SCIIA

Abstract

The Industrial Intelligent Network has great potential to drive structural transformation of the national economy and the transformation of social engineering systems. This article reviews the evolutionary process from the Industrial Internet to the Industrial Intelligent Network, distilling its multi-layered connotations and analyzing its important role in empowering the construction of a modern industrial system within a horizontal framework. Currently, the global Industrial Intelligent Network is at a critical period of technological acceleration, expansion of application scenarios, and scaling up. The United States, China, Japan, and Germany have certain first-mover advantages; technological innovation is mainly focused on core empowering capabilities and engineering applications; new links, new processes, and new entities are continuously emerging; and the importance of technological standards and development security is increasingly emphasized. China has achieved significant results in the practice of the Industrial Intelligent Network, with continuous improvement in top-level design, expansion of industrial scale, deepening regional collaboration, and continuous expansion of application scenarios. However, there are still issues such as insufficient supply capacity of key technologies, bottlenecks in empowering certain industries, an undeveloped talent training system, and an urgent need to improve the multi-dimensional security guarantee system. To promote the high-quality development of the Industrial Intelligent Network and fully leverage its role in constructing and empowering a modern industrial system, it is necessary to improve the new national system for tackling key technological challenges, break down barriers to collaborative innovation; leverage the advantages of application volume data scenarios to unleash industrial development potential; build a complete professional talent supply and demand system, and strengthen talent team building; and construct a high-standard industrial chain security system to ensure comprehensive industrial safety.

Keywords

Industrial Intelligent Network; Industrial Internet; Industrial Networking Technology; Modernization of Industrial System

Funding

Major Innovation Project in National Governance Field of the Chinese Academy of Social Sciences (2023YZD011); Graduate Research Innovation Support Program of the Chinese Academy of Social Sciences University (2023-KY-71).

The report of the 20th National Congress of the Communist Party of China pointed out that to “build a modern industrial system,” we must “focus on the real economy as the main point of economic development and promote new industrialization,” while also “accelerating the development of the digital economy, promoting the deep integration of the digital economy and the real economy, and creating internationally competitive digital industry clusters.” As a product of the deep integration of a new generation of information technology and industrial economy, industrial networking technology empowers industrial enterprises to transform towards digitization, networking, and intelligence, changing the underlying architecture of traditional industrial production, nurturing new production factors and processes, and continuously optimizing resource allocation, becoming a key force in promoting high-quality industrial development. With the in-depth development of industrial and technological revolutions, the concept and technology of the Industrial Intelligent Network are gradually emerging, becoming a strategic innovation direction to enhance industrial international competitiveness and reshape the global industrial development pattern.

Building a complete industrial ecosystem for the Industrial Intelligent Network and promoting the leapfrog upgrade of existing industrial Internet and industrial IoT industrial chains and technological systems towards “intelligent networking” has significant practical implications for accelerating the construction of a modern industrial system in China, promoting the construction of a strong manufacturing country, a quality strong country, and a network strong country, and consolidating and enhancing China’s position in the global industrial chain, value chain, and innovation chain. This article reviews the evolutionary process of the concept, analyzes its mechanism in promoting the construction of a modern industrial system based on the connotation framework of the Industrial Intelligent Network. At the practical level, it analyzes the current global development status and trends of the Industrial Intelligent Network and, in conjunction with China’s current stage of practical achievements and main issues, proposes targeted countermeasures and suggestions.

1

Industrial Intelligent Network: Vertical Concept Evolution and Horizontal Empowerment Framework

(1) Vertically: From “Interconnection” to “Intelligent Networking” Concept Evolution

The integration of industrial technology and information technology began as early as the mid-20th century. In the 1970s and 1980s, the global information technology revolution rapidly elevated the status of the information industry within the national economic system, while also reshaping traditional manufacturing industries. Since the 21st century, new generation information technologies and digital technologies represented by 5G, artificial intelligence, and big data have made breakthroughs, propelling traditional industries into the fast lane of digital development, with industrial networking technology becoming a key focus for digital transformation in the industrial sector. Overall, the development of industrial networking technology has gone through three evolutionary stages: from the Industrial Internet to the Industrial Internet of Things, and then to the Industrial Intelligent Network.

In 2012, General Electric first proposed the concept of the Industrial Internet in its white paper “Industrial Internet: Breaking the Boundaries Between Wisdom and Machines,” defining it as the flow and interaction of data, hardware, software, and intelligence, establishing an adaptive intelligent industrial network through sensor networks, big data analysis, and software. The concept of the Industrial Internet quickly attracted the attention of major countries worldwide, as it was believed to have the potential to empower existing industries, achieve ubiquitous interconnection, and induce structural changes in the national economy, promoting high-quality economic development.

With the in-depth development of the industrial technological revolution, the concept and technology of the Internet of Things (Industrial Internet of Things) have rapidly gained popularity. With the support of IoT technology, the concept of the Industrial Internet has gradually evolved into the concept of the Industrial Internet of Things. At the end of 2017, the IEEE Computer Society listed the Industrial Internet of Things as one of the top ten technology development trends for 2018. Compared to the Industrial Internet, the Industrial Internet of Things emphasizes the connection between networking systems and material elements, and equipment terminals, integrating industrial equipment, cloud computing, edge computing, and other resources into the networking system, achieving extensive deep interconnection down to the end-edge devices through the perception access layer and control operation layer.

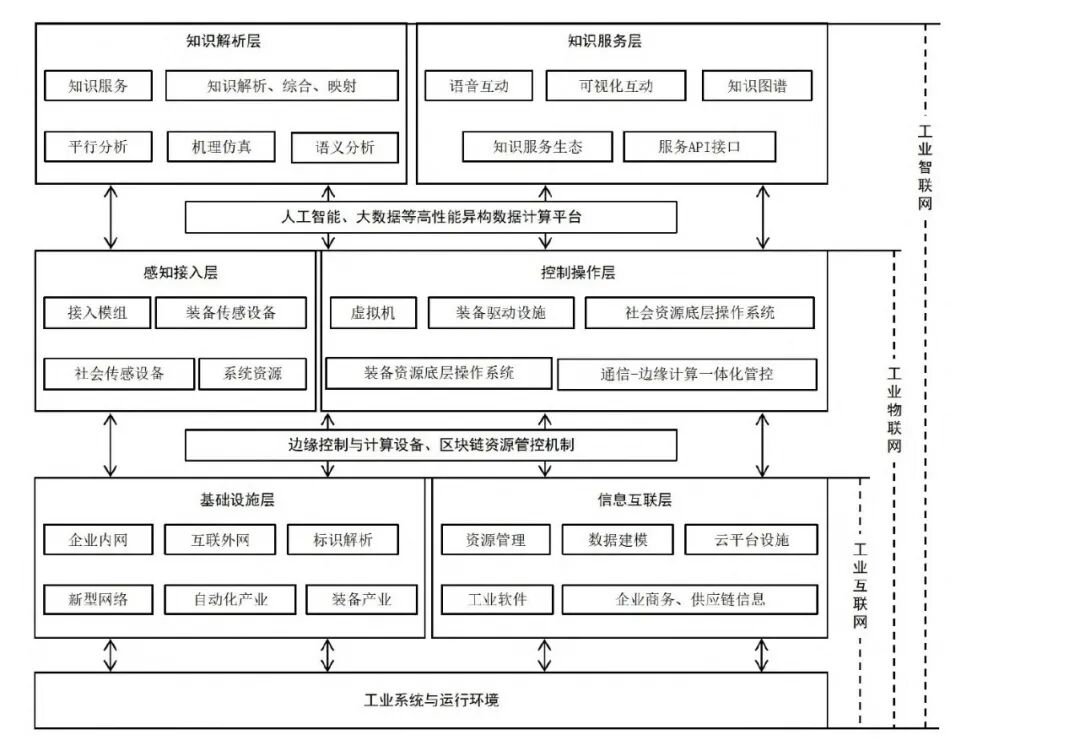

Currently, the representative technologies of the new round of information technology revolution exhibit a trend of integrated innovation, with high-performance heterogeneous data computing platforms oriented towards artificial intelligence, big data, and blockchain technologies coupled with industrial networking technology, giving rise to the concept and technology of the Industrial Intelligent Network (Industrial Internet of Minds), which aims to address issues of system resource utilization efficiency, adaptability, autonomy, self-organization, and security, achieving automated knowledge parsing and automated services in industrial processes. The Industrial Intelligent Network effectively integrates intelligent system engineering technology at a higher level of intelligence, providing technical support for the new generation of industrial intelligent industries.

Figure 1

The Concept Evolution Process from Industrial Internet to Industrial Intelligent Network

With the expansion of technological concepts (see Figure 1), countries around the world have successively launched a series of industrial networking development frameworks based on their national conditions, development advantages, and stage characteristics, such as the U.S. Smart Manufacturing Ecosystem (2011), Germany’s Industry 4.0 (2012), China’s Intelligent Manufacturing (2015), and Japan’s Industrial Value Chain (2016).

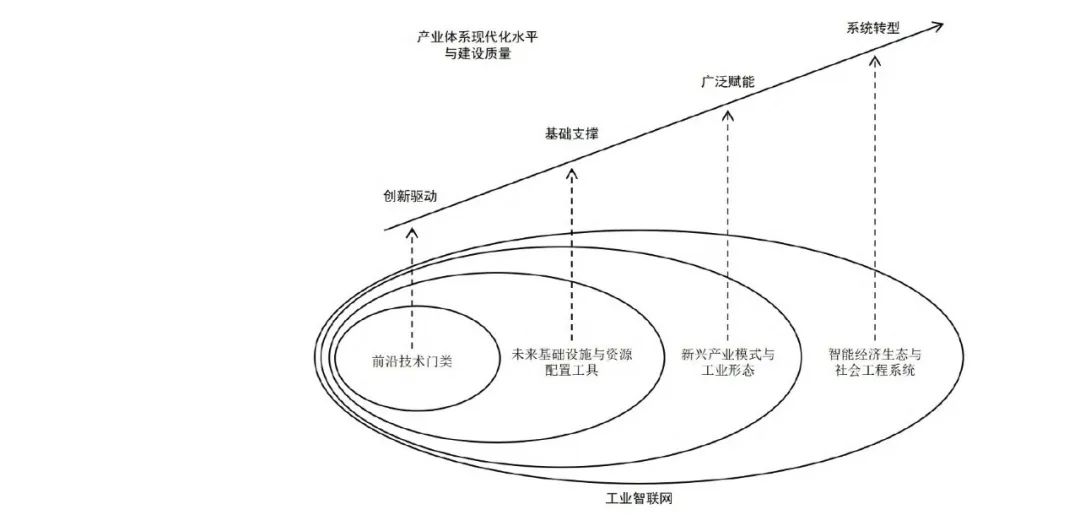

(2) Horizontally: Multi-layered Connotation Framework of the Industrial Intelligent Network Empowering Modernization of the Industrial System

General Secretary Xi Jinping emphasized the need to “lead with technological innovation, accelerate the high-end, intelligent, and green upgrade of traditional industries, cultivate and expand strategic emerging industries, and accelerate the construction of a modern industrial system characterized by intelligence, greenness, and integration, meeting the requirements of integrity, advancement, and safety.” Vertically, the concept of the Industrial Intelligent Network has evolved through stages such as the Industrial Internet and the Industrial Internet of Things. Horizontally, the concept of the Industrial Intelligent Network can be defined through a multi-layered connotation framework (see Figure 2), which includes frontier technologies, infrastructure and tools, new industrial models and industrial forms, intelligent economic ecology, and social engineering systems. As the connotation of the concept expands, the supporting, adjusting, and optimizing roles of the Industrial Intelligent Network for the industrial system also deepen, promoting the construction of a modern industrial system at different dimensions, improving the modernization level and development quality of the industrial system, and enhancing the international competitiveness of the industrial chain and innovation chain.

Figure 2

Multi-layered Connotation Framework of the Industrial Intelligent Network and Path to Enhance the Modernization Level of the Industrial System

1. Frontier Technology Innovation Provides Fundamental Drive for the Construction of a Modern Industrial System

Essentially, the Industrial Intelligent Network is a dynamic and time-varying frontier technology that changes system content, form, method, and structure in real-time through the accumulation of experiential knowledge, directly addressing complex industrial systems and operating environments, aiming to provide automated knowledge parsing and knowledge services, and engage in real-time knowledge interaction and behavioral interaction with the real world. The Industrial Intelligent Network itself requires a good innovation environment and system, further accelerating the flow efficiency of innovative elements such as equipment, talent, and technology, expanding innovation channels, improving the innovation environment, enhancing innovation efficiency, and transforming the driving force of industrial development from investment-driven to innovation-driven, providing fundamental power for the construction of a modern industrial system.

2. Providing Basic Support as Future Infrastructure and Resource Allocation Tool

Based on technological applications, the Industrial Intelligent Network has become a key infrastructure and resource integration and allocation tool for future industries. China’s “14th Five-Year Plan for Digital Economy Development” states the need to “build reliable, flexible, and secure industrial Internet infrastructure to support ubiquitous connection, elastic supply, and efficient allocation of manufacturing resources.” The industrial Internet, based on communication, sensing, base stations, networks, monitoring systems, and industrial apps, achieves extensive connections among people, machines, and materials in industrial processes, providing a complete, efficient, responsive, and secure real-time network for production control for connected enterprises.

On this basis, the Industrial Intelligent Network provides intelligent technology applications and knowledge services supported by multi-layered integrated computing systems, social engineering systems jointly perceiving and driving, enabling massive industrial entities to complete socialized knowledge collaboration, fundamentally transforming industrial production forms, and greatly liberating and enhancing social productivity. As the forefront application field of new infrastructure, the Industrial Intelligent Network promotes power conversion, quality transformation, structural upgrading, efficiency improvement, and environmental optimization, empowering high-quality development of the real economy, providing foundational support for promoting new industrialization and constructing a modern industrial system.

3. Shaping New Industrial Models and Industrial Forms to Enhance the Modernization Level of the Industry

By extensively empowering traditional industrial sectors, the Industrial Intelligent Network gradually shapes a new industrial form and model. The Industrial Internet of Things achieves comprehensive interconnection across devices, systems, factories, and regions based on traditional industrial production models, enabling efficient and precise allocation of various resources. The Industrial Intelligent Network further models, analyzes, and controls various industries, allowing them to operate and develop autonomously with high efficiency, automatically analyzing macro and micro data across all industries, constructing a manufacturing and service application system covering the entire industrial chain and value chain, forming a truly data-driven, knowledge-driven, and intelligent industrial model.

Interactions between traditional industrial systems and virtual industrial systems establish a new industrial system characterized by intelligence, virtual-real interaction, and virtual-real entanglement, supporting production decision-making and asset management, and promoting the integration and collaboration of industrial systems across all scales, elements, and value chains, completing management and control, analysis and optimization of actual industrial systems, significantly enhancing the quality and efficiency of industrial economic development. On one hand, the development of the Industrial Intelligent Network has nurtured and expanded strategic emerging industries such as artificial intelligence, big data, blockchain, and intelligent equipment; on the other hand, it accelerates the high-end, intelligent, and green upgrade of traditional industries, enhancing the modernization level and construction quality of the industrial system.

4. Promoting Economic and Social System Transformation to Improve the Development Quality of the Modern Industrial System

In the broadest sense, the Industrial Intelligent Network empowers the entire economic and social domain, shaping an intelligent economic ecology and promoting the transformation of intelligent social engineering systems. The Industrial Intelligent Network promotes the evolution from point intelligence to comprehensive integrated intelligence, accelerating profound changes in innovation mechanisms, organizational forms, and business paradigms, establishing a new collaborative digital trust, perception control, and knowledge automation system that directly covers all economic entities.

Social system disciplines believe that the “physical space” physical engineering system, “cyber space” artificial engineering system, and “social space” social engineering system together constitute a complete social system. Under the development background of the Industrial Intelligent Network architecture, agricultural intelligent networks, transportation intelligent networks, energy intelligent networks, and enterprise intelligent networks have emerged, enabling artificial engineering systems to achieve real-time control over physical engineering systems and guide social engineering systems. The social system also provides real-time feedback to physical and artificial systems, ultimately achieving interconnection among physical space, cyber space, and social space, constructing a complete intelligent social engineering system. The Industrial Intelligent Network expands the construction of a modern industrial system to the social level, aligning more closely with the requirements of integrity, advancement, and safety, and receiving real-time feedback from the economic ecology and social engineering systems, making timely adjustments and corrections to improve the quality of industrial system construction, truly creating a modern industrial system that meets social needs, adapts to social characteristics, and fits social forms.

2

Current Status and Trends of Global Industrial Intelligent Network Development

Currently, the global Industrial Intelligent Network is at a critical period of technological acceleration, expansion of application scenarios, and scaling up, with the industrial pattern not yet fully determined, presenting significant development potential. In terms of industrial status, the United States, China, Japan, and Germany have certain first-mover advantages in the Industrial Intelligent Network based on their existing industrial Internet foundations; in terms of technological trends, innovation is mainly concentrated in two directions: core empowering capabilities and engineering application breakthroughs; in terms of industrial ecology, new links, new processes, and new entities are continuously emerging; and in terms of overall ecology, diverse entities are strengthening cooperation, with greater emphasis on technological standards and development security.

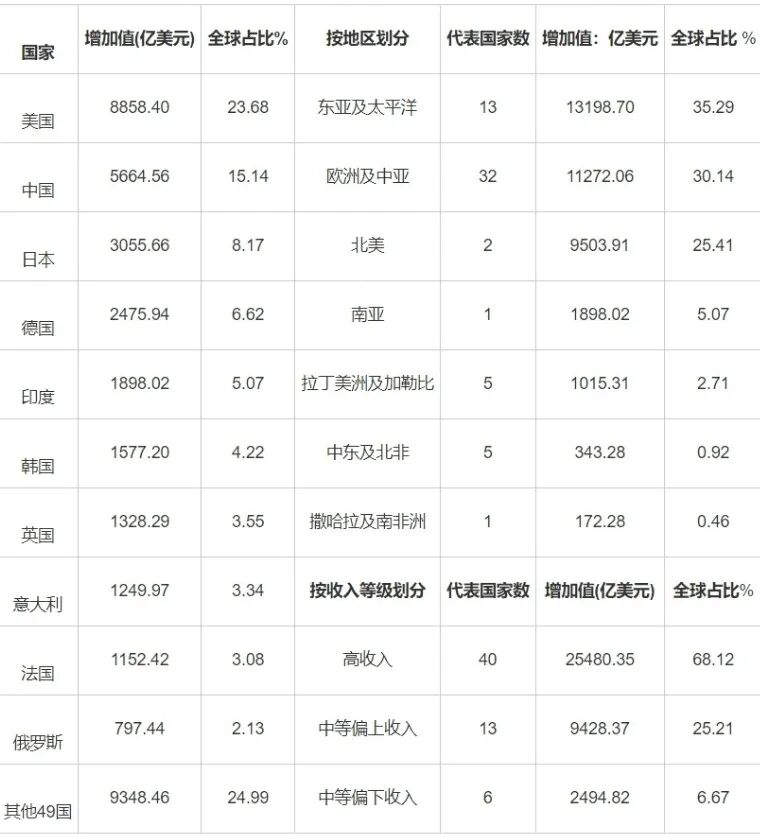

(1) The U.S., China, Japan, and Germany dominate the foundational industrial scale, while upper-middle-income countries seize opportunities

The Industrial Intelligent Network is still an emerging technological concept, and major countries or organizations in the world have not yet reached a consensus on its industrial and technological standards, nor do they have a unified statistical caliber. Given that the Industrial Intelligent Network is based on the earlier development form of the Industrial Internet, this section describes the foundational situation of the Industrial Intelligent Network industry in terms of the added value scale of the Industrial Internet industry. Based on data from the OECD and the World Bank, the China Industrial Internet Research Institute has estimated the scale of the Industrial Internet industry in 59 representative countries (see Table 1). In 2020, the total added value of the Industrial Internet in these 59 countries was $3.74 trillion. The top four were the United States at $885.84 billion, China at $566.46 billion, Japan at $305.57 billion, and Germany at $247.59 billion, with the combined scale of the U.S., China, Japan, and Germany exceeding 50% of the global scale.

According to regional classification, the combined share of the Industrial Internet scale in East Asia and the Pacific, Europe and Central Asia, and North America exceeds 90%. Among them, East Asia and the Pacific accounted for $1.32 trillion, or 35.29%, with a growth rate of 5.21%; Europe and Central Asia accounted for $1.13 trillion, or 30.14%, with a growth rate of 2.37%; and North America accounted for $0.95 trillion, or 25.41%, with a growth rate of 1.51%. In addition, the combined added value of the Industrial Internet in South Asia, Latin America, and the Caribbean accounts for about 9% of the global total. By income level, high-income countries have a total scale of $2.55 trillion, accounting for 68.12%, with a growth rate of 1.41%; upper-middle-income countries have a scale of $0.94 trillion, accounting for 25.21%, with a growth rate of 7.34%; and lower-middle-income countries have a scale of $0.25 trillion, accounting for 6.67%, with a growth rate of 1.59%. It can be seen that high-income countries have a first-mover advantage in industrial foundations due to their developed industrial systems, but upper-middle-income countries such as China, Russia, and Brazil are striving to seize the opportunities of the new round of technological and industrial revolutions, strengthening the application of the Industrial Intelligent Network in their national economic systems, aiming to achieve a “curve overtaking” in the development of the Industrial Intelligent Network.

Table 1

Top Ten Countries and Regions in Global Industrial Internet Added Value in 2020 and Income Classification

Data Source: Compiled based on the “White Paper on the Economic Development of China’s Industrial Internet Industry (2021).”

(2) Technological innovation mainly focuses on core empowering capability growth and engineering application breakthroughs

Currently, technological innovation in the Industrial Intelligent Network mainly targets two directions: one is upward towards more complex knowledge processing and higher performance requirements for core empowering capability growth; the other is downward towards engineering breakthroughs for industrial deployment and implementation.

In terms of core empowering capabilities, first, data science focuses on more complex and diverse industrial problems, conducting innovations centered on deep learning. Deep Reinforcement Learning (DRL) optimizes multi-decision execution in dynamic environments and complex scenarios through continuous iteration and trial-and-error in industrial practice, demonstrating strong optimization capabilities in product design and development, scheduling control, processing paths, operation management, and strategies. Generative Adversarial Networks (GAN) increase the number of effective industrial samples through the competition between two neural networks, improving the quality of industrial data and providing a data foundation for industrial model training. Second, based on deep learning, application innovations focus on enhancing the ability to identify key issues and knowledge service capabilities related to production and customers. Industrial vision technology focuses more on high-precision small target recognition scenarios and processing capabilities under low-quality data conditions. Natural Language Processing (NLP) enhances user interaction recognition capabilities in user service segments, improving service efficiency and quality by analyzing knowledge graphs and deeply mining customer needs. Third, knowledge engineering is moving towards graph-based, automated construction and updating, and quantitative complex decision-making. The core links of industrial knowledge, including data acquisition, knowledge processing, and knowledge application, have been clarified, and the automated construction and updating architecture of industrial knowledge graphs is gradually taking shape, with the semantic processing link transitioning from manual processing to automated extraction and fusion, and the graph updating link achieving dynamic self-updating. Some institutions have established knowledge “open crowdsourcing” mechanisms for graph management. The application of industrial knowledge graphs is gradually shifting from semantic information retrieval and qualitative decision-making to quantitative complex decision-making, enhancing graph inference capabilities through the integration of machine learning models in core decision-making execution links. Fourth, the interaction and learning methods of industrial robots are shifting towards human-machine, brain-like, and brain-machine technologies, with breakthroughs in bidirectional brain-machine interfaces and brain-like + brain-machine interfaces profoundly changing human-machine collaboration patterns, although this field is still in theoretical research and experimental stages.

In terms of engineering applications, technological innovation focuses on model efficiency, process interpretability, data quality, industrial integration, and large-scale implementation. First, chips and model hardware and software work together to solve model efficiency issues. Currently, chip architectures primarily based on the von Neumann structure face the “memory wall” challenge, with domestic and foreign AI companies and chip manufacturers such as Hailo and KunYun Technology launching acceleration modules, edge computing boxes, and other hardware, focusing on architectural design and scenario optimization for diverse explorations. Currently, techniques for improving model efficiency, such as knowledge graph distillation, knowledge refinement, and parameter pruning and quantization, are widely concerned, but their specificity and academic nature limit their industrial implementation and promotion. Second, enhancing process interpretability in fields such as equipment management and process optimization. On one hand, in scenarios such as quality inspection and equipment anomaly identification, causal/correlational relationships are mined based on feature visualization methods and output visually; on the other hand, in scenarios such as fault root cause analysis and production defect prediction, local/global approximations of interpretable models such as decision trees, decision rules, and industrial knowledge graphs are used to enhance interpretability. Third, focusing on the small sample dilemma and industry-specific dataset construction issues to improve data availability. The small sample dilemma arises from the fragmentation, marginalization, and weak correlation of current industrial data, making it difficult to extract knowledge. Currently, there are mainly several solution paths, including data augmentation, introduction of prior knowledge, and optimization of model structures. At the industry level, intelligent algorithm models are developed based on datasets to enhance the ability to solve common industry problems, while at the domain level, common needs are explored to enhance the ability to solve scenario-specific problems. However, these solutions still face constraints such as data asset/commercial confidentiality leakage, immature privacy computing technologies, and incomplete legal regulations. Fourth, AI frameworks are gradually becoming the core area for accelerating industrial integration and large-scale implementation. TensorFlow, PyTorch, and Baidu PaddlePaddle have become widely used AI frameworks in the domestic industrial field, connecting differentiated industrial applications above and diverse industrial hardware below, providing a unified, scalable infrastructure layer to enhance model training performance, while also providing targeted adaptation and specific optimization for target hardware to ensure model deployment and inference speed on the edge, with the ultimate goal of enhancing the adaptability and usability of AI frameworks, promoting industrial integration and large-scale implementation.

(3) Overall industrial ecology construction gives rise to new links, processes, and competitive entities

As industrial networking technology continues to develop, developed countries are increasingly recognizing the importance of networking technology in reshaping the overall industrial ecology and enhancing national industrial competitiveness. The development goal has shifted from the early revitalization of local manufacturing to fully leveraging the penetration, empowerment, and transformation effects of the Industrial Intelligent Network to enhance the overall quality of industrial development. The United States has further increased government support for industries such as artificial intelligence, 5G, and advanced manufacturing, continuously adding R&D investments. Germany has continued to release a series of strategic policies such as “Digital Strategy 2025” and “German Industrial Strategy 2030,” promoting the formation of multi-layered industrial networking industry clusters. Large high-tech multinational companies such as Siemens and SAP are integrating advantages to accelerate global industrial transformation and layout. The European Union and its member states continue to promote the development of emerging industries and the re-creation of high value-added links in existing industries. Japan has launched the “Industrial Value Chain Plan” to establish a localized interconnected industrial support system.

Under the overall industrial ecology construction goal, new links and processes such as industry data labeling have emerged, with AI-centered service enterprises becoming typical representatives of new market entities. The data labeling and other data service industries are concentrated in warehousing logistics and security scenarios, including recent companies such as Motor Intelligence, Iceberg Data, and Awakening Vector, where large-scale, high-quality labeled datasets have gradually become a rigid demand for industrial development. The fragmented characteristics of industrial scenarios require industrial intelligent models to continuously iterate and optimize, and a number of AI technology-centered industrial service enterprises have emerged in high-value equipment health management and other fields, injecting AI capabilities into industrial production management processes to provide users with intelligent services such as equipment supervision, operation and maintenance, and predictive maintenance. In addition to AI service enterprises, large consulting firms have also joined the competition in the intelligent service market, expanding market share with customized intelligent solution advantages. Companies like Accenture and Deloitte have rich industrial consulting experience and a wide range of intelligent technology ecosystem partners, such as Accenture, which has over 50 years of global consulting service experience and more than 9,000 technical consultants covering over 40 industries, and has close cooperation with Microsoft, Google, and Amazon. These companies build technological advantages by establishing research institutions and provide industrial AI services such as factory design, operational consulting, solution development, and deployment for clients. The collaborative model of industrial enterprises around AI core empowerment is gradually taking shape, with one being product-binding cooperation, obtaining data from industrial enterprises and empowering industrial products and equipment; the other being knowledge-binding cooperation, leveraging the professional knowledge of industrial enterprises to utilize the advantages of general AI technology to create intelligent product solutions.

(4) Diverse stakeholders collaborate, emphasizing technological standards and industrial development security

There are generally two types of development models for industrial networking technology. The enterprise-led model represented by the United States promotes the integration of physical systems and digital networks through industry alliances in a “bottom-up” manner, breaking down technical barriers across industries and regions; the government-led model represented by Germany conducts cooperation between the government and stakeholders in a “top-down” manner, gathering enterprises at all levels to promote standardization, R&D, and testing. Whether “bottom-up” or “top-down,” collaborative cooperation among diverse entities such as governments, research institutions, service providers, factory operators, machinery manufacturers, and platform operators has become a mainstream trend. The Industrial Internet Consortium (IIC) in the United States has gathered 270 companies from 38 countries and regions, coordinating between government, industry, and academia to promote the global deployment and application of industrial networking technology, with members including giants like SAP, Bosch, and Siemens. Germany’s Industry 4.0 strategy establishes partnerships among government, academia, and the private sector, including government departments such as the Ministry of Education and Research and the Ministry of Economic Affairs and Technology, with academia represented by the Fraunhofer Society, the National Academy of Sciences and Engineering, and the German Research Center for Artificial Intelligence, and the private sector including IT industry associations, machinery industry associations, and electronics industry associations. Japan has established the Industrial Value Chain Promotion Association (IVI) to create an open and secure manufacturing ecosystem primarily through corporate alliances and has released the “Strategic Implementation Framework for Japan’s Interconnected Industrial Value Chain,” constructing a top-level framework for the development of Japan’s Industrial Intelligent Network.

As the importance of building technological standards and the uniqueness of security issues in industrial networking technology become increasingly prominent, countries around the world are gradually increasing the policy weight of standard construction and security issues, forming a three-pronged focus on “technology – standards – security” for industrial development. According to statistics from the European Union’s Internet of Things Innovation Alliance, there are currently over 100 industrial networking technology standardization organizations globally, with Germany and the United States in a leading position. In 2016, Germany established the Global Industry 4.0 Research Institute to formulate digital manufacturing standards and participate in domestic and international standard coordination. The U.S. AllSeen Alliance and the Open Connectivity Foundation (OCF) actively participate in formulating industry standards, with many of their strategies and solutions being widely promoted. The European Union’s Digital Single Market (DSM) strategy focuses on data free flow, responsibility allocation, ownership, interoperability, availability, and access to achieve interoperability and standardization. Regarding security issues, countries are strengthening the leading role of governments in industrial security systems, focusing on enhancing cybersecurity, data security, and other aspects, with regulatory security standards tending towards unification. In 2018, the U.S. established the Cybersecurity and Infrastructure Security Agency (CISA) to oversee the security of networks and infrastructure. In 2019, it introduced the “Internet of Things Device Security Act,” the “Energy Infrastructure Security Act,” the “Cybersecurity Technology Protection for Grid Resources Act,” and the “Supply Chain Cybersecurity Risk Management Guidelines,” comprehensively ensuring the information security of critical infrastructures such as IoT, energy, and healthcare. The European Union Agency for Cybersecurity (ENISA) released the “Cybersecurity Challenges and Recommendations for Industry 4.0” to guide the construction of industrial information security. Subsequently, it released strategic documents such as the “Protecting Information Age Social Security Strategy,” the “EU Cybersecurity Strategy,” the “Critical Infrastructure Protection Plan,” and the “General Data Protection Regulation.” Germany is building a layered security management system centered on cyber-physical systems, issuing multiple documents such as the “Industry 4.0 Security Guidelines,” “IT Security in Industry 4.0,” “Cross-Enterprise Secure Communication,” and “Secure Identity Identification.” In 2019, Japan released the “Cyber/Physical Security Countermeasures Framework” to ensure the overall security of new supply chains. In 2019, South Korea issued the “National Cybersecurity Basic Plan” to guide the improvement of the security environment for information communication networks and information infrastructures, enhancing the security of critical infrastructures.

3

China’s Industrial Intelligent Network Practice Achievements and Issues

China’s Industrial Intelligent Network technology and industry have gradually deepened after the initial development phase. Overall, significant achievements have been made in top-level design, industrial scale, regional collaboration, and application ecology. At the same time, a series of issues have emerged in China’s Industrial Intelligent Network practice, including weak coordination in technological supply and innovation, bottlenecks in industrial empowerment, an incomplete talent training system, and an inadequate security guarantee system.

(1) Continuous Improvement in Top-Level Design and Expansion of Industrial Scale

Under the decision-making and deployment of the Central Committee of the Communist Party of China and the State Council, China’s top-level design for the Industrial Intelligent Network continues to improve, with continuous introduction of supportive policies in various fields. Overall, China has formed a relatively complete support system for the development of the industrial networking industry, gradually forming a synergy in the three aspects of “technology – standards – security.”

In terms of technology, the country has formulated high standards for bottom-level technological innovation development plans, strengthening infrastructure construction, and making progress in network systems, identification and resolution systems, multi-layered platform systems, industrial apps, and other aspects. High-quality enterprise external networks have been established, covering over 300 cities nationwide, connecting 180,000 industrial enterprises, with internal networks accelerating transformation and upgrades, and IPv6 large-scale deployment continuously advancing. Five national top-level nodes in Wuhan, Guangzhou, Beijing, Shanghai, and Chongqing have been established and are operating stably, with an average daily resolution volume exceeding 100 million times, and 197 secondary nodes covering 29 provinces and regions, with 127,000 enterprises connected. The number of platforms with certain industry and regional influence has exceeded 100, connecting 76.86 million industrial devices, with the number of industrial mechanism models reaching 588,000, serving 1.6 million enterprises. Excellent private cloud platform construction cases from companies such as Zoomlion’s “ZValleyOS,” China Electronics’ “China Electronics Cloud Network,” and BAIC Foton’s “BAIC Cloud” continue to emerge, with the number of industrial apps exceeding 250,000.

In terms of standards, enterprises, governments, research institutions, and other entities are promoting the steady development of the standard system, with the framework of basic common standards, network connection standards, identification and resolution standards, data computing standards, application standards, and security standards gradually maturing, with a number of achievements reaching international leading levels. In March 2021, China’s globally first industrial networking international standard—ITU-T Y.2623 “Technical Requirements and Architecture for Industrial Internet Networks (Based on Packet Data Network Evolution)” was passed at the International Telecommunication Union’s standardization bureau meeting, which first defined the network networking framework and standardized the main functional components and interrelations of network interconnection and data intercommunication. In May 2022, the globally first international standard for industrial networking system functional architecture, IECPAS63441, led by China, was passed by IEC/TC65 (Industrial Measurement and Control and Automation) voting. China is driving the global industrial ecosystem construction through standards, continuously improving the global industrial networking technology standard system, contributing the “China solution” to global industrial transformation.

In terms of security, China’s industrial intelligent network security policies and security management systems are becoming increasingly complete, with industrial enterprises’ security awareness significantly enhanced, and the level of industrial information security assurance technology has improved significantly, promoting the comprehensive development of the industrial networking security industry. Currently, nearly 50 local industrial networking technology-related policies have been introduced across 31 provinces, forming a basic industrial network security management pattern of cross-departmental collaboration, government guidance, enterprise主体, and third-party support. The “Industrial Internet Security Standard System (2021)” has been launched, covering 3 major categories, 16 sub-fields, and 76 specific directions of security standard construction guidelines.

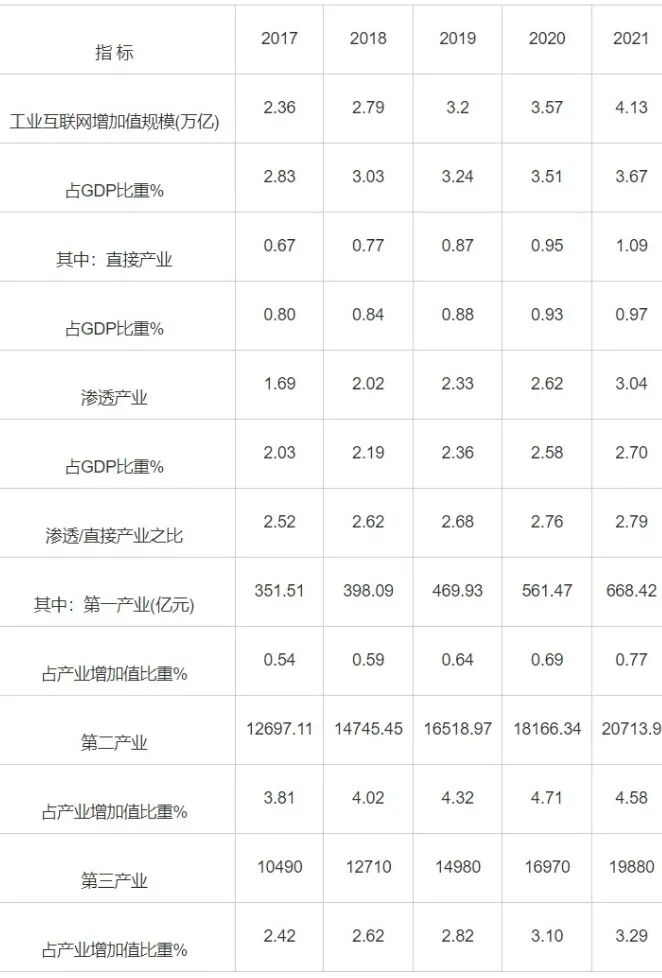

According to estimates, from 2017 to 2021, the scale of China’s industrial Internet added value grew from 2.36 trillion to 4.13 trillion, with a growth of 1.77 trillion, an annual growth rate of 15.02%, and the proportion of GDP rising from 2.83% to 3.67%, becoming an important factor in promoting China’s GDP growth. Among them, the direct industrial scale grew from 0.67 trillion to 1.09 trillion, with an annual growth rate of 12.94%, and the penetrating industrial scale grew from 1.69 trillion to 3.04 trillion, with an annual growth rate of 15.81%. The ratio of penetrating industry to direct industry added value has risen to 2.79, indicating that the industrial Internet is accelerating its deep integration with various industries. The industrial Internet has a significant driving effect on the three primary industries, with the scale of the first industry growing to 66.84 billion, an annual growth rate of 17.43%; the scale of the second industry growing from 12,697.11 billion to 20,713.9 billion, an annual growth rate of 13.02%, with the industry proportion rising from 3.81% to 4.58%; and the scale of the third industry growing from 10,490 billion to 19,880 billion, with an annual growth rate of 17.33%, and the industry proportion rising from 2.42% to 3.29% (see Table 2). Overall, the empowering effect of the industrial Internet on the first industry is gradually becoming apparent, with accelerated growth; the driving effect on the second industry has declined; and the penetration effect of the third industry has both scale and speed, expected to exceed that of the second industry.

Table 2

Scale and Structure of China’s Industrial Internet Added Value in the Past Five Years

Data Source: China Industrial Internet Research Institute “White Paper on the Economic Development of China’s Industrial Internet Industry (2021),” with 2021 data being estimated. The proportions are calculated based on data from the “China Statistical Yearbook 2021.”

2. Deepening Regional Collaboration and Expanding Application Scenarios

Currently, more than 30 provinces and cities nationwide have clarified support policies for the “Industrial Intelligent (Inter) Network,” initially forming a systematic promotion, stepwise development, and complementary advantages of industrial regional collaborative development pattern. The Yangtze River Delta region is accelerating the construction of the “Integrated Development Demonstration Zone for the Industrial Intelligent Network,” with Shanghai, Jiangsu, Zhejiang, and Anhui signing the “Strategic Cooperation Agreement for Jointly Promoting the Construction of the Integrated Development Demonstration Zone for the Yangtze River Delta Industrial Internet” in 2020, and in 2021, the four regions jointly established the “Special Task Force for the Integrated Construction of the Yangtze River Delta Industrial Internet Identification,” aiming to promote the integrated construction of the Yangtze River Delta Industrial Intelligent Network. The Guangdong-Hong Kong-Macao Greater Bay Area combines manufacturing and information communication technology industry advantages, focusing on “5G + Industrial Internet.” Guangdong has successively introduced policies to open up new development space with the idea of “network first, benchmark leading, classified measures, and promoting construction through use.” The Beijing-Tianjin-Hebei region has signed the “Framework Cooperation Agreement for Building a Collaborative Development Demonstration Zone for Beijing-Tianjin-Hebei Industrial Internet,” jointly promoting the construction of a collaborative development demonstration zone for the Industrial Intelligent Network. Beijing has issued the “Action Plan for Accelerating the Construction of New Infrastructure in Beijing (2020-2022),” precisely optimizing the innovation development environment for the Industrial Intelligent Network, while Tianjin focuses on cultivating industrial intelligent network benchmark demonstrations, and Hebei emphasizes creating application scenarios for the Industrial Intelligent Network. The Chengdu-Chongqing region fully leverages policy, industry, and resource advantages, signing the “Strategic Cooperation Agreement for the Integrated Development Demonstration Zone for Chengdu-Chongqing Industrial Internet” to support the collaborative promotion of industrial construction in the region.

The Ministry of Industry and Information Technology, relying on policies such as the “512” project, has guided nearly 70 billion yuan in total investment, forming a number of demonstration-driven projects, industrial bases, and big data centers. The four bases in Shanghai, Beijing, Wuhan, and Shenzhen have become important levers for leading the industrial intelligent network industry cluster. The national new-type industrialization demonstration base in Songjiang District, Shanghai, achieved an industrial output value of 447.69 billion yuan in 2020, with over 5,000 enterprises; the national new-type industrialization demonstration base “Industrial Internet · Wuhan, Hubei” achieved an industrial output value of 351.2 billion yuan in 2020, covering the complete industrial chain of “optical core screen terminal network cloud intelligence,” serving as the national digital design and manufacturing innovation center, information optoelectronics innovation center, and advanced storage industry innovation center, and is also China’s largest optical communication R&D, optical fiber and cable production, and optoelectronic device production base. The National Industrial Internet Big Data Center, following the “1+N” system, has laid out approximately 2.9 billion industrial data covering the Yangtze River Delta, Guangdong-Hong Kong-Macao, Beijing-Tianjin-Hebei, and Chengdu-Chongqing regions, covering about 7.03 million enterprises, with a basic national industrial data center system taking shape. The Industrial Internet Industry Alliance has over 2,000 member units.

The potential for the integration and application of the Industrial Intelligent Network in different fields is gradually being released, with the breadth and depth of applications continuously expanding, and innovative application models actively emerging, covering key national economic industries such as steel, machinery, electricity, transportation, and energy, forming a series of new models and new business formats. First, platform-based design and intelligent manufacturing. Digital functional components, technical means, and software tools are provided for traditional R&D design, significantly reducing R&D costs, while also promoting the development of specialized platforms in the cloud design field, supporting multi-entity collaborative design across enterprises, departments, regions, and disciplines, with excellent cases such as Huawei’s platform-based design and Shanghai Waigaoqiao’s “Supply Chain Collaborative Cloud.” Intelligent manufacturing applications based on integrated production data from enterprises are continuously emerging, with companies like Haier’s Shenyang Refrigerator Connected Factory and COMAC significantly shortening R&D cycles, increasing capacity, and reducing operating costs through intelligent manufacturing applications. Second, networked collaboration and personalized customization. Through data intercommunication and business interconnection, enterprises in the supply chain share various information resources such as customers, orders, designs, production, and operations, promoting resource sharing, capability trading, and business optimization. The flexibility of design and production and the agility of manufacturing are continuously improving, with the shared manufacturing model of “platform order-taking, process decomposition, and multi-factory collaboration” integrating to continuously reduce production and transaction costs for enterprises. Currently, industrial apps for customer service, logistics tracking, and other applications are widely used in the clothing industry market. Third, service extension and digital management. Enterprises extend from manufacturing business to high value-added links at both ends of the value chain, achieving integrated development through “manufacturing + service” and “product + service.” Enterprises internally connect data chains and mine data value, optimizing strategic decision-making, operational management, R&D manufacturing, and market services, constructing a new data-driven operational model. Excellent cases include SANY Group’s Root Cloud Platform, Midea’s Cloud Platform, and Ansteel Group’s “Precision Steel” platform, which enhance the resource allocation capabilities of suppliers and distributors through supply chain management, significantly reducing production cycles and inventory costs.

(2) Current Major Issues in China’s Industrial Intelligent Network Development

1. Insufficient Local Supply Capacity of Key Technologies and Lack of Coordination Among R&D Innovation Entities

While recognizing the achievements, it should also be noted that there are still gaps between China and developed countries in many aspects such as industrial ecological foundation, management standardization level, information technology level, cross-industry capabilities, data quality, and modeling capabilities. From 2000 to October 2018, nearly 50,000 global industrial Internet patent applications were filed, with the United States accounting for 48%, ranking first globally, while China ranked second with 25%. Among the top ten patent applicants globally, only Huawei ranks eighth, while IBM, with nearly 7,000 patents, ranks first, close to the total of the other nine companies. In terms of network interconnection technology, China leads globally in overall technological innovation, with the number of global patents for fieldbus, industrial Ethernet, and OPC unified architecture being 9,500, 5,776, and 763 respectively, with the proportions from China being 62%, 58%, and 57%. However, Siemens from Germany ranks first in all three technologies. Although State Grid, the Shenyang Institute of Automation of the Chinese Academy of Sciences, and Northeast University have entered the global top ten, they rank lower. The global total of Time-Sensitive Networking (TSN) technology patents is 536, with the U.S. ranking first with 33% and China second with 19%, with Huawei ranking fifth among applicants, while the rest are all foreign enterprises. In terms of network identification and resolution technology, China performs well in object identifiers (OID) and unified item coding (Ecode) for the Internet of Things, but lacks competitiveness in technologies such as object name resolution service (ONS) and Handle systems, with global patent proportions of only 14% and 5%. In the field of industrial cloud technology patents, edge computing/fog computing technology has a U.S. share of 33% and a Chinese share of 31%; platform as a service (PaaS) and multi-tenant technology have Chinese patent shares of 11% and 15%, far less than the U.S. shares of 63% and 66%.

High-end industrial software and industrial control systems are almost entirely monopolized by foreign enterprises, with insufficient local supply capacity for key technologies such as networking, identification and resolution, cloud computing, and platforms. The collaborative and shared innovation pattern among leading enterprises, upstream and downstream enterprises, hardware, communication equipment, operations, internet companies, governments, research institutes, and universities has not yet been established, and the competitiveness of the supply chain innovation chain is weak. At the same time, there are deviations in the R&D focus of different innovation entities in China, with rigid boundaries between the industrial end and the R&D end, and the dual path of market incentives for R&D and R&D empowerment for industry is not smooth, making it difficult for elements such as technology, talent, systems, and data to flow freely, and obstructing the channels for product services and information data flow.

2. Bottlenecks in Empowering Development in Some Industries, and Difficulties in Industry Platform Development

According to estimates from the China Industrial Internet Research Institute, the scale of China’s Industrial Intelligent (Inter) Network industry will reach 4.13 trillion in 2021, but in some industries, the proportion of related industry scale has declined, with the empowerment ratio of the manufacturing industry dropping from 5.59% in 2020 to 5.35%, the wholesale and retail industry from 2.71% to 2.61%, and the transportation, warehousing, and postal industry from 3.34% to 3.12%, indicating that the empowerment development is facing bottlenecks.

Taking the automotive manufacturing industry as an example, industrial platforms are mostly constructed by vehicle manufacturers, which account for less than 1% of the industry, failing to effectively meet the diverse needs of the complex sub-sectors of the automotive industry, while the majority of parts manufacturers and distributors are in a “low, scattered, and weak” stage, with relatively lagging development of specialized platforms for parts. Open, comprehensive, co-creation, and sharing are the basic requirements for the Industrial Intelligent Network to create value, while closed, differentiated, and self-protective attributes are inherent in the industrial field. This contradiction is particularly severe for mature industries with numerous sub-sectors and replicable experiences. Manufacturers rationally and objectively protect core technologies, knowledge, and experiences to ensure their sustainable competitive advantages in industry sub-sectors, especially in an environment where intellectual property protection and business cooperation models are not yet clear, leading to significant difficulties in platform promotion. Different enterprises of varying fields and scales have strong personalized demands for platform applications, but the unclear costs of project implementation and the unclear benefits of project landing have also led to stagnation in the development of the Industrial Intelligent Network platform.

3. Low Standardization Level of Industry-Related Positions, and an Incomplete Talent Training System

The development of the Industrial Intelligent Network requires not only OT, IT, and CT composite talents but also enterprise management talents, industry leaders, professional technical talents, and industrial workers across multiple dimensions and levels. It requires both academic talents with outstanding innovation capabilities and application talents with strong practical abilities who can solve problems in work. Currently, there are issues on both the demand and supply sides of talent for the Industrial Intelligent Network in China. On the demand side, enterprises have a high demand for talent, but the standardization level of job naming, business, and capabilities is low, with significant differences in job capability descriptions among different enterprises, which is not conducive to universities formulating training programs for related majors. On the supply side, the talent training system has not yet been fully established, facing many difficulties. Some universities are actively exploring talent training for the Industrial Intelligent Network, but due to a lack of courses, teaching materials, faculty, and specialized training environments, the teaching process faces significant challenges. There is insufficient integration of industry and education in talent training, and the talent training model of deep cooperation between industry and education has not yet formed. The proportion of related specialized majors is low, with high flexibility in professional adjustments but insufficient foundational capabilities. Continuing education is actively exploring talent training for the Industrial Intelligent Network, but the system is still lacking. Overall, there is a lack of high-quality talent, and the matching degree between talent supply and demand is not high.

4. Urgent Need to Improve Multi-dimensional Security Guarantee System, with Severe Industrial Security Risk Situation

Due to the unique nature of the Industrial Intelligent Network’s penetration into various industries of the national economy, its industrial security guarantee issues are extremely important. Currently, China’s multi-layered security guarantee system covering industrial intelligent network devices, hosts, CNC equipment, robots, IoT devices, internet networks, identification and resolution systems, 5G networks, industrial apps, and industrial data has not yet been fully established. The large number of industrial hosts, relatively outdated operating systems, and insufficient security protection; high-end industrial control systems are mainly foreign brands, posing risks of remote maintenance backdoors, and are difficult to upgrade in a timely manner, with the number of vulnerabilities in industrial control systems reaching a new high in 2020; the inherent security of industrial intelligent network platforms is insufficient, with most platforms not forming systematic security protection mechanisms according to standards, merely adding some security protection devices; and the variety of industrial data presents security risks in aspects such as collection, storage, communication, permission control, etc.

As the global Industrial Intelligent Network industry develops, the means of cyber attacks are becoming increasingly diverse, including contaminating software development, testing, deployment, and maintenance environments or tools, pre-installing malicious software on devices, infecting legitimate applications, and stealing legitimate certificate signatures for malicious software. China’s security vendors have insufficient product accumulation and service experience in industrial information security and industrial intelligent network security, still in the stage of tackling key issues. Most enterprises have weak awareness of responding to cyber attacks, imperfect security management systems, inadequate security detection and assessment mechanisms, and insufficient guidance on network security for industrial enterprises.

4

Countermeasures and Suggestions

In response to the current issues in China’s Industrial Intelligent Network development regarding technological supply, collaborative innovation, industrial empowerment, talent supply and demand systems, and security guarantee systems, the following countermeasures and suggestions are proposed to fully leverage the Industrial Intelligent Network’s role in constructing and empowering a modern industrial system.

(1) Improve the New National System for Tackling Key Technological Challenges, Breaking Down Barriers to Collaborative Innovation

Establish a new national system for tackling key technological challenges, leveraging effective market vitality, strengthening the role of enterprises as the main body of technological innovation, efficiently allocating scientific and technological forces and innovation resources, and enhancing cross-field and cross-disciplinary collaborative tackling. Support industrial organizations, industry alliances, and professional institutions in compiling and publishing field knowledge property layout guidelines, guiding leading enterprises to implement intellectual property management standards, and enhancing the awareness and capabilities of innovation entities regarding intellectual property strategies. Leverage policy guidance to promote the integration of production, learning, research, and application, establishing and improving collaborative promotion mechanisms among governments, enterprises, industry organizations, industry alliances, think tanks, etc., further strengthening coordination between industrial enterprises and digital enterprises in technological tackling, standard formulation, and other aspects. Adhere to the synchronous resonance of R&D tackling, product application, and industrial cultivation, creating a good innovation ecology for the Industrial Intelligent Network, opening up channels for the circulation of innovation resources among different innovation entities, and promoting high-quality development of the Industrial Intelligent Network innovation chain.

(2) Leverage the Advantages of Application Volume Data Scenarios to Unleash Industrial Development Potential

Based on China’s super-large-scale, multi-layered, and diversified domestic demand market, leverage China’s advantages in having a wide range of industrial categories, large industrial scale, diverse application scenarios, and comprehensive data types to eliminate bottlenecks and blockages in the industrial networking industry, promoting smooth connections among various links, industries, and regions. Further promote the transformation and upgrade of industrial enterprises’ internal networks, advancing IP-based, flat, and flexible technological transformations and constructions, breaking down information silos and data barriers, laying a good foundation for broader interconnection. Accelerate the construction of industrial enterprises’ external networks, speed up the improvement of broadband network infrastructure and upgrades, expand network coverage, and optimize and upgrade the national backbone network to ensure ubiquitous interconnection and smooth data flow among all links of the industrial chain. Reduce the information network service costs for small and medium-sized enterprises, supporting the integrated development of large, medium, and small enterprises. Accelerate the exploration and application of new network technologies such as 5G, MEC, and TSN, launching more network solutions closely aligned with the transformation and upgrading needs of manufacturing enterprises. At the same time, promote the construction of a new development pattern that mutually promotes domestic and international development at a high standard, driving a high-value, high-level, and systematic supply-demand cycle, and constructing a complete, safe, and reliable industrial intelligent network supply chain system.

(3) Build a Complete Professional Talent Supply and Demand System, Strengthening Talent Team Building

Establish a knowledge property expert consultation system, set up a knowledge property expert committee and expert database, and select and cultivate a batch of leading talents in manufacturing knowledge property. Encourage and support relevant universities to strengthen the cultivation of application-oriented talents in manufacturing knowledge property, promoting the establishment of training bases for in-service talents in manufacturing knowledge property. Conduct training on intellectual property strategies and skills for leading enterprises in the industry. Build a national-level talent data platform for the Industrial Intelligent Network, aggregating data on industrial intelligent network infrastructure investment, job recruitment, and graduates of related majors from various regions to support the construction of the industrial talent supply and demand system. Formulate a career and job survey system, regularly conducting surveys targeting various enterprises in the Industrial Intelligent Network field. Carry out talent certification work for the Industrial Intelligent Network, establishing a certification system for typical positions, including certification courses, certification exams, and certification authorization points. Collaborate with research institutes, enterprises, universities, social organizations, suppliers, etc., to jointly build a national talent cultivation ecosystem for the Industrial Intelligent Network, complementing each other’s advantages and cooperating in division of labor to jointly construct a complete talent supply and demand system for the Industrial Intelligent Network, improving the quality and efficiency of talent cultivation.

(4) Build a High-Standard Industrial Chain Security System to Ensure Comprehensive Industrial Safety

Focus on industries with a good foundation and fields with urgent security needs, carrying out pilot demonstrations and promoting the application of security technologies, products, and solutions. Construct a security assessment and certification system for industrial intelligent network devices, networks, and platforms, relying on third-party institutions to conduct security protection capability verification tests. Establish a data security management system for the entire industrial chain of the Industrial Intelligent Network, clarifying the responsibilities and specific requirements for data security protection related to various themes, and strengthening security protection capabilities in data collection, storage, processing, transfer, and deletion. Establish a graded and classified management system for industrial data, forming a data flow management mechanism for the Industrial Intelligent Network, clarifying data retention and data leakage notification requirements, strengthening the implementation of network security responsibilities by relevant enterprises in the Industrial Intelligent Network, guiding enterprises to increase security investment, enhance security protection and monitoring disposal technical means, and carry out pilot demonstrations of industrial intelligent network security to improve security protection capabilities. Fully leverage the role of national research institutions and social forces to enhance the national-level technical support capabilities for industrial intelligent network security, focusing on improving capabilities for hidden danger investigation, attack detection, emergency response, and attack tracing.

Notes

① Xi Jinping: “Upholding the Great Banner of Socialism with Chinese Characteristics to Unite and Strive for the Comprehensive Construction of a Modern Socialist Country—Report at the 20th National Congress of the Communist Party of China,” Beijing: People’s Publishing House, 2022, p. 30.

[1] Yang Shuai: “Industry 4.0 and Industrial Internet: Comparison, Enlightenment, and Response Strategies,” Contemporary Finance, 2015, No. 8.

[2] Wang Feiyue, Zhang Jun, Zhang Jun, Wang Xiaoy: “Industrial Intelligent Network: Basic Concepts, Key Technologies, and Core Applications,” Acta Automatica Sinica, 2018, No. 9.

[3] Xinhua News Agency: “Xi Jinping Listens to the Work Report of the Shaanxi Provincial Party Committee and Provincial Government,” https://www.gov.cn/yaowen/liebiao/202305/content_6874465.htm.

[4] Guo Chaoxian, Fang Ao: “The Generative Logic and Priority Strategies of New Infrastructure Empowering High-Quality Development of the Real Economy,” Journal of Xinjiang Normal University (Philosophy and Social Sciences Edition), 2023, No. 6.

[5] Li Li, Lin Yilun, Zheng Nanning & Wang Fei-Yue, “Parallel Learning: A Perspective and a Framework,” IEEE/CAA Journal of Automatica Sinica, 4(2017):389—395.

[6] Wang Fei-Yue, Zhang Jun Jason & Wang Xiao, “Parallel Intelligence: Toward Lifelong and Eternal Developmental AI and Learning in Cyber-Physical-Social Spaces,” Frontiers of Computer Science, 12(2018).

[7] China Academy of Information and Communications Technology, Industrial Internet Industry Alliance: “Industrial Intelligence White Paper (2022),” 2022.

[8] Li Xiaomei: “The Evolution and Enlightenment of Industrial Internet Policies in Major Developed Countries,” Regional Economic Review, 2022, No. 4.

[9] China Academy of Information and Communications Technology, Industrial Internet Industry Alliance: “Industrial Intelligence White Paper (2022),” 2022.

[10] Industrial Internet Industry Alliance: “China Industrial Internet Security Situation Report (2019),” 2020.

[11] Zhang Ni, Liu Lianru, Tian Zhihong, et al.: “Progress and Trends in Industrial Internet Security,” Journal of Guangzhou University (Natural Science Edition), 2019, No. 3.

[12] At the overall level, there are guiding opinions on deepening the development of the “Internet + Advanced Manufacturing” Industrial Internet, the Industrial Internet Development Action Plan (2018-2020), and the Industrial Internet Innovation Development Action Plan (2021-2023). In terms of technology, there are guidelines for the construction and promotion of the Industrial Internet network, notices on the implementation of the “5G + Industrial Internet” 512 project, the Industrial Internet identification management measures, the Industrial Internet platform construction and promotion guidelines, and the Industrial Internet APP cultivation project implementation plan (2018-2020). In terms of standards, there are guidelines for the construction of a comprehensive standardization system for the Industrial Internet.

[13] China Industrial Internet Research Institute: “Report on the Effectiveness of Industrial Internet Innovation Development (2018-2021),” 2021.

[14] Sina Finance: “National Top-Level Node Identification Resolution Volume Exceeds 138.1 Billion, How Will the Industrial Internet Advance?” https://baijiahao.baidu.com/s?id=1735201585531634439&wfr=spider&for=pc.

[15] China Industrial Technology Software Industry Alliance, Industrial Internet Industry Alliance: “Industrial APP White Paper (2020),” 2020.

[16] “China’s Ministry of Industry and Information Technology Leads the Completion of the First International Standard in the Field of Industrial Internet Networks,” Intelligent Manufacturing, 2021, No. 2.

[17] “The First International Standard for Industrial Internet System Functional Architecture Passed Voting,” Mold Industry, 2022, No. 6.

[18] Li Yangchun, Wang Hailong, Li Yuxiao, Chen Lei, Li Youping: “Research on the Layout of Industrial Internet Security Industry Abroad and Its Enlightenment,” China Engineering Science, 2021, No. 2.

[19] The China Industrial Internet Research Institute divides the industrial Internet industry into direct and penetrating industries, where direct industries include networks, platforms, and security, while penetrating industries refer to the total growth created by the new industrial ecology and industry applications driven by the industrial Internet from multiple dimensions.

[20] Industrial Internet Industry Alliance: “Analysis of the Patent Situation of Key Technologies in the Industrial Internet,” 2019.

[21] Shao Mingkun, Lei Xiaobin, Ma Dongyan, Quan Huyang: “Current Application Status, Restrictive Factors, and Countermeasures of Industrial Internet Platforms in China’s Automotive Industry,” Science and Technology and Industry, 2021, No. 10.

Guo Chaoxian

Researcher, Director of the Industrial Organization Research Office, Institute of Industrial Economics, Chinese Academy of Social Sciences

Reply Guo Chaoxian in the public account to view detailed information

Fang Ao

PhD student, School of Applied Economics, Chinese Academy of Social Sciences University.

Guo Chaoxian, Fang Ao. From Industrial Internet to Industrial Intelligent Network: Global Development Trends and China’s Strategies. Journal of Shanxi Normal University (Social Sciences Edition), 2023, 50(05): 76-87.

✦

End

✦

The 35th Batch of “Digital Transformation New Infrastructure Products and Services Certification” Organization Application Collection Notice

What aspects does a smart park reflect? What to build? Includes 8 cases

Alliance Introduction /Profile/

The Zhongguancun Smart City Information Industry Alliance (SCIIA) was established in 2015 and is a national 4A social organization with independent legal status. Its member units cover well-known institutions, universities, enterprises, and public institutions in the fields of smart city research, preparation, application, testing, and services both domestically and internationally.

SCIIA aims to carry out smart city-related cooperation globally, accelerate the expansion of industrial clusters, and actively commit to the construction of new infrastructure for a green digital China and future smart society, creating an international high-quality smart city industrial ecosystem.

<< Alliance Services Swipe to view the next image >>

Smart City Industry Digital Service Platform

Website|www.sciia.org

The same world, different wisdom

Zhongguancun Smart City Information Industry Alliance

Public Account ID|zgc_sciia

<< Scan to Subscribe

China’s New Smart City Talent Resource Platform—Smart Trust Circle

Want to have more networking resources?

<<< Come join us

If you see this, please like it!