‖ System Learning

Life is like a marathon; sometimes you need to pause and take a breather to go further.

Why does Modbus RTU always appear with RS-485?

What is RS-485?

Before we dive into this issue, let’s first understand what RS-485 is, which you may have heard of but not fully grasped.In official terms:RS-485 is a typical physical layer protocol that defines the electrical characteristics of differential signal transmission (such as voltage standards, impedance matching), multipoint connection capabilities, and topological structure. Its core value lies in suppressing electromagnetic interference through differential signals (A/B twisted pair), supporting long-distance transmission (up to 1200 meters) and multi-node access (up to 128 devices).In simpler terms, it is a wiring method where you can communicate using just two signal wires, A and B.

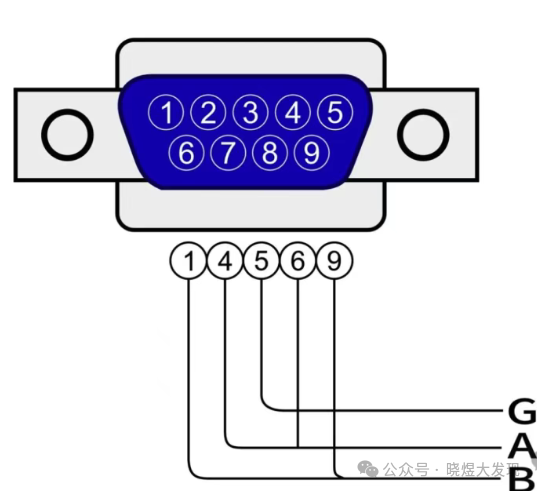

These wiring terminals can be directly connected to the terminals.

They can also be connected to a DB9 or a 32-pin connector, etc.; essentially, you just need to find two signal wires.

Of course, some devices require grounding while others do not; this depends on the device’s specifications, but it’s best to ground them all.

What is Modbus RTU?

Modbus RTU is a standard communication protocol. You may have also heard of Modbus TCP. The difference between them is that one uses network cables while the other uses serial ports, which refers to the two signal wires I just mentioned.Modbus RTU is an application layer protocol that specifies the data frame structure (address code, function code, data area, CRC check) and master-slave communication logic. Its core functions include device addressing, function definitions (such as register read/write), and error checking, without relying on a specific physical layer.If you want to learn more, you can check out my previous articles on Modbus.Click here: Understanding Modbus Protocol in Simple Terms

Why does Modbus RTU always appear with RS-485?

1.Matching Technical Characteristics

RS-485 provides reliable transmission for Modbus RTU: Differential signal transmission ensures data integrity in high-noise industrial environments, while Modbus RTU’s CRC check mechanism further guarantees accurate parsing of application layer data.

Modbus RTU relies on RS-485’s multipoint capability: The master-slave architecture of Modbus RTU requires physical layer support for multiple device connections. RS-485’s bus topology allows a single master to efficiently communicate with multiple slaves, avoiding the complexity of point-to-point connections.

2.Adaptability to Industrial Scene Requirements

Anti-interference and long-distance transmission: Industrial sites have strong electromagnetic interference (such as motors and inverters), and RS-485’s differential signals can effectively resist common-mode noise. Its transmission distance (hundreds to thousands of meters) far exceeds that of RS-232 and other serial protocols, making it suitable for distributed device control scenarios.

Cost-effective: RS-485 uses twisted pair wiring, which reduces hardware costs and supports flexible node expansion. The open protocol characteristics of Modbus RTU (no licensing fees) further lower the integration threshold for multiple devices, making their combination a cost-effective solution.

Real-time and determinism: Modbus RTU is based on a polling mechanism for serial communication, where the master sequentially accesses the slaves. Although it is not parallel processing, its simple frame structure (fixed length, no protocol header) and RS-485’s high baud rate (e.g., 9600 bps) can meet most industrial control real-time requirements.

Real-time and determinism: Modbus RTU is based on a polling mechanism for serial communication, where the master sequentially accesses the slaves. Although it is not parallel processing, its simple frame structure (fixed length, no protocol header) and RS-485’s high baud rate (e.g., 9600 bps) can meet most industrial control real-time requirements.

Conclusion

The collaborative application of Modbus RTU and RS-485 stems from their highly complementary technical characteristics: RS-485, as a physical layer, achieves strong anti-interference capability and long-distance communication (up to 1200 meters) through differential signal transmission, supporting bus-type multi-node connections (up to 128 devices); Modbus RTU, as an application layer protocol, facilitates data exchange between master and slave devices with a simple frame structure (address code, function code, CRC check). The combination of the two meets the demands of high noise and distributed device control in industrial environments while also considering cost-effectiveness (twisted pair wiring, open protocol), making it a classic combination in the field of industrial automation. The promotion by standardization organizations (such as MODBUS-IDA) further solidifies this binding relationship, making it widely used in scenarios such as PLC and smart instrument networking.Teaching a man to fish is better than giving him a fish.