The Huawei DriveONE motor, featured in the Avita 11, is one of its core highlights, providing not only robust power support but also optimizing vehicle energy efficiency and driving experience through highly integrated and intelligent control technologies.

The Huawei DriveONE motor is an efficient, integrated electric drive system developed by Huawei Technologies Co., Ltd. This motor is renowned for its high efficiency, compact design, and powerful output, representing one of Huawei’s significant technological achievements in the field of new energy vehicles. This article provides a detailed explanation of the motor controller.

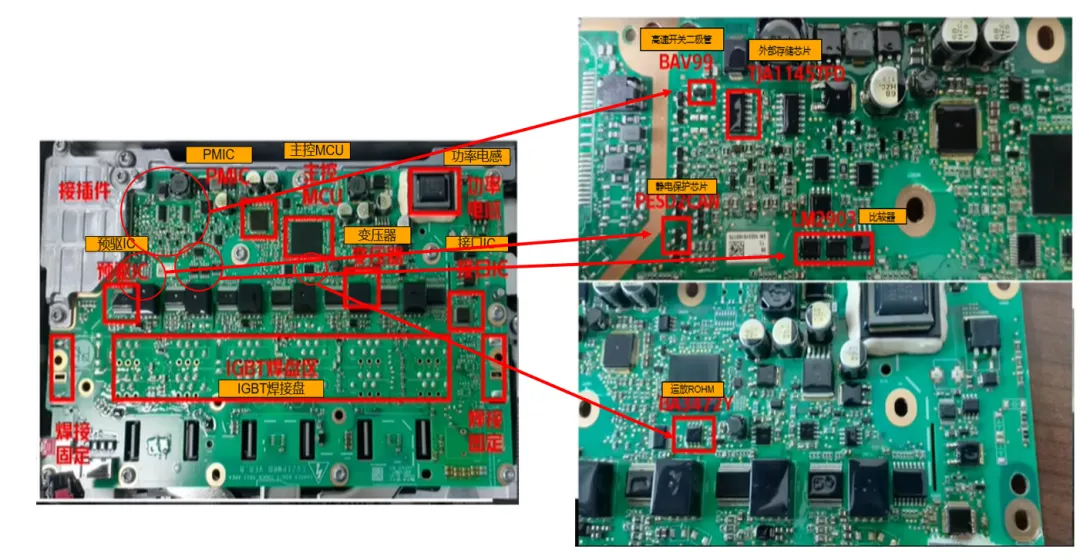

As shown in the figure, the disassembled main control board contains the power module and the motor control module. The specific disassembly results are shown in the table below.

Next, we will analyze in detail:

The Huawei main control board integrates the main control module and the pre-driver module onto a single board, featuring high integration, a neat layout, and the use of high-temperature resistant Infineon or ST chip solutions (operating temperature up to 150°C, with an unusual 125°C). It employs multiple transformers for signal isolation, ensuring robust EMC design, with connectors shielded by metal to eliminate interference, making the overall design reliable and safe.

01#

Main Control MCU

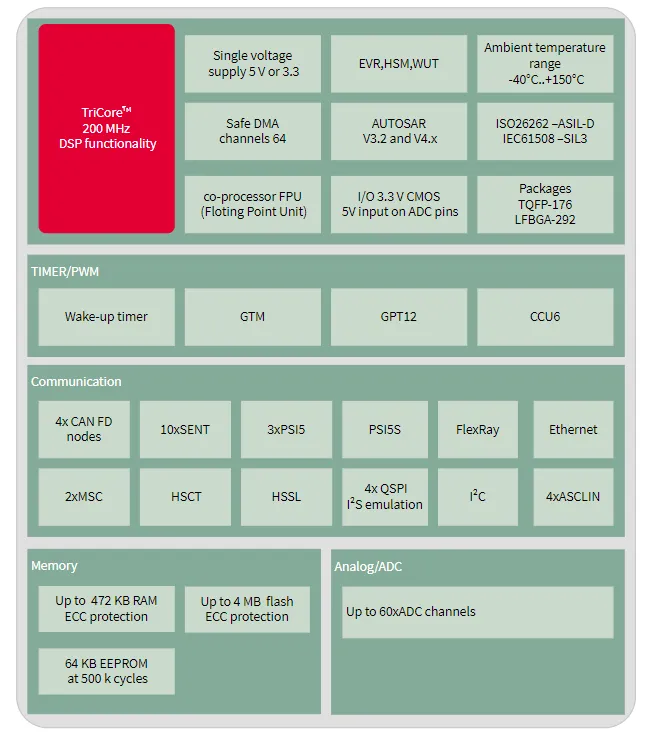

The Huawei DriveONE uses the Infineon SAL-TC277TP-64F200N DC, a powerful 32-bit AURIX TriCore microcontroller, capable of independently executing complex control logic, suitable for automotive and industrial applications.

It features a frequency of 200MHz, up to 4MB of Flash memory, and an LFBGA-292 package. This microcontroller belongs to the TC27xT series, with an innovative multi-core architecture based on up to three independent 32-bit TriCore CPUs, designed to meet the highest safety standards while significantly enhancing performance. It is equipped with a triple TriCore running at 200 MHz, 4MB of Flash memory, and a powerful General Timer Module (GTM). The TC27xT series aims to reduce complexity, optimize power consumption, and achieve significant cost savings, with an operating temperature range of -40°C to 150°C, and ASILD automotive safety level.

In the motor controller main control board, the main control MCU (Microcontroller Unit) chip is the core processor responsible for executing complex control algorithms, processing sensor data, generating control signals, and managing the operation of the entire system.

Main Control MCU chips typically have the following features:

▶ Processing Power: The main control MCU chip has sufficient processing power to execute complex control tasks, including real-time control and signal processing.

▶ Memory: Built-in or external memory for storing program code and data, ensuring the system can execute preset algorithms and logic.

▶ Communication Interfaces: Equipped with various communication interfaces such as UART, SPI, I2C, CAN, etc., to facilitate communication with other components and external devices.

▶ Input/Output (I/O) Ports: Provides a rich set of I/O ports for connecting various sensors, actuators, and other electronic components.

▶ Analog and Digital Conversion Functions: Some main control MCU chips have analog-to-digital (ADC) and digital-to-analog (DAC) conversion functions for processing analog signals.

▶ Timer/Counters: Built-in timer/counters for time measurement and timing control.

▶ Safety Features: Some main control MCU chips have safety features such as encryption functions to protect the system from unauthorized access.

▶ Power Management: Integrated power management functions to optimize the system’s power usage and performance.

The selection of the main control MCU chip depends on the specific application requirements of the motor controller, including control precision, response speed, power levels, environmental conditions, etc. In the design of the motor controller, the choice of the main control MCU chip is crucial for ensuring the system’s performance, efficiency, and reliability.

02#

Power Management IC (PMIC)

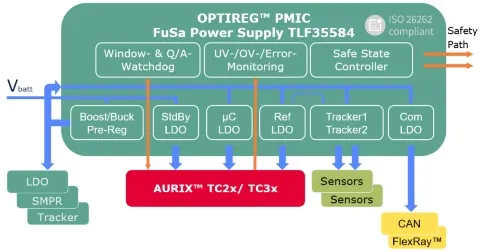

The Huawei DriveONE uses the Infineon TLF35584QVVS1, a multifunctional output system power supply, particularly suitable for safety-related applications.

It operates with an input voltage of 3 to 4V, supporting back-boost (buck-boost conversion), powering transceivers and sensors. This product features a wide switching frequency range: 500k to 2.2MHz, allowing optimization between efficiency and the use of small filtering components, with low output voltage ripple, and can serve as a reference voltage for peripherals like MCU ADCs. The TLF35584QVVS1 integrates functional safety features, supporting ASIL-D level, suitable for various microcontrollers (μC).

Additionally, this product has various safety features such as UV/OV monitoring, flexible watchdog, error monitoring, a safety state controller with two outputs, and built-in self-test functions to ensure the normal operation of relevant safety features. All safety-related configurations are protected and can only be changed through a special and successful unlock/lock sequence.

In the motor controller main control board, the PMIC (Power Management Integrated Circuit) is a key component responsible for managing and regulating power supply.

The main functions of PMIC include:

▶ Voltage Regulation: PMIC is responsible for converting the voltage supplied by the power source (such as a battery) to the voltage levels required by various components on the main control board. For example, microcontrollers (MCUs) and other integrated circuits may require different operating voltages.

▶ Current Protection: PMIC typically includes overcurrent protection features to prevent damage to the circuit due to excessive current.

▶ Power Switching: In some designs, PMIC can switch between different power sources based on system requirements, such as switching from battery to external power.

▶ Power Monitoring: PMIC can monitor power status, such as voltage, current, and temperature, ensuring that the power supply operates within safe limits.

▶ Energy Management: PMIC may include energy-saving modes that reduce power consumption when the system is in a low-power state.

▶ Thermal Management: Some PMICs also have thermal management features that can monitor chip temperature to prevent overheating.

In the motor controller, PMIC is crucial for ensuring stable, efficient, and safe power supply. It helps extend battery life and improve overall system performance through efficient management and regulation of power.

03#

Pre-driver IC

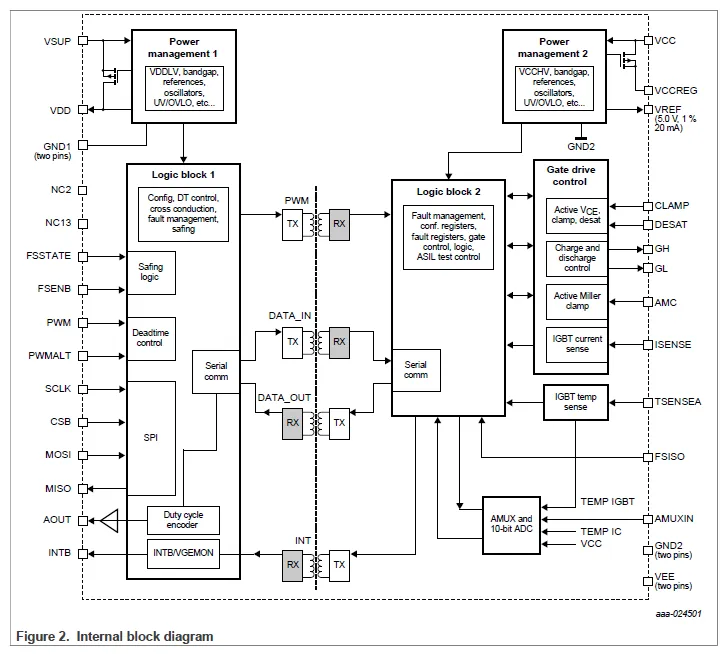

The Huawei DriveONE uses the NXP MC33GD3100EK, a gate driver for electric vehicle traction inverters, suitable for IGBT and SiC power devices. It features an SPI interface for monitoring and programming, low latency, and integrated signal isolation.

This product features integrated electrical isolation and low on-resistance driving transistors, providing high charging and discharging currents, low dynamic saturation voltage, and rail-to-rail gate voltage control. Current and temperature sensing minimizes stress on the IGBT during fault conditions.

The MC33GD3100EK is designed to meet the stringent requirements of automotive applications, fully compliant with AEC-Q100 Grade 1 standards. This device also features an SPI interface for safety monitoring, programmability, and flexibility, as well as low propagation delay and minimal PWM distortion. It is compatible with IGBT/SiC rated from 200V to 1700V, with a power range exceeding 125kW, operating frequency over 40kHz, providing 5.0V and 3.3V tolerance for MCU interfaces, and a temperature range of -40°C to 125°C, with a 32-pin wide-body SOIC package.

In the motor controller main control board, the pre-driver IC (Pre-driver Integrated Circuit) is an important component located between the main control MCU (Microcontroller Unit) and power devices (such as IGBTs or MOSFETs).

The main functions of the pre-driver IC include:

▶ Signal Amplification: The pre-driver IC receives control signals from the main control MCU and amplifies these signals to ensure they can effectively drive power devices.

▶ Driving Optimization: The pre-driver IC optimizes driving signals to reduce switching losses, improving system efficiency and reliability.

▶ Protection Features: The pre-driver IC typically includes protection features such as overcurrent protection and short-circuit protection to safeguard power devices from overload and short-circuit damage.

▶ Interface Matching: The pre-driver IC can adapt to different types of power devices and main control MCUs, ensuring compatibility and optimal performance between them.

▶ Timing Control: Some advanced pre-driver ICs may also include timing control functions for precise control of power device switching timing, further optimizing system performance.

The selection and configuration of the pre-driver IC are crucial for ensuring system performance, efficiency, and reliability. It not only enhances the lifespan of power devices but also improves the overall safety and stability of the system. In the design of the motor controller, the pre-driver IC works in conjunction with the main control MCU, PMIC, interface IC, and power devices to achieve precise motor control and stable system operation.

04#

Input Interface IC

The Huawei DriveONE uses the ST L9966C, a specially designed analog-to-digital converter (ADC)/digital-to-analog converter (DAC), belonging to a special type of integrated circuit that allows users to modify sensors without changing the PCB.

It features a 10-bit resolution and provides various output types, including voltage, current, and synchronous/parsed output, with 15 programmable interfaces, 12 connections for external analog loads, 12-bit voltage measurement, and 15-bit precise resistance measurement, capable of interfacing with magnetic resistance sensors/hall sensors. Additionally, the L9966C has a wide operating temperature range, extending from -40°C to 150°C. These features make the L9966C highly suitable for applications requiring high-precision analog and digital signal conversion.

In the motor controller main control board, the input interface IC (Integrated Circuit) is responsible for processing and converting external input signals. These input signals typically come from various sensors, such as temperature sensors, speed sensors, position sensors, and control signals from driver operations, such as accelerator pedal position and brake pedal status.

The main functions of the input interface IC include:

▶ Signal Acquisition: Collecting analog or digital signals from sensors and other input sources.

▶ Signal Conditioning: Conditioning the acquired signals, such as amplification, filtering, and shaping, to meet the requirements of the main control MCU or other processing units.

▶ Signal Conversion: Converting the conditioned signals into a format that the main control MCU can understand and process.

▶ Data Processing: Performing preliminary processing on the signals, such as calculating speed, position, and other key parameters, providing foundational data for subsequent algorithm processing.

▶ Communication: Transmitting the processed signals to the main control MCU or other processing units for further decision-making and control.

The selection and design of the input interface IC are crucial for ensuring that the system can accurately and timely acquire and process external input signals. It directly affects the performance and response speed of the motor controller. In designing the motor controller, the choice and layout of the input interface IC are vital for ensuring the system’s accuracy and reliability.

05#

Transformer

The Huawei DriveONE uses the Pulse Electronics PM3045NL, a forward gate drive transformer designed specifically for IGBT device switching in automotive applications. This transformer is a 2W forward transformer providing +15V for device switching on and -7.5V for strong switching off. The package structure provides a withstand voltage of 3750KV ac, on a compact (15.8×12.5×10.2mm) SMD platform. This platform meets a minimum creepage distance of 10mm and complies with IEC62368-1’s reinforced insulation requirements. It uses triple insulated wire to meet the high reliability requirements in automotive applications.

A typical application is in the three-phase inverter drive system of electric vehicles, with a typical input voltage of 15V and a switching frequency of 100KHz. The coils (6-8) provide +15V output, with a full-bridge rectifier used for IGBT switching on, and the coils (5-7) provide -7.5V, with a half-bridge rectifier used for switching off.

In the motor controller main control board, the transformer is a key component used to change voltage levels, typically used to isolate high-voltage and low-voltage circuits to enhance system safety and anti-interference capabilities.

The main functions of the transformer include:

▶ Voltage Conversion: The transformer can convert the input voltage to the desired output voltage to meet the operating voltage requirements of different components.

▶ Isolation: The transformer provides electrical isolation, reducing interference from high-voltage circuits to low-voltage circuits while protecting low-voltage circuits from high-voltage circuit impacts.

▶ Anti-Interference: The isolation characteristics of the transformer help improve the system’s anti-interference capability, reducing the impact of external electromagnetic interference on the circuit.

▶ Power Supply: The transformer supplies power to other components on the motor controller main control board, ensuring they operate under appropriate voltage and current.

▶ Power Protection: The transformer helps prevent overvoltage and undervoltage of the power supply, protecting the entire system from power anomalies.

The transformer plays a crucial role in the motor controller, ensuring stable and reliable power supply to the system, which is vital for the system’s performance and longevity. In designing the motor controller, the selection and layout of the transformer are critical for ensuring the system’s safety and stability.

06#

High-Speed Switching Diode

The BAV99 is commonly used in circuit designs to protect circuits from electrostatic interference and overvoltage, especially in automotive electronics and high-speed communication systems. Its design and functionality make it a reliable and effective ESD protection and voltage limiting component.

In the motor controller main control board, the high-speed switching diode is an electronic component primarily used to protect circuits from reverse voltage impacts and to help prevent overvoltage in switching power circuits.

The main features and functions of high-speed switching diodes include:

▶ Reverse Voltage Protection: When the voltage in the circuit reverses, the high-speed switching diode can quickly block reverse current, protecting other components in the circuit from damage.

▶ Overvoltage Protection: In switching power circuits, high-speed switching diodes can quickly respond to overvoltage situations, preventing damage to components in the circuit.

▶ Switching Speed: Due to their high-speed characteristics, high-speed switching diodes can switch quickly, with short response times, making them suitable for high-frequency circuits.

▶ Low On-Resistance: High-speed switching diodes have lower on-resistance, helping to reduce switching losses and improve system efficiency.

▶ Voltage Rating: Some high-speed switching diodes have high voltage ratings, capable of withstanding significant voltage fluctuations.

In the design of the motor controller, the selection and layout of high-speed switching diodes are crucial for ensuring system stability and reliability. They typically work in conjunction with the main control MCU, pre-driver IC, PMIC, transformer, and other components to achieve precise motor control and stable system operation.

07#

External Memory Chip

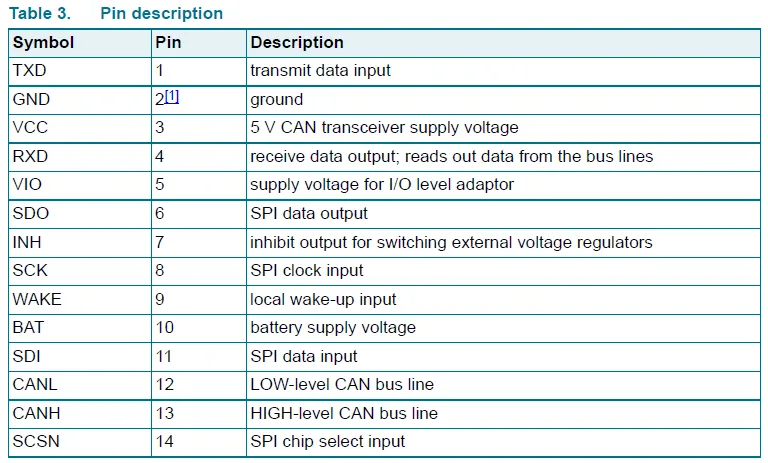

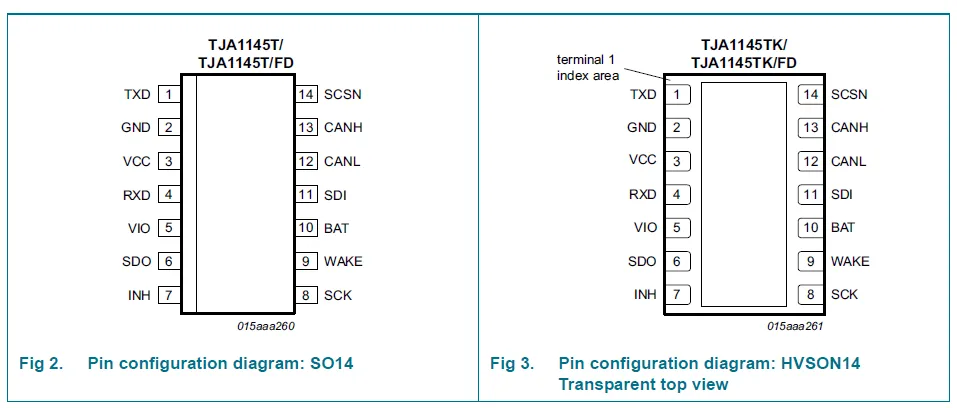

The Huawei DriveONE uses the NXP TJA1145TFD, a high-speed CAN transceiver that provides an interface between the controller area network (CAN) protocol controller and the physical two-wire CAN bus. This transceiver is designed for high-speed CAN applications in the automotive industry, providing differential signal transmission and reception capabilities for microcontrollers with CAN protocol controllers. The TJA1145TFD features ultra-low power consumption in standby and sleep modes and supports local area networking compliant with ISO 11898-2:2016, with selective wake-up functionality.

The TJA1145TFD product features CAN FD frame detection, preventing false wake-up situations. It also implements the current ISO11898 standards (ISO11898-2:2003, ISO11898-5:2007, and ISO11898-6:2013) and the upcoming updates defined in ISO 11898-2:2016. In CAN FD fast phase, reliable communication can be achieved even at data rates up to 2 Mbit/s.

Additionally, the TJA1145TFD provides an SPI interface for executing transceiver control and retrieving status information. When power is disconnected, the bus connection becomes a true floating connection. This product is suitable for 12V and 24V systems, offering SO14 and pinless HVSON14 packages, and has received AEC-Q100 certification, being a deep green product (halogen-free, compliant with the Restriction of Hazardous Substances (RoHS) directive).

The advanced ECU power management system of the TJA1145TFD includes ultra-low current standby and sleep modes, with full wake-up functionality, allowing the entire node to power down through output suppression, and supports local and remote wake-up functionalities. The I/O levels are automatically adjusted to the controller’s I/O levels, allowing the TJA1145 to connect directly to microcontrollers from 3.3V to 5V.

The TJA1145TFD also features protection functions such as 16, 24, or 32-bit SPI for configuration, control, and diagnostics, over-temperature warnings and shutdown, undervoltage detection and recovery for VCC, VIO, and BAT pins, and cold start diagnostics.

In summary, the TJA1145TFD is a high-performance, low-power CAN transceiver suitable for high-speed CAN applications in the automotive industry, providing reliable communication and effective power management.

In the motor controller main control board, the external memory chip is an important component used to expand the storage capacity of the main control MCU (Microcontroller Unit). External memory chips typically include Flash memory, EEPROM (Electrically Erasable Programmable Read-Only Memory), or other types of non-volatile memory.

Their main functions include:

▶ Storing Program Code and Data: External memory chips are used to store program code, data, and configuration settings that may not be suitable for or fit within the internal memory of the main control MCU.

▶ Data Backup: External memory chips can be used to store critical data, such as fault logs, configuration settings, and user data, for use in case of main control MCU failure or reprogramming.

▶ Expanding Storage Capacity: External memory chips provide additional storage space, allowing the main control MCU to handle more data and program code, thereby enhancing system performance and functionality.

▶ Improving System Performance: By storing data and program code in external memory chips, the main control MCU can access this information more quickly, improving system response speed and performance.

▶ Power Failure Protection: External memory chips are non-volatile memory, meaning that data stored will not be lost even if the system loses power.

In the design of the motor controller, the selection and configuration of external memory chips are crucial for ensuring system reliability and performance. They work in conjunction with the main control MCU and other components to achieve precise motor control and stable system operation.

08#

Electrostatic Protection Chip

The Huawei DriveONE uses the NXP PESD2CAN, a small SOT23 surface mount device (SMD) designed to protect two automotive controller area network (CAN) buses from electrostatic discharge (ESD) and other transients.

In the motor controller main control board, the electrostatic protection chip is an electronic component used to protect circuits from the effects of electrostatic discharge (ESD). Electrostatic discharge is a common source of damage in electronic devices, especially in conditions of low humidity or poor contact.

The main functions and features of electrostatic protection chips include:

▶ ESD Protection: Electrostatic protection chips can quickly absorb or divert electrostatic energy when electrostatic discharge occurs, protecting other sensitive components in the circuit from damage.

▶ Voltage Threshold: Electrostatic protection chips typically have a specific voltage threshold, and when the voltage exceeds this threshold, the chip quickly activates its protection function.

▶ Response Speed: Electrostatic protection chips have very fast response speeds, capable of activating protection functions within nanoseconds.

▶ Protection Range: Electrostatic protection chips can provide various levels of protection to meet different application needs.

▶ Passive Device: Most electrostatic protection chips are passive devices that do not require external power to operate.

In the design of the motor controller, the selection and layout of electrostatic protection chips are crucial for ensuring system stability and reliability. They typically work in conjunction with the main control MCU, pre-driver IC, PMIC, transformer, and other components to achieve precise motor control and stable system operation.

09#

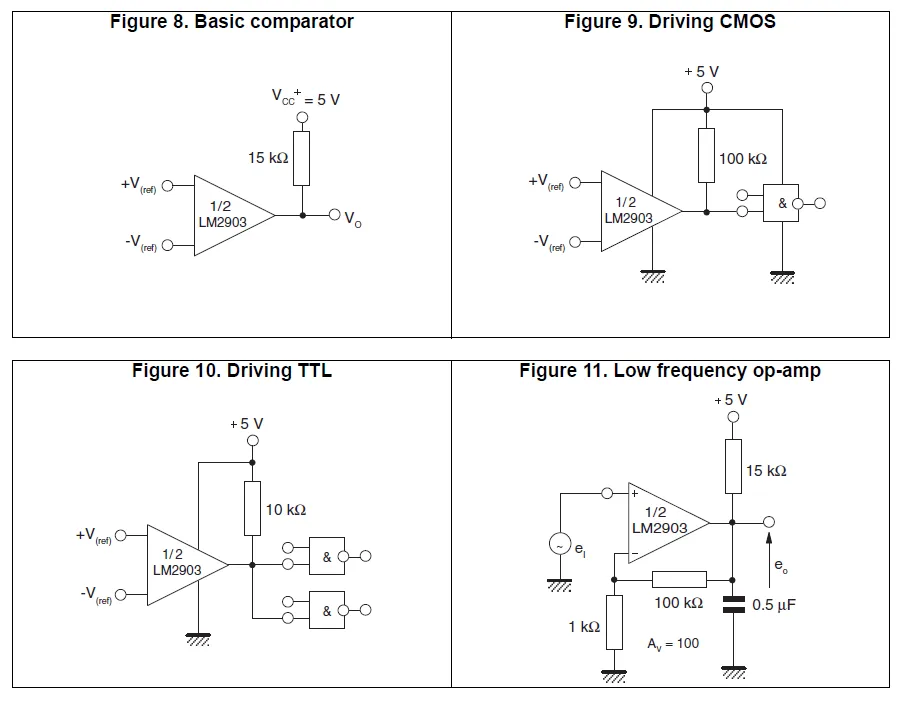

Comparator

The Huawei DriveONE uses the ST LM2903, a low-power dual voltage comparator that includes two independent low-power voltage comparators designed to operate from a single power supply over a wide voltage range.

This device has the unique feature of operating from a single power supply voltage while the input common-mode voltage range includes the negative power rail. Its parameter values include an input offset voltage of 7mV, input bias current of 250nA, and operating voltage of 1V to 18V or 2V to 36V.

In the motor controller main control board, the comparator is a key electronic component used to compare the levels of two voltages or currents and output the comparison results.

The main functions and features of comparators include:

▶ Voltage or Current Comparison: Comparators can compare the voltage or current at two input terminals and output a logic level signal indicating the relationship between the input signals.

▶ Threshold Setting: By adjusting the reference voltage of the comparator, the threshold can be set to detect voltage or current changes within a specific range.

▶ Signal Processing: Comparators are commonly used in signal processing circuits, such as waveform shaping, threshold detection, and limiting.

▶ Control Signal Generation: The output signal of the comparator can be used to generate control signals, triggering other circuits or executing specific operations.

▶ Anti-Interference Capability: Comparators typically have high anti-interference capabilities, allowing them to accurately compare signals in noisy environments.

In the design of the motor controller, the selection and layout of comparators are crucial for ensuring system accuracy and reliability. They typically work in conjunction with the main control MCU, pre-driver IC, PMIC, transformer, and other components to achieve precise motor control and stable system operation.

10#

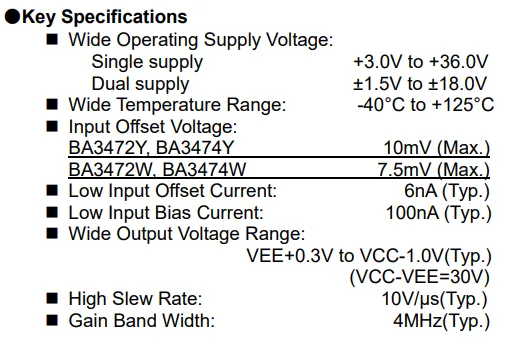

Operational Amplifier

The Huawei DriveONE uses the ROHM BA3472YF-C, a high-speed ground-sensing operational amplifier, belonging to the BA3472Y series.

The main features of this operational amplifier include:

▶ High-Speed Characteristics: It has a conversion rate of 10V/µs and a gain bandwidth product of 4MHz.

▶ High Gain: Provides high gain performance.

▶ Low Power Consumption: Designed with a focus on low power consumption.

▶ Wide Operating Voltage Range: Capable of operating within a voltage range of +3V to +36V (single supply) or ±1.5V to ±18V (dual supply).

▶ Built-in Phase Compensation Capacitor: Integrates 2 or 4 independent operational amplifiers and phase compensation capacitors on a single chip.

▶ Functional Safety: Suitable for automotive use, supporting functional safety analysis.

▶ Electrostatic Protection: Built-in electrostatic protection circuit, with human body model (HBM) up to ±5000V.

▶ Temperature Range: Capable of operating within a temperature range of -40°C to +125°C.

▶ Package Size: Uses a 5×6.2mm (t=1.71mm) package.

The BA3472YF-C is suitable for various applications requiring high-speed performance, high gain, and a wide operating voltage range, especially in automotive electronics.

In the motor controller main control board, the operational amplifier (op-amp) is a very important electronic component used to amplify electrical signals, perform analog signal processing, filtering, and other signal conditioning functions.

The main functions and features of operational amplifiers include:

▶ Signal Amplification: Operational amplifiers can amplify input signals, providing high-gain amplification.

▶ Signal Processing: Operational amplifiers can perform various signal processing tasks, such as filtering, oscillation, integration, and differentiation.

▶ Feedback Network: Operational amplifiers are typically used with feedback networks to achieve specific gain and frequency response.

▶ Precision: Modern operational amplifiers have high precision, providing stable gain and phase response.

▶ Anti-Interference Capability: Operational amplifiers typically have high anti-interference capabilities, allowing them to accurately process signals in noisy environments.

▶ Temperature Stability: The design of operational amplifiers considers temperature variations to ensure stable performance across different temperatures.

In the design of the motor controller, the selection and layout of operational amplifiers are crucial for ensuring system accuracy and reliability. They typically work in conjunction with the main control MCU, pre-driver IC, PMIC, transformer, and other components to achieve precise motor control and stable system operation.

11#

IGBT Module

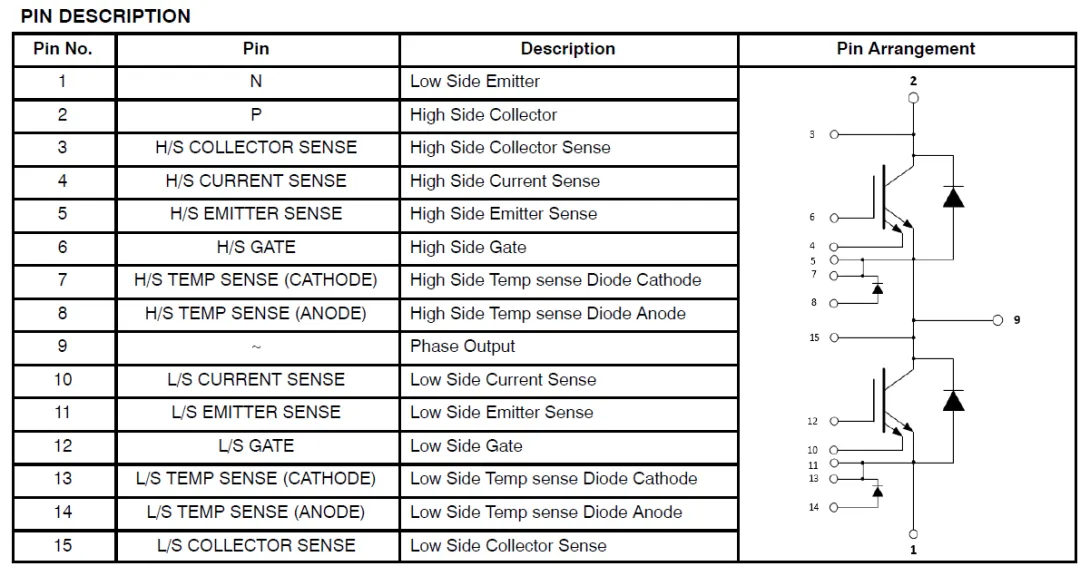

The Huawei DriveONE uses the ON Semiconductor NVG450A120L5DSC, the latest member of the VE-Trac Dual power module series, specifically designed for 800V bus voltage applications in hybrid electric vehicles (HEVs) and electric vehicles (EVs) traction inverters.

This module contains two latest 1200V Ultra Field Stop (UFS) IGBTs in a half-bridge configuration. The UFS IGBT chipset utilizes mature Trench Ultra Field Stop IGBT technology, providing high current density while offering robust short-circuit protection and higher blocking voltage. Additionally, the UFS IGBT and co-packaged soft diode enable soft switching during low-power operation, helping to improve the overall system efficiency of HEV/EV main drive applications.

The main features of this module include:

▶ Dual-side cooling;

▶ Integrated chip-level temperature and current sensors;

▶ Tvj max = 175°C;

▶ Automotive grade;

▶ Low conduction and switching losses.

This product is suitable for traction inverters in hybrid and electric vehicles as well as high-power DC-DC converters. Its design considers high efficiency and compact packaging, making it very suitable for electric vehicles and other high-performance applications. In the motor controller, the insulated gate bipolar transistor (IGBT) module plays a core role, with its main functions including:

▶ Switching Function: The primary function of the IGBT module is to control the current in the motor windings, enabling the motor to start, stop, accelerate, and decelerate. Through rapid switching, the IGBT module can precisely control the current and voltage in the motor, achieving accurate control of motor speed and position.

▶ Energy Conversion: In the motor controller, the IGBT module is responsible for converting direct current (DC) to alternating current (AC) to drive AC motors, or converting AC to DC for battery charging and other applications.

▶ Efficiency Optimization: The high efficiency characteristics of the IGBT module help reduce energy losses, improving the overall efficiency of the motor system. This is especially important in electric vehicles (EVs) and hybrid electric vehicles (HEVs), as the battery capacity and range of these vehicles directly benefit from high-efficiency energy conversion.

▶ Protection Features: IGBT modules typically include or integrate with external circuits to provide overcurrent protection, overheat protection, and other mechanisms to prevent damage to the motor and controller under abnormal conditions.

▶ Adaptation to Different Applications: The design of IGBT modules allows them to adapt to different types of motors and various operating conditions, including high current and high voltage applications.

▶ Thermal Management: Since IGBT modules generate heat during switching, they typically require effective heat dissipation solutions, such as heat sinks or liquid cooling systems, to maintain operating temperatures within safe ranges.

▶ System Integration: IGBT modules are closely integrated with other parts of the motor controller (such as microcontrollers, sensors, driver circuits, etc.) to implement complex control strategies, such as vector control or direct torque control.

In summary, the IGBT module is crucial in the motor controller, ensuring efficient and precise control of the motor while enhancing the reliability and performance of the entire system.

Disclaimer: The content of this article is sourced from Xiao Ling RIO Electric Drive. For sharing purposes only, it does not represent the position of this account. If there is any infringement, please contact the editor for deletion. Thank you!

Follow Official WeChat

Join Group Chat