In the field of industrial automation, the design and SMT processing of industrial controller PCBs are critical factors that determine product performance, quality, and cost. A deep understanding of the data details, yield influencing factors, and cost composition is essential for companies to optimize production and enhance competitiveness.

1. Specific Data of PCB Design

(1) Trace Width and Current Carrying Capacity

Generally, for industrial controller PCBs, a trace width of about 1mm is suitable for carrying a current of 1A. If the current increases, the trace width must also increase; for a current of 3A, the trace width should be approximately 2-3mm. This is because overly narrow traces generate excessive heat when carrying large currents, affecting the stability of the PCB and potentially burning out the traces. For example, in a high-power industrial controller, the initially designed trace width of only 0.8mm for carrying 2A current frequently caused failures after a period of operation. The issue was resolved by increasing the trace width to 1.5mm.

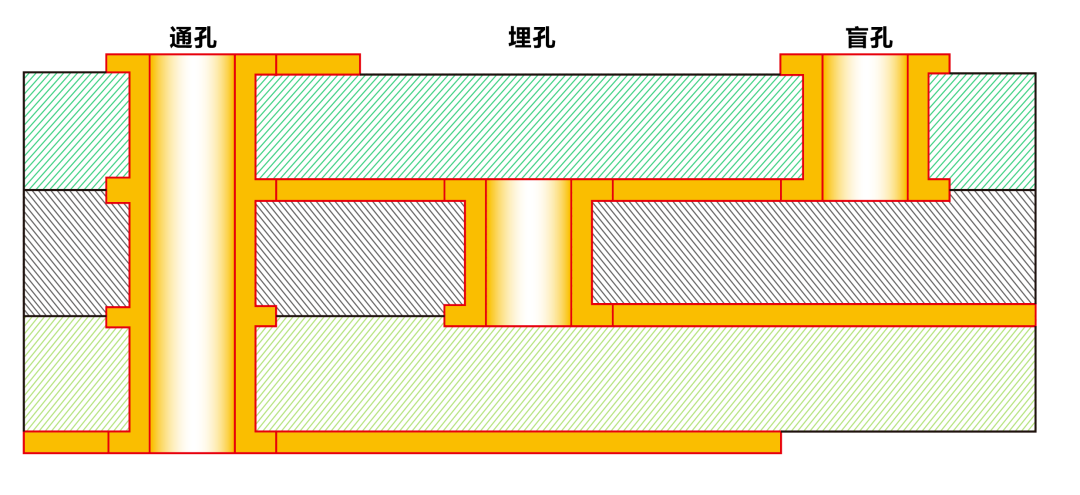

(2) Via Size and Signal Transmission

Vias serve as channels connecting different layers of traces on the PCB, and their size significantly impacts signal transmission. Typically, for PCBs designed for high-speed signal transmission, a via diameter of 0.3-0.5mm and an inner diameter of 0.1-0.2mm are recommended. Vias that are too small increase the resistance and inductance of signal transmission, leading to signal attenuation and delay; conversely, vias that are too large occupy excessive space, affecting routing density. In practical applications, such as industrial Ethernet controller PCBs, optimizing the via size from 0.2mm to 0.3mm significantly reduced the bit error rate of signal transmission.

2. Yield Analysis of SMT Processing

(1) Relationship Between Equipment Precision and Yield

High-precision SMT machines play a key role in improving the yield of SMT processing. For example, a certain brand of high-end SMT machine has a placement accuracy of ±0.05mm, which can improve the yield by 10%-15% compared to a standard SMT machine with an accuracy of ±0.1mm when placing 0402 and smaller components. This is because high-precision equipment can more accurately place components on the PCB pads, reducing misalignment and other defects.

(2) Impact of Process Parameters on Yield

The soldering temperature, time, and other process parameters in SMT processing are crucial. In reflow soldering, the peak temperature is generally controlled between 230-250°C, and the soldering time should be around 60-90 seconds. If the temperature is too high or the time is too long, it can lead to component damage and cold solder joints; if the temperature is too low or the time is too short, the soldering will not be secure. A company producing industrial controller PCBs increased the soldering temperature from 240°C to 260°C, resulting in a sharp drop in yield from 90% to 75%. The yield only returned to normal after adjusting back to the appropriate temperature.

3. Cost Analysis

(1) Design Costs

The cost of PCB design mainly includes labor costs and software tool costs. A senior PCB designer’s monthly salary is about 20,000-30,000 RMB, and completing the design of a medium-complexity industrial controller PCB usually takes 1-2 months. Additionally, professional design software like Altium Designer costs tens of thousands of RMB for a legitimate license. Overall, design costs range from tens of thousands to hundreds of thousands of RMB, depending on the complexity of the design and labor input.

(2) SMT Processing Costs

SMT processing costs encompass equipment depreciation, material loss, labor costs, etc. A high-end SMT machine costs between 500,000-1,000,000 RMB, and the annual depreciation cost is significant when calculated over a lifespan of 5-8 years. Material loss mainly includes solder, adhesive, etc., costing about 0.5-1 RMB per PCB. Labor costs vary by region and factory size, averaging 20-50 RMB per hour. For producing 1,000 PCBs, the SMT processing cost is approximately 10,000-30,000 RMB.

Every aspect of the design and SMT processing of industrial controller PCBs is closely related to data, yield, and cost. Companies must accurately grasp these key points and continuously optimize design and processing workflows to stand out in the fierce market competition.

Do you also pay attention to these data, yield, and cost issues in the design and SMT processing of industrial controller PCBs? Do you have unique experiences or confusions? Feel free to leave a message to share, and let’s discuss together!

Editor

Editor

Xiao Zhen Huang

Reviewer

Mei Li

Official Account

htcx2012

Phone

18911726991 (WeChat synced)

Official Website

www.htcxpcb.com

Address

4th Floor, Middle Staircase, Building B5, Yijing Industrial City, Tianliao Community, Yutang Street, Guangming District, Shenzhen, Guangdong Province

Official Account QR Code

Official Account QR Code Video Account QR Code

Video Account QR Code Official Website QR Code

Official Website QR Code

Disclaimer: The content shared on this platform comes from the internet, WeChat public accounts, etc. We maintain neutrality in our opinions and judgments, and it is for readers’ reference and learning only. The final ownership of the above statement belongs to the original author. If there is any infringement, please contact us for deletion to avoid unnecessary losses for both parties.