1. Common Kinematic Configurations

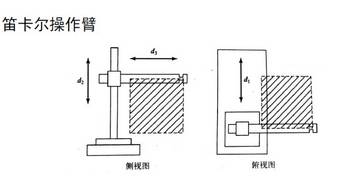

1. Cartesian Manipulator

Advantages: Easily implemented through computer control, achieving high precision. Disadvantages: obstructs work, occupies a large area, low movement speed, and poor sealing.

① A series of tasks such as welding, handling, loading and unloading, packaging, palletizing, depalletizing, inspection, flaw detection, classification, assembly, labeling, coding, (soft modeling) spraying, target tracking, bomb disposal, etc.

② Particularly suitable for flexible operations with multiple varieties and small batches, playing a crucial role in stability, improving product quality, enhancing labor productivity, and facilitating rapid product updates.

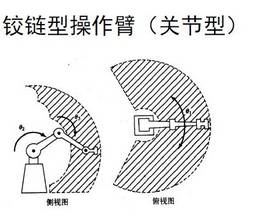

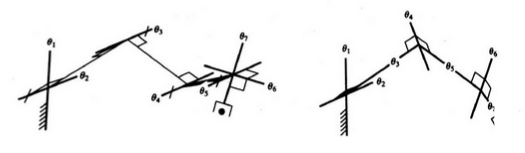

2. Articulated Manipulator (Joint Type)

All joints of articulated robots are rotational, similar to a human arm, making it the most common structure in industrial robots. Its working range is relatively complex.

① Rapid inspection and product development for automotive parts, molds, sheet metal parts, plastic products, sports equipment, glass products, ceramics, aviation, etc.

② Three-coordinate measurement and error detection for body assembly, general machinery assembly, and manufacturing quality control.

③ Rapid prototyping of antiques, artworks, sculptures, cartoon characters, and portrait products.

④ On-site measurement and inspection of complete vehicles.

⑤ Measurement of human body shapes, production of medical devices such as bones, human shape modeling, and medical cosmetic procedures.

3. SCARA Manipulator

SCARA robots are commonly used for assembly tasks, characterized by their high flexibility in the x-y plane and strong rigidity along the z-axis, thus exhibiting selective flexibility. These robots have found good applications in assembly tasks.

① Widely used for assembling printed circuit boards and electronic components.

② Moving and placing objects, such as integrated circuit boards.

③ Extensively applied in the plastic industry, automotive industry, electronics industry, pharmaceutical industry, and food industry.

④ Handling parts and assembly work.

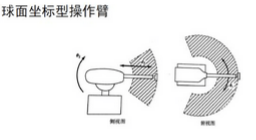

4. Spherical Coordinate Manipulator

Characteristics: A large working range near the central support, two rotating drive devices are easy to seal, covering a large working space. However, the coordinates are complex, difficult to control, and the linear drive devices have sealing issues.

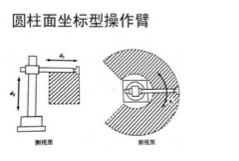

5. Cylindrical Coordinate Manipulator

Advantages: Simple calculations; linear parts can use hydraulic drive, providing large power; capable of reaching inside cavity-type machines. Disadvantages: The space reachable by its arm is limited, unable to reach near columns or close to the ground;

Linear drive parts are difficult to seal and dustproof; when the rear arm operates, the back end of the arm may collide with other objects within the working range.

6. Redundant Mechanism

Typically, spatial positioning requires 6 degrees of freedom, and additional joints can help the mechanism avoid singular configurations. The image below shows a 7-degree of freedom manipulator configuration.

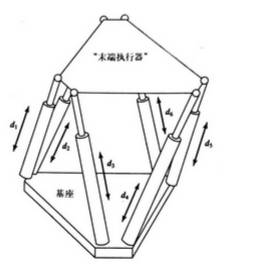

7. Closed-loop Structure

A closed-loop structure can improve the rigidity of the mechanism but will reduce the range of joint motion, resulting in a certain reduction in working space.

① Motion simulators;

② Parallel machine tools;

③ Micro-operation robots;

④ Force sensors;

⑤ Cell operation robots in biomedical engineering, capable of performing cell injection and segmentation;

⑥ Microscopic surgical robots;

⑦ Attitude adjustment devices for large radio astronomical telescopes;

⑧ Hybrid equipment, such as the Tricept hybrid manipulator module from SMT Company, which is a successful example of modular design based on parallel mechanism units.

Common structural forms of industrial robots (image)

2. Main Technical Parameters of Robots

The technical parameters of robots reflect the work they can perform and their highest operational performance, which are essential considerations in the design and application of robots. The main technical parameters of robots include degrees of freedom, resolution, working space, working speed, and working load.

1. Degrees of Freedom

The number of independent coordinate axes of motion that a robot possesses. The degrees of freedom of a robot refer to the number of independent motion parameters required to determine the position and posture of the robot’s end effector in space. The opening and closing of fingers, as well as the degrees of freedom of finger joints, are generally not included. The number of degrees of freedom of a robot typically equals the number of joints. Commonly, the number of degrees of freedom does not exceed 5 to 6.

2. Joints

Also known as motion pairs, they are mechanisms that allow relative motion between the various parts of the robot arm.

3. Working Space

The total spatial area that the robot arm or end effector can reach. Its shape depends on the number of degrees of freedom and the types and configurations of the moving joints. The working space of a robot is usually represented using graphical and analytical methods.

4. Working Speed

The distance or angle moved by the mechanical interface center or tool center point in unit time during uniform motion under working load conditions.

5. Working Load

Refers to the maximum load that the robot can bear at any position within its working range, generally expressed in terms of mass, torque, and moment of inertia. It is also related to the direction of running speed and acceleration, with the weight of the workpiece that can be grasped during high-speed operation generally used as the load capacity indicator.

6. Resolution

The minimum movement distance or minimum rotation angle that can be achieved.

7. Accuracy

Repeatability or repeat positioning accuracy: refers to the degree of variation when the robot repeatedly reaches a specific target position. Or the dispersion of the robot’s position when repeatedly executing the same position command. It measures the density of a series of error values, i.e., repeatability.

3. Common Materials for Robots

1) Carbon structural steel and alloy structural steel. These materials have good strength, especially alloy structural steel, which increases strength by 4 to 5 times, has a large elastic modulus E, and strong resistance to deformation, making them the most widely used materials.

2) Aluminum, aluminum alloys, and other lightweight alloy materials. These materials share the common characteristic of being lightweight, with a relatively low elastic modulus E, but their low density allows the E/ρ ratio to be comparable to that of steel. Some rare aluminum alloys have seen significant improvements in quality, such as aluminum alloys with 3.2% (by weight) lithium, which increase elastic modulus by 14% and E/ρ ratio by 16%.

3) Fiber-reinforced alloys. These alloys, such as boron fiber-reinforced aluminum alloys and graphite fiber-reinforced magnesium alloys, achieve E/ρ ratios of 11.4×107 and 8.9×107, respectively. These fiber-reinforced metal materials have a very high E/ρ ratio but are expensive.

4) Ceramics. Ceramic materials have good quality but are very brittle and difficult to process. Japan has already trial-produced ceramic robot arm samples for use in small, high-precision robots.

5) Fiber-reinforced composite materials. These materials have an excellent E/ρ ratio and outstanding damping properties. Traditional metal materials cannot achieve such high damping, so the application of composite materials in high-speed robots is becoming increasingly common.

6) Viscoelastic high-damping materials. Increasing the damping of robot link components is an effective method to improve the dynamic characteristics of robots. Currently, many methods are used to increase the damping of structural materials, one of the most suitable methods for robots is to apply viscoelastic high-damping materials for constrained layer damping treatment of original components.

4. Main Structures of Robots

1. Robot Drive Devices

Concept: To make the robot operate, it is necessary to install drive devices for each joint, i.e., each degree of freedom. Function: to provide the original power for the movements of various parts and joints of the robot.

Drive systems: Can be hydraulic, pneumatic, electric, or a combination of these systems; can be direct drive or indirect drive through mechanical transmission mechanisms such as synchronous belts, chains, gear systems, and harmonic gears.

1. Electric Drive Devices

Electric drive devices have simple energy sources, a wide range of speed variations, high efficiency, and high speed and position accuracy. However, they are often associated with reduction devices, making direct drive more difficult.

Electric drive devices can be divided into DC, AC servo motor drives, and stepper motor drives. DC servo motors have brushes that wear easily and can create sparks. Brushless DC motors are becoming increasingly popular. Stepper motor drives are mostly open-loop control, simple to control but with low power, commonly used in low-precision, low-power robot systems.

Before powering on the electric drive, the following checks should be made:

1) Is the power supply voltage appropriate (overvoltage may damage the drive module); for DC input, the +/- polarity must not be reversed, and the motor model or current setting on the drive controller must be appropriate (do not set it too high initially);

2) Ensure control signal lines are securely connected; in industrial settings, consider shielding (e.g., using twisted pairs);

3) Do not connect all necessary wires at once; only connect the basic system first, and after it runs well, gradually connect more.

4) Be clear about grounding methods, whether to use floating or not.

5) Closely monitor the motor’s status during the first half hour of operation, such as whether the movement is normal, sounds, and temperature rise; if any issues arise, stop and adjust immediately.

2. Hydraulic Drive

Achieved through high-precision cylinders and pistons, linear motion is realized through the relative movement of the cylinder and piston rod.

Advantages: High power, can eliminate reduction devices by connecting directly to the driven rod, compact structure, good rigidity, fast response, and servo drive has high precision.

Disadvantages: Requires a hydraulic source, prone to fluid leaks, unsuitable for high or low-temperature environments, thus hydraulic drive is mostly used in very high-power robot systems.

Select suitable hydraulic oil. Prevent solid impurities from entering the hydraulic system, and prevent air and water from invading the hydraulic system. Mechanical operations should be gentle and smooth; avoid rough handling, as it will inevitably produce impact loads, leading to frequent mechanical failures and significantly shortening service life. Pay attention to cavitation and overflow noise. During operation, always listen for sounds from the hydraulic pump and overflow valve; if the hydraulic pump produces “cavitation” noise that cannot be eliminated after venting, investigate the cause and resolve the issue before use. Maintain an appropriate oil temperature. The working temperature of the hydraulic system is generally controlled between 30-80°C.

3. Pneumatic Drive

Pneumatic drive has a simple structure, is clean, has sensitive actions, and provides cushioning. However, compared to hydraulic drive devices, it has lower power, poorer rigidity, and higher noise, making it less suitable for precision control robots.

(1) Features fast speed, simple system structure, easy maintenance, and low cost, making it suitable for medium and small load robots. However, due to difficulties in achieving servo control, it is mostly used in program-controlled robots, such as in loading and unloading and stamping robots.

(2) In most cases, it is used for two-position or limited point control in medium and small robots.

(3) Currently, most control devices use programmable logic controllers (PLC). In flammable and explosive environments, pneumatic logic elements can be used to form control devices.

2. Linear Transmission Mechanisms.

The transmission device is a key part connecting the power source and the moving link. Depending on the joint form, common transmission mechanisms include linear and rotational transmission mechanisms.

Linear transmission methods can be used for X, Y, Z direction drives in Cartesian coordinate robots, radial drives in cylindrical coordinate structures, and vertical lifting drives, as well as radial telescopic drives in spherical coordinate structures.

Linear motion can be converted from rotational motion through transmission elements such as gear racks, lead screws, or can be driven directly by linear motors or by the pistons of cylinders or hydraulic cylinders.

1. Gear Rack Device

Typically, the rack is fixed. The rotational motion of the gear is converted into linear motion of the support plate.

-

Advantages: Simple structure.

-

Disadvantages: Large backlash.

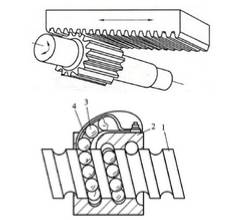

2. Ball Screw

Ball bearings are embedded in the helical grooves of the screw and nut, allowing the balls to circulate continuously through the guiding grooves in the nut.

-

Advantages: Low friction, high transmission efficiency, no crawling, high precision.

-

Disadvantages: High manufacturing costs, complex structure.

Self-locking issue: Theoretically, ball screws can also be self-locking, but in practice, this self-locking is not used due to poor reliability or high processing costs; because the diameter to lead ratio is very large, a set of self-locking devices such as worm gears is usually added.

3. Rotational Transmission Mechanisms

The purpose of using rotational transmission mechanisms is to convert the high speed output from the motor’s drive source into lower speed while obtaining greater torque. Common rotational transmission mechanisms in robots include gear chains, synchronous belts, and harmonic gears.

1. Gear Chain

(1) Speed relationship

(2) Torque relationship

2. Synchronous Belt

The synchronous belt has many shaped teeth and meshes with a similarly toothed synchronous pulley. During operation, it acts like a flexible gear.

-

Advantages: No slipping, good flexibility, low cost, high repeat positioning accuracy.

-

Disadvantages: Has a certain degree of elastic deformation.

3. Harmonic Gear

The harmonic gear consists of three main parts: a rigid gear, a harmonic generator, and a flexible gear, with the rigid gear generally fixed and the harmonic generator driving the flexible gear to rotate. Main features:

(1) Large transmission ratio, single-stage 50-300.

(2) Smooth transmission, high load capacity.

(3) High transmission efficiency, reaching 70%-90%.

(4) High transmission accuracy, 3-4 times higher than ordinary gear transmission.

(5) Small backlash, can be less than 3′.

(6) Cannot obtain intermediate output, flexible gear has lower rigidity.

Harmonic transmission devices have been widely used in countries with advanced robot technology. In Japan alone, 60% of robot drive devices use harmonic transmission. The robots sent to the moon by the United States used harmonic transmission devices in all their joint parts, with one upper arm using 30 harmonic transmission mechanisms. The mobile robot “Lunokhod” sent to the moon by the former Soviet Union had eight wheels driven by closed harmonic transmission mechanisms. The ROHREN, GEROT R30 robot developed by Volkswagen and the VERTICAL 80 robot developed by Renault in France also use harmonic transmission mechanisms.

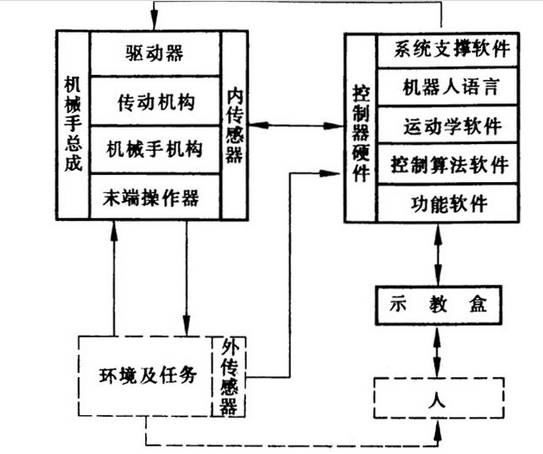

4. Robot Sensor Systems

1. The sensing system consists of internal sensor modules and external sensor modules, used to obtain meaningful information about the internal and external environmental states.

2. The use of intelligent sensors enhances the robot’s mobility, adaptability, and level of intelligence.

3. The use of intelligent sensors enhances the robot’s mobility, adaptability, and level of intelligence.

4. For some specific information, sensors are more effective than human sensory systems.

5. Robot Position Detection

Rotary optical encoders are the most commonly used position feedback devices. Photoelectric detectors convert light pulses into binary waveforms. The angle of the shaft is obtained by calculating the number of pulses, and the rotation direction is determined by the relative phase of two square wave signals.

Inductive synchronizers output two analog signals—the sine signal and cosine signal of the shaft’s rotation angle. The angle of the shaft is calculated from the relative amplitudes of these two signals. Inductive synchronizers are generally more reliable than encoders, but they have lower resolution.

Potentiometers are the most direct form of position detection. They are connected in a bridge circuit and can generate a voltage signal proportional to the shaft’s rotation angle. However, they have low resolution, poor linearity, and are sensitive to noise.

Speedometers can output an analog signal proportional to the shaft’s speed. If such speed sensors are not available, speed feedback signals can be obtained by differentiating the detected position concerning time.

6. Robot Force Detection

Force sensors are typically installed at three positions on the manipulator arm:

1. Installed on the joint driver. It can measure the torque or force output of the driver/reducer itself. However, it cannot effectively detect the contact force between the end effector and the environment.

2. Installed between the end effector and the terminal joint of the manipulator arm, referred to as wrist force sensors. Typically, they can measure three to six force/torque components applied to the end effector.

3. Installed on the “fingertips” of the end effector. Typically, these force-sensitive fingers are equipped with strain gauges that can measure one to four components of force applied to the fingertips.

7. Robot-Environment Interaction Systems

1. The robot-environment interaction system is a system that enables industrial robots to connect and coordinate with devices in the external environment.

2. Industrial robots and external devices are integrated into a functional unit, such as processing and manufacturing units, welding units, assembly units, etc. It can also be an integration of multiple robots, multiple machine tools or devices, and multiple parts storage devices.

3. It can also be an integration of multiple robots, multiple machine tools or devices, and multiple parts storage devices into a functional unit to perform complex tasks.

8. Human-Machine Interaction Systems

The human-machine interaction system is a device that allows operators to participate in robot control and communicate with the robot. This system can be broadly classified into two categories: command input devices and information display devices.

5. Robot Control Systems

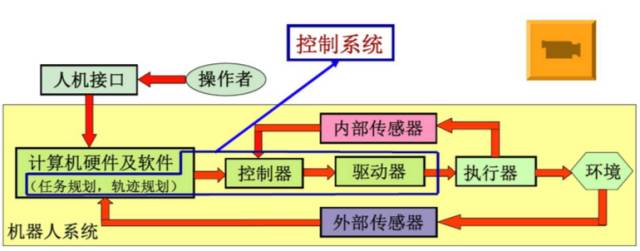

1. The robot’s control system

The purpose of “control” is to make the controlled object exhibit the behavior expected by the controller. The basic condition of “control” is to understand the characteristics of the controlled object. The essence is to control the output torque of the driver.

2. Robot Teaching Principles

The basic working principle of robots is teaching and reproduction; teaching, also known as guidance, is when the user guides the robot step by step through the actual task, and the robot automatically memorizes the position, posture, motion parameters/process parameters of each action during the guidance process, generating a continuous program to execute all operations. After teaching is completed, the robot only needs a start command to execute all operations precisely according to the taught actions.

3. Classification of Robot Control:

1) Divided into open-loop control and closed-loop control based on feedback;

Conditions for precise open-loop control: precisely knowing the model of the controlled object, and this model remains unchanged during the control process.

2) Divided into position control, force control, and hybrid control based on the desired control quantity;

Position control is divided into single-joint position control (position feedback, position speed feedback, position speed acceleration feedback), multi-joint position control, and multi-joint position control is divided into decomposed motion control and centralized control; force control is divided into direct force control, impedance control, and force-position hybrid control;

3) Intelligent control methods: fuzzy control, adaptive control, optimal control, neural network control, fuzzy neural network control, expert control, and others;

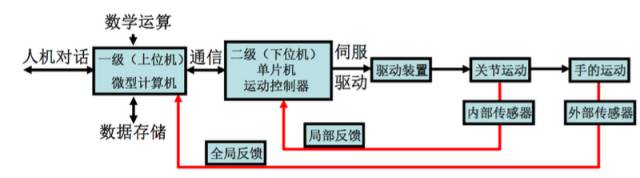

4. Hardware Configuration and Structure of Control Systems:

Due to the large number of coordinate transformations and interpolation calculations involved in the robot’s control process, as well as lower-level real-time control, most current robot control systems adopt a layered structure of microcomputer control systems, typically using a two-level computer servo control system.

1) Specific Process:

After the main control computer receives the work instructions input by the staff, it first analyzes and interprets the instructions to determine the motion parameters of the hand.

Then it performs kinematic, dynamic, and interpolation calculations, ultimately deriving the coordinated motion parameters for each joint of the robot. These parameters are output to the servo control level through communication lines as the set signals for each joint’s servo control system. The joint driver converts this signal from D/A to drive each joint to produce coordinated motion. Sensors feed back the motion output signals of each joint back to the servo control level computer, forming a local closed-loop control, thus achieving more precise control of the robot’s end effector movement in space.

2) PLC-based Motion Control Two control methods:

1. Using certain output ports of the PLC to generate pulse output instructions to drive the motor, while using general I/O or counting components to achieve closed-loop position control of the motor.

2. Using external position control modules of the PLC to achieve closed-loop position control of the motor, mainly by generating high-speed pulses, which belongs to the position control method, with point-to-point position control being more common.

Content Source: Network

Editor for this issue: Xiao Ke Phone: 021-37709286Email: [email protected]Copyright Statement: Westec respects copyright and appreciates the hard work and creativity of every author; except for articles that cannot be traced, we have noted the source at the end of the article; if any videos, images, or text in the article involve copyright issues, please contact us immediately, and we will confirm copyright based on the proof materials you provide and pay remuneration according to national standards or delete the content immediately!