1. Background and Issues of the Research

With the development of the Industrial Internet of Things, steel enterprises face numerous problems in system operation and maintenance. Issues include weak device perception capabilities, difficulties in processing high-frequency data, challenges in integrating multi-source and multi-dimensional data, and the presence of many information silos in the dimension of equipment connectivity; in terms of early warning diagnosis and decision-making, there are problems such as low efficiency in state recognition, poor diagnostic accuracy, inability to grasp degradation trends, low reliability of maintenance decision-making, and difficulties in converting experience into knowledge; in benchmarking operation and maintenance of similar equipment and production lines, there are inconsistencies in equipment terminology, variations in fault descriptions, differences in equipment granularity, disorderly data representation, and significant discrepancies in data processing. Considering the reliability, safety, and economy of complex systems, fault prediction and health management, centered around predictive technology, directly impact industrial production and have become an important foundation for autonomous logistics support systems.

The “14th Five-Year Plan for Intelligent Manufacturing Development” issued by the Ministry of Industry and Information Technology, the National Development and Reform Commission, and other eight departments explicitly mentions the implementation of health monitoring and remote operation and maintenance of large manufacturing equipment to ensure safe operation of processes; it also emphasizes the creation of a data sharing platform for the entire lifecycle to achieve optimization of the entire industry chain, mentioning “fault prediction and health management software (PHM), and integrated operation and maintenance management (MRO)” in the column on breakthroughs in industrial software. As an emerging, interdisciplinary comprehensive technology, intelligent operation and maintenance is leading a new round of reform in the maintenance support system for manufacturing equipment worldwide. The development of this project has significant importance: (1) implementing national strategic deployment and building a self-controllable industry; (2) enhancing platform resource utilization and constructing a new operation and maintenance ecological system; (3) breaking through key operation and maintenance technologies and forging new advantages for business transformation; (4) expanding operation and maintenance application scenarios and unleashing new potential for cross-industry collaboration; (5) promoting the development of high-end industries and cultivating new service-oriented manufacturing formats; (6) practicing the “dual carbon” green transformation and creating a new situation for efficient energy use.

Intelligent operation and maintenance can help steel enterprises achieve intelligent management and maintenance of equipment. Through sensors, monitoring devices, and IoT technology, real-time monitoring and collection of equipment operating status data can be conducted, enabling remote monitoring and fault early warning to promptly address equipment failures and maintenance needs, thus avoiding production line downtime and losses. Intelligent operation and maintenance can improve the accuracy of production planning and scheduling through data analysis and prediction. The production process in the steel industry is complex and variable, requiring a significant amount of production planning and scheduling work. By analyzing historical data and applying machine learning algorithms, production demand can be predicted, production plans optimized, and plans adjusted based on real-time data, thereby enhancing resource utilization and production efficiency. Intelligent operation and maintenance can provide real-time data monitoring and analysis, aiding enterprises in quality control and risk prevention. By monitoring and analyzing key parameters and indicators during the production process, potential quality issues and production risks can be detected promptly, allowing for appropriate adjustments and improvements to ensure product quality and production safety.

2. Ideas and Technical Solutions for Problem Solving

1. Overall Technical Approach

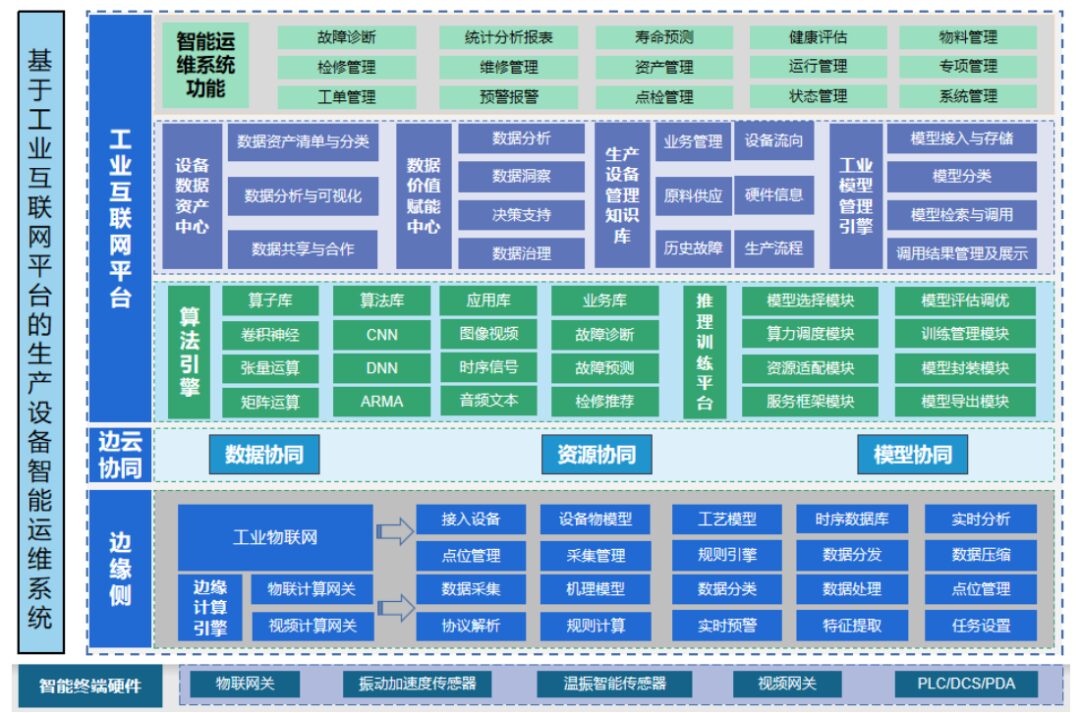

This project is based on an industrial internet platform, utilizing edge-side IoT computing gateways and video computing gateways to comprehensively collect and process data on the operating status, performance indicators, and design and manufacturing data of production equipment. It forms a data exchange channel between edge intelligent endpoints and cloud applications through the industrial IoT platform, storing, distributing, and managing the data collected from the edge intelligent endpoints using a time-series database for massive millisecond-level data storage. For high availability functional modules and data content, standard API data interfaces are provided, allowing data services to publish data to algorithm engines and artificial intelligence training reasoning platforms for data sedimentation and unified management. Different industry needs are addressed through the operator library, algorithm library, application library, and business library within the algorithm engine, with model training and deployment conducted via the reasoning platform, forming a data asset center for equipment, a data value empowerment center, a production equipment management knowledge base, and an industrial model management engine. Through API interfaces and preset models, algorithm results are output externally to achieve functions such as production equipment fault diagnosis, lifespan prediction, health assessment, early warning alarms, repair and maintenance management, status management, work order management, and statistical analysis. The overall system architecture diagram is as follows:

Figure 1 Overall Architecture of the Intelligent Operation and Maintenance System in the Steel Industry

2. Key Technologies

Conducting technical breakthroughs in intelligent operation and maintenance for the steel industry, focusing on key technologies such as multi-source heterogeneous data perception and processing technology, cloud-edge collaborative mechanism and AI-integrated equipment fault diagnosis models, data-driven and mechanism model-based industrial multi-dimensional comprehensive predictive maintenance technology, and knowledge graph-based predictive maintenance technology.

(1) Multi-source Heterogeneous Data Perception and Processing Technology for Multiple Industries

This project creatively proposes a multi-source heterogeneous data perception and processing technology for multiple industries, which integrates the Advanced U-net model for processing unstructured data and the Encoder-decoder architecture technology for structured data processing. Based on deep learning methods, this framework effectively perceives the spatial and temporal characteristics of various types of data (such as measurement data collected in real-time from distributed multi-sensors, production equipment data, and image data) and performs processing and fusion, gathering massive heterogeneous monitoring data in industrial enterprises’ key production equipment and production environments, standardizing and normalizing the data. This significantly improves the speed and accuracy of edge-side data processing, further enhancing the accuracy of fault diagnosis and prediction.

(2) Mechanism and AI Integrated Equipment Fault Diagnosis Model Based on Cloud-Edge Collaboration

This model innovatively combines cloud computing, edge computing, mechanism models, and data-driven AI models to construct a collaborative framework that enables rapid and accurate diagnosis and prediction of equipment faults. In terms of cloud-edge collaboration, cloud computing serves as the central node for data processing and analysis, undertaking the tasks of large-scale data storage and computation. The cloud platform collects sensor data, operating status information, and historical fault data from various devices, creating powerful algorithms and models through training on massive data to conduct data mining, feature extraction, and pattern recognition, which can determine the probability and trends of equipment faults and issue algorithm adjustments to edge devices. Edge computing provides real-time data collection and processing capabilities for intelligent terminals. Edge devices can perform preliminary fault detection and classification using the issued equipment fault diagnosis model and execute local computations and data preprocessing. Additionally, edge devices can transmit the collected data and diagnosis results back to the cloud platform for further analysis and validation.

In the integration of mechanism and AI, one aspect is based on mechanism models and professional knowledge, assisting in the development and training of AI models by constructing equipment digital twins, synthesizing the required datasets, and extracting fault-related features. The other aspect is that through methods such as machine learning, deep learning, and model optimization, AI can learn the normal operating patterns and fault characteristics of equipment from large amounts of data, building complex fault diagnosis and classification models to accurately assess equipment status and existing issues, ultimately creating an equipment fault diagnosis model to serve intelligent equipment.

(3) Industrial Multi-dimensional Comprehensive Predictive Maintenance Technology Based on Data-Driven and Mechanism Models

This innovative solution based on data-driven and mechanism models achieves more precise and timely maintenance compared to traditional preventive maintenance, better balancing the issues of excessive maintenance and untimely maintenance. This technology employs advanced machine learning algorithms and data analysis techniques, fully utilizing the vast amounts of real-time data from industrial equipment to learn and identify potential fault patterns and trends through multi-dimensional analysis of sensor data, historical operation data, and operational records, conducting feature engineering and selection to gain a more comprehensive understanding of equipment status and behavior, thus improving the accuracy of fault early warnings. In the process of building mechanism models, techniques such as cross-validation and evaluation metrics are used to optimize and assess models, continuously improving their performance to ensure generalization ability, stability, and accuracy across different datasets. Moreover, this technology can timely identify existing faults or potential issues in equipment, effectively overcoming the timeliness and accuracy bottlenecks of traditional fault early warning methods, providing a more reliable and efficient solution for the operation and maintenance of industrial equipment.

(4) Predictive Maintenance Technology Based on Knowledge Graphs

This project innovatively introduces knowledge graph technology, combining it with predictive maintenance and repair, constructing a labeled corpus, establishing a vocabulary for the equipment maintenance field, supporting knowledge extraction from unstructured data and labeling structured data, forming a basic entity library and relationship library. It then analyzes the operational and maintenance work feature points, defect feature points, and control feature points to build a top-down knowledge graph model, achieving management and maintenance of knowledge graph knowledge and relationship mining, providing knowledge support for field personnel in a visual human-computer interaction form. This supports operational planning and decision-making for key production equipment in the industry.

Based on knowledge graphs, natural language processing, intelligent search, and other core AI technologies, a knowledge base for equipment covering the entire lifecycle is created, providing front-line employees with efficient and convenient capabilities for knowledge construction, organization, and application to meet the intelligent service needs of various business scenarios in equipment management, enhancing the company’s equipment management level. This achieves the inheritance and replication of historical experiences and promotes successful experiences, optimizing and refining knowledge outcomes through continuous knowledge reuse to maximize the efficiency and returns of the company’s knowledge assets.

3. Major Innovative Achievements

1. System Function Innovation:

(1) Establish a production equipment management knowledge base and propose optimized predictive maintenance and repair plans;

(2) Build models for monitoring production equipment efficiency, fault detection, corrosion prediction, lifespan prediction, and fault diagnosis;

(3) Based on the industrial internet platform, comprehensively collect and unify management of production equipment operating status, performance indicators, and design and manufacturing data, achieving online diagnosis, health status monitoring, and analysis and assessment of production equipment.

2. System Development Technology Innovation:

(1) Develop no less than 20 edge-deployed industrial models and no less than 10 industrial apps;

(2) Develop no less than 15 production equipment management components;

(3) Formulate no less than 5 predictive maintenance and repair plans.

3. Innovation in Edge-side Computing Engine Construction:

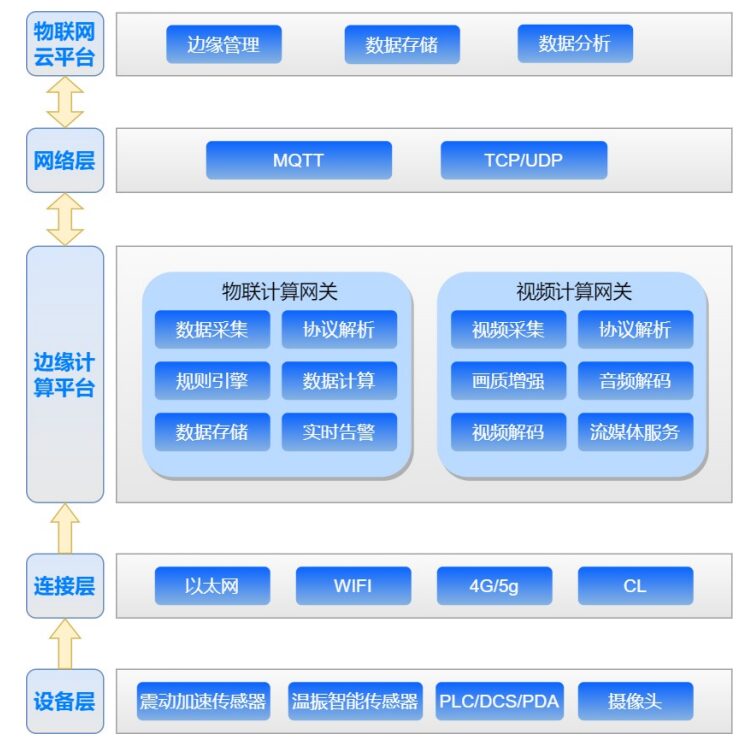

Through the construction of edge-side system functions, complete a series of intelligent operation and maintenance solutions including data processing, rule computation, data classification, feature extraction, real-time early warning, and mechanism models.

Figure 2 Edge-side System Architecture Diagram

4. Application Situation and Effects

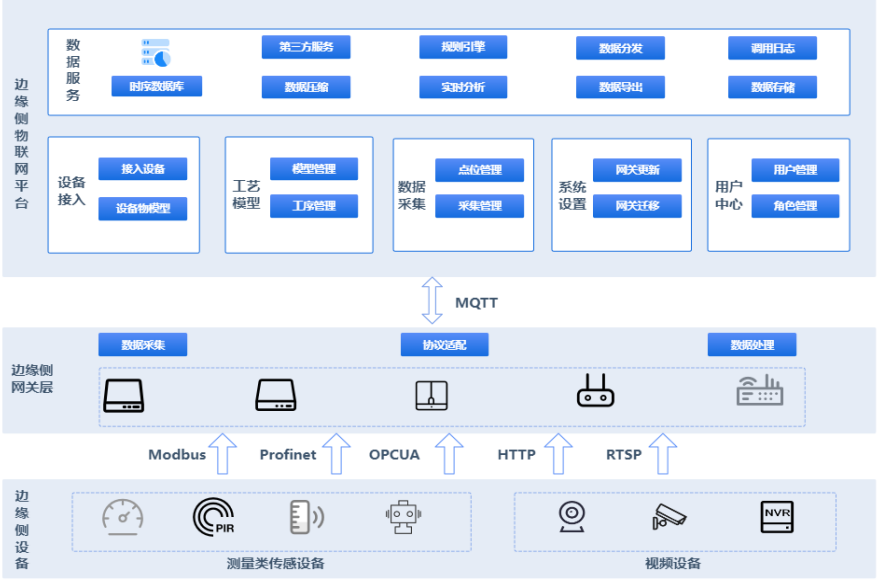

1. Application of Edge-side Industrial IoT Platform

The edge-side industrial IoT platform pushes data processing and analysis capabilities to edge devices, utilizing edge computing and edge storage technologies to achieve real-time responses and local decisions for industrial equipment, reducing reliance on the cloud and data transmission delays.

Figure 3 Functional Architecture Diagram of Edge-side Industrial IoT Platform

2. Application of Cloud-side Algorithm Engine Platform

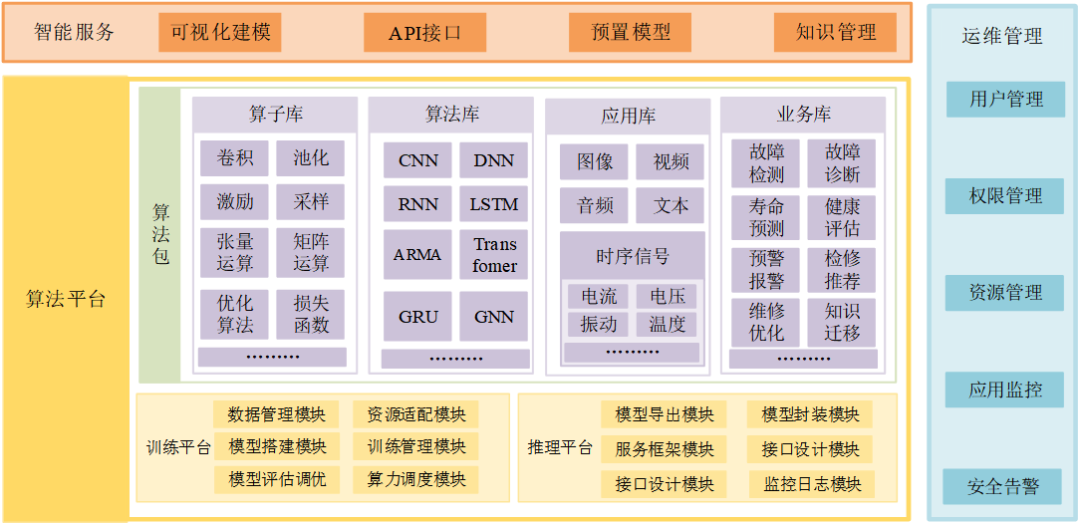

Figure 4 Overall Application of Cloud-side Algorithm Engine

The cloud-side algorithm engine platform supports intelligent model training, deployment, management, and related services, as illustrated in the overall construction plan above. The cloud-side algorithm engine platform includes three main components: algorithm platform, intelligent services, and operation and maintenance management; the algorithm platform further consists of algorithm package construction, training platform construction, and inference platform construction; intelligent services mainly provide comprehensive services to users and output algorithm results externally; operation and maintenance management is for standardizing and managing the use of the algorithm engine platform.

3. Application of Cloud-side System Functions

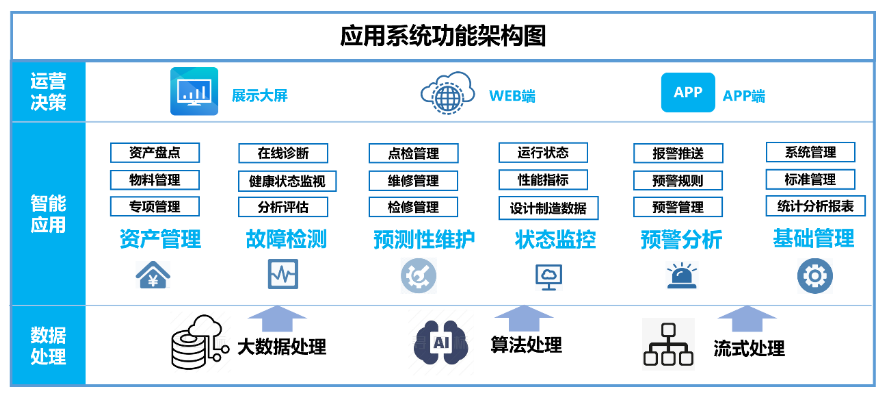

Provides comprehensive equipment management and maintenance solutions, achieving intelligent monitoring, fault prevention, and efficient maintenance of equipment. The aim is to achieve real-time monitoring and assessment of equipment status, performance, and health through data collection, analysis, and decision support. Through functional construction, asset management, fault detection, predictive maintenance, status monitoring, early warning analysis, and basic management of production equipment in the steel industry can be achieved.

Figure 5 Application System Functional Architecture Diagram

Source: Hebei Steel Digital Technology Co., Ltd.

If you wish to view all articles on recent technological advancements, please click “Read the original text”.