Introduction

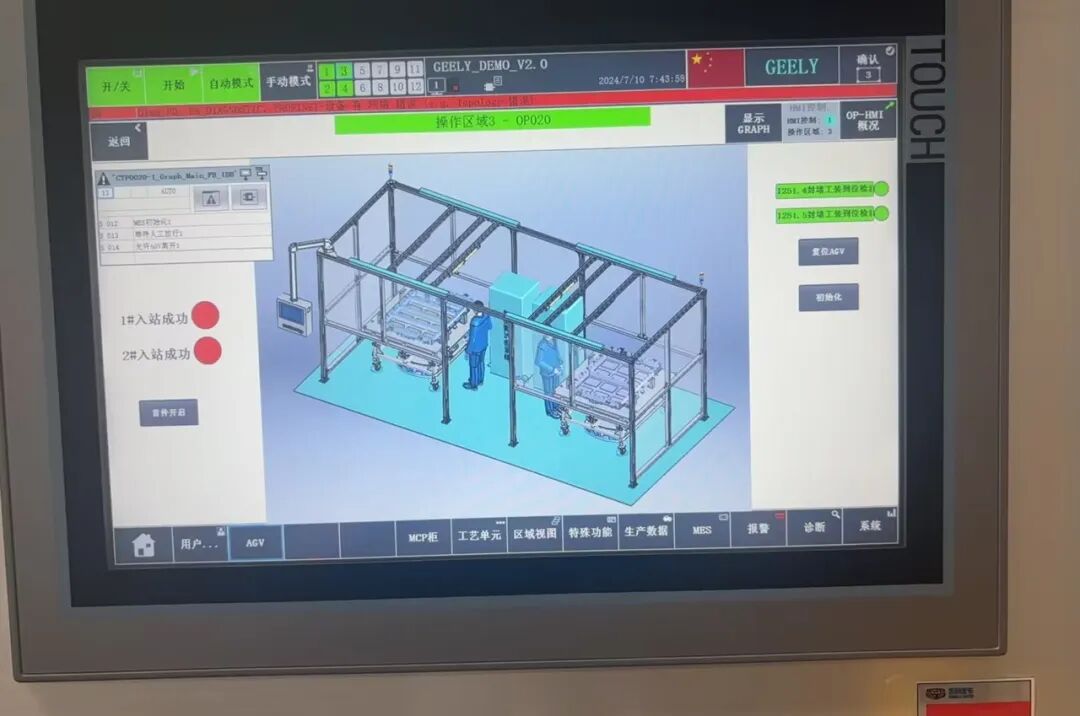

With the rapid development of smart manufacturing, Automated Guided Vehicles (AGVs) and Programmable Logic Controllers (PLCs) are increasingly applied in production lines. AGVs achieve automated control of the production process through interaction with PLCs, enhancing production efficiency and product quality. However, there are several issues in the interaction between AGVs and PLCs. This article will analyze these issues in detail and propose corresponding solutions.

Analysis of AGV and PLC Interaction Issues

-

AGV Request to Enter Workstation Issue

- Issue Description: The AGV continuously sends a signal requesting to enter the workstation until the PLC allows entry, at which point the signal is disconnected.

- Cause Analysis: There may be an issue with the signal sending mechanism of the AGV while waiting for the PLC’s response, causing the signal to not disconnect in a timely manner.

- Solution: Optimize the AGV’s signal sending logic to ensure that the request signal is promptly disconnected upon receiving the PLC’s allow signal.

AGV Entering Signal Issue

- Issue Description: The AGV continuously sends an entering signal until it sends a signal indicating it has reached the workstation (the position signal is continuously sent).

- Cause Analysis: There may be an issue with the AGV’s position signal sending mechanism, causing the signal to not disconnect in a timely manner.

- Solution: Optimize the AGV’s position signal sending logic to ensure that the entering signal is promptly disconnected upon reaching the workstation.

AGV Position Signal Issue After Arrival

- Issue Description: The AGV continuously sends a position signal after arriving.

- Cause Analysis: There may be an issue with the AGV’s position signal sending mechanism, causing the signal to not disconnect in a timely manner.

- Solution: Optimize the AGV’s position signal sending logic to ensure that the position signal is promptly disconnected upon arrival at the workstation.

AGV Leaving Signal Issue

- Issue Description: After receiving the PLC’s allow to leave signal, the AGV closes the position signal while simultaneously sending a leaving signal.

- Cause Analysis: There may be an issue with the AGV’s leaving signal sending mechanism, causing the signal to not be sent in a timely manner.

- Solution: Optimize the AGV’s leaving signal sending logic to ensure that the leaving signal is promptly sent after receiving the PLC’s allow to leave signal.

AGV Signal Issue After Leaving the Grating Area

- Issue Description: The AGV closes the leaving signal after exiting the grating area.

- Cause Analysis: There may be an issue with the AGV’s leaving signal sending mechanism, causing the signal to not close in a timely manner.

- Solution: Optimize the AGV’s leaving signal sending logic to ensure that the leaving signal is promptly closed after exiting the grating area.

Abnormal Signal Interaction Between AGV and PLC

- Issue Description: Abnormal signal interaction between AGV and PLC leads to production line stoppage.

- Cause Analysis: There may be issues with the communication protocol or signal definitions between AGV and PLC, leading to abnormal signal interaction.

- Solution: Check and optimize the communication protocol and signal definitions between AGV and PLC to ensure the accuracy and reliability of signal interaction.

Common Issues and Solutions During AGV Operation

-

AGV Vehicle Unexpected Stopping

- Issue Description: The AGV vehicle unexpectedly stops during operation, causing production line stoppage.

- Cause Analysis: The AGV vehicle may stop unexpectedly due to mechanical failure, signal loss, or path blockage.

- Solution: Regularly check the mechanical equipment of the AGV vehicle, ensure the stability of signal transmission, and clear path blockages.

AGV Path Planning Issue

- Issue Description: There are issues with path planning during AGV operation, leading to inability to operate normally.

- Cause Analysis: There may be issues with the AGV’s path planning algorithm, or environmental changes may cause path planning failures.

- Solution: Optimize the AGV’s path planning algorithm and update environmental information in real-time to ensure the accuracy of path planning.

Communication Issues Between AGV and Production Line Equipment

- Issue Description: Communication issues between AGV and production line equipment lead to production line stoppage.

- Cause Analysis: There may be issues with the communication protocol or network configuration between AGV and production line equipment, leading to communication failure.

- Solution: Check and optimize the communication protocol and network configuration between AGV and production line equipment to ensure communication stability and reliability.

AGV Power Management Issue

- Issue Description: The AGV stops operating due to insufficient power, leading to production line stoppage.

- Cause Analysis: There may be issues with the AGV’s power management system, leading to insufficient power.

- Solution: Optimize the AGV’s power management system to ensure stable power supply and regularly check battery status.

AGV Task Drop-off Issue

- Issue Description: The AGV drops off tasks during operation, leading to inability to complete tasks normally.

- Cause Analysis: There may be issues with the AGV’s task management system, or communication interruptions may lead to task drop-off.

- Solution: Optimize the AGV’s task management system to ensure communication stability and regularly check the operational status of the task management system.

Optimization Suggestions for AGV and PLC Interaction Issues

-

Improve AGV Signal Monitoring

- It is recommended to add a signal monitoring module between AGV and PLC to monitor the sending and receiving status of signals in real-time, ensuring the accuracy and reliability of signal interaction.

Optimize AGV Path Planning

- It is recommended to optimize the AGV’s path planning algorithm, updating environmental information in real-time to ensure the accuracy and reliability of path planning.

Strengthen Communication Management Between AGV and PLC

- It is recommended to strengthen communication management between AGV and PLC to ensure the accuracy and reliability of communication protocols and network configurations.

Improve AGV Power Management

- It is recommended to improve the AGV’s power management system to ensure stable power supply and regularly check battery status.

Regular Maintenance and Inspection

- It is recommended to regularly maintain and inspect AGV and PLC equipment to ensure normal operating conditions and prevent potential issues.

Case Analysis

-

Case 1: AGV Vehicle Lifting Abnormality

- Issue Description: The AGV vehicle experiences lifting abnormalities during operation, leading to production line stoppage.

- Cause Analysis: The lifting mechanism of the AGV vehicle may experience mechanical failure or signal abnormalities, causing lifting issues.

- Solution: Check and repair the lifting mechanism of the AGV vehicle, optimizing the stability of signal transmission.

Case 2: AGV Unable to Exit Station

- Issue Description: The AGV vehicle is unable to exit the station during operation, leading to production line stoppage.

- Cause Analysis: The AGV vehicle may be unable to exit due to signal loss or path blockage.

- Solution: Check and repair signal transmission issues, clear path blockages, and ensure the AGV vehicle can exit normally.

Case 3: AGV Task Drop-off

- Issue Description: The AGV vehicle drops off tasks during operation, leading to inability to complete tasks normally.

- Cause Analysis: There may be issues with the AGV’s task management system, or communication interruptions may lead to task drop-off.

- Solution: Optimize the AGV’s task management system to ensure communication stability and regularly check the operational status of the task management system.

Conclusion

The interaction between AGV and PLC plays a crucial role in smart manufacturing, and its stability and reliability directly affect the operational efficiency of the production line. By analyzing and resolving the interaction issues between AGV and PLC, significant improvements can be made in production line efficiency and product quality. It is recommended that enterprises regularly maintain and inspect AGV and PLC equipment in practical applications, optimize signal transmission and path planning, and ensure the accuracy and reliability of AGV and PLC interaction to achieve efficient operation of the production line.

—END—Previous Recommendations:

[Calculation] Tracked Vehicle Steering and Driving Torque

Simulation of Trajectory for Latent Traction AGV

[PFMEA Series Four] Failure Analysis: Understanding Failure Effects and the Relationship Between PFMEA and DFMEA[Special] AGV Products and Their Application Processes in the Automotive Industry