Banner | Promotion

Author | Guan Er (Jihua Laboratory)

Do you remember the 2012 movie “CZ12” starring Jackie Chan? One segment vividly showcases a futuristic technology concept of scanning and replicating three-dimensional animal heads — 3D printing. In the real world, the pace of technological advancement is unstoppable.

Recently, General Electric in the United States is integrating parts made through 3D printing into jet engines, and a space company claims to use this technology to manufacture all components of rockets with plans for a fully 3D printed rocket launch in 2022. Our country also successfully completed its first space 3D printing last year, which is of great significance for the expansion and long-term operation of the space station. 3D printing technology is showing extraordinary development potential and vitality.

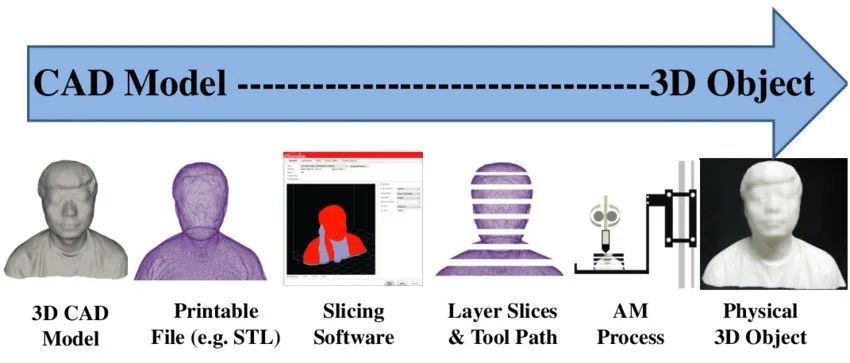

3D printing technology is also known as additive manufacturing, a technology that builds real three-dimensional objects by layering adhesive materials based on a digital model file. As one of the “12 disruptive technologies that will determine the future economy” and the engine of the third industrial revolution, 3D printing marks a significant industrial transformation from traditional manufacturing to intelligent manufacturing, triggering a new wave of technological revolution.

Compared to traditional manufacturing technologies, 3D printing technology features characteristics such as “no molds, reduced waste, and lowered inventory”, optimizing structures, saving materials, and conserving energy in production. It greatly improves manufacturing efficiency, realizing the innovative concept of design-driven manufacturing.

Looking at the history of 3D printing technology, its origins can be traced back to 1984 when American scientist Charles Hull invented stereolithography (SLA). Subsequently, technologies such as selective laser sintering (SLS), selective laser melting (SLM), and three-dimensional printing and gluing (3DP) gradually emerged.

Since the 21st century, 3D printing technology has made new breakthroughs, officially entering a phase of rapid development globally, and various innovative sub-techniques have emerged under the subdivision of major technologies to meet the specific needs of various industries, forming an effective complement to traditional manufacturing.

Classification of 3D Printing Methods

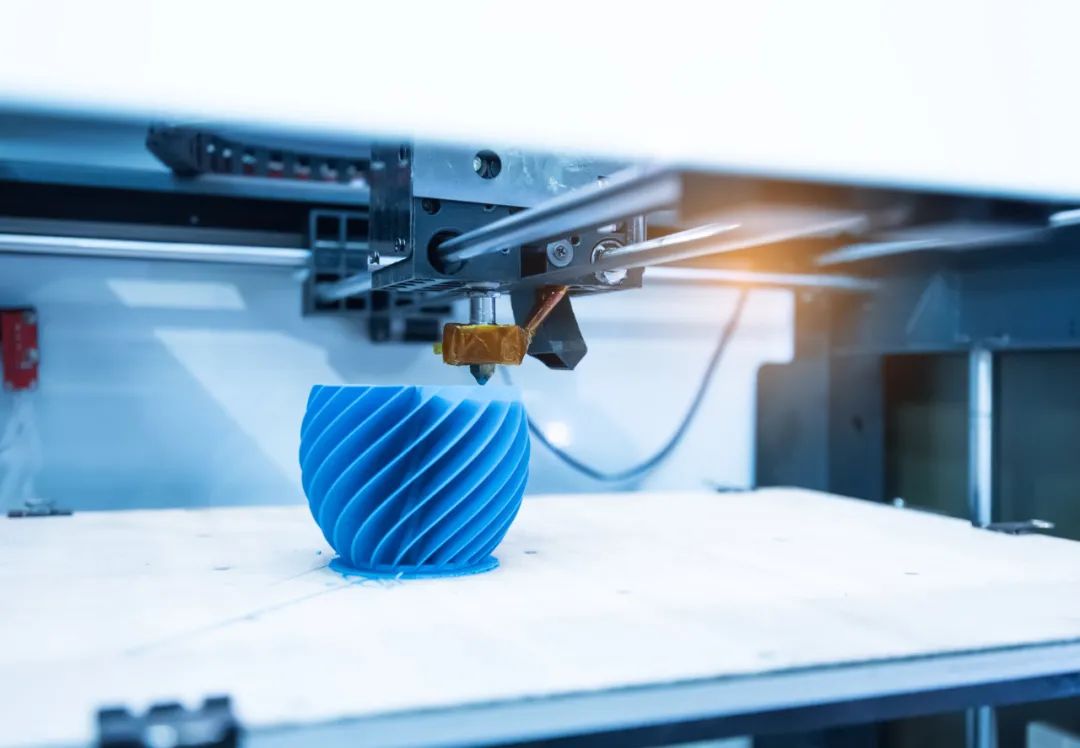

1. Material Extrusion

Material extrusion

Deposits materials selectively through nozzles or openings. For example, fused deposition modeling (FDM) is the most intuitive and common printing method. During printing, the device heats and melts filament thermoplastic materials, extruding and selectively depositing the material onto a platform through a nozzle with a fine tip, forming a layer of cross-section as it cools, and printing layer by layer until the entire entity is formed. The printing materials mainly include polymers and plastics, such as polylactic acid (PLA), thermoplastic polyurethane (TPU), and acrylonitrile-butadiene-styrene (ABS).

-

Advantages: Low cost of equipment and materials, wide range of materials, and high strength of printed products.

-

Disadvantages: Lower printing precision and greater surface roughness of printed samples.

2. Vat Photopolymerization

Uses specific wavelengths of light for selective photopolymerization of liquid polymers. The materials used in this technology are photosensitive resins, which undergo a phase change from liquid to solid when exposed to light, thus achieving the printing process. Depending on the type of light source, irradiation method, and forming method, it can be divided into stereolithography (SLA) and digital light processing (DLP), each with different principles and printing processes. SLA uses lasers to scan the liquid resin surface point by point, curing in a point-line-plane order to complete a layer, and combining with the movement of the forming platform to layer by layer construct a three-dimensional entity. DLP, on the other hand, uses full-area exposure to form a layer, with the light source often being LED ultraviolet light, and the exposure pattern for each layer generated by digital dynamic mask chips or spatial light modulators.

-

Advantages: High processing precision, smooth surface of printed products, and high efficiency of full-area exposure forming. -

Disadvantages: Limited range of materials and weaker material performance.

Video 1: Stereolithography

3. Directed Energy Deposition

Utilizes focused thermal energy to melt materials in a melt-and-deposit process. This mainly includes laser engineered net shaping (LENS, LBMD, LSF) and electron beam direct manufacturing (EBDM), often used for constructing or repairing existing structures. The process involves a laser beam or other energy source creating a melt pool in the deposition area and moving at high speed, with a nozzle feeding filament or powder materials (such as titanium and cobalt-chromium alloys) into the high-temperature zone to be heated to melting point, depositing layer by layer after melting. The nozzle or working platform is mounted on a highly movable arm for high flexibility in movement.

-

Advantages: No support needed, high processing flexibility, and can achieve high-efficiency preparation and repair of components.

-

Disadvantages: Surface precision is limited, formed samples require post-processing (e.g., with milling machines), and it is difficult to repair structurally complex parts.

Video 2: Laser Engineered Net Shaping

4. Material Jetting

A three-dimensional evolution of 2D inkjet printers. Material jetting can be divided into continuous material jetting (CMJ), nanoparticles jetting (NPJ), and drop-on-demand (DOD). The basic principle is to accurately position the ejected material on the printing platform using charged deflection plates and electromagnetic fields, and solidifying it using ultraviolet light. Material jetting is very similar to the aforementioned stereolithography (SLA), except that the former can eject hundreds of tiny droplets at once, while SLA cures point by point in a vat of resin using lasers. The ejected photosensitive liquid droplet materials include polymers and plastics, such as acrylonitrile-butadiene-styrene (ABS) and polypropylene (PP).

-

Advantages: Achieves highly precise full-color rapid printing, enhancing the aesthetic quality of prototypes and final components.

-

Disadvantages: Limited range of materials, expensive, and requires post-processing to remove excess material.

5. Binder Jetting

Also known as three-dimensional printing and gluing (3DP), it achieves powder forming through binder jetting. The main process involves placing powdered materials such as ceramics or polymers into a container, using an inkjet print head to spray adhesive onto the powder, similar to how sand mixed with water forms a stronger structure. A layer of powder bonds in the selected area, and this process is repeated, with the next layer of powder bonding with the previous layer through the penetration of the adhesive, forming layer by layer. When using metals and ceramic materials, high-temperature sintering is required to remove the binder and achieve metallurgical bonding between powder particles, giving the finished product certain strength and density.

-

Advantages: High forming efficiency, can print different colors in the same batch, and does not require support structures.

-

Disadvantages: High roughness, lower density of formed parts, and requires post-processing for metals and ceramics (e.g., debinding and sintering), while polymers may require additives like wax to increase structural strength.

Video 3: Binder Jetting

6. Powder Bed Fusion

This is another powder bed-based method, mainly used for printing metal parts. Unlike the previously mentioned printing methods, powder bed fusion does not involve depositing binders for printing, with major representatives being selective laser sintering (SLS), selective laser melting (SLM), and electron beam selective melting (EBSM). The process of powder bed fusion generally involves using a powder roller to evenly coat the powder material stored in a hopper and reservoir onto the surface of the printing platform. In a vacuum environment, high-power lasers or electron beams are used to melt and sinter the powder, binding it together, and then another layer of powder is coated for the next sintering until the entire entity is formed. Among them, electron beam selective melting preheats the powder bed, with the temperature in the entire chamber reaching up to thousands of degrees, significantly reducing the residual stress of the formed parts; SLS requires additional binders like low-melting-point metals or resin materials.

-

Advantages: High precision, can print various materials including metals (such as titanium, aluminum, copper, stainless steel, and high-temperature alloys), ceramics, and nylon.

-

Disadvantages: High cost, prone to warping when printing large objects, and slower speed.

Video 4: Selective Laser Sintering

7. Sheet Lamination

Involves cutting materials with a laser and bonding them together using adhesives or welding to form solids. Unlike the other methods listed above, sheet lamination printing technology can use materials other than metal sheets, even paper and almost any other material that can be rolled. Sheet lamination mainly includes laminated object manufacturing (LOM) and ultrasonic additive manufacturing (UAM). LOM uses glue to bond multiple layers of paper and cuts them with sharp knives without heating or melting. The cutting method for each sheet of paper is slightly different. UAM uses ultrasonic welding machines to bond metal sheets or metal strips, with each metal layer being rolled onto the growing structure, providing a significant technical advantage due to its low temperature, suitable for temperature-sensitive low-melting-point materials.

-

Advantages: Fast forming speed, high precision, and minimal warping.

-

Disadvantages: Poor interlayer adhesion, obvious anisotropy in structural strength of formed samples, low material utilization, and can only make simple structural components.

Driven by significant R&D investments in the scientific and industrial sectors, 3D printing aims to upgrade manufacturing with innovation, introducing depth and breadth from the application end to empower and create revolutions in downstream industries, covering fields including aerospace, automotive, marine, energy, medical, cultural creativity, and architecture.

In the aerospace and energy sectors, recently, Arris Composites in the US has collaborated with Airbus to focus on mass production in the 3D printing carbon fiber composite market, creating lightweight cabin brackets; Solvay has partnered with OEM 9T Labs to introduce 3D printed carbon fiber reinforced plastic parts into mass production for medium and small-sized components required in aerospace, automation, and oil and gas industries.

Looking back domestically, the 3D printing industry is experiencing rapid development under the guidance of “Made in China 2025”, aiding the swift development of domestic commercial rockets. In February 2021, Chongqing Yiling Space first used 3D printed attitude control power system products for flight; in July 2021, the Deep Blue Aerospace liquid rocket, manufactured using 3D printing, successfully completed a low-altitude vertical recovery flight test. It can be seen that 3D printing has spawned a new track in rocket manufacturing and is gradually becoming an important supporting technology in the rocket manufacturing process.

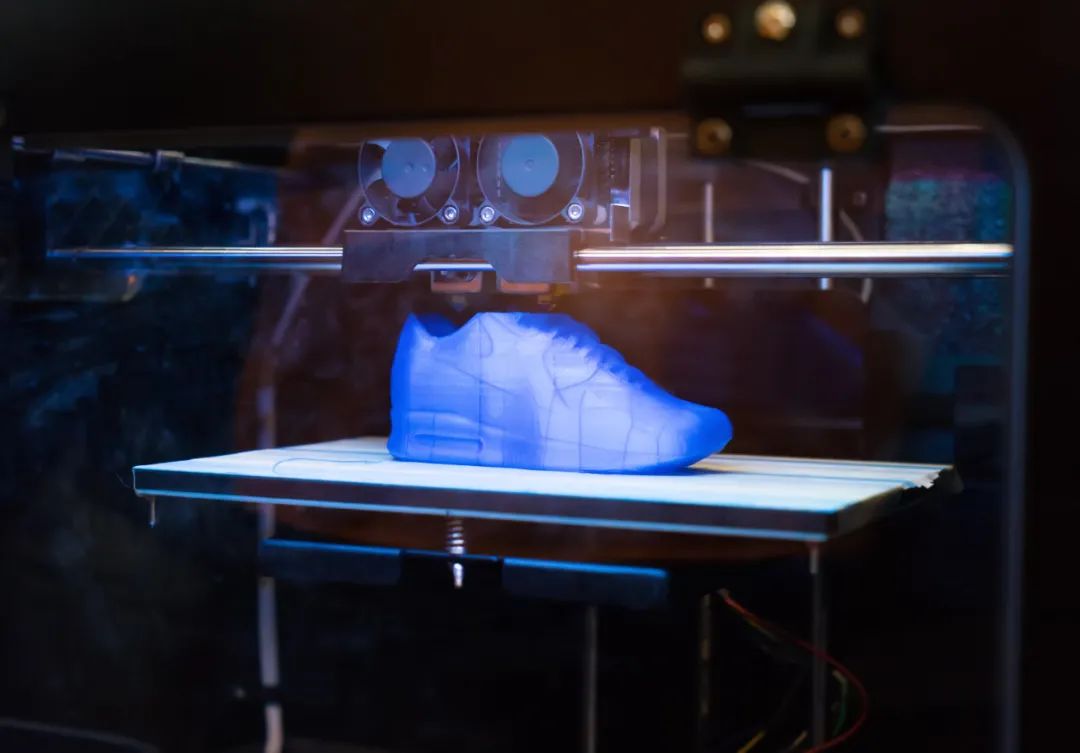

In the footwear and apparel industry, Nike has used 3D printing technology to create prototypes of Vapor Laser Talon football shoes for American football players, while Adidas’s FutureCraft series is among the first globally to achieve sales of 100,000 pairs of 3D printed shoes.

In the automotive and appliance sectors, in June 2021, BMW’s additive manufacturing center officially opened with an investment of over 15 million euros, utilizing innovative 3D printing technology to produce millions of automotive parts. At the same time, Michelin plans to collaborate with General Motors to develop the first 3D printed airless tire, injecting new vitality and value into the automotive industry.

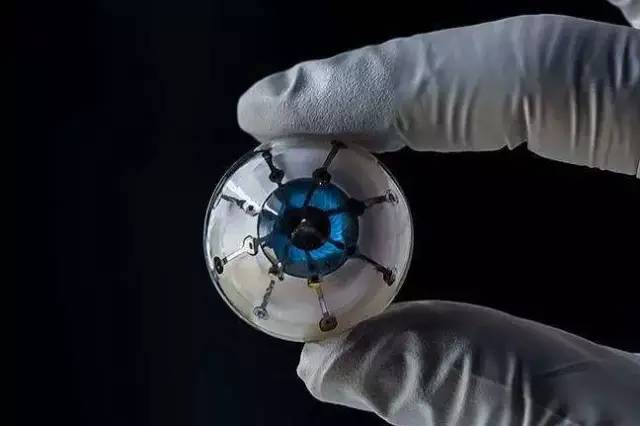

In the development of manufacturing medical prosthetics, it is not limited to orthopedics and prosthetic ears, but also includes ocular prosthetics. In November 2021, breakthroughs in the clinical application of 3D printed prosthetic eyes by the Fraunhofer Institute in Germany indicate the commercialization trend of 3D printed medical prosthetics.

It is believed that with the continuous exploration of demand, sustained policy guidance, and gradual standardization of industry standards, the breadth and depth of 3D printing applications will further accelerate expansion.

3D printing technology has only been around for a little over thirty years since its inception in the 1980s, yet it is leading a global manufacturing revolution. As a representative of “Internet + Intelligent Manufacturing”, it almost perfectly meets the requirements of customization and mass production, demonstrating limitless creativity in various fields. The 3D printing industry is entering a growth phase, and by 2026, the global 3D printing output value is expected to reach 37.2 billion USD, with global competition already underway. However, achieving precision, intelligence, universality, and convenience is an important topic facing 3D printing technology, and we look forward to its continuous improvement and refinement bringing milestone changes to future intelligent manufacturing.

1. Jake Port. How does 3D printing work? , cosmosmagazine, 7 December 2021

2. “3D Printing and Industrial Manufacturing” — Machinery Industry Press

3. 2021 3D Printing Industry In-Depth Research Report — Western Securities