Although sensors are the most fundamental perception devices in the Internet of Things (IoT), some people often think of sensor manufacturers when it comes to data collection. However, from a business perspective, the primary issue to address in the practice of Industrial IoT is how to connect to controllers. This is because there is already a wealth of available data within the controllers, which is closely related to equipment failures, status, process parameters, energy consumption parameters, and more. Additionally, in some application scenarios, commands need to be sent to the controllers (such as sending recipes, starting/stopping, or modifying process parameters). Therefore, connecting to the controllers is the primary consideration from a business perspective. Sensors are more often considered when the data dimensions from the controllers are insufficient, or in the case of new applications, new devices, or devices that lack controllers (either very old or purely mechanical devices).

Today, we will discuss the classification of industrial box manufacturers and my personal views on the trends of gateway products.

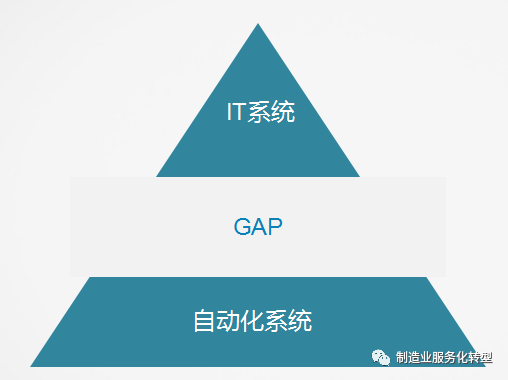

As mentioned earlier, the responsibility of industrial gateways is to collect data, and due to the demands of industrial cloud platforms, they also undertake the mission of connecting automation and IT. They can be seen as a product that bridges the gap.

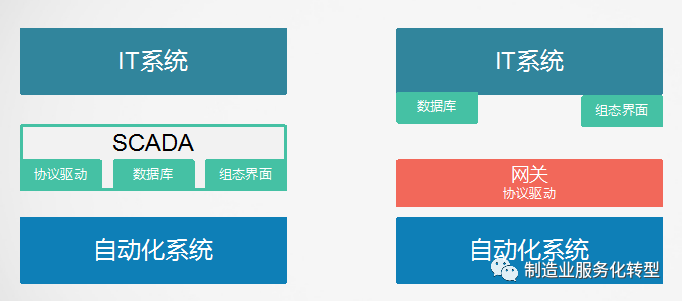

The traditional approach is generally to use SCADA software within automation systems to collect local device data and store it in the corresponding databases. Then, IT systems connect to the database to access the collected data. This method is not only costly (especially for equipment maintenance primarily based on equipment), but also inefficient. Therefore, industrial gateways (boxes) have gained more market share.

The traditional approach is generally to use SCADA software within automation systems to collect local device data and store it in the corresponding databases. Then, IT systems connect to the database to access the collected data. This method is not only costly (especially for equipment maintenance primarily based on equipment), but also inefficient. Therefore, industrial gateways (boxes) have gained more market share.

The traditional SCADA market will gradually slow down, as IT systems possess more powerful capabilities in terms of configuration (high concurrency, distributed storage, H5 technology, 3D, etc.) at the database and data display level, while more flexible industrial gateways will replace traditional protocols.

The traditional SCADA market will gradually slow down, as IT systems possess more powerful capabilities in terms of configuration (high concurrency, distributed storage, H5 technology, 3D, etc.) at the database and data display level, while more flexible industrial gateways will replace traditional protocols.

Generally, industrial gateways need to have the following capabilities:

1. Capability to parse protocols for the lower level (automation systems) (communication protocols: Modbus, PPI, MPI, CNC, etc.; bus protocols: CAN, PROFIBUS, etc.; industrial wireless protocols: WirelessHART, 433, etc.). Current gateways primarily focus on communication protocols, with only a few manufacturers considering lower-level bus protocols and wireless protocols. Traditional bus protocol converters are also referred to as industrial gateways, making it difficult to distinguish between them.

2. Capability for protocol integration with the upper level (IT systems), including communication capabilities (Ethernet, WIFI, 3G, 4G, NB-IoT, etc.).

3. Capability for secondary development of private protocols for both upper and lower levels.

4. Capability for data caching and local computing (fog computing).

Only with such capabilities can a gateway be considered comprehensive. On the other hand, industrial site applications are very complex, and the cost of data access is currently very high, often accounting for over half of the costs when owners wish to implement information systems. Therefore, gateway manufacturers will position their products based on market size. However, currently, both domestic and foreign gateway manufacturers find it challenging to cover all applications, and the lack of unified communication protocols for IT system integration further contributes to high access costs, significantly impacting the application of cloud and big data.

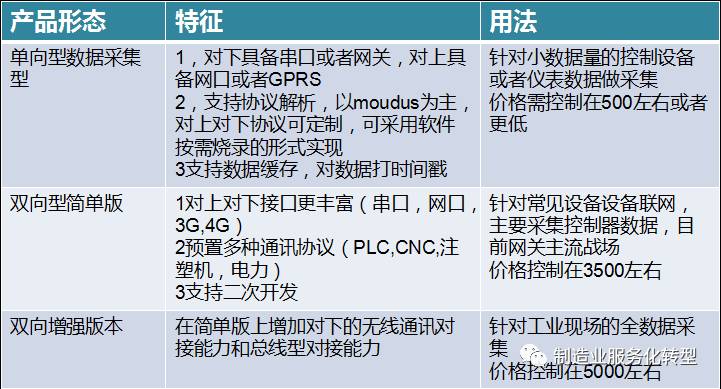

Based on my years of experience in the industry, an ideal gateway should have the following product forms:

Currently, industrial gateways are concentrated in the second type, which also has the highest demand. The first and third types currently do not have clear markets; while there is strong demand in certain industries, their replicability is not as high as that of the second type, so fewer people are developing them.

Currently, industrial gateways are concentrated in the second type, which also has the highest demand. The first and third types currently do not have clear markets; while there is strong demand in certain industries, their replicability is not as high as that of the second type, so fewer people are developing them.

At the same time, the first and third types carry certain risks when selecting wireless communication protocols (for upper or lower levels), as they do not generally use 3G and 4G like the second type. The ideal state is for the first type of gateway to use NB-IoT for upper-level protocols, and the third type to select 1-2 suitable industrial lower-level wireless communication protocols (currently, process industries tend to prefer WirelessHART and 433; discrete industries temporarily use IWIF as a substitute, which is not very effective).

However, having these capabilities alone is not enough to become an excellent industrial gateway company. Currently, the cost of connecting gateways to the cloud remains very high, and I believe the main reasons are as follows:

1. The industrial IoT market is vast, and many gateway manufacturers are eyeing the cloud market. On one hand, many gateway companies were born from configuration and possess certain software development capabilities (although I do not believe they have the ability to develop cloud solutions, the market is mixed, and any B/S software claims to be cloud). On the other hand, the cloud currently lacks strong enterprises and corresponding standards.

2. As the primary data entry point for industrial IoT, industrial gateways often have more access to demand in the early stages of the market. However, once data access is resolved, gateways will no longer be important, as the value of data needs to be shared in the cloud (through core relationship software sharing internally and sharing through the industrial collaboration ecosystem) and mined to be realized. Simply collecting data and seeing its value is very low. Therefore, some people often say that the starting point of industrial IoT is data monitoring, while many believe that data can be realized through B/S software. This situation poses a high risk of obsolescence for industrial gateway manufacturers in the future. Additionally, due to the lack of standard communication protocols with the cloud, gateway manufacturers often need to create some cloud configuration tools, which leads to each gateway manufacturer wanting to develop their own set of cloud middleware, resulting in high connection and conversion costs.

Therefore, I hope that those who have been engaged in the general gateway (DTU, routers, gateways) market for over five years will encourage various gateway manufacturers to adopt a service-oriented mindset (customer-centric). If your gateway is positioned in a general market, then consider how to support downstream companies in cloud and big data. The general market usually employs the strategy of minimizing total costs, so how to further reduce the costs of IoT systems from a solution perspective is something companies in the general market must consider. Currently, I believe Advantech is doing very well in this regard, while other manufacturers often hesitate, with relatively vague strategies and no clear strategic planning and positioning.

Finally, the market for industrial gateways (or general gateways: DTU, routers, bus gateways) can directly reflect the current development level of the industrial IoT in China. As someone who has been involved in industrial IoT since the concept began to take hold in China, I believe that to gauge the development of industrial IoT in the country, one can assess the current stage by observing the development of domestic industrial gateways.

By the way, last year, the domestic manufacturer of industrial routers, Beijing Yingtong, achieved over 50% growth. Advantech invested $100 million to acquire the general gateway supplier B+B. Undoubtedly, if the period from 2008 to 2015 was the exploratory phase of industrial IoT in China, characterized by government-led developments in smart transportation, smart grids, etc., then in the second half of 2015, industrial IoT is transitioning to a market led by enterprises, with industrial gateways serving as a bridge to stably collect data and connect information technology with automation. For those interested in industrial IoT, one should first pay attention to industrial gateways, as the current market for cloud and big data is relatively weak. However, it is undeniable that the future belongs to them, and gateways have their own historical mission.

》》》》》》》》》》》》》》》》》》》》》》》》》》

For more information related to the service-oriented transformation of the manufacturing industry, including policies, trends, technologies, and case studies, please follow us, as we will continue to track the latest trends in the service-oriented transformation of the manufacturing industry. I will also continue to focus on the driving forces and key roles of foundational technologies such as industrial IoT, industrial big data, and blockchain in the transformation of the manufacturing industry.