Published: 2018-12-03 | Source: Guangdong Plastics Network – Guangdong Plastics Industry Association | Editor: gdpia

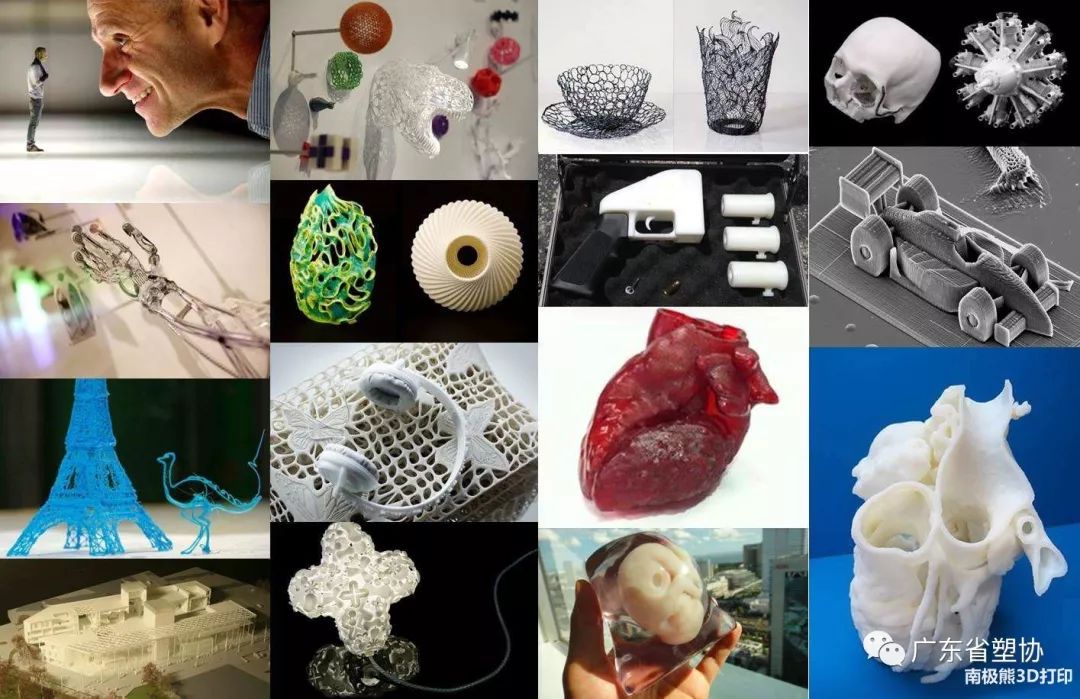

3D printing materials are an important material foundation for 3D printing technology, mainly including polymer materials, metal materials, ceramic materials, etc. This article first briefly introduces the various common materials used in 3D printing, and then describes their characteristics, performance requirements, and related applications. Finally, combined with the latest research progress, it looks forward to the new materials for 3D printing and their prospects.

1. 3D Printing

3D printing technology, also known as Additive Manufacturing (AM) technology, is an advanced manufacturing technology that originated in the 1980s, integrating machinery, computer science, numerical control, and materials. The basic principle of this technology is to manufacture solid parts or prototypes layer by layer based on the two-dimensional cross-sectional information obtained from slicing three-dimensional solid parts, using points, lines, or surfaces as basic units. Additive manufacturing differs from traditional subtractive (such as machining) and formative (such as forging) manufacturing methods, enabling the manufacturing of complex structural parts that are difficult or impossible to achieve with traditional methods, significantly reducing processing steps and shortening processing cycles, thus gaining widespread attention from researchers worldwide.

The earliest applications of 3D printing technology were in rapid prototyping, hence it was also known as Rapid Prototyping (RP) in its early days. Due to limitations in material types, early 3D printing technologies mostly used organic polymer materials, which often could not meet the mechanical and chemical performance requirements for practical applications. As material technology and equipment technology have developed, the desire to apply this technology to end part manufacturing has become increasingly urgent, resulting in higher requirements not only for 3D printing equipment but also for the performance of 3D printing materials.

3D printing materials are an important material foundation for 3D printing technology, and their performance largely determines the overall performance of the formed parts. To date, the types of materials have become very rich, mainly including polymer materials, metal materials, and ceramic materials. This article will introduce several recent advancements in the research and application of 3D printing materials, focusing on polymer materials, metal materials, and ceramic materials used in 3D printing.

2. Polymer Materials for 3D Printing

3D printing polymer materials mainly include photosensitive resins, thermoplastics, and hydrogels. Paper, starch, sugar, chocolate, and other materials can also be included under polymer materials; some scholars and companies have conducted 3D printing research on these materials, but due to space limitations, they will not be elaborated on here.

Photosensitive resins are among the earliest materials used in 3D printing, suitable for Stereolithography Apparatus (SLA) processes. The main components are small molecular resins (prepolymers, monomers) that can undergo polymerization reactions, with additives such as photoinitiators, inhibitors, and leveling agents that allow curing under specific light (generally ultraviolet light). Photosensitive resins are not a new type of material; similar principles are found in photoresists, photocurable coatings, and photocurable inks, which have been widely used in electronics manufacturing, holography, adhesives, printing, and medical fields. In the coatings field, photopolymerization technology is considered an environmentally friendly green technology due to its fast curing speed, excellent curing performance, low pollution, and energy efficiency. However, the curing thickness of resins used in 3D printing (generally >25μm) is significantly greater than the coating thickness of traditional coatings (generally <20μm), and their formulations differ from those of traditional photocurable coatings and inks.

According to the polymerization system, they can be classified into free radical polymerization and cationic polymerization, each with different polymerization mechanisms and active groups. Free radical polymerization relies on the unsaturated double bonds in the photosensitive resin for the polymerization reaction, while cationic polymerization relies on epoxy groups in the photosensitive resin. Free radical polymerization systems cure quickly and have low raw material costs but exhibit some degree of oxygen inhibition in the air, which can affect curing performance and part properties; cationic polymerization systems have no oxygen inhibition, with minimal or no curing shrinkage, but are sensitive to moisture and have higher raw material costs. Therefore, the photosensitive resins currently used in 3D printing predominantly utilize free radical polymerization systems.

The photosensitive resins used for 3D printing mainly adopt a free radical polymerization acrylate system. There are various types of commercial acrylates, and formulations need to be adjusted according to different requirements. In general, the following requirements are placed on photosensitive resins for 3D printing:

(1) Stable performance before curing, generally requiring no curing under visible light exposure;

(2) Fast reaction speed; a higher reaction rate can achieve high-efficiency forming;

(3) Moderate viscosity to match the recoating requirements of light curing equipment;

(4) Low curing shrinkage to reduce deformation and internal stress during forming;

(5) Sufficient mechanical strength and chemical stability after curing;

(6) Low toxicity and irritation to minimize harm to the environment and human health.

In addition, there are other specific requirements for certain applications; for example, photosensitive resins used in casting require low ash content or even ash-free, and resins used for dental aligners or implants need to be non-toxic or biodegradable. Currently, there is a wide variety of photosensitive resins available on the market that can meet the needs of different fields.

Thermoplastic polymers are one of the most common 3D printing materials, with common thermoplastics including Acrylonitrile Butadiene Styrene (ABS), Polylactic Acid (PLA), Nylon (PA), Polycarbonate (PC), Polystyrene (PS), Polycaprolactone (PCL), Polyphenylsulfone (PPSF), Thermoplastic Polyurethane (TPU), and Polyether Ether Ketone (PEEK).

Depending on the 3D printing method, the required form of the material varies. Fused Deposition Modeling (FDM) uses filament, while Selective Laser Sintering (SLS) uses powder. Since the polymer raw materials commonly used in industry are mostly granules, processing them into filaments or powders requires secondary processing, increasing the cost of 3D printing consumables. Currently, some organizations have begun to develop 3D printing equipment using granules as raw materials. Below are introductions to several representative materials.

PLA and ABS are the most commonly used consumables for FDM due to their low cost and widespread popularity. ABS is a common engineering plastic with good mechanical properties, but it has strict printing conditions, is prone to warping during printing, and emits an irritating odor. PLA is a biodegradable, environmentally friendly plastic with good printing performance, making it a relatively ideal thermoplastic polymer for 3D printing, widely used in education, medical, construction, and mold design industries. Additionally, PLA has good biocompatibility, and PLA modified with hydroxyapatite can be used for manufacturing tissue engineering scaffolds.

PA is a semi-crystalline polymer that can achieve high density and strength parts after SLS forming, making it one of the main consumables for SLS. The PA used in SLS must have high sphericity and uniform particle size, typically prepared by low-temperature milling. By adding inorganic materials such as glass microspheres, clay, aluminum powder, and carbon fibers, PA composite powders can be prepared, which significantly enhance certain performance aspects like strength, heat resistance, and conductivity to meet application needs in various fields.

PCL is a non-toxic, low melting point thermoplastic, primarily used as a consumable for 3D printing pens for children due to its low forming temperature (80-100°C), which offers high safety. Notably, PCL has excellent biocompatibility and degradability, making it a material for tissue engineering scaffolds in biomedical applications. By doping with nano-hydroxyapatite and other materials, its mechanical properties and biocompatibility can also be improved. Additionally, PCL has a certain shape memory effect, showing potential in 4D printing.

TPU is a thermoplastic polymer with good elasticity, wide and adjustable hardness, certain wear resistance, and oil resistance, suitable for manufacturing shoe materials, personal consumer goods, and industrial parts. Combined with 3D printing technology, it can create complex porous structures that are difficult to manufacture with traditional molding processes, resulting in parts with unique and controllable mechanical properties. The elastic performance and usage strength of porous TPU insoles printed using SLS have reached market standards.

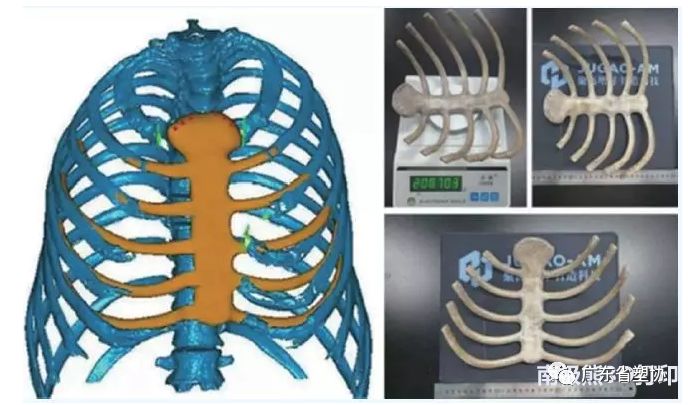

PEEK is a semi-crystalline polymer with a high melting point (343°C) and excellent mechanical properties, as well as outstanding biocompatibility, making it one of the most researched 3D printing materials. The Young’s modulus of pure PEEK is 3.86±0.72GPa, which can reach 21.1±2.3GPa when reinforced with carbon fibers, closely matching the Young’s modulus of human bone, effectively avoiding stress shielding and loosening after implantation in the human body, making it an ideal material for orthopedic implants. PEEK implants manufactured using 3D printing technology (Figure 1) can well meet the personalized implant customization needs of different patients, and domestic 3D printed PEEK implants have achieved good clinical results.

Figure 1 CAD model of sternum prosthesis and actual product. Hydrogels are a type of polymer structure with a cross-linked three-dimensional network that can absorb and retain a large amount of moisture (up to 99%). Depending on the source of the polymer, they can be divided into natural hydrogels and synthetic hydrogels. The former, such as gelatin, agar, and sodium alginate, have high swelling properties but relatively poor mechanical properties, limiting their application range. The latter, due to the adjustable composition, structure, and cross-linking degree of synthetic hydrogels, allow for a wide range of performance tuning; at the same time, synthetic hydrogels have good reproducibility, enabling large-scale production, thus gaining widespread attention from researchers domestically and internationally.

Traditional hydrogels have achieved considerable applications in manufacturing contact lenses and wound healing. As an ideal material for tissue engineering, hydrogels have broad application prospects in this field. Furthermore, hydrogels can also serve as sensor materials, utilizing their swelling behavior and diffusion coefficients that change with environmental variations. Traditional hydrogel forming mainly relies on molds, which cannot manufacture complex structures; however, using 3D printing technology to form hydrogels not only enables the manufacturing of complex shapes but also allows for the creation of intricate pores or even gradient structures, giving 3D printed hydrogels properties unattainable by traditional manufacturing methods. Additionally, living cells can be added to hydrogels, making 3D printing of human organs possible.

The 3D printing methods for hydrogels include photopolymerization and Direct Ink Writing (DIW). The components of hydrogels used for photopolymerization are similar to those of photosensitive resins, including solvents, monomers, crosslinkers, photoinitiators, etc., and inorganic fillers can be added to achieve performance tuning of the hydrogels. DIW is a more common form of 3D printing for hydrogels. During printing, the hydrogel is placed in a syringe, and a computer controls the syringe’s movement and extrusion based on the designed structure. The extruded hydrogel cures under external stimuli (temperature, moisture, pH, light, etc.). To meet 3D printing requirements, the curing speed of hydrogels must be fast enough or their rheological properties must ensure no deformation during printing, ensuring successful printing. Currently, there are few commercial hydrogel printing materials available, most of which are still in experimental development stages.

3. Metal Materials for 3D Printing

According to the 2018 Wohlers Report, the metal additive manufacturing industry has seen significant development. The report indicates that 1,768 sets of metal 3D printing equipment were sold in 2017, an increase of nearly 80% compared to 983 sets in 2016. As a very important material in 3D printing, metal materials have broad application prospects in industries such as automotive, molds, energy, aerospace, and biomedical.

3D printing metal materials are mainly available in powder and filament forms. Powder materials are the most commonly used materials, applicable for various 3D printing processes such as Selective Laser Melting (SLM), Laser Engineered Net Shaping (LENS), and Electron Beam Melting (EBM); filament is suitable for Wire and Arc Additive Manufacturing (WAAM) processes.

To meet the requirements of 3D printing processes, metal powders must meet certain criteria. Powder flowability is one of the important characteristics of powders; all 3D printing processes using metal powders as consumables involve powder flow during manufacturing, and the flowability of metal powders directly affects the powder spreading uniformity in SLM and the powder feeding stability in LENS. Poor flowability can lead to reduced printing accuracy or even printing failure. The flowability of powders is influenced by various factors, including particle size, particle size distribution, powder shape, and moisture absorption. To ensure good flowability, the powders are generally required to be spherical or near-spherical, with particle sizes ranging from a few micrometers to a hundred micrometers. Excessively small particle sizes can cause powder agglomeration, while excessively large particle sizes can reduce printing accuracy. Additionally, to achieve denser parts, it is generally desired that the bulk density of the powders be as high as possible; using graded powders is more likely to achieve a higher bulk density than using powders with a single particle size distribution. Currently, the main preparation methods for metal powders used in 3D printing are atomization methods, which include water atomization and gas atomization. Powder produced by gas atomization has higher purity, lower oxygen content, controllable particle size, lower production costs, and higher sphericity, making it the primary development direction for high-performance and special alloy powder preparation technology.

Metal filaments used in 3D printing are similar to traditional welding wires; theoretically, any metal that can be melted under processing conditions can be used as a 3D printing material. The technology for filament manufacturing is well-established, and the material costs are significantly lower than those for powders.

Based on material types, 3D printing metal materials can be categorized into iron-based alloys, titanium and titanium alloys, nickel-based alloys, cobalt-chromium alloys, aluminum alloys, copper alloys, and precious metals.

Iron-based alloys are one of the earliest and most thoroughly studied categories of 3D printing metal materials. Common iron-based alloys include tool steel, 316L stainless steel, M2 high-speed steel, H13 mold steel, and 15-5PH martensitic aging steel. Iron-based alloys have low usage costs, high hardness, and good toughness, along with excellent machinability, making them particularly suitable for mold manufacturing. 3D printed conformal cooling channel molds are a significant application of iron-based alloys; traditional processes struggle to machine complex cooling channels, while 3D printing can control the arrangement of cooling channels to closely match the geometric shape of the cavity (Figure 2), enhancing the uniformity of the temperature field, effectively reducing product defects, and extending mold lifespan.

Figure 2 Schematic of conformal cooling channel in mold.

Titanium and titanium alloys, with their notable high specific strength, good heat resistance, corrosion resistance, and biocompatibility, have become ideal materials in fields such as medical devices, chemical equipment, aerospace, and sports equipment. However, titanium alloys are typically difficult to machine, with high stress and temperature during processing leading to severe tool wear, limiting their widespread application. 3D printing technology is particularly suitable for manufacturing titanium and titanium alloys; during 3D printing, the process occurs in a protective atmosphere, preventing titanium from reacting with oxygen, nitrogen, and other elements, while localized rapid heating and cooling limit the volatilization of alloying elements. Furthermore, complex shapes can be manufactured without the need for cutting processes, and the high material utilization of powder or filament materials minimizes raw material waste, significantly reducing manufacturing costs. Currently, the types of titanium and titanium alloys available for 3D printing include pure Ti, Ti6Al4V (TC4), and Ti6Al17Nb, which can be widely used in aerospace parts (Figure 3) and artificial implants (such as bones and teeth).

Figure 3 3D printed nickel-based alloys are among the fastest developing and most widely applied high-temperature alloys, possessing high strength and certain oxidation and corrosion resistance at temperatures between 650-1000°C, widely used in aerospace, petrochemical, shipbuilding, and energy fields. For example, nickel-based high-temperature alloys can be used in the turbine blades and turbine discs of aircraft engines. Common 3D printed nickel-based alloy grades include Inconel 625, Inconel 718, and Inconel 939.

Cobalt-based alloys can also be used as high-temperature alloys, but their development is limited due to resource scarcity. Because cobalt-based alloys exhibit better biocompatibility than titanium alloys, they are currently primarily used as medical materials for dental and orthopedic implants. Common 3D printed cobalt-based alloy grades include Co212, Co452, Co502, and CoCr28Mo6.

Aluminum alloys are lightweight, exhibit good corrosion resistance, high fatigue resistance, and possess high specific strength and stiffness, making them ideal lightweight materials. The aluminum alloys used in 3D printing are casting aluminum alloys, with common grades including AlSi10Mg, AlSi7Mg, and AlSi9Cu3. The Korean communication satellites Koreasat-5A and Koreasat-7 utilized lightweight components manufactured via SLM using AlSi7Mg, which not only consolidated multiple parts into a single integrated component but also reduced component weight by 22% compared to the original design, lowered manufacturing costs by 30%, and shortened production cycles by 1-2 months.

Figure 4 Lightweight components used in communication satellites.

Other metal materials such as copper alloys, magnesium alloys, and precious metals have less demand than the aforementioned metal materials but still have their respective application prospects. Copper alloys possess excellent thermal conductivity, making them suitable for manufacturing inserts for molds or combustion chambers in rocket engines. NASA has utilized 3D printing technology to create a combustion chamber composed of GRCop-84 copper alloy for the inner wall and nickel alloy for the outer wall, with the inner wall manufactured using SLM and the outer wall completed using electron beam melting. This combustion chamber maintained good shape after full power ignition tests, demonstrating that 3D printing technology can achieve results comparable to traditional processes while saving significant time and cost. Magnesium alloys are currently the lightest metals in practical applications, exhibiting good biocompatibility and biodegradability, with a Young’s modulus closely matching that of human bone, making them suitable for lightweight materials or implant materials. However, the 3D printing process for magnesium alloys is still immature and has not been widely promoted. Precious metals such as gold, silver, and platinum are often used in the customization of jewelry and luxury goods, thus having limited application scope.

Shape Memory Alloys (SMA) are a type of shape memory material that can “remember” or retain a previous shape when subjected to certain stimuli (such as thermal, mechanical, or magnetic changes). SMAs have broad application prospects in fields such as robotics, automotive, aerospace, and biomedical. NiTi alloys are the most mature SMA currently developed, but they are difficult to machine. Applying 3D printing technology to the manufacturing of SMA components not only holds promise for solving the machining difficulties of SMAs but also enables the creation of complex lattice structures unattainable by traditional processes. In recent years, many scholars have explored the SLM process for NiTi alloys and achieved certain results. Currently, SLM printed NiTi alloy components have shown good shape memory effects, exhibiting approximately 5% recoverable strain after eight compression cycles. Moreover, the shape memory behavior of SLM formed NiTi samples is highly correlated with aging processes, with samples aged at 350°C for 18 hours demonstrating nearly perfect superelasticity.

4. Ceramic Materials for 3D Printing

Ceramic materials are one of the oldest materials used by humans, but they are relatively “young” in the field of 3D printing. This is because ceramic materials generally have high melting points or even no melting point (such as SiC, Si3N4), making direct forming using external energy fields challenging, and most require post-processing (drying, sintering, etc.) after forming to obtain the final products, which limits the promotion of 3D printing with ceramic materials. However, their advantages, such as high hardness, high-temperature resistance, and stable physical and chemical properties, which are not found in polymer and metal materials, enable broad application prospects in aerospace, electronics, automotive, energy, and biomedicine fields. As a mold-free forming method, 3D printing offers higher structural flexibility than traditional forming methods, facilitating the customized manufacturing of ceramics or improving the performance of ceramic parts. Below, traditional ceramics and advanced ceramics will be introduced regarding ceramic materials in 3D printing.

Traditional ceramics can be defined as those ceramic products that make up the silicate industry, mainly including clay, cement, and silicate glass. The raw materials for traditional ceramics are mostly natural mineral materials, which are widely distributed and inexpensive, suitable for manufacturing daily ceramics, sanitary ceramics, refractory materials, abrasives, and building materials. The forming of traditional ceramics mostly requires molds; applying 3D printing technology to the manufacturing of ceramics or glass products can achieve customization of ceramic products, enhancing added value and potentially endowing them with unique artistic value.

Clay minerals are the most widely used ceramic raw materials, characterized by their plasticity when mixed with water, which forms the basis of many commonly used forming processes. By adding an appropriate amount of water to clay to create a well-plasticized ceramic paste, it can then be extruded using 3D printing. Ceramic components manufactured using extrusion 3D printing processes can retain the unique layering patterns characteristic of 3D printing, imparting a distinct aesthetic. The formed ceramic green bodies can be transformed into ceramic components after drying, sintering, and glazing. This process and material cost is low, making it suitable for education and cultural creativity industries.

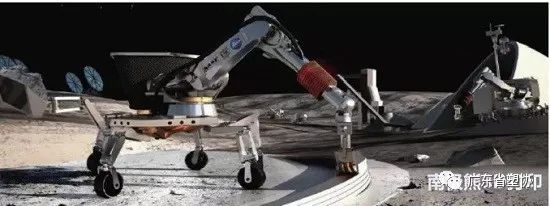

By scaling up the aforementioned extrusion 3D printing equipment, concrete can be used as a material for 3D printing in building houses. To ensure the smooth implementation of 3D printed buildings, the concrete materials used in 3D printing must meet higher requirements than traditional concrete, such as sufficient flowability during transmission and extrusion, adequate stability after extrusion, and sufficient strength, stiffness, and durability after hardening. 3D printed concrete can be applied to the construction of complex-shaped buildings, including nonlinear and freeform surfaces, and in the future, it is expected to utilize local resources for base construction in space exploration (Figure 5).

Figure 5 Conceptual diagram of NASA ACME project: 3D printed buildings in space. Porous or honeycomb ceramics made from raw materials such as kaolin and cordierite are commonly used as catalyst carriers and filtration devices. Using SLS or Three-Dimensional Printing (3DP) to form macroscopic complex pore channels, and further utilizing pore-forming agents to obtain microscopic porous structures, can yield porous ceramics with both macroscopic and microscopic pore structures. Both SLS and 3DP utilize powders as raw materials, requiring good flowability of ceramic powders; powders for 3DP can be obtained via spray granulation, while SLS powders, which require the addition of low-melting-point binders, can be prepared using mechanical mixing or coating methods.

Coating sands are commonly used molding materials in the casting industry, but traditional coating sands require molds for forming, which limits the complexity of mold shapes and incurs high production costs, making them unsuitable for small-batch casting production. 3D printing technology can achieve the overall manufacturing of molds (cores), eliminating the traditional multi-block assembly process, saving time costs while improving casting accuracy.

Glass is an amorphous material, and its forming methods differ from those of ceramic materials. Since glass is in a molten state during forming, it is usually shaped through blowing, pressing, pulling, rolling, or casting. The most successful glass 3D printing process is the FDM process, where molten glass is stored in a high-temperature crucible and extruded through a nozzle to form solidified shapes. This process can produce glass products with good light transmission, but due to the harsh conditions for glass printing, it has not yet become widespread.

Advanced ceramics are a class of high-performance ceramics made from high-purity raw materials, allowing for controlled chemical compositions and structural arrangements. Compared to traditional ceramics, advanced ceramics exhibit significantly improved mechanical properties and various sound, light, heat, electrical, and magnetic functions not found in traditional ceramics. Advanced ceramics can be categorized into structural ceramics and functional ceramics based on their uses. Structural ceramics are commonly used to manufacture structural components, requiring high hardness, toughness, wear resistance, and high-temperature performance; functional ceramics are used to manufacture functional devices, such as piezoelectric ceramics, dielectric ceramics, ferroelectric ceramics, sensitive ceramics, and bioceramics. From a chemical composition perspective, advanced ceramics can be divided into oxide ceramics and non-oxide ceramics. To achieve higher performance ceramics, not only the composition needs to be optimized and improved, but also the manufacturing processes must meet higher requirements. Forming, as an important part of ceramic manufacturing, has also drawn increasing attention from researchers in the 3D printing of advanced ceramics.

Oxide ceramics have stable physical and chemical properties and relatively simple sintering processes, making them the most researched materials in ceramic 3D printing. The types of 3D printing processes suitable for oxide ceramics are also the most diverse, including 3DP, SLS, FDM, DIW, SLA, SLM, and LENS.

Powder-based 3DP and SLS utilize liquid or low-melting-point organic binders for forming; due to the low density of the obtained green bodies, achieving complete densification during sintering is difficult, making them mostly used for forming porous ceramics. Processes combining SLS with isostatic pressing and slurry-based SLS can effectively increase the density of green bodies, enabling the manufacturing of dense oxide ceramics.

The consumables for FDM are ceramic powders mixed with thermoplastic polymers to produce filaments, typically with solid content above 50 vol%, but due to high filament production costs and low part precision, FDM is rarely used.

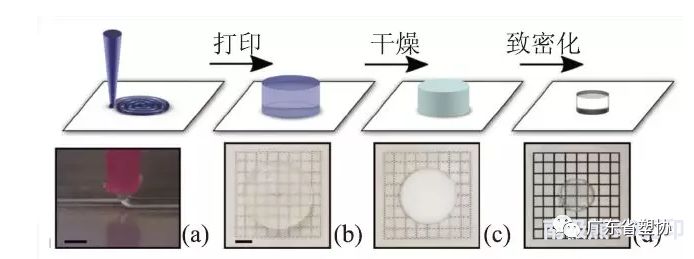

DIW uses paste-like ceramic slurries suitable for extrusion, commonly used for the manufacture of tissue engineering scaffolds from hydroxyapatite, calcium phosphate, and bioglass. By mixing hydrophilic treated nano-silica powder, tetraethylene glycol dimethyl ether, and PDMS, a printable ceramic ink can be obtained, which can produce highly transparent quartz glass after DIW printing, drying, and sintering (Figure 6).

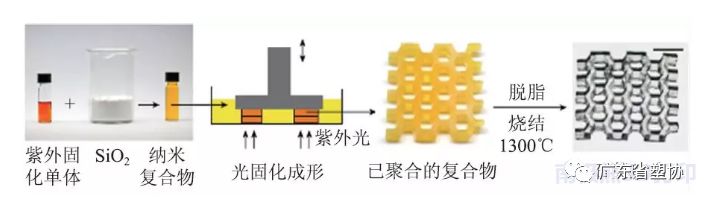

Figure 6 Process flow for preparing transparent quartz glass using DIW technology. The SLA technology for ceramics was originally developed from the slip casting and gel injection molding techniques, known for high part precision, good surface quality, and performance, making it one of the fastest developing and promoting technologies in current 3D printing. Some companies have already launched commercial 3D printing equipment and supporting consumables. SLA ceramic materials mainly consist of high solid content ceramic photosensitive slurries/pastes, with common materials including silica, alumina, zirconia, hydroxyapatite, calcium phosphate, and lead zirconate titanate. Although there is a rich variety of oxide ceramics suitable for SLA, how to use SLA technology to manufacture complex shapes of transparent ceramics has always been a challenge. The Karlsruhe Institute of Technology in Germany used a mixture of high-purity nano-melted quartz and photosensitive resin as raw materials to produce green bodies using SLA technology, which were then sintered at 1300°C to yield products with high light transmittance (Figure 7).

Figure 7 Process flow for preparing transparent quartz glass using SLA technology. Direct SLS, SLM, and LENS technologies share some similarities, utilizing high-energy laser beams to sinter or melt oxide ceramic powders for forming; however, these methods are still immature, facing issues such as high thermal stress, defects in formed parts, and low precision.

Carbide and nitride ceramics represent non-oxide ceramics, exhibiting excellent high-temperature mechanical properties, good thermal stability, and high hardness; however, they currently pose challenges in 3D printing for the following reasons:

(1) Carbides and nitrides have very high melting points or even no melting point, making direct melting forming using high-energy beams challenging;

(2) Carbides and nitrides easily react with oxygen at high temperatures, generating low-temperature phases that affect the high-temperature performance of the parts;

(3) The organic binders commonly used in 3D printing are difficult to completely remove after forming, affecting the densification process.

Currently, the most effective 3D printing methods for carbides and nitrides include SLS, DIW, and SLA. SLS is the most researched method for 3D printing carbides and nitrides. The materials used in SLS for carbides and nitrides mainly comprise inorganic powders and organic binders, where the inorganic powders can be the carbides or nitrides themselves (possibly containing sintering aids) or precursors that can be chemically converted into the target ceramic materials (such as Si, SiO2, C, etc.). After forming the green body, specific post-processing is conducted to obtain the desired carbide or nitride ceramic parts. For example, SiC ceramics can be obtained through two methods: one is forming a skeleton primarily composed of Si and SiC via SLS, followed by resin infiltration and pyrolysis to generate porous carbon, and finally silicon infiltration to obtain SiC ceramics; the other is forming a polymer skeleton, pyrolyzing to obtain a carbon skeleton, and then silicon infiltration to obtain SiC ceramics. However, both methods cannot guarantee complete conversion to pure SiC phases, and residual Si or C can negatively impact the performance of SiC ceramics.

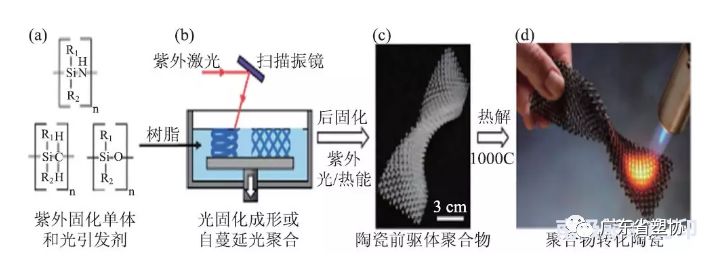

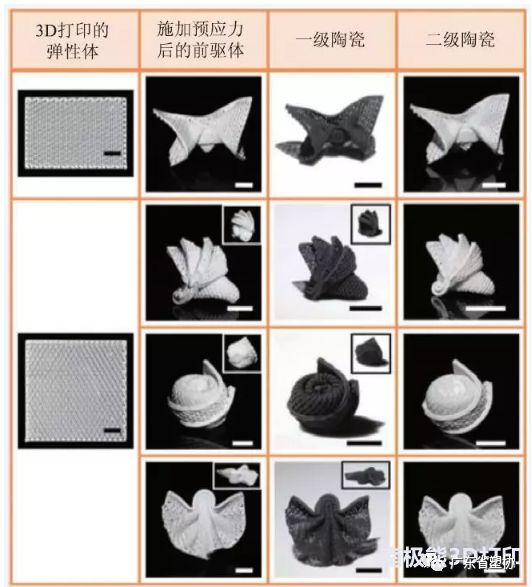

Figure 8 Process flow for preparing SiOC precursor ceramics using SLA technology. DIW and SLA techniques primarily use polymer ceramic precursors, which are converted into target ceramics through pyrolysis after forming. Common types of ceramic precursors include polycarbosilane, polysilazane, polyborosilazane, and polyoxysilane, with the corresponding pyrolysis products being silicon carbide, silicon nitride (carbon nitride), boron nitride, and silicon oxycarbide. The HRL Laboratories in the United States successfully formed complex structures of precursor polymers using SLA technology, yielding SiOC ceramics with excellent strength and heat resistance after pyrolysis (Figure 8). Professor Lyu Jian’s team at City University of Hong Kong used elastic silicone rubber (PDMS) mixed with nano-zirconia to prepare ceramic pastes, which were formed using DIW technology to create elastic ceramic precursors that can undergo expected deformations under designed stress conditions, later yielding SiOC ceramic products after high-temperature pyrolysis, marking the first realization of 4D printing of ceramics globally.

Figure 9 4D printed elastic precursor-derived ceramic origami structure.

5. Conclusion

Since the development of 3D printing materials, it has gone through a process from polymer materials to metal materials to ceramic materials. Currently, new materials continue to emerge in each field, reflecting the vitality of 3D printing technology. Although the categories of 3D printing materials now encompass most material systems, the materials successfully applied to 3D printing still represent only a tiny fraction compared to the vast material systems available today. In the face of the future trend of integrated structural functionality in 3D printing, continuous innovation in new materials, new technologies, and new equipment for 3D printing is required. In addition to the development of new 3D printing materials, the standardization and industrialization of 3D printing materials also present important challenges for the development of 3D printing materials. With the ongoing development of 3D printing materials, processes, and equipment, 3D printing technology will more effectively support our country’s transition toward becoming a manufacturing powerhouse.