” in the field of industrial automation, mastering troubleshooting techniques for Modbus TCP is crucial for every engineer. I hope this summary of frontline experiences helps you avoid detours. Remember, troubleshooting communication issues should be analyzed step by step from the physical layer to the application layer, and avoid blind attempts.

Finally, I leave you with a saying: **”In industrial control, no detail is too small; stable communication is fundamental.”**