(Report produced by: Shenwan Hongyuan Research)

1. Quasi Direct Drive Actuators: Emerging Actuator Technology with High Dynamic Response

1.1 Quasi Direct Drive Actuators: Emerging Actuator Technology for Legged Robots

The Quasi Direct Drive (QDD) actuator first gained public attention through the MIT Cheetah quadruped robot. The QDD is an emerging actuator technology that relies on open-loop force control without the need for additional force or torque sensors. It can perceive the interaction forces between the robot’s feet and the environment, leading MIT researchers to refer to it as a proprioceptive actuator. To meet the demands for high torque output density and dynamic physical interaction capabilities in legged robots, a combination of high torque density motors and low gear ratio reducers is used, resulting in high bandwidth force control and good impact resistance, along with high precision and efficiency.

Joint actuators are core components for achieving motion in legged robots, akin to human “limb joints”, and are a key focus in robotics hardware research. According to the paper “A Review of Domestic and International Research on Bipedal Humanoid Robot Actuators”, the research on bipedal humanoid robot actuators has evolved from rigid actuators to elastic actuators, and then to quasi direct drive actuators. 1) In 1983, Waseda University’s WL-10R robot utilized rigid actuators (TSA – traditional stiffness actuator), marking the widespread adoption of rigid actuators as joint power sources. 2) In 1995, MIT’s Pratt et al. introduced the concept of the series elastic actuator (SEA), initiating research in elastic actuators. NASA’s Valkyrie robot and the Italian Institute of Technology’s Walk-Man robot both employed elastic actuators. 3) In 2016, MIT proposed the concept of quasi direct drive actuators and applied them to the quadruped Cheetah and biped Hermes robots, making QDD actuators a hot research topic in recent years. The recently developed Artemis robot at UCLA features QDD actuators, showcasing excellent motion capabilities.

Although the principles of the three types of actuators are similar, they differ slightly in structure and components, leading to varying performance in accuracy, response speed, and other metrics: (1) TSA (Rigid Actuator): Conventional high-speed motors + high gear ratio reducers + high stiffness torque sensors, with reducers typically being harmonic gear reducers due to their high reduction ratio, light weight, and compact efficiency. The torque sensors are placed at the joint’s end for perception control. (2) SEA (Elastic Actuator): Conventional motors + high gear ratio reducers + encoder-based elastic elements, which achieve impact resistance by integrating elastic elements at the output stage. (3) QDD (Quasi Direct Drive Actuator): High torque density motors + low gear ratio reducers, often employing low-speed, high-torque flat torque motors and compact planetary gear reducers with low gear ratios. The output inertia is minimal, and current can be used as a measurement method for torque, eliminating the need for torque sensors.

1.2 Core Components: Actuators, Frameless Motors, Planetary Gear Reducers, etc.

As one type of rotary actuator, the quasi direct drive actuator mainly consists of actuators, frameless motors, planetary gear reducers, and other components. Referencing the paper “A Low Cost Modular Actuator for Dynamic Robots”, the composition of MIT’s Cheetah robot’s QDD includes: controller (including DC power supply, CAN bus, etc.), frameless torque motor (rotor, stator), planetary gear reducer (including sun gear, planet carrier, planet gears, planet needle bearings, output pins), bearings, and front and rear covers.

1) Controller

The controller is an electronic circuit or device responsible for complete motor control, such as torque control, speed control, direction control, and feedback control. Typically, a controller consists of four parts: input, output, intermediate control unit, and power supply section. The input receives signals from sensors and other measuring devices, processes them, and passes them to the intermediate control unit; the intermediate control unit controls the output signals to the output end, managing parameters like speed and direction of the motor; the output end sends the processed power signals to the motor to control its operation; the power supply section provides energy to the entire circuit. The controller has the following functions: ① obtaining multiple inputs from various input devices and peripherals to generate control signals for the motor; ② precisely controlling the motor’s torque, speed, and direction; ③ acquiring feedback signals from the motor to monitor its operational status and processing these signals for further control; ④ executing all the software programs controlling the motor.

2) Frameless Torque Motor: Rotor, Stator

Motors provide driving force for electrical appliances or various machines, based on the principle of electromagnetic induction—electric energy generates a rotating magnetic field in the coil, driving the rotor to rotate. The basic structure includes: stator (core, winding, and base), rotor (core, winding). QDD typically uses frameless torque motors. Frameless torque motors are a typical motor type for humanoid robots, lacking a casing, consisting only of the rotor and stator as core components. The rotor rotates while the stator remains fixed. The rotor is usually an internal component made of a rotating steel ring assembly with permanent magnets, mounted on the machine shaft, while the stator is an external component, surrounding steel sheets, and copper windings to generate electromagnetic force. The entire structure is hollow, facilitating internal wiring. The rotor and stator together account for about half of the total mass of the actuator. The stator’s large through-hole allows the entire planetary gearbox to fit into the center of the stator, creating a compact actuator structure. Due to the high torque density, small space occupation, lightweight, and fast machine response, frameless torque motors meet the requirements of robots for compact structures, high torque density, and high dynamics.

3) Planetary Gear Reducer

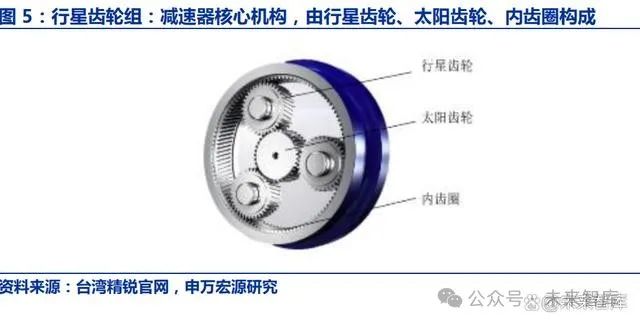

Single-stage planetary reducers generally have a reduction ratio of less than 10, with lower precision and technical barriers, making them widely used in various scenarios. A planetary reducer mainly consists of motor-side (input side) bearings, motor-side flanges, input shafts, planetary gear sets, output shafts, output-side (load side) flanges, and load-side bearings. The planetary gear set consists of planet gears, sun gears, and internal tooth rings, arranged similarly to planets revolving around a sun in the solar system. The reduction principle is straightforward: as the sun gear rotates driven by the servo motor, the meshing action with the planet gears causes the planet gears to rotate, while also rolling along the inner tooth ring in the same direction as the sun gear due to the self-rotating driving force. The speed at which the planet gears revolve around the sun gear is lower than the sun gear’s rotation speed, achieving the reduction effect. The MIT proprioceptive actuator uses a planetary gear reduction scheme with a reduction ratio of 6:1.

4) Encoder

Encoders are devices that encode or convert signals or data into usable forms for communication, transmission, and storage, serving as sensors for measuring speed, angle, or linear motion. The encoders used in QDD are position sensors. The role of position sensors is to detect the position of the main rotor during motion, converting the positional signals of the rotor’s magnetic poles into electrical signals to provide correct commutation information for logic switch circuits, controlling their conduction and cutoff, allowing the current in the motor’s armature windings to be sequentially commutated as the rotor’s position changes, forming a stepwise rotating magnetic field in the air gap that drives the permanent magnet rotor to rotate continuously. The motor controller synchronizes the inverter’s commutation with the rotor by receiving signals from the position sensor, enabling the motor to operate continuously. Position sensors reduce motor operating noise, improve motor lifespan and performance, and also help reduce energy consumption.

5) Bearings

Bearings are essential components in mechanical equipment. Their main function is to support rotating bodies and reduce friction during motion while ensuring rotational accuracy. The bearings connecting the planet gears in QDD typically use needle bearings. Needle bearings are roller bearings with cylindrical rollers that are relatively thin and long compared to their diameter (roller diameter D≤5mm, L/D≥2.5, with L being the roller length), hence the name needle. They have a compact radial structure, and when their inner diameter size and load capacity match those of other bearing types, their outer diameter is minimized, making them particularly suitable for support structures with limited radial installation dimensions. Despite their small cross-section, the bearings still possess high load-bearing capabilities, allowing for the selection of bearings without inner rings or with needle and cage assemblies. In such cases, the surfaces of the shaft neck and housing holes that match with the bearing directly serve as the inner and outer rolling surfaces of the bearing, requiring the hardness, machining precision, and surface quality of the rolling surfaces to be similar to those of the bearing rings. Such bearings can only bear radial loads.

6) Thermal Management: Liquid Cooling

The heat dissipation of QDD is higher than that of other actuators, increasing the importance of thermal management. A notable drawback of using proprioceptive actuators is that due to the low reduction ratio, they generate more Joule heat compared to other solutions, making it difficult for the actuator to withstand peak loads over extended periods. To address this issue, robots require extensive cooling systems to operate continuously. Built-in coolant channels on the actuator’s casing allow for liquid cooling using centralized cooling systems. The principle of liquid cooling technology is to utilize the high heat capacity and thermal conductivity of liquids to transfer heat generated by electronic devices to the liquid, which then carries the heat away through its flow. Compared to traditional air cooling methods, liquid cooling is more efficient and can enhance the actuator’s torque output, thereby allowing for the use of lighter actuators. The Panda BEAR quasi direct drive actuator developed by Westwood Robotics incorporates a compact micro-turbine pump designed specifically for liquid cooling in robots, weighing only 60g, which can automatically balance flow and pressure during high-power operation, providing sufficient cooling to ensure stable and efficient output from the robot’s actuators.

1.3 Characteristics: Excellent Current Loop Force Feedback and Dynamic Response Capabilities

As one of the core components of humanoid robots, actuators account for a significant portion of the robot’s weight, and their performance directly affects the output capability of the robot’s joints, determining the upper limits of the robot system’s dynamic performance. The performance requirements for actuators in current robotic application scenarios can be summarized in five key points: 1) High-frequency dynamic response capability; 2) Accurate force feedback capability; 3) Low-cost implementation capability; 4) Certain load-bearing capacity; 5) Compact axial space implementation capability.

Currently, the three mainstream actuator schemes exhibit strengths and weaknesses across different performance metrics: 1) The advantage of rigid actuators lies in their large transmission ratio, low speed, and high torque density with precise force control. However, due to their high inertia, they cannot address the strength issues of components when subjected to external impacts and are only suitable for slow and relatively static movements, which led to the emergence of elastic actuator solutions. 2) Elastic actuators, built on rigid actuators, incorporate elastic components for impact protection, resulting in joints that exhibit compliance, safety, high energy efficiency, and strong impact resistance. However, lower stiffness can affect bandwidth, subsequently reducing response speed and increasing control difficulty. 3) Quasi direct drive actuators excel in dynamic robots, possessing certain torque output capabilities, reliable and precise current loop force feedback, and high dynamic force control response capabilities. QDD actuators feature high power density, broad force control bandwidth, and strong impact resistance due to their regenerative characteristics, enhancing safety. The mechanical performance of elastic actuators in terms of impact resistance and energy storage can be achieved at the motor control level of proprioceptive actuators, and QDD actuators are more efficient and exhibit greater explosive power. Additionally, due to the lower cost of the low gear ratio reducers used in QDD, they are cheaper than rigid high gear ratio reducers and do not require additional sensors for torque control, providing a price advantage.

The characteristics of quasi direct drive actuators are as follows:

1) Low Reduction Ratio

Low reduction ratio reducers facilitate meeting the requirements for high-frequency dynamic response capability, accurate force feedback capability, and low-cost implementation capability in legged robots. An effective way to enhance the actuator’s torque density is to use higher gear reduction ratios; however, as increasingly complex control algorithms are implemented, the controllability of force and torque becomes crucial for actuators. The ideal solution for achieving force control is to directly drive the motor and estimate the actuator’s torque output using current; however, due to limitations in motor technology and processes, the torque density of motor direct drive actuators cannot meet the demands of robotic applications. Therefore, a motor combined with a small reduction ratio reducer is employed to amplify torque density. The reason for not using a large reduction ratio reducer is that the friction losses of the gearbox or other nonlinear factors lead to the inability to operate based on current torque control with high reduction ratio actuators. Small reduction ratio reducers minimize rotational inertia, enhancing the controllability of force and torque, allowing actuators to withstand higher impacts and enabling highly dynamic behaviors. For robots that require high mobility, such as those that need to stand up after falling, high explosive power is required. Robots with high reduction ratio actuators can only achieve very slow and relatively static movements. For example, using planetary reducers can instantaneously increase torque to 100N·m and decrease it instantaneously to 50N·m. Due to structural limitations, harmonic reducers are very fragile and easily impacted, making them incapable of instantaneously increasing and decreasing torque. Single-stage planetary reducers have a flatter shape, making them more suitable for the compact axial space of quasi direct drive actuators. From a cost perspective, planetary reducers have a simple structure and principle, resulting in a lower price compared to harmonic reducers.

2) Current Loop Force Feedback

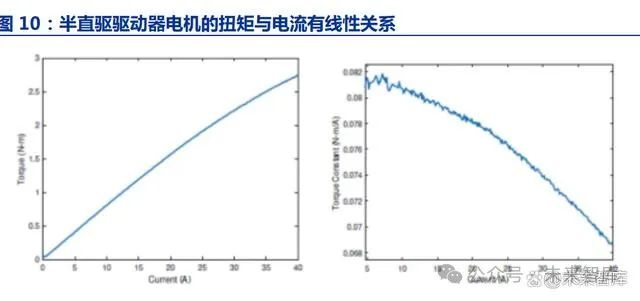

Current loop force feedback measurement is achieved through the motor’s current closed loop for force closed loop feedback control. It is applicable to scenarios involving direct drive motors or motors with small reduction ratio reducers, such as small impedance-controlled robotic arms and small quadruped robots like MIT Cheetah. A significant advantage of using quasi direct drive actuators is that they can achieve force control without additional mechanical structures and expensive sensors. This is because the nonlinear errors of small reducers can be negligible, allowing for direct use of the motor’s current loop and corresponding reduction ratios to obtain the output torque at the actuator end. According to research from MIT, the torque/current characteristics of their quasi direct drive actuator motors demonstrate a fairly linear relationship, with approximately a 12% error at maximum current. If a two-stage planetary or harmonic reduction scheme with a reduction ratio exceeding 30 is employed, the unmodelable static friction will greatly negatively impact accurate force measurement, leading to high force feedback measurement errors.

Quasi direct drive actuators use current loops for torque measurement, effectively saving costs. Since there is no need for additional sensors for torque control, the entire joint structure is simpler. Taking MIT’s Mini Cheetah as an example, the overall design philosophy of the robot’s actuator is to achieve the highest performance at the lowest price, with the cost of a single actuator controlled to around $300.

3) High Motor Torque, Large Diameter, Short Axial Length

To achieve a certain load-bearing capacity, the actuator’s torque must be sufficiently high. Currently, quasi direct drive actuators can achieve good applications in quadruped robots. Although quadruped robots are smaller in size and weight compared to biped humanoid robots, they still have certain requirements for load-bearing capacity, i.e., the output torque of the actuators. For the 12kg class small-sized Cheetah Mini robot, the peak torque of the hip joint actuator in the pitch direction must reach around 18N·M, while for the 45kg class large-sized Cheetah 3, the peak torque of the hip joint actuator must reach around 230N·M to exhibit strong explosive motion capabilities. Due to the low reduction ratio, it is best to select frameless torque motors with higher output torque and lower speed. The significant features of frameless torque motors are a larger aspect ratio and a greater number of magnetic poles, ensuring good high torque output performance while also exhibiting lower speed characteristics. From the perspective of the output torque principle of frameless torque motors, the motor’s output torque is proportional to the square of the rotor radius (using the air gap radius concept in motor design) and the axial length. Under the same volume constraints, increasing the air gap radius can more effectively enhance torque density. To ensure good performance of torque motors, it is necessary to select larger rotor radii and smaller cross-section thicknesses and axial lengths. Currently, frameless torque motor products typically have diameters below 120mm, but the motors required for quasi direct drive actuators need to reach 150-180mm, with most products on the market requiring custom development.

4) External Rotor + Embedded Gear Reducer

To maximize the peak torque produced by the proprioceptive actuator, the air gap radius should be set as large as possible. With this design philosophy, motors with an air gap radius of 90mm have been designed for hip pitch and knee pitch drives. Permanent magnets can serve as internal rotors (Cheetah’s first generation) or external rotors (Cheetah Mini version). The external rotor design maximizes the air gap radius. From the schematic diagram of the actuator structure, it can be seen that embedding the gear reducer within the motor allows full utilization of axial space, forming a compact flat structure.

2. Application: Extending from Quadruped Robots to Humanoid Robots

2.1 Quadruped Robots: Emphasizing High Power Density and High Torque Density

Current requirements for quadruped robots include strong mobility, high-frequency dynamic response capability, accurate force feedback capability, and low-cost implementation capability. Elastic actuators, due to their lower stiffness, lead to lower force control bandwidth, increasing control difficulty and reducing response speed, resulting in weak dynamic physical interaction capability. The quasi direct drive actuator best meets these requirements, making it most suitable for quadruped robots.

2.1.1 MIT Cheetah

The MIT Cheetah quadruped robot is capable of walking, running, and jumping, achieving a maximum running speed of 48 kilometers per hour since the first generation. Such behaviors involve repeated high impact forces and brief ground contact times, necessitating a system with high bandwidth force control to manage ground reaction forces within such short time frames. Therefore, the quadruped robot employs quasi direct drive actuators—large radius frameless torque motors (with a reserved diameter space of 125mm for joints), achieving a pure motor torque density of 27Nm/kg; the reducer selected is a single-stage planetary gear reducer with a reduction ratio of 5.8:1, which enhances dynamic motion capabilities; additionally, the actuators for the hip and knee are co-axially located at the hip, with one actuator driving the hip directly while the other drives the knee through parallel linkages, aiming to minimize mass and leg inertia to maximize impact mitigation. The third generation of MIT Cheetah robots, weighing 41kg, employs MIT’s custom high torque high performance quasi direct drive actuators, with maximum joint torque reaching 230N·m. By utilizing high torque density motors and a single-stage planetary gear reducer capable of regenerative drive (reduction ratio of 5.8), along with low inertia legs, the robot can control ground reaction forces through proprioceptive control without using any force sensors, torque sensors, or compliance in joints or feet, with a motion range exceeding ±45°, and the new hip and knee joint designs allow the robot to perform forward, backward, and flipping actions while potentially using its legs for simple operational tasks and movements.

In 2019, MIT researchers developed the Mini Cheetah robot based on the Cheetah. The Mini Cheetah weighs only 20 pounds (approximately 9kg) and is the first quadruped robot capable of performing backflips. By bending and swinging its legs, it can walk upside down or on uneven terrain, achieving speeds about twice that of an average person’s walking speed. The Mini Cheetah can change ground forces very rapidly. When it runs, its feet only stay on the ground for 150 milliseconds at a time, during which the computer instructs it to increase the force on its feet, then changes to balance, and quickly decreases the force to lift. This allows it to perform truly dynamic actions, such as jumping in the air with every step or running on the ground with both feet at once. Most robots lack the capability to do this, resulting in much slower movement. To achieve low-cost objectives, each leg of the Mini Cheetah is powered by three identical low-cost motors. This design provides three degrees of freedom and a vast range of motion, enabling quick, dynamic maneuvers while delivering high forces to the ground without damaging the gearbox or limbs, with a simple overall structure that allows each motor to be easily replaced with a new one. MIT’s self-developed motors are highly powerful, lightweight, high torque, and low inertia, with energy output densities 4.2 times that of Kollmorgen motors and 3.2 times that of high torque output motors from Emoteq.

2.1.2 Yushu Technology

Yushu Technology focuses on the research, production, and sales of high-performance quadruped robots for consumer and industrial applications, being a well-known startup in the global robotics community and the world’s first publicly available high-performance quadruped robot company. Yushu Technology has proposed a new structure for quasi direct drive actuators. A clutch structure has been added between the motor base and the internal tooth ring, which activates when the external load impact approaches the limit of the reducer parts, converting external impact energy into frictional heat to protect the reducer from damage. Additionally, position encoders are installed at both the motor and output ends of the actuator, with the motor shaft adopting a hollow structure. The G1 quadruped robot features a powerful and reliable power system. The G1 robot utilizes Yushu Technology’s newly patented ultra-lightweight, low-noise, and long-life power joints, achieving peak torque of 23.70N·m at the body/thigh joint and up to 35.55N·m at the knee joint, with a maximum joint speed of 21rad/s. It employs industrial-grade crossed roller bearings with long lifespans and strong axial impact resistance. Four foot pressure sensors accurately capture foot support information, enhancing reliability, efficiency, and convenience. The controller reads all sensor data and sends position, speed, and torque commands to each motor, quickly regaining balance in emergencies such as impacts or falls. Moreover, a patented heat pipe auxiliary cooling system is built near the knee joint motor. The G1 robot’s maximum sustained running speed is 3.3m/s (11.88km/h), making it the fastest and most stable small to medium-sized quadruped robot in China.

2.2 Humanoid Robots: Requirements for High Efficiency, High Dynamics, and High Power Density

Humanoid robot motors have three key points: high efficiency, high dynamics, and high power density. ① High efficiency: Low energy consumption and low friction losses are crucial since robots are typically battery-powered and must withstand harsh operating conditions, allowing for frequent forward and backward movements and acceleration/deceleration while handling overloads in a short time. ② High dynamics: The inertia of the entire actuator (motor, mechanism, wiring, sensors, and controller) should be as low as possible, and the time from receiving command signals to achieving the required operational state should be short. ③ High power density: Robotic applications require high-speed, high-torque motors that are also compact and lightweight.

Humanoid robots’ tasks often involve heavy lifting, high-speed operations, etc., and emphasize safety in human-robot collaboration. Therefore, reducing size and weight while enhancing output capability and dynamic performance has become a key focus and challenge in the field of collaborative humanoid robots in recent years. The design of humanoid robots’ lower bodies typically requires: 1) reducing overall weight; 2) enhancing structural stiffness; 3) raising the center of mass (especially in the calves and thighs); 4) minimizing leg inertia. Depending on the target functions and application scenarios, the motion capability requirements of robots vary, leading to different performance requirements for actuators.

2.2.1 UCLA ARTEMIS

According to the recent PhD dissertation “Design of a Highly Dynamic Humanoid Robot” by Zhu, Taoyuanming from UCLA, the humanoid robot ARTEMIS stands 1.42 meters tall, weighs 37kg, and has 20 degrees of freedom: 5 degrees for each leg × 2, 4 degrees for each arm × 2, and 2 degrees for the neck. The robot has been tested to achieve robust untethered walking, with a walking speed exceeding 2m/s, demonstrating strong mobility.

Leg structure: The hip joint has 3 degrees of freedom (yaw, roll, pitch), the knee joint has 1 degree of freedom (pitch), and the ankle joint has 1 degree of freedom (pitch), omitting the ankle rotation degree of freedom to minimize the distal weight and inertia of the leg (which also results in the robot being unable to balance on one leg). The yaw and roll degrees of freedom for the hip joint utilize a harmonic reducer + frameless torque motor as the rotary actuator, hidden within the robot’s pelvis; the pitch degree of freedom for the hip and the pitch degree of freedom for the knee are co-axial, with the knee actuator positioned higher, transmitting through linkages, belts, or chains to the joint; the ankle actuator is raised to near the knee position. This design concentrates the leg’s weight near the pelvis, accounting for over 60% of the total leg weight, resulting in higher acceleration and sturdiness for the robot.

The actuators of Artemis are from the BEAR series, developed jointly by UCLA’s RoMeLa lab and Westwood Robotics, essentially functioning as quasi direct drive actuators. Different actuator specifications are used based on joint locations, with the hip and knee pitch direction bearing the heaviest loads. The robot’s hip/knee P-axis actuator employs a wide air gap motor (weight 0.89kg, diameter 180mm, peak torque 45Nm) + planetary gear reducer (reduction ratio of 5.9), with a total actuator weight of 3kg, continuous torque of 80Nm (peak 250Nm), and torque density of 27Nm/kg (peak 83Nm/kg). The robot’s legs exhibit low reflective inertia and high transmission transparency (force control and end feedback), enabling the robot to achieve proprioceptive force control while reducing impact forces during running and jumping, with higher operational efficiency, lower noise, and greater environmental friendliness, while also avoiding performance degradation issues caused by liquid leakage.

2.2.2 Westwood BRUCE

BRUCE stands for Bipedal Robot Unit with Compliance Enhanced, developed jointly by Westwood Robotics and UCLA’s RoMeLa lab, serving as a small humanoid robot open platform for research and education. Weighing only 4.8kg and standing 70cm tall, BRUCE has 5 degrees of freedom in each leg and 3 degrees of freedom in each arm, totaling 16 degrees of freedom. Each leg actuator weighs just 250g, with an explosive torque of 8Nm. Thanks to the powerful explosive force and dynamic performance provided by the Koala BEAR actuator, BRUCE is one of the few humanoid robots in the world capable of jumping. The Koala BEAR actuator features: 1) Liquid cooling technology, providing solid assurance for stable dynamic output; 2) In-depth biomimetic design and topological optimization, granting BRUCE flexible dynamic capabilities; 3) Lightweight and high strength; 4) Ultra-low rotational inertia and drive transparency, unifying real systems and simulation models, enabling BRUCE to control foot placement with ease; 5) Robustness, with all 16 degrees of freedom adopting a highly modular design for easier maintenance.

3. High Technical Barriers, Yet to Achieve Large-Scale Industrialization

3.1 Barriers: Challenges in Balancing High Torque Density and Lightweight Design

Currently, there are very few products internationally capable of achieving high-performance motors for robotics, primarily due to the difficulty in coordinating motor output torque with size. In joint robots, the larger the robot, the higher the torque output requirements for the actuators, making technical realization increasingly challenging. Generally, adult humanoid robots require peak torque output of at least 200N·M in the dynamic motion of the hip or knee pitch direction; for instance, UCLA’s ARTEMIS has a peak torque of 250N·M in the hip pitch direction, but very few manufacturers have mastered this technology. The current output density of motors has reached a bottleneck, mainly due to the magnetic saturation of the cores, meaning that more magnetic lines cannot be generated per unit volume, resulting in insufficient magnetic attraction and torque. Most quasi direct drive actuators currently available can only provide peak torque around 100Nm, with large torque motor output density still being insufficient.

Larger physical dimensions can lead to bulky joints in multi-degree-of-freedom, small-sized humanoid robots, severely impacting the robot’s motion performance. According to the paper “Research on High Torque Density Humanoid Robot Drive Units”, YU et al. designed a quasi direct drive unit for portable exoskeleton robots with a torque density of 20.7N·m/kg and dimensions of 110mm×51mm. SINGH et al. designed a quasi direct drive unit with a maximum torque density of 29.2Nm/kg and dimensions of 126mm×68mm. Suzhou Maita Intelligent’s RMD-X8S2 drive unit has a torque density of 33.33N·m/kg and dimensions of 98mm×58mm. Westwood Robotics’ Panda Bear drive unit has a torque density of 24.53N·m/kg and dimensions of 113mm×49.7mm.

Smaller torque densities will prevent humanoid robots from performing tasks with high load demands, severely limiting the application scenarios for robots. KATI designed a small drive unit with dimensions of 96mm×40mm, but with a torque density of only 15.68N·m/kg. T-motor’s AK80-9 drive unit also has a small size, measuring 98mm×38.5mm, but with a torque density of only 18.6N·m/kg. Yushu Technology’s A1 drive unit has dimensions of 98mm×45mm, but with a torque density of only 10.41N·m/kg. In summary, the existing quasi direct drive units have not effectively balanced small size and high torque density; high torque density drive units are bulky, while smaller drive units have insufficient torque density.

3.2 Customization by Robot Mainframe Manufacturers, Future Motor Manufacturers Will Have Mass Production Advantages

Due to the limited application scenarios for high torque density quasi direct drive motors in the current industry, very few third-party motor and actuator companies have ready-made products. Companies producing quadruped or humanoid robots often adopt self-manufacturing or customization approaches. Therefore, the current market is primarily dominated by robotics companies. However, as the industry matures, traditional motor manufacturers will have advantages in mass production, stability, and reliability.

1) Westwood Robotics: Westwood Robotics’ BEAR series actuators mainly consist of three products, listed from smallest to largest: Koala BEAR, Panda BEAR, and Kodiak BEAR. ① Koala BEAR measures 63.5×62×37mm, weighs 250g, and uses a reducer with a ratio of 9, rated torque of 4.2N·M, and peak torque of up to 10.5N·M, featuring extremely high transparency and very low inertia; ② Panda BEAR measures 113×113×49.7mm, weighs 685g, uses a reducer with a ratio of 6, rated torque of 16.8N·M, and peak torque of up to 33.5N·M, featuring built-in liquid cooling system and dual encoders, providing superior torque output and control capabilities. The Plus version of Panda BEAR maintains the same dimensions but weighs 925g, with a rated torque of 33N·M and peak torque of 67N·M; ③ Kodiak BEAR measures 200×200×50mm, is flatter, weighs 1.5kg, and can achieve rated torque of up to 50N·M while ensuring agile torque sensing and control capabilities.

2) Yushu Technology: A1 Motor: stable and efficient, easy to maintain; ultra-thin design; optimally designed planetary reducer; multifunctional, small body, weighing only 605g. The A1 motor is suitable for quadruped robots and other heavy-duty machinery, with a maximum output torque of 33.5N·m and a maximum joint speed of 21rad/s, easily achieving powerful instantaneous explosive force. This motor utilizes oversized industrial-grade crossed roller bearings with strong axial impact resistance and high precision for long life. GO-M8010-6 permanent magnet synchronous motor: designed for high-performance robots, offering high integration for powerful performance. Measuring 96.5×92.5×42.3mm and weighing approximately 530g, it uses a reducer with a ratio of 6.33, with a maximum torque of 23.7NM and maximum speed of 30rad/s (measured at 24℃). The motor and reducer are perfectly matched, featuring built-in FOC control algorithms and built-in temperature and absolute value encoders. It can be widely applied to various robot joints and power components.

3) TQ Motors

TQ’s ILM-E series frameless motors have leading torque densities and maximum design flexibility for integrated drive engineering. With a frameless structure, hollow shaft, high design flexibility, lightweight, low voltage (12V – 48V), low thermal loss, and excellent dynamic control capabilities and precision, they are suitable for various applications. Among them, the ILM-E85×30 specification is the largest, weighing 822g, with a rated torque of 3.3N.m and peak torque of up to 10.64N.m.

4) Kollmorgen

Kollmorgen’s TBM2G series motors feature high load capacity, high energy efficiency, faster actions, and smoother movements, providing the seven most popular frame sizes used in collaborative and surgical robots, each with three winding stack options, totaling 21 options. The minimum diameter is 50mm, and the maximum diameter is 115mm, with maximum continuous torque reaching 4N·m.

5) T-MOTOR

T-MOTOR’s AK series power modules can be widely used in quadruped robotic dogs, exoskeletons, and more. Among them, the AK80-9 power module is a well-known product, adopting a lightweight design, weighing only 485g, with a planetary gear set reducer with a ratio of 9, rated torque of 9N·M, and peak torque of up to 18N·M, combining efficiency and power; the AK10-9 V2.0 power module weighs 960g, with a planetary gear set reducer with a ratio of 9, rated torque of 18N·M, and peak torque of up to 48N·M, featuring built-in dual encoders for absolute positioning of the output shaft.

6) Xiaomi

On August 14, 2023, Xiaomi released the second generation bionic quadruped robot, CyberDog2. This robot is equipped with Xiaomi’s latest self-developed CyberGear micro motors, with three degrees of freedom on each leg, totaling 12 degrees of freedom. The CyberGear micro motor belongs to the quasi direct drive actuator, weighing 317g±3g, with an outer diameter of 80.5mm and a height of 36.55mm, using a planetary gear reducer with a ratio of 7.75, continuous torque of 4N·m, peak torque of 12N·m, torque density reaching 37.85N.m/kg, and power density reaching 511.04W/kg. CyberGear adopts a design philosophy that integrates the reducer, motor, and driver, optimizing the reducer and electromagnetic design to enhance cooling speed and further strengthen torque density; optimizing the motor control algorithms to improve motor torque control precision, combined with FOC control, reducing the response time for the motor to reach 0-90% peak torque to 20ms.

4. Overview of Relevant Companies in the Industry Chain

4.1 Frameless Motors: Source of Driving Force, Core Component of QDD

Buka Co., Ltd.: Sales of frameless torque motors in the millions, third-generation products benchmark against global leaders

Buka Co., Ltd.’s main products include human-machine interfaces, programmable logic controllers, servo systems, stepping systems, low-voltage variable frequency drives, and other core components for industrial automation equipment control. In the use of humanoid robots’ large joints, frameless torque motor products can meet functional requirements. According to the company’s investment relations activities, the sales of frameless torque motors currently account for a relatively small proportion of the company’s overall sales, in the millions. However, the company has identified many scenarios for practical application, with a clear market development direction, and is collaborating with several customers on related products. The company’s third-generation frameless torque motor products can benchmark against internationally leading products, with certain models having competitive advantages. Furthermore, as the company expands its product scale and innovates its processes, there will be potential for cost reduction, making its frameless torque motor products more competitively priced.

Jiangsu Leili: Annual motor shipments exceed 200 million units, with a full product series

Jiangsu Leili is a publicly listed company with significant influence in micro motor product research, design, and manufacturing, shipping over 200 million motors annually. Its main products include micro stepper motors, synchronous motors, brushed DC motors, brushless DC motors, micro pumps, and various other motor products. The company’s products have gained significant influence in the home appliance industry and will continue to promote coordinated development in automotive parts, industrial applications, sports health, and robotics. According to the company’s annual report, it is actively developing encoder + controller + hollow cup motors + precision gearboxes in the industrial control field. Based on the company’s investment relations activities, the humanoid robot industry is in its early development phase, with no mature solutions ready for mass production, and the company is actively positioning its micro motors, reducers, and linear drive components in this field, exploring industry opportunities with several companies in the supply chain.

Inovance Technology: A benchmark for domestic industrial automation control, offering a comprehensive product series with strong R&D capabilities

Inovance Technology is a benchmark enterprise in domestic industrial automation control, with five major business areas: general automation, smart elevators, new energy vehicles, industrial robots, and rail transit. In the general automation field, the product line includes: variable frequency drives, servo systems, control systems, sensors, high-performance motors, and high-precision lead screws, providing a comprehensive product range. According to the company’s annual report, the company’s general servo system held approximately 21.5% market share in China in 2022, ranking first with strong market competitiveness; the market share of small PLC products in China was approximately 11.9%, ranking second (first among domestic brands). Based on the company’s investment relations activities, the company is currently in the insight stage concerning humanoid robots, evaluating technical paths, application scenarios, product requirements, and costs.

Hechuan Technology: Significant advantages in servo systems among domestic brands, with plans for significant investment in robotics

Hechuan Technology focuses on the industrial automation industry, primarily producing servo systems and PLCs. The company’s core product, the servo system, is equipped with self-developed encoders, excelling in core performance indicators such as positioning accuracy, speed control, and rated torque, maintaining a competitive position among domestic brand manufacturers. In 2022, the company achieved sales revenue of 758 million yuan from servo systems, a year-on-year increase of 15%; PLC sales revenue reached 121 million yuan, a year-on-year increase of 204%. According to industrial data, the company’s general servo system held approximately 3% market share in 2020, ranking second among domestic brands. Recent fundraising projects indicate plans to develop ball screw pairs and guide rail businesses, with ball screws requiring craftsmanship accumulation and currently still in the R&D stage. The company believes that in the future, there will be extensive applications in robotics for precision drive core components and electromechanical integration components, leading to increased investment in the robotics sector.

Wolong Electric Drive: A major global manufacturer of motors and drives with strong R&D capabilities

Wolong Electric Drive is a comprehensive manufacturer of motors and drives in the new energy vehicle motor industry, producing various motors, generators, control drives, and industrial automation products. The company has reached a leading level in research and development in home appliance motors and control technology, high-power drive control technology, and efficient motors, with some products achieving international leading standards. Based on the company’s annual report, in the field of large industrial motor drives, the company leads the industry, especially in the Asia-Pacific market where its market share exceeds 50%. In the control drive field, motor controls are critical for stable output in new energy vehicles, primarily reflecting power torque and acceleration performance, with technical aspects similar to those of robotic joint actuators, providing the company with a leading edge in R&D based on its long-term research and product foundation.

Weichuang Electric: Establishing a robotics division to develop a series of motors for robots

Weichuang Electric has deepened its focus on electrical transmission and industrial control fields, with its main products including variable frequency drives, servo systems, and control systems. According to the company’s official website and announcements, it established a robotics division in 2022 to enter the robotics industry chain, with products covering mobile robot power units, general low-voltage servo systems, low-voltage servo integrated wheels, robotic joint modules, hollow cup motors, and frameless torque motors among core components. Among them, the hollow cup motor has a diameter of 13mm, no-load speed of 85000rpm, maximum output power of 58W, and maximum rated torque of 7mNm, suitable for humanoid robots’ dexterous hand joints.

Leisai Intelligent: Launching high-density frameless motors and servo systems to empower the humanoid robot industry

Leisai Intelligent has been deeply engaged in the motion control industry for over 20 years, providing a series of products and solutions for motion control, including motion controllers, servo systems, and stepper motors. In November 2023, the company officially launched the FM1 series high-density frameless motors and micro servo drivers. The frameless motors feature high torque density, high power density, small volume, lightweight, large rotor inner diameter, low heat generation, and small torque fluctuations, designed to address the application scenarios and user pain points in collaborative and humanoid robots. The company provides seven standard frame sizes including 25/38/50/60/70/85/115mm, and can optimize and customize motor sizes and electrical parameters based on customer needs. At the same time, the company launched the LD3mini micro servo driver to match the FM1 frameless motor, covering power ratings of 50W/200W/400W/750W, with advanced features such as E-bus interface, the fastest 125 microsecond total line cycle, three-ring vector control, and high, medium, and low frequency vibration suppression. The FM1 frameless motor and micro driver are currently in the trial production and trial sales phase: prototypes are expected to be provided to target customers for testing and selection in December 2023, with small-scale production starting in January 2024 and mass production and sales expected by March.

4.2 Gear Reducers: Mechanical Transmission Components, Key Breakthroughs in Actuator Technology

Shuanghuan Transmission: A high-precision gear manufacturer, extending from automotive to robotics, with RV reducers reaching a production capacity of 100,000 units

Shuanghuan Transmission started with gear manufacturing and has been deeply engaged in the mid-to-high-end gear manufacturing field for over 40 years. Its main products include passenger car gears, commercial vehicle gears, construction machinery gears, motorcycle gears, and electric tool gears, extending into the RV reducer field for industrial robots. According to the company’s official website, the company began laying out robot reducers in 2013, achieving the number one market share for domestic RV reducers in 2020, and breaking through a production capacity of 100,000 reducers in 2022. The company possesses decades of gear processing experience, excellent customer channel resources, and a deep understanding of the robotics industry, making it better equipped than other automotive gear companies to provide suitable products for robot manufacturers, thus creating greater potential in the robotics reducer field.

Zhongdali De: A comprehensive reducer manufacturer, with reducer products covering motors, planetary, harmonic, and RV reducers

Zhongdali De is a comprehensive industrial automation component manufacturer in China, with products covering reduction motors, precision reducers, drivers, and intelligent actuators in three main categories, including precision reducer products such as planetary reducers, RV reducers, and harmonic reducers, with a complete product line suitable for industrial robots, intelligent logistics, new energy equipment, industrial mother machines, textile machinery, and other industrial automation fields. According to the company’s annual report, in 2021, the company’s reducer (including RV reducers, harmonic reducers, and planetary reducers, with precision planetary reducers as the main focus) revenue reached 254 million yuan, accounting for 27% of total revenue, and with downstream demand driving rapid growth in shipment volumes.

4.3 Thermal Management: Enhancing Heat Dissipation and Torque Output, Increasing Importance in QDD

Sanhua Intelligent Control: Global leader in thermal management technology, focusing on electromechanical actuator business in robotics

Sanhua Intelligent Control is a global leader in thermal management, with main products including electronic expansion valves, four-way valves, solenoid valves, and other thermal management components for air conditioning and automotive applications. According to the company’s investment relations activities, it is actively laying out the robotics industry, focusing on the electromechanical actuator business for bionic robots, including both linear and rotary actuators. Through continuous investment and joint research and development, the company has established partnerships with multiple customers, gaining first-mover advantages. By extending from thermal management to robotics, the company possesses multiple advantages: ① The motor is the power source for electromechanical actuators, and Sanhua has rich technical accumulation in motors, having begun extensive R&D on motor products as early as 2005, with electronic expansion valves, water pumps, Omega pumps, drainage pumps, etc., all being motor products; ② Humanoid robots will utilize high power density batteries and motors, leading to high thermal management requirements, where the company has obvious advantages; ③ The company has established long-term cooperative foundations with existing customers, collaborating across multiple fields with strong comprehensive capabilities.

Yinlun Co., Ltd.: A leading manufacturer of thermal management products in China, a potential supplier of components for robotics

Yinlun Co., Ltd. is a privately-owned listed company specializing in the research, manufacturing, and sales of various thermal management and exhaust after-treatment products, consistently ranking among the top in the domestic industry for thermal exchangers. According to the company’s investment relations activities, it has successfully developed and supplied liquid cooling products for North American major clients, such as FSD (autonomous driving systems). As the intelligent and informational capabilities of electric vehicles continue to rise, it is expected that liquid cooling will become mainstream for FSD. With years of R&D achievements in thermal management, the company has first-mover advantages in the field of liquid cooling treatment for robotic joint actuators, and its existing technical reserves can be applied to intelligent humanoid robots, making it a potential supplier of components for future robotics.

1、Automotive AI Incubation Accelerates: We welcome AI startup partners to participate together, relying on OEM resources to provide support in consulting, brand promotion, financial support, and product integration.

2、We welcome angel round and A round enterprises from the entire automotive industry chain (including the power battery industry chain) to join the group (We will recommend to 800 automotive investment institutions, including top institutions);There is a communication group for leaders of scientific and technological innovation companies、automotive industry vehicles, automotive semiconductors, key components, new energy vehicles, intelligent connected vehicles, aftermarket, automotive investment, autonomous driving, vehicle networking, and dozens of other groups. Please scan the administrator’s WeChat to join the group (Please indicate your company name)