Bottle-type high-pressure hydrogen storage vessels are the main hydrogen storage containers at hydrogen refueling stations and are classified as high-risk pressure vessels. They must withstand internal pressure loads exceeding 45 MPa and cyclic loads during the filling and discharging processes. Given that hydrogen is flammable and explosive, the failure of these vessels can lead to severe consequences. This article discusses the current state of research on the damage mechanisms of bottle-type high-pressure hydrogen storage vessels and analyzes the monitoring requirements. It proposes an intelligent monitoring scheme based on IoT technology for four types of damage: corrosion damage, fatigue damage, hydrogen embrittlement damage, and manufacturing damage, aiming to reduce the costs of regular inspections, shorten downtime, and improve service quality and management efficiency.

Introduction

Currently, countries around the world urgently need to address or mitigate environmental degradation and energy shortages. In today’s society, hydrogen energy, as a clean and green energy source, is becoming increasingly important and has broad application prospects in both domestic and international markets. Hydrogen refueling stations play a crucial role in the utilization of hydrogen energy, where hydrogen storage devices typically use bottle-type high-pressure hydrogen storage vessels. These vessels are primarily made of seamless steel cylinders, with CrMo steel being the main material for manufacturing large seamless steel cylinders. Bottle-type high-pressure hydrogen storage vessels can withstand high gas pressures, and their safety performance has always been a major concern due to potential hazards. The main causes of vessel failure include corrosive cracking, fatigue cracking, hydrogen-induced cracking, and manufacturing damage. If vessels are not adequately monitored over time, small cracks may propagate, ultimately leading to brittle fracture and serious accidents such as medium leakage. In China, there is still a lack of unified standards and regulations for monitoring bottle-type high-pressure hydrogen storage vessels. Therefore, it is necessary to study the damage mechanisms of these vessels and propose effective IoT monitoring solutions for different types of damage.

1. Current State of Damage Mechanism Research

1.1 Corrosion Damage

Research in literature [11] suggests that insufficient purity of the medium can lead to corrosion cracks in steel cylinders. Under the simultaneous action of a humid HS environment and tensile stress, local corrosion occurs in the steel cylinder, leading to crack formation. The tensile stress can damage the brittle oxide film at the crack tip, exposing new anodes; the sides of the crack are passivated, forming a cathode, resulting in electrochemical corrosion that further propagates the crack. Literature [2] conducted a comparative analysis of cylinders filled with hydrogen of different purities, finding that the presence of significant amounts of sulfides and moisture can cause corrosive cracking and pitting in the container under internal pressure, potentially leading to crack penetration in severe cases. Literature [3] studied the failure mechanism of cylinders made of 34CrMo4 steel, revealing that the condensation of CO2 acidic water vapor on the inner surface of the cylinder can lead to severe pitting corrosion on the steel surface. These studies indicate that impurities such as sulfides and CO2 in the hydrogen medium can react with water, creating a corrosive environment harmful to the vessel, leading to localized corrosion damage.

1.2 Fatigue Damage

During use, bottle-type high-pressure hydrogen storage vessels undergo typical fatigue processes. Continuous pressurization and depressurization subject the vessel to periodic alternating loads, causing stress concentration in localized areas, which can damage the protective film on the surface and form micro-cracks. These micro-cracks can accelerate damage in a harmful corrosive environment, ultimately leading to vessel damage and failure. Literature [4] simulated the actual working conditions of the cylinders and conducted corrosion fatigue crack propagation tests on steel samples under different experimental conditions, finding that the crack propagation rate is inversely proportional to the load application frequency and directly proportional to the stress ratio. Literature [5] found through actual surveys that if the operation during the pressurization of bottle-type pressure vessels is not standardized, the internal pressure may exceed the normal 20 MPa, and the temperature inside the vessel can rise with increasing pressure, reaching up to 70-80 °C. High pressure and high temperature conditions can accelerate crack propagation. These studies indicate that under the action of repeated pressurization and depressurization, changes in internal gas pressure and temperature can damage the vessel, leading to localized fatigue damage.

1.3 Hydrogen Embrittlement Damage

Long-term exposure to high-pressure, high-purity hydrogen conditions can lead to localized plasticity reduction in metallic materials, accelerating crack propagation and decreasing equipment durability, a phenomenon known as high-pressure hydrogen embrittlement. Literature [6] analyzed the heat treatment processes and tensile strength changes of 34CrMo4 and 30CrNiMo8 steels, studying the mechanisms of hydrogen-induced stress cracking and delayed corrosion cracking. Under the same experimental conditions, creep tests were conducted on both traditional and isothermally treated steel samples, revealing that both types of steel exhibited hydrogen-induced stress corrosion cracking. Literature [31] used scanning electron microscopy to observe the crystal structure of cracks on the steel surface, identifying some hydrogen embrittlement cracks originating from the tips of corrosion pits, with their propagation limited by voids generated by hydrogen traps. The research indicates that under high-purity hydrogen conditions, hydrogen atoms may penetrate into the metal, combining with certain impurities to form hydrogen molecules, which gradually accumulate within the metal, causing damage to the base material and resulting in a series of stepwise hydrogen embrittlement cracks.

1.4 Manufacturing Damage

Since the primary material for large seamless steel cylinders is CrMo steel, some scholars have studied the properties of CrMo steel. Literature [7] analyzed the effects of quenching structure stress and thermal stress on quenching cracks in 34CrMo4 steel, finding that thermal stress is the main cause of fire cracks. Literature [8] discovered that during the production of 34CrMo4 hot-rolled seamless steel pipes, fragmentation can occur. Sampling and testing confirmed that 34CrMo4 steel can develop different forms of cracks during quenching and hot-rolling processes. Literature [1] provided a detailed analysis of defects in large seamless steel cylinders, showing that during the high-temperature extrusion process of manufacturing the cylinders, uneven temperature distribution during metal solidification can lead to micro-cracks at the mouth of the vessel. Additionally, manufacturing processes can produce folds and heavy skin, which can lead to surface cracks during subsequent frequent filling and unloading processes due to continuous expansion and contraction. These studies indicate that manufacturing defects can form during the processing of the vessels, which may further propagate during later use, leading to vessel failure.

2 Analysis of Damage Types and Monitoring Requirements

When cylinders are exposed to humid environments containing sulfides or CO2, corrosion occurs on the surface, gradually reducing effective thickness and forming damage in localized areas. The stress concentration in the damaged areas can accelerate the propagation of corrosion damage cracks. Therefore, monitoring the concentration of sulfides or acidic impurities in the gas medium, changes in the thickness of critical areas of the vessel, and humidity changes inside and outside the vessel is essential to detect potential corrosion damage issues early, allowing for maintenance and repair measures to ensure the safe operation of bottle-type high-pressure hydrogen storage vessels.

During the repeated filling and discharging of the cylinders, high filling and discharging pressures and rates can cause rapid changes in stress and temperature in critical areas of the vessel wall, increasing the risk of vessel damage. Under the action of alternating cyclic loads during repeated filling and discharging, the vessel wall can experience cross-sectional expansion displacements, and the micro-deformations caused by these displacements can serve as initiation points for cracks. Therefore, cross-sectional expansion displacement is a significant factor in the fatigue damage of the vessel. To ensure effective operation during the filling process, real-time monitoring of internal pressure, temperature, and cross-sectional expansion displacement of the vessel is necessary to detect fatigue cracking damage promptly, develop maintenance plans, and enhance the safety of the vessel. Bottle-type high-pressure hydrogen storage vessels working long-term in high-pressure, high-purity hydrogen environments are prone to hydrogen-induced cracking. During the processing of the cylinders, due to the influence of processing technology and subsequent usage methods, cracks can easily occur on the mouth and thread surfaces. The impacts of hydrogen embrittlement cracks and manufacturing damage cracks cannot be avoided, but monitoring of these two types of cracks should be strengthened to prevent damage propagation that could lead to vessel failure.

3 Intelligent Monitoring Scheme for Bottle-Type Hydrogen Storage Pressure Vessels

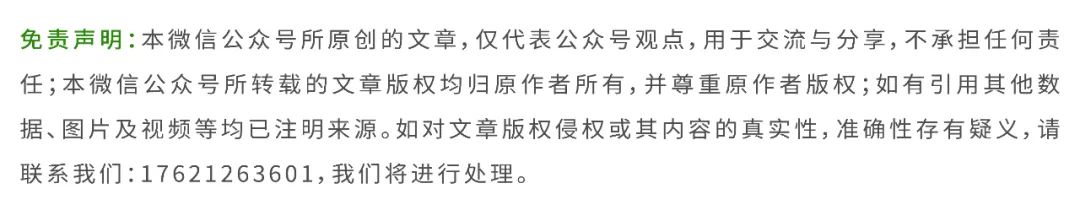

Based on the analysis of the damage mechanisms of bottle-type pressure vessels, the main types of damage include corrosive cracking, fatigue cracking under alternating loads, and high-pressure hydrogen embrittlement cracking. This article focuses on real-time monitoring of these damage conditions. The IoT technology architecture for intelligent monitoring of high-pressure hydrogen storage vessels is shown in Figure 1.

For monitoring the corrosion cracking damage of the cylinders, ultrasonic thickness sensors can be used to monitor the corrosion thinning state of the cylinders in real-time; hydrogen sulfide monitoring sensors can monitor the content of impurities such as hydrogen sulfide inside the cylinders; humidity monitoring sensors can monitor the humidity inside and outside the cylinders, thus achieving real-time monitoring and early warning of corrosion cracking damage conditions. For fatigue damage caused by alternating loads during filling and discharging, pressure sensors can monitor the pressure experienced by the vessel during filling and discharging in real-time, and eddy current displacement sensors can monitor changes in the expansion of the vessel’s cross-section during filling and discharging. For high-pressure hydrogen embrittlement damage and manufacturing damage, acoustic emission sensors can monitor the crack propagation status in real-time, and temperature sensors can monitor changes in the temperature of the vessel body in real-time. A multi-source data fusion system can be developed for sensors such as ultrasonic thickness, eddy current displacement, acoustic emission, hydrogen sulfide, humidity, temperature, and pressure to collect and process various data; a wireless data transmission module can be used for long-distance data transmission; and a monitoring and early warning platform for bottle-type pressure vessels can be developed and integrated with the monitoring and data collection system.

4 Conclusion

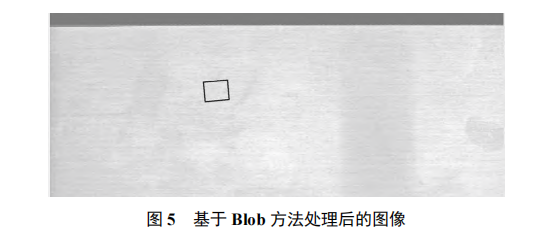

This article summarizes the main types of damage to bottle-type high-pressure hydrogen storage vessels as corrosion damage, fatigue damage, hydrogen embrittlement damage, and manufacturing damage. For different types of damage, monitoring methods in the areas of acoustic emission, eddy current, pressure, temperature, and ultrasonic thickness have been designed, and a complete intelligent monitoring scheme based on IoT technology has been developed using morphological operations and feature extraction from the Blob method. Morphological operations include dilation, erosion, opening, closing, top-hat, and bottom-hat operations, with the main operations being dilation and erosion, as shown in Figure 5.

Source: Comprehensive Perception, China Special Equipment Inspection and Research Institute

Authors:Cai Kangjian, Xu Wei, Guo Xinran, He Yu, Zhou Yunyi, Shi Kun

Editor: FAN | Reviewer: HOHO