3D printing technology can be considered a rising star in today’s technology, garnering increasing attention. Many friends around us discuss 3D printing, yet there are certain misconceptions in their understanding. Very few people truly have an in-depth understanding of 3D printing technology. Today, let’s explore the relevant knowledge about 3D printing.

When it comes to printing, people first think of traditional paper printers, which use computers or other electronic devices to transfer visible data such as text or images onto paper or other recording media.

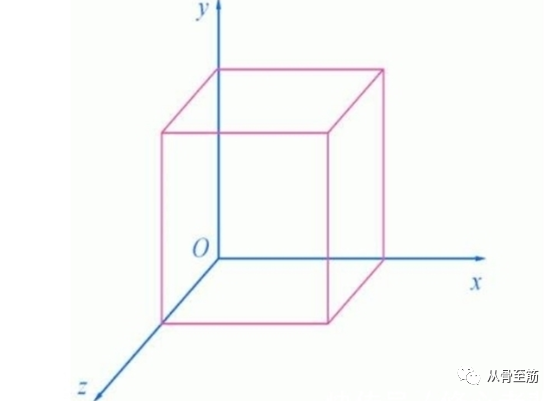

So what does 3D mean?

3D is an abbreviation for the English term “3 Dimensions“, which translates to three-dimensional or spatial. The concept of 3D space consists of three coordinate axes: X, Y, and Z. In contrast to a plane (2D) that only has length and width, 3D adds a height coordinate axis.

Based on these two fundamental concepts, what is 3D printing?

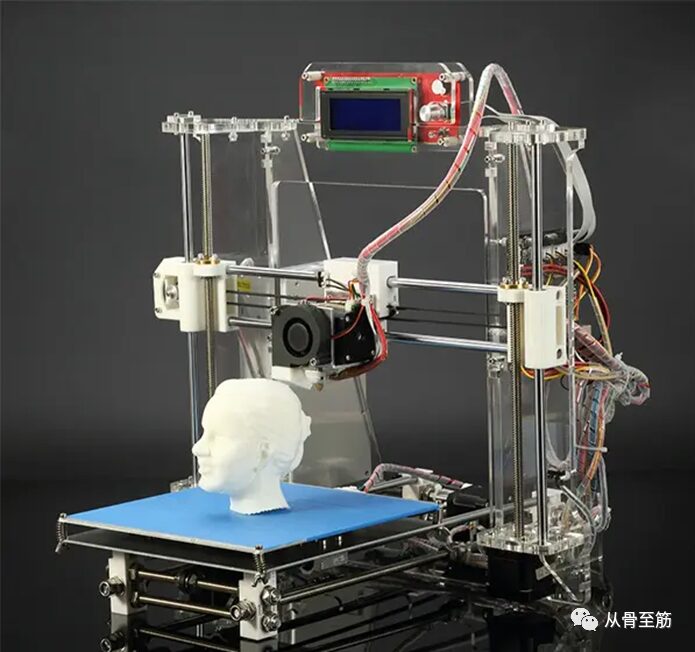

3D printing (3DP) is a rapid prototyping technology that constructs objects based on digital model files using powder-like materials or plastics and other adhesive materials through a layer-by-layer printing method.

The current applications of this technology span various fields, including the electronics processing industry, mechanical processing industry, automotive parts manufacturing, aerospace manufacturing, military, communications, medicine, art, and many others.

The main types of 3D printing technologies currently available on the market are as follows:

1. Fused Deposition Modeling (FDM) Materials: Thermoplastic, eutectic metal systems, usable materials.

2. Stereolithography (SLA) Materials: Photosensitive resin.

3. Digital Light Processing (DLP) Materials: Photosensitive resin.

4. Gypsum 3D Printing (PP) Materials: Gypsum.

5. Selective Laser Sintering (SLS) Materials: Thermoplastic, metal powder, ceramic powder.

6. Selective Heat Sintering (SHS) Materials: Thermoplastic powder.

7. Selective Laser Melting (SLM) Materials: Titanium alloy, cobalt-chromium alloy, stainless steel, aluminum.

8. Electron Beam Melting (EBM, EBF) Materials: Almost any alloy, including titanium alloys.

The process of creating a standard 3D printing model includes the following steps:

Proposing design ideas, designing models, optimizing processes, slicing, printing, and post-processing.

A good model not only requires corresponding processes but should also include precision requirements for the printing equipment. Thus, mainstream 3D printers generally specify printing resolution precision, referring to the thickness of the printing layers and wide resolution, measured in dots per inch (dpi) or micrometers (um). The layer thickness is generally 100 micrometers, equivalent to 1 millimeter. Therefore, for items requiring higher printing precision, current technology cannot meet those needs.

The advantages of 3D printing include:

1. The most direct benefit is the conservation of materials, eliminating waste and increasing material utilization, thus reducing costs by eliminating production lines.

2. It can achieve relatively high precision and complexity, capable of expressing curved designs.

3. Traditional tools, fixtures, lathes, machine tools, or mold-based processing are no longer required; any shape part can be generated directly from computer graphics.

4. It can automatically, quickly, and accurately convert computer files into models, shortening product development cycles.

5. It can form in a matter of hours, reducing upfront development and assembly costs.

However, even the best technology and products have certain drawbacks, such as limitations imposed by materials and machines.

The disadvantages of 3D printing include:

1. Strength issues; various printing methods ultimately rely on the reorganization of materials, so some special components produced by 3D printing may have slightly lower strength than those produced by machining.

2. Precision issues; even though current mainstream printers have achieved precision of 1 millimeter or better, there is still significant room for improvement when used for precision parts, such as the nanometer-level precision of lithography machines, where 1 nanometer equals 0.000001 millimeters.

3. Material limitations; currently, the materials available for 3D printers are quite limited, such as gypsum, photosensitive resin, and plastics, with a relatively narrow range of applicable materials. Additionally, printers are very selective about materials.

4. Printing speed issues; the printing speed of mechanical transmission or laser printing methods is still not fast enough, with significant room for improvement.

5. Large-scale printing issues; a single printer can only handle one or a batch of parts at a time, and compared to mass production on assembly lines, it still cannot form an industrial effect.

6. The design and printing costs are relatively high.

We believe that after reading this article, everyone will have a more comprehensive and detailed understanding of 3D printing. We will continue to bring you applications of 3D printing in the medical field.