In current microcontrollers, many older models lack Bluetooth module functionality, while new microcontrollers (MCUs) with Bluetooth modules are rarely featured in existing textbooks. Thus, after researching some materials, this article presents a method to add Bluetooth functionality to standard MCU chips, effectively addressing the integration of older microcontroller models with new technologies.

1. The Necessity of Bluetooth Functionality in MCUs

Wireless technologies, once independently applied, are now converging into a single “chip”. In the context of smart hardware integrated with “Internet+” applications, various wireless interconnection technologies are competing with each other, each achieving its own success. However, in today’s fragmented IoT market, achieving dominance is an impossible task; “coexistence” has become a viable option. Connecting applications across different platforms through universal wireless standards is a core task for developing the IoT world.

Low-power Bluetooth has become the most affordable universal wireless technology in the consumer electronics market due to the robust ecosystem of the massive smartphone market, resulting in the highest penetration rate among wireless technologies. According to the 2018 report on the latest Bluetooth market insights, by 2022, 97% of shipped Bluetooth chips will adopt low-power Bluetooth technology. This report also indicates that the shipment volume of Bluetooth point-to-point data transmission devices alone will exceed 550 million this year.

At the same time, emerging applications such as the Internet of Things, Industry 4.0, AI, and intelligent driving have imposed new requirements on MCUs, including enhanced processing capabilities, data collection speed and accuracy, communication protocol interfaces, reliability, and stability. Consequently, there is a need for high-performance, low-power, highly reliable MCUs with large-capacity Flash and RAM, supporting various network interfaces, wireless technologies, and OTA (over-the-air upgrades), as well as strict functional safety and network security. These new technologies will lead to a technological upgrade of the next generation of MCUs. “With the maturity of wireless technology, wireless functionality as a standard peripheral of MCUs is inevitable,” summarized industry expert Tang Xiaoqian, who has been researching MCUs.

However, when using low-power Bluetooth technology as a universal wireless technology to connect different MCU IoT platforms for applications, many challenges arise: how to configure the chip’s hardware resources to support diverse application requirements; how to maintain high reliability and low cost amidst increasing chip complexity; and how to enhance the reliability and usability of development tools for wireless applications.

The wireless technology gap faced by general MCUs

For MCU chip manufacturers, the biggest challenge over the years has been maintaining differentiation, high quality, solution capabilities, and comprehensive development software amidst intense market competition. Differentiation means that the definition of MCU chips must respond rapidly to market demands. Typically, it takes about 3 to 6 months from defining an MCU product to bringing it to market.

Moreover, radio frequency technology, represented by Bluetooth, has many differences from the design and manufacturing application processes of MCUs:

1. The development cycle for a radio frequency SOC chip is much longer than that for an MCU chip. In design, the operating frequency of radio frequency technology is usually above 1GHz, handling analog signals that are continuously distributed in time and intensity. In contrast, MCU technology typically operates around 100MHz, processing discrete logical signals of “0” and “1”. The mathematical and physical models and implementation methods for designing these two types of chips are vastly different, requiring designers with completely different knowledge backgrounds. Their work experience, design processes, and ways of thinking also differ significantly. Generally, a brand new radio frequency chip, under the work of a designer with over five years of experience, will have a development cycle of about 2 to 5 years. In manufacturing, radio frequency chips typically require unique process flows such as on-chip inductors and dielectric capacitors, while MCU manufacturing usually involves processes like Flash technology. These two types of manufacturing processes cannot be fully reused, leading to increased wafer manufacturing costs. Additionally, in terms of packaging, testing, and quality control standards, the equipment costs and process complexities for radio frequency chips are significantly higher than for MCUs.

2. In application development for chips, developers of radio frequency chips need more experience in RF to address issues such as signal interference, feedback, and matching. The debugging instruments required, such as spectrum analyzers and network analyzers, differ from those in the MCU ecosystem. Debugging MCU solutions primarily addresses functional issues, while RF solution development focuses more on signal integrity issues on PCBs. This raises the requirements for developers significantly.

In summary, MCU chips and radio frequency chips will encounter significant differences in development technology, knowledge accumulation, application development, design cycles, and processes. This is a major reason why we see that the wireless departments of MCU companies struggle to grow. These issues exist not only among international MCU giants but are likely even more severe among domestic MCU companies.

2. The Bridge Between Microcontrollers and Bluetooth BLE RF

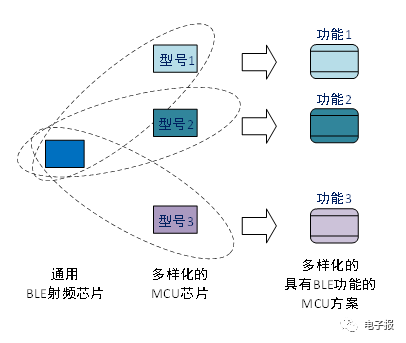

The differentiation of MCU products means that in the fragmented IoT market, adopting traditional SOC (System on Chip) designs that integrate RF circuits and MCUs on the same wafer poses a massive burden for MCU companies, including personnel, design environment, manufacturing processes, IP licensing, and R&D management. For MCU companies targeting fragmented markets, this approach is economically impractical and unrealistic. The challenge is how to equip MCUs with wireless functionality in the fastest and most economical way, effectively “giving them the wings of low-power Bluetooth.” This is a common challenge we face.

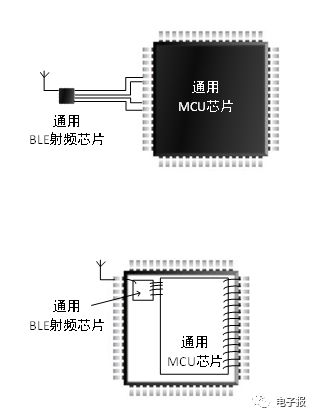

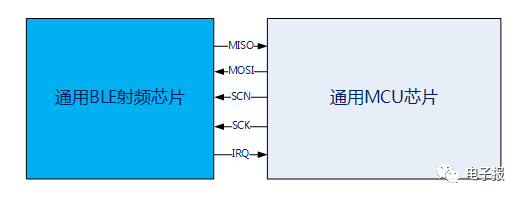

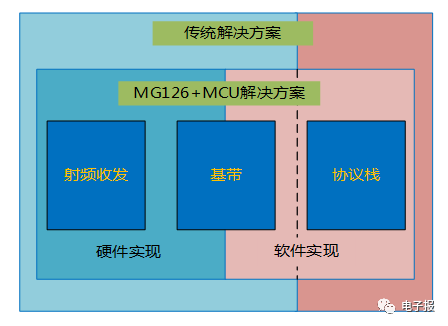

A cost-effective and reliable BLE RF front-end chip can communicate with general MCU chips through a simple interface, representing an optimized wireless MCU solution. In this solution, the design, manufacturing, and quality control of the RF chip follow the process of analog RF chip circuits, while general MCU chips are completed following traditional logic chip circuit processes. This approach significantly reduces overall cost-effectiveness and time-to-market. Moreover, MCU chips can focus their primary design efforts on application-related development, simplifying and optimizing the entire design process and investment.

The two chips can complete functional combinations through PCB modules or integrated packaging. This work can be accomplished either by the MCU or RF chip manufacturer or through solution providers. RF chip manufacturers support the implementation of wireless functionality by providing chip drivers and software protocol stacks.

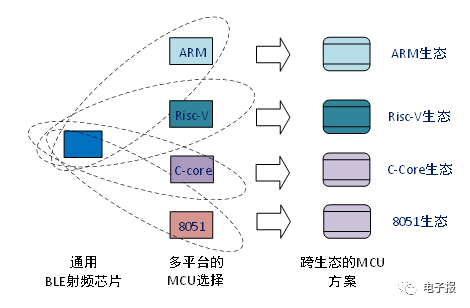

Thus, through the combination of general BLE RF chips and diverse MCU chips, manufacturers can quickly create a variety of flexible BLE single-chip or modular solutions to meet different ecological and market demands.

3. Functions and Features of Universal Wireless RF

The interface between RF chips and MCUs should be very simple and universal. The SPI interface is the most commonly used and compatible interface in the MCU industry. This interface is not limited to clock asynchrony between two chips, ensuring a high success rate of signal transmission.

The structure of RF chips is simple and cost-effective. The structure of RF chips needs to be simple enough, with low costs and small packaging or wafer areas, to facilitate the design of modules and integrated solutions.

The corresponding protocol stack design for RF chips should be streamlined. If the protocol stack is implemented in software and runs on the MCU, the space and computational resources occupied by the code and programs will impact the MCU’s application program development capabilities, making it the biggest consideration in the MCU ecosystem. A streamlined protocol stack will be the greatest factor in lowering the entry barrier for MCU integration.

RF chip suppliers must provide complete compatibility guarantees. Bluetooth compatibility is the most challenging and open issue faced by all Bluetooth chip suppliers. Quickly, timely, and effectively resolving customers’ compatibility issues is the most critical technical guarantee provided by universal Bluetooth RF chip suppliers.

RF chip suppliers should not only provide packaged chips but also offer professional support for packaging testing in wafer-level packaging production. Providing small-volume packaged chips can meet the requirements for system validation and early debugging while also catering to some small-batch solution providers’ needs. Additionally, chip suppliers need to offer complete support for RF testing processes. This specialized skill set is not typically possessed by MCU companies.

4. Universal BLE RF Front-End Chip MG126 and Its Applications

How can existing MCUs quickly gain BLE functionality? Providing integrated BLE protocol stacks and SIP solutions enables MCU manufacturers to economically and rapidly integrate BLE, better adapting to the IoT market. Companies that can provide universal BLE wireless front-end chips are rare in the industry. This chip’s hardware design is very streamlined, but the accompanying protocol stack and software support require long-term experience with Bluetooth and mobile ecosystems, alongside a deep understanding of various MCU ecosystems. This solution spans a significant technological gap. The MG126 provided by Shanghai Giant Micro Integrated Circuit Co., Ltd. is one of the best examples.

The MG126 targets the MCU chip ecosystem, offering cost-effective solutions that flexibly adapt to fragmented IoT applications by pairing with suitable MCU chips based on application and functional requirements.

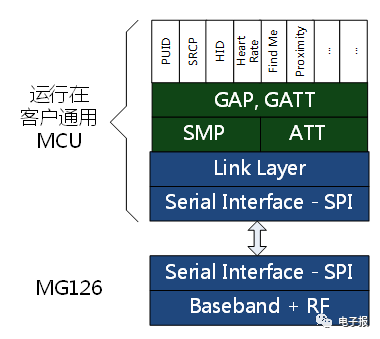

The MG126 uses an innovative architecture design, adopting a common SPI communication interface, and the chip itself does not require additional wake-up signals, saving MCU IO resources. The front-end chip includes RF and BLE digital baseband, completing BLE broadcasting and data reception/transmission, modulation/demodulation, and baseband data conversion. The BLE protocol stack runs on the MCU, leveraging the MCU’s powerful processing and control capabilities to enhance resource utilization. This chip comes in a QFN16 package, measuring only 3mm x 3mm.

1. Innovative Architecture Design of MG126

In the design of the BLE protocol stack, the upper-layer protocols are strictly designed according to layered design and modular division to enhance design independence and code readability. The Host protocol stack includes L2CAP, ATT/GATT, GAP, SM, and commonly used profiles. The Giant Micro protocol stack complies with BLE specifications and has passed Bluetooth SIG BQB certification testing.

2. Division of Giant Micro BLE Protocol Stack

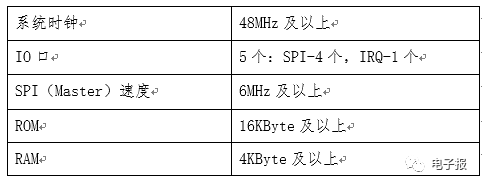

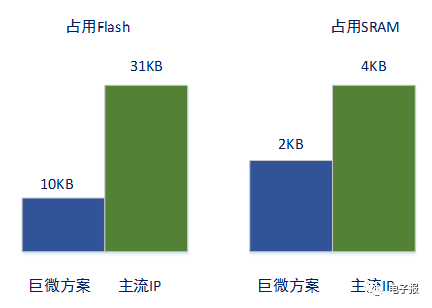

At the same time, the Giant Micro BLE protocol stack is fully optimized and reduces the resource requirements placed on the MCU. Taking the ARM Cortex-M0 as an example, the system resources required for BLE connection applications are as follows:

After four years of continuous refinement, combined with 15 years of immersion in the Bluetooth field, the unique low-power Bluetooth protocol stack solution designed by Giant Micro’s Bluetooth experts has a code size and operational resource consumption that far surpasses those of mainstream international IP suppliers.

Giant Micro provides BLE protocol stack porting services based on customer MCU platforms and common BLE application development example source code, offering packaging support for SIP and BLE RF testing support to help MCU manufacturers/customers bridge the long development gap between BLE RF chips and protocol stacks, achieving rapid time-to-market for BLE products and promoting win-win cooperation.

It is worth mentioning that the universal RF front-end chip solutions provided by Giant Micro can not only address the pain points of general MCU companies lacking RF cores, saving MCU companies significant R&D, IP, and wafer costs but also allow chip companies in other fields, such as sensor chips and WiFi chips, to quickly combine and generate combinations of chips and solutions that hold market value.