In electronic devices, PCBs are the core hub, where a single action can affect the entire system. The manufacturing process is complex and interconnected. Currently, the PCB industry is deeply mired in management difficulties, with production processes shrouded in fog, making quality traceability challenging. How to clear the fog and achieve full process transparency and control, enhancing quality traceability capabilities, has become a pressing “bottleneck” issue for the entire industry.

Xuelong CNC, as a dedicated player in the industry, has meticulously crafted a digital blueprint based on the WPT traceability trilogy, using rich practical experience as the pen and technological innovation as the ink. This ingenious solution aims to build a “bridge” for PCB companies that connects the entire link from raw material entry to finished product delivery, seamlessly linking all production stages and helping PCB companies leap over traditional manufacturing barriers to ascend to new heights of smart manufacturing.

WPT Traceability TrilogyBuilding the Foundation for Full Process Traceability

WPT Traceability TrilogyBuilding the Foundation for Full Process Traceability

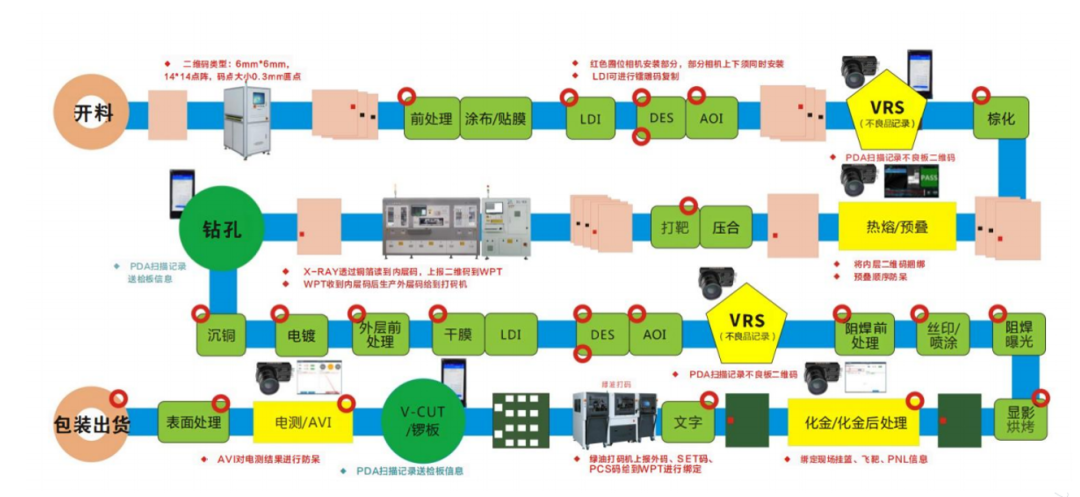

PCB manufacturing involves complex process flows. To achieve full process transparency management, the industry has proposed the WPT traceability trilogy (Whole Process Traceability), covering key stages from production to delivery:

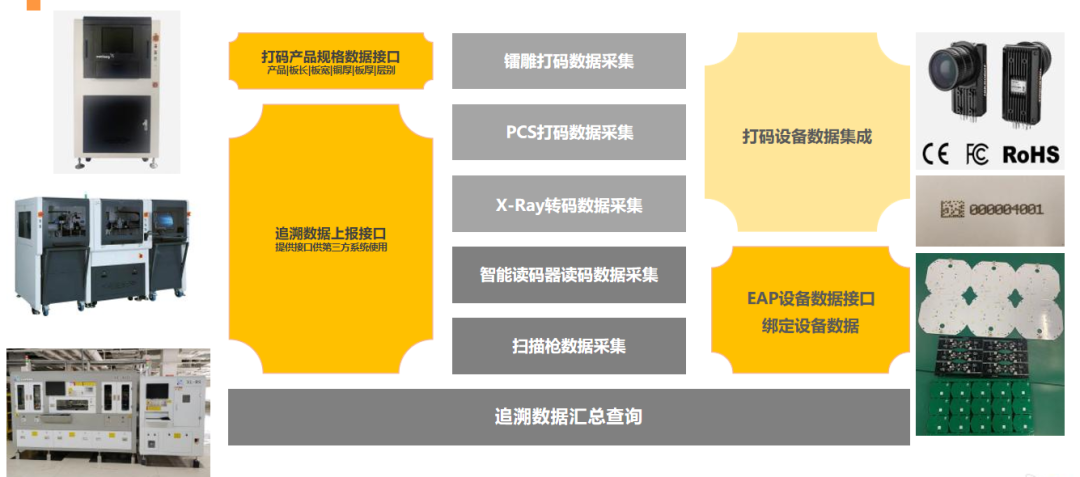

01 Hardware Coding and Decoding

By using high-precision laser coding equipment, unique identity markers (such as QR codes or RFID) are assigned to PCB substrates, semi-finished products, and finished products, ensuring accurate identification and data collection at each stage.

02 Binding Traceability Data

Real-time binding of production parameters (such as temperature, pressure), quality inspection results, and operator information to the unique identification code forms a complete “data chain,” achieving seamless connection between processes.

03 Digital Delivery

In the delivery stage, production data, test reports, and customer requirements are integrated to generate digital files, supporting customers in one-click querying of product lifecycle information, enhancing collaborative efficiency.

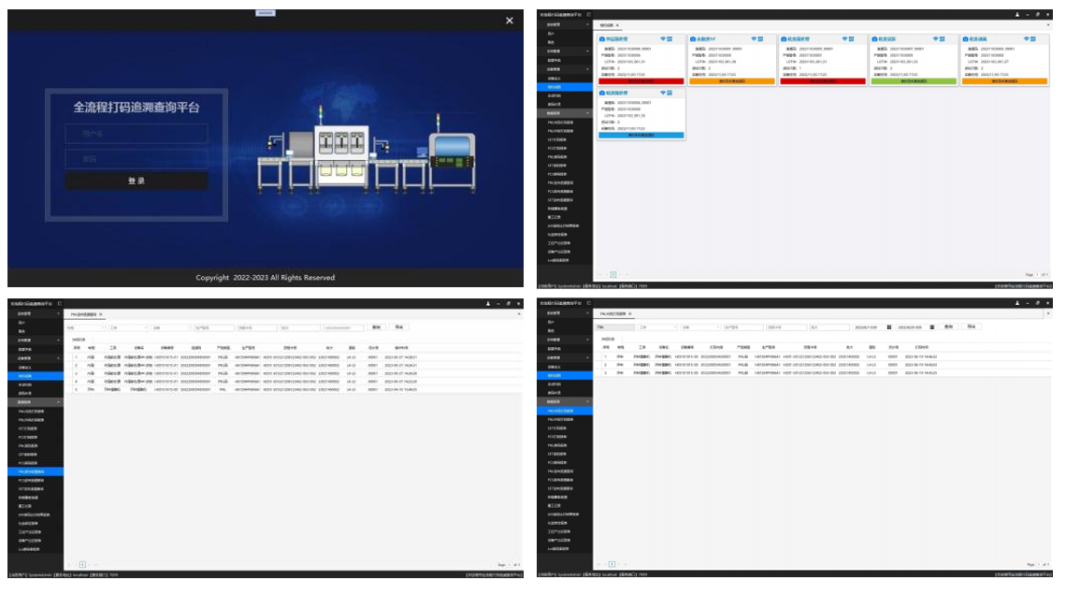

Full Process Coding and Traceability Query PlatformData-Driven Intelligent Hub

The Xuelong CNC full process traceability platform is the core of the solution, integrating data collection, processing, analysis, and application. The collection layer uses industrial cameras and sensors to capture process and environmental information in real-time, ensuring the integrity and timeliness of raw data. The processing layer employs AI algorithms to clean abnormal data and interacts with MES and ERP systems to achieve precise data updates and efficient utilization..

The visual dashboard of the Xuelong CNC full process traceability platform is an excellent assistant for enterprise managers. It presents key indicators such as yield statistics and process deviation warnings in clear graphical formats, providing multi-dimensional analysis perspectives, allowing managers to quickly grasp production conditions and make precise decisions. Additionally, the platform’s mobile scanning query function is extremely convenient, enabling workshop inspection personnel to scan at any time and place to obtain detailed traceability information. Remote managers can also use this function to grasp production dynamics in real-time, breaking the dual constraints of time and space, achieving efficient management.

Xuelong CNC’s SolutionIntelligent Engine for Full Process Traceability

Xuelong CNC’s SolutionIntelligent Engine for Full Process Traceability

Xuelong CNC has built a production traceability digital delivery platform with advanced digital technology, focusing on five core modules: people, machines, materials, methods, and environment, organically integrating production management, quality management, and equipment management functions. From the initial stages of PCB production to the final product, the platform achieves full process coverage, facilitating seamless collaboration across all stages and ensuring that the entire production process is under transparent control. With a powerful data-driven engine and intelligent decision-making mechanism, this platform effectively empowers enterprises, significantly enhancing production efficiency and quality control capabilities, enabling them to meet the stringent factory audit standards of customers with ease..

The platform operates based on three pillars: data foundation, interactive network, and intelligent rules.By collecting production information in real-time through IoT devices, a complete data chain is constructed; breaking down data silos across systems to achieve dynamic resource optimization; and driving intelligent production scheduling, AGV dispatching, and process mistake-proofing based on rule engines, promoting the implementation of automated production and dark factory operations. The three elements work together to form a closed loop, transforming data value into productivity.

Functionally, the focus is on three major breakthroughs:Full Process Transparency Real-time tracking of Lot-Panel-PCS multi-level production status, ensuring the integrity of the traceability chain; Paperless Quality Inspection Standardizing processes and accelerating abnormal response; Precise Resource Control Enhancing yield through equipment efficiency analysis and intelligent material allocation.

In lean production practices, the platform uses data-driven real-time adjustments, intelligent scheduling to optimize equipment utilization, and AGV coordination to reduce manual intervention, constructing a “precise-flexible-automated” production paradigm.

As digitalization continues to deepen, Xuelong CNC’s traceability platform will continue to empower the PCB industry.

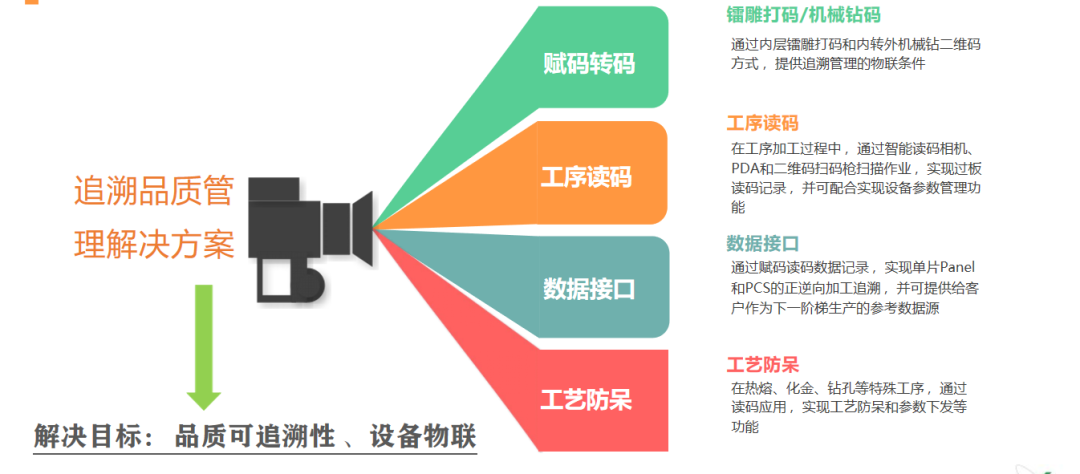

Characteristics of Traceability Empowering Quality and Intelligent Upgrades in PCB ManufacturingXuelong CNC’s traceability system aims to enhance quality control capabilities and accelerate production intelligence, focusing on solving the core pain points in quality traceability and flexible production within the PCB industry.The design characteristics of this system can be summarized in two dimensions:01 Key Points of Traceability

Based on Lot as the object, Panel as the management unit, and managing down to PCS with process and equipment as management touchpoints, extending the traceability scope to associate various management resources’ information during the processing.

02 Management Objectives

Achieving the correlation control of various process environmental processing states during the product processing lifecycle enhances the reliability of quality traceability and data basis, providing conditions for tracing customer complaint anomalies and enabling automation, intelligent manufacturing, and automated transport management through coding and decoding IoT conditions.

Business Composition Four Major Modules Constructing a Quality Control Closed Loop

Xuelong CNC’s traceability quality management solution focuses on “quality traceability” and “equipment IoT” as core objectives, through laser coding, process decoding, data interfaces, and process mistake-proofing to construct a full process closed-loop control system, empowering enterprises to achieve controllable quality and efficiency leaps in intelligent manufacturing.

The digital traceability solution meticulously crafted by Xuelong CNC is not just an ordinary technical means, but a key support for PCB enterprises to bravely advance into the field of intelligent manufacturing. With a full process transparent management model, it clarifies the production stages; using a data-driven decision-making mechanism, it accurately guides development directions; relying on automated collaborative operations, it enhances overall operational efficiency. In a fiercely competitive market environment, it helps enterprises build a solid barrier for product quality, steadily achieving long-term goals of cost reduction and efficiency enhancement, and realizing sustainable development. Looking to the future, as technology continues to evolve and upgrade, Xuelong CNC will uphold the spirit of innovation, continue to exert efforts, and work hand in hand with the PCB industry to jointly create a new glorious chapter in lean intelligent manufacturing.

The digital traceability solution meticulously crafted by Xuelong CNC is not just an ordinary technical means, but a key support for PCB enterprises to bravely advance into the field of intelligent manufacturing. With a full process transparent management model, it clarifies the production stages; using a data-driven decision-making mechanism, it accurately guides development directions; relying on automated collaborative operations, it enhances overall operational efficiency. In a fiercely competitive market environment, it helps enterprises build a solid barrier for product quality, steadily achieving long-term goals of cost reduction and efficiency enhancement, and realizing sustainable development. Looking to the future, as technology continues to evolve and upgrade, Xuelong CNC will uphold the spirit of innovation, continue to exert efforts, and work hand in hand with the PCB industry to jointly create a new glorious chapter in lean intelligent manufacturing.