Follow and “pin” us for more learning knowledge!

Longfeng focuses on providing the best intelligent industrial control training!

National chain – After registration, you can study at any campus!

How to Learn Programmable Logic Controllers (PLC)?

Longfeng’s philosophy: “Empowering millions of electricians and beginners to master PLC programming and engage in programming work!”

Warm congratulations on Longfeng’s 17th anniversary! Launching a peak gratitude event worth 16,888 yuan!

Content to master: How to learn programmable logic controllers (PLC)?

Learning Siemens PLC is not as difficult as imagined, summarized in one sentence: For beginners, the SR20 with over 600 meters is sufficient, If detailed, it involves the hardware composition of PLCs, programming software, system instructions, and program structure, Next, I will introduce the key points of learning PLC from the aspects of PLC selection, PLC entry, and PLC expansion modules and advanced topics.

1. Selection and Cost

Recommendation: SR20, Reason for recommendation:

This starts with the Siemens PLC product family, Siemens has been making PLCs for over 40 years, and the latest product family is the SIMATIC S7, Siemens has launched different product series for various market needs, such as the high-end S7-1500 series, mid-range S7-1200 series, and low-end S7-200 SMART (hereinafter referred to as SMART) series.

For beginners, starting with the SMART series is the most suitable, SMART is a new generation PLC developed by Siemens for the Chinese market, widely used in packaging, textiles, machine tools, food, subways, and many other fields, It can effectively improve equipment performance and reduce costs, offering excellent cost-performance ratio and reliability, SMART is mainly divided into two major series: ST and SR, The primary difference between the SR series and ST series is that the ST series can receive/output high-speed pulse signals, Therefore, the ST series can be applied in motion control, common packaging production lines, and currently popular robotic arms, etc. Generally, these functions are not used during the learning phase, Moreover, there is no difference in programming and usage between ST and SR, and communication between them is also very easy to achieve.

In the SR series, for beginners, I highly recommend SR20.

Reason 1: High cost-performance, available from Siemens dealers on major e-commerce platforms, priced at only over 600 meters;

Reason 2: Configuration software is free, low learning and migration costs;

The configuration software for the SMART series (commonly referred to as the upper computer) is STEP 7-Micro/WIN SMART (abbreviated as Micro/WIN), The design concept of Micro/WIN is consistent with the configuration software TIA Portal of the other two high-end PSC series, S7-1200 and S7-1500, and supports mutual communication with S7-1200 and S7-1500, If in the future you need to learn Siemens’ mid to high-end PLC product series, the learning and migration costs will be very low.

The true face of the SR20 PLC, Next, let’s take a look at the appearance of the SR20 PLC.

A: The blue wire is the network cable for communication between Micro/WIN and PLC;

B: The top row of terminals is the signal input terminals and power supply terminals;

C: The bottom row of terminals is the output terminals and power supply terminals for the expansion module;

D: The lower left corner is the RS485 interface;

E: There are some identification information on both sides, such as order number, FS number, etc.;

In summary, the cost of learning PLC:

1. Purchase SR20: 600 meters;

2. Configuration software is free;

3. SR2 can be powered directly by 220V power supply or can use 24V power supply. From a safety perspective, it is recommended to use the 24V power supply, I once used an SR20 with some external devices to create a fully automated small irrigation system, with a total cost of no more than 1000 meters, Interested friends can see the simple design scheme and wiring method later.

2. PLC Entry

PLC is a highly integrated system, in actual work, only some functions may be used, but during learning, it is necessary to comprehensively understand the functions of PLC, the SMART PLC is a very good entry series, as mentioned earlier, the operation tool for SMART PLC is Micro/WIN, We will also exchange experiences in learning SMART PLC internally, and the general feeling is that the learning cost of the SMART series is very low, When designing the functions of the SMART PLC, we prioritize ease of use, so even without programming experience, one can become familiar with most of the functions of PLC products in a short time.

High cost-performance, easy to use, and reliable, this is one of the reasons why the SMART series is so successful in China, There are many books available on what to learn about PLC, and I won’t elaborate here, while regarding the tutorial for operating Micro/WIN, the following websites also have introductory operation video courses, all of which are free, www.pxplc.com, www.uy123.net, Long-term exposure to PLC, I have a few efficient learning tips to share with everyone, These tips are easily overlooked, but they are very important for beginners.

1. Set PG/PC Interface

When first installing Micro/WIN, you need to set the PG/PC interface, the SR/20 integrates a standard Ethernet port, allowing direct communication between the PC’s physical network card and the PLC, so there is no need to purchase expensive and low-speed PPI cables, What is PG/PC interface? Many students who are new to Siemens PLC have such doubts, PG/PC actually refers to the computer, and speaking of this, there is a small story about the PLC being “forced to change its name”.

In the 1970s, PLC was not called PLC, it was called PC, the original term was “programmable controller” meaning “programmable controller”; but later the personal computer (Personal Computer) became dominant and was also abbreviated as PC, leading to confusion, so the programmable controller had to be “forced” to change its name, adding the word “Logic” to “programmable controller”, becoming “Programmable Logic Controller”, abbreviated as PLC, while PG originally meant “Programmer”, which means “programmer”, actually referring to the computer.

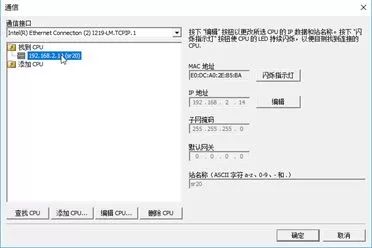

Next, in the Access Point of the Application, select MWSMART, meaning we need to set a network interface for Micro/WIN to connect to the PLC, and select the wired Ethernet port from the list.

2. Connect and Set PLC

When connecting to the CPU, first select the communication interface, here select the physical network card, which serves the same purpose as the above PG/PC setting, click “Find CPU”, and the SR20 will respond to the command and send identification information to Micro/WIN.

Select SR20 and click OK, Micro/WIN and PLC will successfully establish a connection, and through “Edit” you can set the PLC’s identity information, and through “Blinking” the indicator light, you can make the PLC’s LED lights blink alternately, Here, it should be mentioned that for SMART, “CPU” and “PLC” refer to the same thing, so there is no need to be confused.

3. View and Set More Information

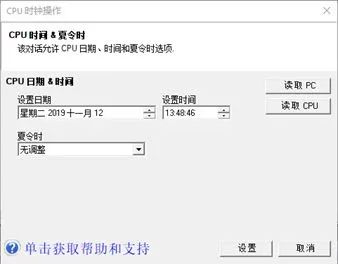

Once connected to the PLC, you can start operating the PLC, Many people do not know where to set the time, you can set the time by selecting “Set Clock” in the “PLC” menu.

The clock setting operation generally only needs to be performed when first connecting to the PLC, the PLC has an independent clock that can maintain for 7 days when powered off, and the PLC will also correct clock errors in real-time during operation, even after running for several years, the error will not exceed 2 seconds, in small PLCs this is a very high precision, In an automated system, one of the steps we often perform is to check whether the system is currently running normally, what the performance status is, and whether there are any alarm messages, All of these are in the “PLC” function block under the “PLC” menu, and during the debugging and operation of the PLC, we will often open this interface to check the operation status of the PLC.

4. Debugging and Simulating PLC

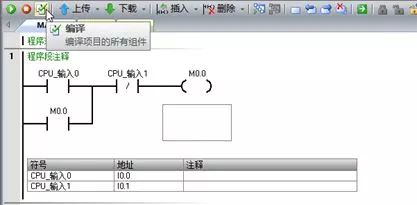

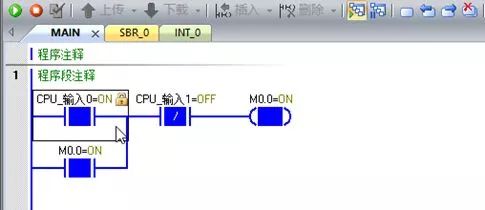

The debugging and simulation function is a very important feature of Micro/WIN, this function is very practical and easy to operate, it can conveniently simulate parameters that cannot be generated during actual operation, allowing operators to discover problems in programs and configurations in advance, and generate optimal parameters, effectively reducing system risks, However, often some experienced engineers do not know or cannot use this function, so I will elaborate on it here, Below is a simple ladder diagram for a start-stop circuit, and these instructions can be added through the “Instruction” directory in the left project tree.

The blue indicates that energy can flow, the gray indicates that energy cannot flow, from the figure, it can be seen that since the input terminal corresponding to I0.0 did not detect a high level, the value of this input impression area I0.0 is 0, the contact is open, so energy cannot flow to the back, and M0.0 is also not connected, remaining in an open state, If the input terminal corresponding to I0.0 is not connected to the electrical signal, then how to debug? Micro/WIN has a powerful tool, the “Status Chart”. We write to I0.0 and then click the monitoring button, we can see that the value of I0.0 is 0, then give it an input value of 1, and then click the “Force” button next to the monitor, and try again.

It can be seen that I0.0 has been forced to 1, the PLC no longer detects electrical signals from the input terminal, but reads the written value as I0.0, and forced operations can be executed on all accessible memory areas, which is very useful for debugging, Below is the state of the program after forcing:

M0.0 is closed, canceling the force on I0.0 and observing again, will see that M0.0 is still in a closed state, this is the function of the start-stop circuit.

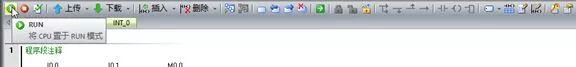

It should be noted that when the user is in monitoring mode, system blocks, wizards, and other functions cannot be operated, if you click a button and Micro/WIN does not respond, it is mostly because you are currently in monitoring mode, As shown below, add two more instructions and then download them to the PLC.

Then monitor the program running status, When I0.0 is forced again, Q0.0 immediately becomes 1, and you can hear the sound of relay Q0.0 closing, If a load, such as a motor or lamp, is connected to the PLC, then the device will start running immediately.

Here, let me explain how to wire:

Step 1: Connect the positive terminal of the 24V power supply to the output terminal of SR20, 1L;

Step 2: Connect the positive input of the load (such as a motor) to the output terminal like Q0.0;

Step 3: Connect the negative terminal of the 24V power supply to the negative input of the load;

If there are multiple loads, then connect from Q0.1 to Q0.7, each output terminal can carry a maximum current of 2A, so be careful not to overload, On the other hand, there are a total of 8 Q points, divided into two groups, Q0.0-Q0.3, all need to be connected to the 24V switch power supply through the input terminal 1L, If you need to connect more loads, then you need to power the input terminal 2L, connecting through Q0.4 to Q0.7 to the load.

3. Expansion Modules and Advanced Learning

Expansion Modules: The reason SMART has a high cost-performance ratio is that it integrates only core functions, for personalized automation projects/product functions, it is realized through expansion modules, So customers do not have to pay for unnecessary features, The directory of SMART’s expansion modules can be viewed in the online help document, The installation of expansion modules is also very simple, the rectangular plastic piece on the right side of the PLC can be pried off, and the position for inserting the module is behind it, After inserting the module, select the newly inserted expansion module in the “System Block” EM row to complete the configuration.

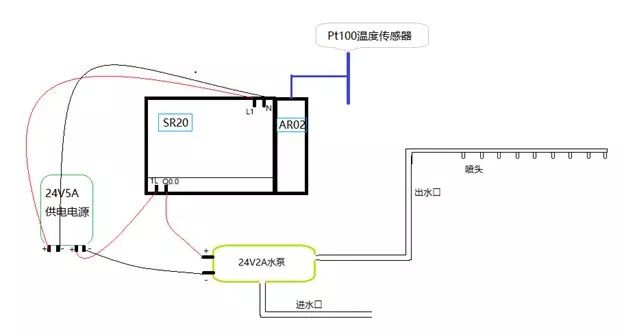

The most common module is AR02, the fully automated agricultural irrigation system I mentioned above was realized using the AR02 expansion module, Applying what has been learned, The AR02 expansion module is specially designed for temperature detection, It does not require additional power supply, the two terminals L+ and M under the 24VDC text on the lower right of the PLC can power it, Add a temperature sensor Pt100, connect it to the input terminals on AR02, After the wiring is complete, read real-time temperature through AIW16, and process differently based on temperature in the program, In this way, a fully automated agricultural irrigation system is completed.

The simplified design scheme for this fully automated agricultural irrigation system is as follows:

1. Hardware devices used in the simplified version:

A: One Pt100 to collect real-time temperature;

B: One AR02 expansion module to receive and process data from the temperature sensor;

C: One SR20 controller to process user programs;

D: One 24V2A water pump;

E: Water pipes and spray heads, purchase as needed;

F: PVC plastic pipe for fixing water pipes and spray heads (this is not mandatory);

G: One 24V5A power supply to power the controller and water pump;

H: Other items such as wires, brackets for fixing the PLC, etc., purchased as needed;

2. Wiring diagram: The detailed wiring method has been covered in the second part, the schematic diagram of the simplified version is as follows:

3. Expansion Training:

Expansion 1: Different plants often have inconsistent water needs, and can irrigate more plants by adding pumps and modifying programs;

Expansion 2: Connect heating equipment (such as a heater) instead of a water pump, automatically adjust indoor temperature based on air temperature;

Expansion 3: PLC can communicate with any device that supports networks (standard TCP/IP) through OUC, such as communicating with a PC, allowing machine learning or neural network programs (e.g., face recognition) to be executed on the PC, sending the actions to be executed to the PLC;

Returning to the original question, if you want to learn PLC better, one way is to apply what you have learned, everyone might as well try during the learning process, This fully automated agricultural irrigation system is just a starting point, PLC can support very complex functions, such as motion control, high-speed counters, Profinet, etc., all of which are under the “Wizard” directory in the left project tree of Micro/WIN, Once familiar with the functions under the Micro/WIN wizard, you can even use SR20 to build an automated production line.

4. Summary

1. It is recommended to choose SR20 as the entry-level PLC product, low cost, strong usability, free software, and strong expandability;

2. To learn PLC, you can use the free Micro/WIN software, there are online help manuals, Free tutorials【www.pxplc.com, https://www.uy123.net】, and the above text also introduces operations that are not commonly seen in regular tutorials;

[END]

[Longfeng Training Academy]

Building a nationwide chain of PLC and industrial robot offline training campuses!

It has the largest live broadcast platform for PLC and industrial robots in the country – [Youyi Classroom]!

National learning hotline: 400 900 2286

Article: Warm congratulations on Longfeng’s 17th anniversary! Launching a peak gratitude event worth 16,888 yuan!

Article: Why many electricians hope to engage in PLC

Article: Differences between FB and FC in Siemens PLC, pin definitions, temporary variables

Article: Concept design solution for mechatronics products of Siemens NX MCD

Article: Japan: We never do equipment maintenance!

Article: Comprehensive instruction manual for Siemens and Mitsubishi, only by gathering them can you realize PLC programming is so easy!

Article: 14 major taboos in distribution box installation, be sure to pay attention!

Article: Two basic circuits that every electrician must master

Article: Beginner’s suggestions for learning PLC programming

Article: How to learn PLC, a few suggestions for PLC learning

Article: Understanding electricity, a brief analysis of PLC

Article: A complete list of commonly used PLC models and introductions, essential skills for selection!

Article: Introduction to Mitsubishi fx5u model

Article: Address allocation of Omron PLC

Article: More differences between EPLAN and CAD?

More articles: What are the anti-interference strategies for PLC and touch screens?

More articles: A good PLC program must meet these 6 standards!

More articles: How to achieve encoder positioning function using PLC

More articles: [May Day] Online learning of PLC and robots, take equipment home for programming practice!

More articles: How to download programs using Ethernet for Mitsubishi PLC

More articles: Take PLC training equipment home for free debugging practice!

More articles: How to choose pulse, analog, and communication control methods for servo motors?

More articles: Understanding PLC in one article

More articles: How should electricians learn and develop?

More articles: 43 questions every qualified electrical engineer should remember

More articles: How to choose thermocouples and thermal resistors in project chapters?

More articles: Key points are here!!! Process for applying for subsidies for special operations certification!

More articles: Upgrading from zero foundation to engineer and eventually becoming a CEO!

More articles: Assembly and debugging skills for non-standard automation equipment!

More articles: Experts write PLC programs, focusing only on these two points!

More articles: How to select the size of the circuit breaker in a project? How to choose? No need to hesitate!

More articles: PLC, mobile APP remote monitoring, mechanical/electrical 3D design courses

More articles: Introduction to PLC wireless communication

More articles: Warm congratulations on the establishment of a new campus for Longfeng Academy – Henan Campus

More articles: Latest | Hot recruitment for “PLC, industrial robots, electrical engineers” talents!

More articles: 100 key automation technology issues and solutions!!!

More articles: Advantages and disadvantages of flow meters, thermometers, pressure gauges, and level gauges

More articles: Complete technology, drawings, and talent training for mask machines

More articles: Mobile APP control PLC and touch screen courses

More articles: Electrical and industrial robot engineer job fair!

More articles: Latest | Hot recruitment for “Electrical/Robot Engineer” positions!

More articles: Take you into the world of electrical drawings

More articles: Layout and structural design of PLC control cabinets

More articles: How to choose A, B, C, D types of miniature circuit breakers? No need to hesitate

More articles: Low voltage test pens play a big role

More articles: 20 sensor principles and application animations

More articles: Common faults and handling methods for field instruments and valves

More articles: Common faults of air compressors, pneumatic knowledge

More articles: ABB robot data

More articles: Analysis of maintenance and troubleshooting of Fanuc robots

More articles: S7-1200 diagnosis methods

More articles: In the era of positioning, where will stepper motors go?

More articles: Types and applications of proximity switches

More articles: PLC engineers teach you to do projects hand in hand

More articles: Why electricians and maintenance workers must learn PLC

More articles: Understand in one article | Machine vision technology

More articles: Knowledge of electrical protection for electrical control cabinets

More articles: Practical engineering project site training in electrical and automation!

More articles: Comprehensive intelligent training equipment and training rooms for PLC and industrial robots!!

More articles: Limited time download | Latest “Siemens S7-1200 programming video” download

More articles: Methods to reduce interference in project design

More articles: Easy download of industrial control learning videos (II)

More articles: Happy May Day, learning is glorious!

More articles: C language industrial control script programming (I)

More articles: Easy download of industrial control learning videos (I)

More articles: Pneumatic triplets in air control!

More articles: Hot recruitment for “Electrical/Robot Engineer” positions!

More articles: Easily master what type of solenoid valve is a few-way valve!

More articles: The impact of 5G on the industrial field!

More articles: Various communication methods between “industrial robots” and “PLC”!

More articles: Functional descriptions and project selection for Siemens S7-1200

More articles: Functional descriptions and project selection for Siemens S7-300 CPU

More articles: Application of Siemens Smart 200 PLC in actual projects

More articles: The most comprehensive PLC brands currently, please keep this!

More articles: Communication functions of the integrated Ethernet interface of S7-1200

More articles: Excellent engineers never “settle”

More articles: DCS control system

Longfeng Automation Training Academy builds a (offline + online) national chain, with more guaranteed quality, a national high-tech enterprise, has been running schools since 2004, for nearly 20 years, always placing the content of learning and the quality of students’ learning first, always emphasizing that students must complete project design from beginning to end after graduation, independently complete project design, and engage in PLC programming design and industrial robot programming design work.

Seize 2021, achieve your brilliant life as a PLC and industrial robot programming engineer!

Longfeng’s philosophy: “Empowering millions of electricians and beginners to master PLC programming and engage in programming work!””

Currently available:

Dongguan Campus: 15362688065/18826957421

Foshan Campus: 18929988716/18988544828

Guangzhou Campus: 13922269164/18620092368

Shenzhen Campus: 18126479989/18948720169

Chongqing Campus: 19923710765

Henan Campus: 13543720626

Wuhan Campus: 18071702297

(Mobile and WeChat same number, you can add WeChat for consultation!)

Students from various campuses can arrive at the school in advance, check in early, and receive materials for preview! Longfeng focuses on providing the best intelligent industrial control training! With one payment, you can study at any campus with senior circular learning, national chain lifetime service, Longfeng is your golden guarantee for achieving the dream of becoming an automation programming engineer!

[Longfeng Academy] July class opening times

Dongguan Campus: July 1

Foshan Campus: July 5

Guangzhou Campus: July 12

Shenzhen Campus: July 19

Chongqing Campus: July 5

Wuhan Campus: July 31

Henan Campus: July 31

[Robot Elite Class]

July 5

August class opening times

Dongguan Campus: August 2

Foshan Campus: August 9

Guangzhou Campus: August 16

Shenzhen Campus: August 23

Chongqing Campus: August 2

Wuhan Campus: August 31

Henan Campus: August 31

Click the QR code to add the teacher’s WeChat for more detailed course content consultation!

If you find the above content helpful, please help share it on your WeChat Moments, thank you very much!