Profibus Bus Technology

1. What is Profibus Fieldbus?

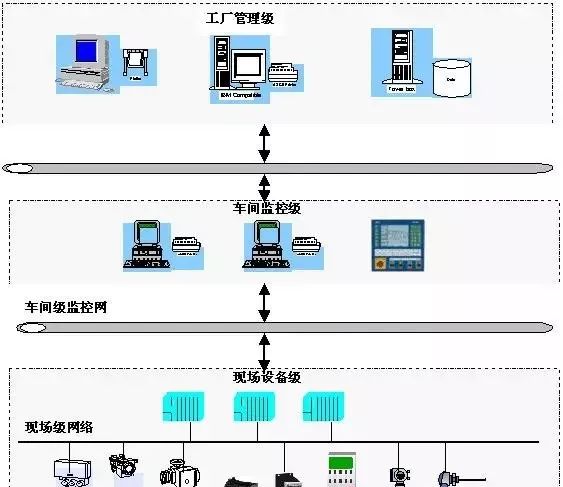

The fieldbus is a serial, digital, multipoint communication bus installed between field devices/instruments in the production process area and the automatic control devices/systems in the control room. Of course, the production process includes both continuous and batch production. Profibus fieldbus is one of them.

In simple terms, Profibus connects various dispersed field devices (sensors and actuators) to controllers or control systems through the bus, while supporting factory automation, process automation, and drive applications.

2. Three Types of Profibus Standards

Profibus fieldbus includes: Profibus-FMS, Profibus-DP, and Profibus-PA. The corresponding communication methods, application fields, and advantages are as follows: FMS is mainly for general-purpose automation, suitable for wide applications with multiple master communications; DP is primarily for factory automation, characterized by speed, plug-and-play, and cost-effectiveness; while PA is mainly used in process automation, application-oriented, requiring bus power supply, and must comply with intrinsic safety standards.

Currently, the main application in the market is still the Profibus-DP network, so I will mainly introduce some knowledge about the DP network.

3. Three Types of Devices Defined by Profibus-DP

1. DP Class 1 Master Device (DPM1)

The central controller that exchanges data with distributed I/O devices (DP-slaves);

Several DPM1s can coexist, with typical devices being PLCs, PCs, and VME.

2. DP Class 2 Master Device (DPM2)

Configuration, monitoring, or engineering tools used to set network parameters or monitor DP-slave devices.

3. DP-Slave Device

Peripheral devices that directly connect to I/O signals;

Typical devices include inputs, outputs, drives, valves, operation panels, etc.

4. Data Transmission Between Profibus-DP Masters and Slaves

1. Parameterization Phase

The slave is parameterized by the DP-master using the current bus parameters, monitoring time, and specific parameters of the slave.

2. Configuration Phase

The DP-master compares the required configuration for the DP-slave with the current configuration.

3. User Data Transmission Phase

After successful parameterization and configuration, the DP-slave changes its state to enter the user data exchange phase.

During this phase, the parameters of the slave can be changed without interrupting data transmission.

Note: During these three phases, diagnostic data and control commands can also be transmitted.

5. Main Applications of Profibus

Profibus bus technology has developed relatively maturely in China and is widely applied across various industries. In factory automation, it is used in vehicle manufacturing, bottling plants, inventory systems, switchgear, glass production, etc.; in process automation, it is used in the chemical industry, petrochemical industry, paper and textile industry, food and grain industry, power plants, wastewater treatment, etc.; additionally, it is also widely used in drive technology and safety applications.

Disclaimer: This article is published by Cold Rolled Electrical Control, and the copyright belongs to the original author. Please indicate the source when reprinting; if there are any biases in the article content, please feel free to correct them; for inquiries about electrical automation issues, please follow our public account to contact us.

Cold Rolled Electrical Control focuses on core technologies such as AGC and ATC, dedicated to improving the automation level of China’s cold rolling equipment.