On April 18, scientists from Pohang University of Science and Technology (POSTECH) achieved a significant breakthrough in materials science by successfully developing a new type of nickel-based high-entropy alloy (High-Entropy Alloy, HEA). This alloy can maintain excellent strength and toughness across an extreme temperature range from -196°C to 600°C.

Traditional metals often lose stability when faced with drastic temperature changes, becoming brittle in winter and overheating in summer, leading to decreased reliability in extreme environments.

To address this issue, the POSTECH research team innovatively proposed the concept of “Hyperadaptor,” developing a new type of nickel-based high-entropy alloy (HEA).

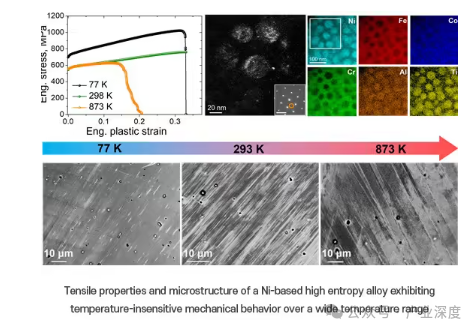

This alloy can maintain strong strength and flexibility across a wide temperature range from -196°C to 600°C. Professor Kim Hyung-seok, the head of the research, stated that this breakthrough breaks the limitations of existing alloys and creates a new category of “temperature-insensitive materials.”

Unlike traditional alloys that are primarily composed of a single element, high-entropy alloys are formed by mixing five or more elements in nearly equal proportions, resulting in a highly random atomic arrangement, known as “high configurational entropy” (high configurational entropy).

This structure endows HEA with exceptional durability, toughness, and resistance to wear and high temperatures. The POSTECH team uniformly distributed nanoscale L1₂ precipitates within the alloy, which effectively prevent deformation, while the alloy structure can adapt to stress, ensuring stability even under extreme conditions. The research results provide significant application prospects in fields such as aerospace, automotive, and nuclear industries.

This new type of HEA is particularly suitable for scenarios that endure sudden temperature changes, such as critical components in engines, exhaust systems, turbines, and pipelines, where its stability and reliability in extreme environments are expected to significantly enhance the safety and efficiency of these applications.