Source: BIMaker

3D printing technology is a rapid prototyping technology based on three-dimensional digital model files, constructing objects through layer-by-layer printing or powder melting. It integrates cutting-edge technologies from digital modeling, electromechanical control, information technology, material science, and chemistry.

“Using mechanical construction and 3D printing is our future,” said the famous Austrian architect Wolf D Prix. As BIM technology matures, the integrated application of emerging technologies with BIM has become a development direction in the construction industry. Next, let’s explore the combination of BIM and 3D technology and see what new experiences it brings to the construction industry!

1. 3D Printing Technology

Traditional craftsmanship for making complex components is greatly affected by human factors, leading to unavoidable deviations in precision and aesthetics. However, 3D printers are computer-controlled, and as long as there is data support, any complex-shaped components can be manufactured quickly and accurately. By combining BIM technology with 3D printing for complex component production, there is no longer a need for complex processes, measures, and molds; simply sending the BIM model of the component to the 3D printer allows for quick printing of complex components. Using 3D printing for a small number of complex components significantly shortens the processing cycle and reduces costs. The precision of 3D printing is very high, ensuring the accuracy of the geometric dimensions and the quality of the solid complex-shaped components.

Conventional printers use ink and paper as raw materials to print and present the flat models designed on the computer. The printing principle of 3D printers is similar, but the difference is that 3D printers use metals, ceramics, or plastics as printing materials, forming objects through melting and stacking. Different printing materials also grant different printing technologies to 3D printers, such as FDM technology (Fused Deposition Modeling, using thermoplastic materials like ABS) used by desktop printers;

Industrial-grade printers adopt SLS technology (Selective Laser Sintering, using thermoplastics, metal powders, ceramic powders) and SLA technology (Stereolithography, using photosensitive resin materials).

2. The Process of 3D Printing BIM Information Models

The 3D printer reads the BIM model information and decomposes the model into several sections (referred to as slicing), which means the printer reads the cross-sectional information of the model file. The printing material melts at high temperatures and, through the nozzle’s movement in three-dimensional space, stacks the model’s cross-section layer by layer, cooling to form a solid object, thus converting the three-dimensional blueprint from the computer into a visual three-dimensional entity. It is evident that 3D printing technology is an additive manufacturing technology and a rapid prototyping technology.

The integrated application of BIM and 3D printing mainly involves using 3D printers to create miniature prints of BIM models during the design phase for plan presentations, reviews, and simulation analyses; during the construction phase, 3D printers directly print BIM models into physical components and entire buildings, partially replacing traditional construction processes. The integration of BIM and 3D printing can be described as the combination of two revolutionary technologies, opening a “highway” for the process from design schemes to physical objects, and providing a more efficient solution for the processing and manufacturing of complex components. Currently, there are three modes of integrated application of BIM and 3D printing: 3D printing of entire buildings based on BIM, making complex components based on BIM and 3D printing, and physical model displays of construction plans based on BIM and 3D printing. The commonly used BIM modeling software in the construction field is Revit, with model file formats being rvt (project files) or rfa (external family files); currently, the universal format recognized by 3D printers in the 3D printing field is STL format, and 3dsmax can convert rvt or rfa file formats to achieve interaction between BIM models and 3D printers.

BIM stands for Building Information Modeling, which uses relevant information data from construction engineering projects as the basis for creating the building information model. It simulates the real information of the physical building through digital simulation. BIM is a digital expression of the project engineering facilities, equipment entities, and functional characteristics. A complete information model can connect data, processes, and resources from different stages of the building project’s life cycle, providing a complete description of the engineering object that can be universally used by all participants in the construction project. The key to BIM is information, the result is the model, the focus is collaboration, and the tool is software.

3D printing of entire buildings based on BIM. Using BIM for architectural design, the design model is delivered to a dedicated 3D printer to print the entire building. Constructing houses using 3D printing technology can effectively reduce labor costs, and the construction process generates minimal dust and construction waste, making it an environmentally friendly process with significant advantages in energy conservation and environmental protection compared to traditional processes.

3D printing (3 Dimensional Printing) is a technology that constructs objects by layer-by-layer printing using powdery metals or plastics as adhesive materials based on digital model files.

3D printing is similar to laser forming technology, using layered processing and stacking forming to complete 3D entity output printing. Each layer’s printing process can be divided into two steps: spraying a layer of special glue in the area to be formed, which does not easily spread, and then spraying a layer of uniform powder as an auxiliary. The powder quickly solidifies and bonds when it contacts the glue, while the areas without glue remain loose. Thus, through alternating layers of glue and powder, the solid model will be “printed” into shape. Once printing is completed, the loose powder can be swept away to “carve” out the model, and the remaining powder can be recycled.

3. New Technologies Help Enterprises Reduce Costs, Improve Quality, and Shorten Cycles

In the construction field, with increasing market competition, owners, design units, and construction units are paying more attention to a series of internal efficiency-enhancing methods such as reducing costs, improving quality, and shortening cycles, prompting enterprises to adopt new technologies more.

With the rapid development of computer hardware technology and three-dimensional graphics and image technology, computers can quickly process big data and high-performance graphics and images. Some complex three-dimensional modeling software, computational analysis, and simulation software that could only run on workstations have been released in microcomputer versions. Therefore, in the field of construction engineering, integrating three-dimensional modeling, visualization, simulation, and data exchange technologies has ushered in a new round of technological revolution around BIM and 3D printing.

Using BIM for architectural design, the processed design model is directly delivered to a dedicated 3D printer for overall printing, allowing buildings to be printed quickly. The time to build a simple building is greatly shortened. Constructing houses using 3D printing technology requires very little labor input. As labor costs gradually increase in our country, 3D printing can effectively reduce labor consumption costs. 3D printing is an “additive manufacturing” technology, and its operation process generates minimal dust and construction waste, making it a green and environmentally friendly process with significant advantages in energy conservation and environmental protection compared to traditional processes.

4. Construction Plans Based on BIM Technology and 3D Printing

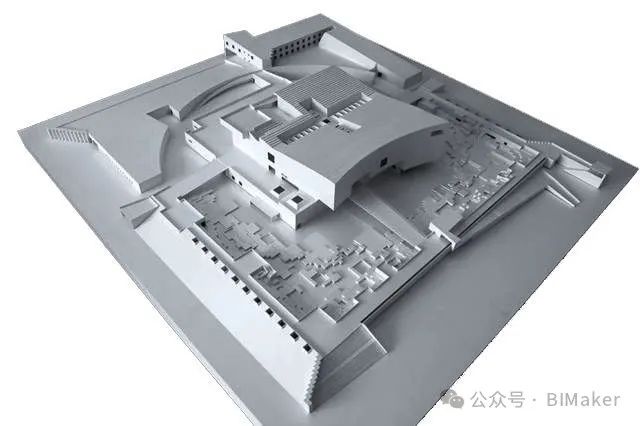

Physical model displays. After the emergence of BIM technology, integrating BIM models with construction plans or deployment is a very practical application method. Combining 3D printing technology to print physical models can enhance the application effect. A miniature model of the construction plan made by 3D printing can help construction personnel better understand the plan’s content intuitively. Moreover, it does not rely on computers or other hardware devices for carrying or displaying, and the physical model can be observed from a 360-degree perspective, overcoming the shortcomings of printed 3D images and three-dimensional videos having a single angle.

5. The Application of 3D Printing and BIM Technology Has a Broad Future

BIM primarily establishes building information models on computers. Although it is three-dimensional, it is not a physical entity. In contrast, 3D printing converts three-dimensional models in computers into physical entities, perfectly combining the two. With the development of various technologies, many technical problems currently existing in the integration of BIM and 3D printing will be resolved. The prices of 3D printers and printing materials will become more reasonable, and the reduction in application costs will expand the application range of 3D printing technology, improving the automation level in the construction industry. Although 3D printing buildings do not have advantages in efficiency and economy for mass production of ordinary civil buildings compared to industrialized prefabricated production, the advantages of 3D printing are very evident in personalized and small-scale buildings. With the rise of the personalized custom building market, the market prospects for 3D printing buildings in this field are very broad.

Currently, many countries around the world attach great importance to the utilization and improvement of BIM and 3D printing technologies, promoting their wide application in the construction engineering field. During the product design and development stage, BIM and 3D printing industries in our country have also received much attention and have begun to be applied in the design and construction of some large complex projects.

BIM technology, as the highest standard for the transformation and upgrading of the construction industry, will have more and more value potential continuously developed, saving costs, improving quality, and generating value. With the rapid development of emerging technologies, the deepening integration of BIM applications and 3D printing technology in the construction field has a broad application potential, creating more possibilities for the construction industry!

Disclaimer: This article is an excerpt or reprint from the internet, and the copyright belongs to the original author. The content reflects the personal views of the original author and does not represent this public account’s agreement with their views or responsibility for its authenticity. If there are any copyright issues, please contact us, and we will delete the content as soon as possible.

If you need to submit articles, please scan and follow the official public account and add the official WeChat! Reply with the text “Submission” in the public account to get the “Public Account Submission Template”.

Scan the WeChat group QR code to join the group! Be sure to add the official WeChat when submitting articles, and send the manuscript via private message! The editor will respond as soon as possible, and please understand the editor’s response speed!

Publicly available documents related to the public account can be sent in the WeChat group.

Waiting for you

END

Follow Us

Add the Official WeChat to Enter the Official Group

Note: (1) Company Name (2) Position (3) Work Direction / Expertise

Reprint with Source Indicated! You can contact the editor to mutually add to the global whitelist for future reprints.