Source: WeChat public account “Sensor Technology”

If you were to select a technology that could change the world today, what would it be? Artificial intelligence, blockchain, AR and VR technology, or the relatively unknown 3D printing technology? Compared to the previously mentioned popular technologies, 3D printing seems like a shooting star, shining brightly for a moment before disappearing, but in reality, 3D printing technology is rapidly changing the world.

The 3D printer is a magical machine designed by an inventor named Enrico Dini. It can not only “print” an entire building but can also print any required items for astronauts in a spacecraft.

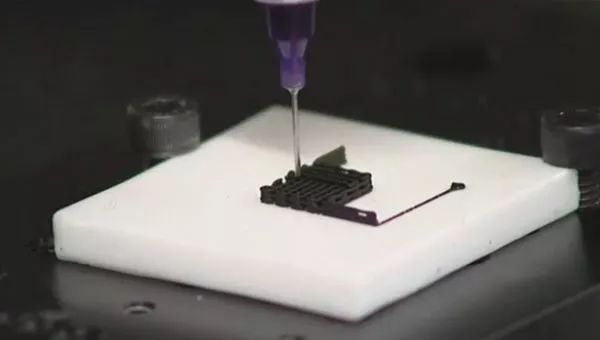

A 3D printer is a type of rapid prototyping technology that constructs objects based on digital model files, using special wax materials, powdered metals, or plastics as bindable materials, and builds objects layer by layer. It is often used in mold manufacturing and industrial design to create models or directly produce some products, indicating that this technology is becoming more widespread.

The Principles of 3D Printing Technology

3D printing is not a new technology; this concept originated in the United States in the late 19th century and was developed and promoted in the 1980s. The China Internet of Things University-Enterprise Alliance calls it “the idea of the last century, the technology of the last century, and the market of this century.” 3D printing usually employs digital technology and materials to achieve printing. The output and sales of these printers have greatly increased since the 21st century, and their prices are decreasing year by year.

Using a printer is like printing a letter: by clicking the “print” button on the computer screen, a digital file is sent to an inkjet printer, which sprays a layer of ink onto the paper to form a two-dimensional image. In 3D printing, the software uses Computer-Aided Design (CAD) to complete a series of digital slices, sending this information to the 3D printer, which stacks continuous thin layers until a solid object is formed. The biggest difference between a 3D printer and a traditional printer is that the “ink” it uses is real raw material.

There are various forms of stacking thin layers. Some 3D printers use an “inkjet” method. For example, an Israeli 3D printer company called Objet uses printer nozzles to spray a very thin layer of liquid plastic onto the casting tray, which is then treated under ultraviolet light. After that, the casting tray descends a tiny distance for the next layer to stack on. Another company based in Minneapolis, USA, Stratasys, uses a technology called “Fused Deposition Modeling” (FDM), where the entire process involves melting plastic inside the nozzle and then depositing plastic fibers to form thin layers.

Some systems use powdered particles as the printing medium. The powder is sprayed onto the casting tray to form a very thin layer, which is then solidified by a sprayed liquid adhesive. It can also use a technology called “laser sintering” to melt into a specified shape. This is the technology used by the German company EOS in its additive manufacturing machines. The Swiss company Arcam utilizes electron beams in a vacuum to melt powdered particles.

The methods mentioned above are just a part of the many forming methods. When encountering complex structures that include holes and cantilevers, a gel or other materials need to be added to provide support or occupy space. This part of the powder will not be melted, and can be washed away with water or airflow to create pores. Nowadays, various materials can be used for printing, ranging from numerous plastics to metals, ceramics, and rubber. Some printers can even combine different materials, allowing the printed object to be hard on one end and soft on the other.

The History of 3D Printing Technology Development

3D printing originated from the photographic sculpture and terrain forming technologies researched in the United States over a century ago, with prototypes appearing in the 1980s under the name “rapid prototyping”.

In the mid-1980s, SLS was developed and patented by Dr. Carl Deckard at the University of Texas at Austin, sponsored by DARPA. In 1979, a similar process was patented by RF Housholder, but it was not commercialized.

In 1995, MIT coined the term “three-dimensional printing” when graduates Jim Bredt and Tim Anderson modified the inkjet printer scheme to squeeze a binding solvent onto a powder bed instead of squeezing ink onto paper.

When talking about 3D printing, one cannot overlook the 3D printer itself. A 3D printer, also known as a three-dimensional printer, is a type of additive manufacturing technology that creates three-dimensional objects by printing layers of adhesive materials. Currently, 3D printers are used to manufacture products. Since 2003, the sales of 3D printers have gradually expanded, and prices have begun to decline.

This technology can be used in jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, and many other fields.

The core manufacturing concept of 3D printing originated in the late 19th century in the United States, and by the late 1980s, 3D printing technology had matured and been widely applied. 3D printing is one of the latest high-dimensional manifestations of the integration of technology.

Currently, the use of three-dimensional printers is still quite limited, but one day in the future, people will be able to print more practical items using 3D printers.

What Can 3D Printing Do?

Print Clothing

As early as 2013, Victoria’s Secret Fashion Show had already showcased clothing made with 3D printing technology, when supermodel Lindsay Ellingson stunned the audience wearing a pair of wings, a bodysuit, and a headpiece created by a 3D printer.

Print Prosthetic Limbs

In 2012, a boy in Sudan lost both of his hands due to injuries sustained during a standoff between two armies. This incident was brought to the attention of Mick Ebeling, who established a lab in Sudan equipped with a 3D printer to help amputees print the prosthetic limbs best suited for them using 3D printing technology.

In 2016, a 3D printing technology company in Hunan developed technology to print human bones and began formal applications. Recently, Yonsei University Health System in South Korea announced that they have developed a commercially viable 3D printed artificial eye, which is nearly indistinguishable from a real one. This indicates that in the future, we may no longer see any physically disabled individuals on the streets.

Print Anything You Want

In fact, by now, almost all common items in life can be manufactured using 3D printing technology. For example, cars can already be made with 3D printing technology, and major engine manufacturers are even attempting to use 3D printing technology to create car engines. Another example is our houses; a construction company in Shanghai has already showcased houses made with 3D printers. Although they may not look very appealing, the cost is extremely low. For less than fifty thousand yuan, you can own a three-bedroom apartment, provided that you own the land. In addition to houses and cars, 3D printing can also produce candy, completely edible candy without any worries about issues, and even art pieces and firearms can be printed.

Types of 3D Printing Technologies

SLA (Stereolithography Appearance)

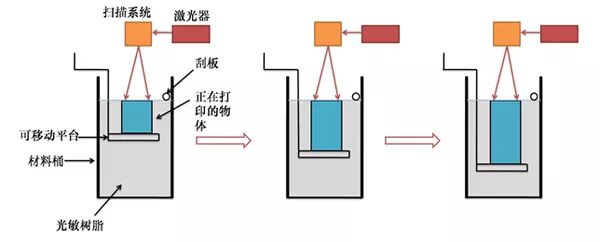

This method focuses a laser of specific wavelengths and intensity onto the surface of photopolymer material, solidifying it sequentially from points to lines to surfaces, completing a layer of drawing work. The platform then moves vertically by the height of one layer to solidify another layer. SLA is the earliest practical rapid prototyping technology, with liquid photopolymer resin as the raw material. Its working principle involves placing liquid photopolymer resin in a processing tank, where the platform’s height initially differs from the liquid surface by one layer thickness. The focused laser scans the surface of the photopolymer resin based on the cross-sectional profile, gradually solidifying the resin that is scanned, thus producing a solid resin piece identical to the cross-sectional profile. The platform then descends by one layer height, and the solidified resin piece becomes submerged in the unscanned liquid photopolymer resin in the processing tank. The laser then begins scanning according to the next layer’s cross-sectional profile, and the newly solidified resin adheres to the layer below. This process continues until the entire piece is processed, followed by polishing, electroplating, painting, or coloring to achieve the desired product.

Advantages:

1. The SLA method is the earliest rapid prototyping process with high maturity;

2. Prototypes are made directly from CAD digital models, with fast processing speeds and short production cycles, eliminating the need for cutting tools and molds;

3. It can process prototypes and molds with complex structural shapes that are difficult to form using traditional means;

4. It visualizes CAD digital models, reducing the cost of error correction;

5. It provides samples for experiments, allowing verification and validation of results from computer simulations;

6. It can be operated online and remotely, facilitating production automation;

Disadvantages:

1. SLA systems are expensive, with high usage and maintenance costs;

2. SLA systems are precision devices that operate on liquids, requiring a stringent working environment;

3. The formed parts are mostly resin-based, with limited strength, rigidity, and heat resistance, making long-term preservation difficult;

4. The software system is complex to operate, difficult to learn; the file formats used are not familiar to many designers;

5. Due to shrinkage during resin solidification, stress or deformation is inevitably produced;

SLS (Selective Laser Sintering)

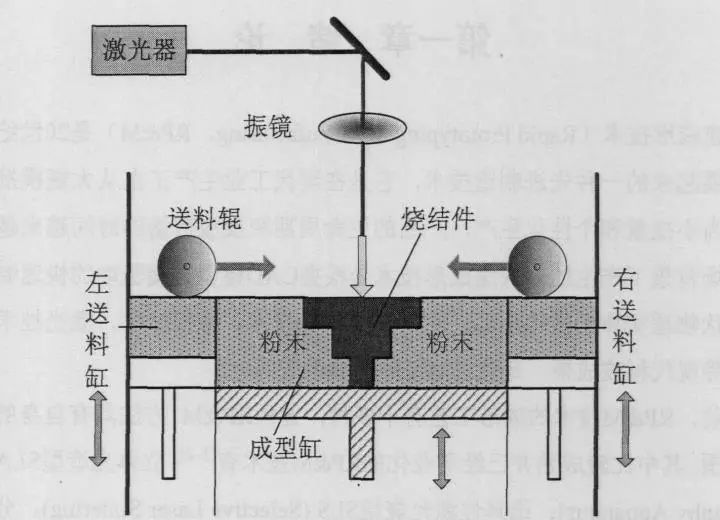

Selective laser sintering uses a laser to selectively sinter solid powder layer by layer, forming the required shape of parts. The entire process includes building and processing the CAD model, powder spreading, sintering, and post-processing.

The entire process device consists of a powder cylinder and a forming cylinder. During operation, the piston of the powder cylinder (feeding piston) rises, and a powder roller evenly spreads a layer of powder on the piston of the forming cylinder (working piston). The computer controls the two-dimensional scanning trajectory of the laser beam based on the sliced model of the prototype, selectively sintering solid powder materials to form a layer of the part. After completing one layer of powder, the working piston descends by one layer thickness, and the powder spreading system spreads new powder. The laser beam is then controlled to scan and sinter the new layer. This cycle continues until the three-dimensional part is formed. Finally, the unsintered powder is returned to the powder cylinder, and the formed part is removed. For metal powder laser sintering, the entire working table is heated to a certain temperature before sintering to reduce thermal deformation during forming and facilitate the bonding of layers.

Advantages:

1. SLS uses a wide range of forming materials. Currently, materials that can be processed by SLS include wax, polymers, metals, ceramic powders, and their composite powder materials. The performance of formed parts is widely distributed, suitable for various applications.

2. SLS does not require the design and manufacturing of complex support systems.

Disadvantages:

Parts processed by SLS often have rough surfaces, and the post-processing to enhance mechanical properties is also quite complex. (Roughness depends on powder diameter)

LOM (Laminated Object Manufacturing)

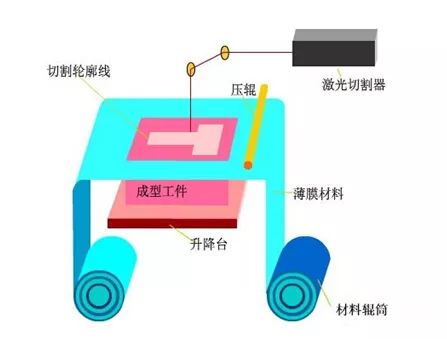

This method uses sheets (such as paper, plastic film, or composite materials) as raw materials, and a laser cutting system cuts out the internal and external contours of the workpiece according to the cross-sectional profile data extracted from the computer. After cutting one layer, the feeding mechanism adds a new layer of paper, using a thermal adhesive pressing device to bond the cut layer together before cutting again. This process continues layer by layer until a three-dimensional workpiece is formed. Common materials for LOM include paper, metal foil, plastic film, and ceramic film. This method can be used not only to manufacture molds and models but also to directly create structural or functional parts.

Advantages:

1. Reliable operation, good model support, low cost, high efficiency. The downside is that pre- and post-processing is time-consuming and labor-intensive, and it cannot produce hollow structures.

2. Forming materials: fiber paper coated with thermosensitive adhesive;

3. Performance of the formed parts: comparable to high-grade wood;

4. Main uses: rapid manufacturing of new product samples, models, or wooden molds for casting.

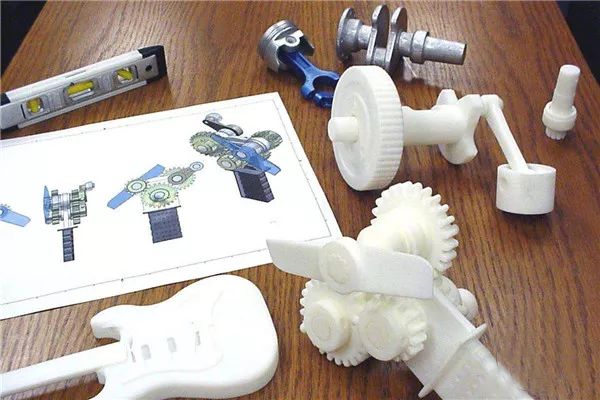

FDM (Fused Deposition Modeling)

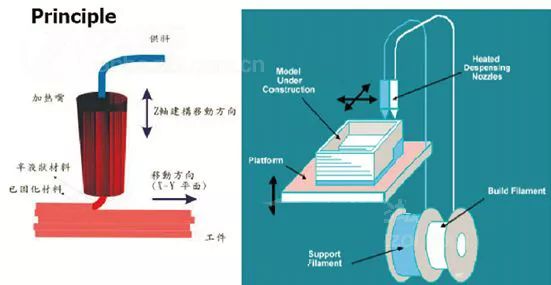

This method uses filamentous materials (wax, metal, plastic, low melting point alloy wire) as raw materials, heating the filament to just above its melting temperature (about 1°C higher than the melting point) using electric heating. Under computer control, the nozzle moves in the x-y plane, covering the worktable with the molten material to form a layer of cross-section. After one layer is formed, the nozzle rises by one layer height to apply the next layer (some literature states that the worktable descends by one layer height, and then the nozzle prints the next cross-section), repeating this process until completion.

The FDM process allows for various materials to be processed, including polycarbonate, engineering plastics, and their mixtures.

This process does not use lasers, is easy to use and maintain, and has a lower cost. Prototypes made from ABS are widely used in product design, testing, and evaluation due to their high strength. Recently, higher-strength forming materials such as PC, PC/ABS, and PPSF have been developed, making it possible to directly manufacture functional parts. Due to some significant advantages of this process, it has developed rapidly, and FDM systems currently have the largest share of installed rapid prototyping systems worldwide.

Advantages:

1. This technology has low pollution, and materials can be recycled, suitable for forming medium and small parts;

2. Forming materials: solid filament engineering plastics;

3. It is possible to use water-soluble support materials to facilitate separation from the workpiece, allowing for the processing of bottle-shaped or other hollow parts;

4. Performance of the formed parts: comparable to engineering plastics or wax molds;

5. Main uses: plastic parts, wax molds for casting, samples, or models.

Disadvantages:

1. Lower processing precision compared to SLA technology;

2. The surface of the workpiece is relatively rough;

3. The processing time is longer.

3DP Technology

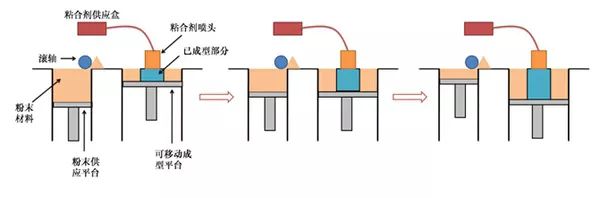

3DP, or 3D printing, uses standard inkjet printing technology, applying a liquid binder on a powder layer to create parts layer by layer according to cross-sectional data, forming three-dimensional solid models. The samples printed using this technology have the same color as the actual products and can even directly depict color analysis results on the model, significantly enhancing the information conveyed by the model samples. This is currently the most mature color 3D printing technology.

Existing Problems of 3D Printing Technologies and Solutions

Material Limitations

Currently, mainstream 3D printing technologies can achieve printing with polymer plastics, certain metals, or ceramics, but there are still many materials that cannot be printed. Material limitations are mainly reflected in two aspects: on one hand, the types of materials that current 3D printing technologies can print are limited and cannot fully adapt to the various materials required in industrial production. This means that 3D printing technology can only be applied in specific situations, with significant barriers to widespread promotion. On the other hand, for specific 3D printers, the types of printable materials are even more limited, requiring specially designed 3D printers for each type or category of material, making their universality inferior to traditional machining. Although there has been some progress in multi-material printing, unless these advancements mature and become effective, materials will continue to be a major obstacle for 3D printing.

Solutions:

To address the above two issues, solutions can be sought in the following ways. First, develop new materials, which is currently a direction strongly promoted by the country. By developing new materials with good printing performance and meeting the requirements of traditional materials, the universality of 3D printing technology can be improved. Second, enhance the universality of 3D printers themselves. This can be approached from a modular design perspective, maintaining consistent structural integrity while only changing certain components like the nozzle for different types or categories of materials, with good disassembly performance for easy replacement.

Low Printing Efficiency

Low efficiency can be analyzed from two angles. First, compared to traditional machining, which removes material from a blank to form parts, the difference in material between the blank and the part is usually small, meaning less material needs to be removed, resulting in faster processing; whereas 3D printing technology must stack all the material needed for the entity through additive methods, leading to a larger material volume. Therefore, comparing the volume of material removed or stacked, the additive volume is usually larger than the subtractive volume. Second, considering the forming motion, traditional machining primarily involves rotational motion, while 3D printing technology involves linear motion, which is easier to achieve higher speeds with rotational motion. The scanning motion of 3D printing technology is linear, making it difficult to attain high speeds. Thus, 3D printing technology not only requires a larger volume of material to process but also has speed limitations, resulting in overall lower processing efficiency.

Solutions:

To address the first issue, consider adding material to a certain rule-based blank material to reduce the amount of material needed for printing, primarily for large-scale production, by pre-designing a series of solid profiles containing the minimum blank. For the second issue, from a mechanism perspective, design mechanisms capable of high-speed motion, such as parallel mechanisms. It is also necessary to coordinate the design of materials to increase their melting or solidifying speeds. Furthermore, software and trajectory planning can be improved, adopting a gradient design approach where areas with strength requirements have a higher filling rate, while other areas have lower filling rates, rather than applying the same filling rate throughout the entire solid.

Low Quality and Precision

First, regarding quality, since 3D printing uses an additive manufacturing process of “layered manufacturing, layer by layer stacking,” even with tightly bonded layers, it cannot compare to parts formed by traditional molds through overall casting. The microstructure and organization of the material of the parts determine their physical properties, such as strength, rigidity, wear resistance, fatigue resistance, and airtightness, which often do not meet the practical engineering requirements. Secondly, regarding precision, due to the inherent forming principles of 3D printing technology and its still-imperfect development, the precision of printed parts—including dimensional precision, shape precision, and surface roughness—is poor, making them unsuitable for functional parts and only usable as prototypes, thus significantly limiting their application.

Solutions:

For quality issues, consider aligning the printing texture with the main stress direction of the parts to increase strength and prevent tearing or damage under force. For precision issues, research high-resolution printing technologies to reduce layer resolution while considering efficiency matching. Additionally, combining additive and subtractive technologies for surface treatment or other post-processing can also be explored.

Editor: Lemon