The touch screen technology is a revolutionary human-computer interaction technology. Users can perform operations by gently touching the symbols or text on the display screen with their fingers or an electronic pen, completely breaking away from the reliance on keyboards and mice, making human-computer interaction more direct, convenient, and simpler.

The infrared optical touch screen uses infrared scanning to determine the touch position by the change in the intensity of the infrared light received by the infrared receiver when an object blocks the infrared light. It features high light transmittance, supports operation with insulating objects (such as gloved touches), and has strong resistance to water mist and electromagnetic interference, making it favored in various industry applications. However, the infrared optical touch screen also has defects such as susceptibility to strong light and dust interference due to its inherent principles.

Status of Infrared Touch Screens

The infrared touch screen operates based on the principle of infrared scanning. The early infrared touch screens appeared in 1992 with a resolution of only 32×32. They were easily affected by environmental interference and required a certain level of light shielding. As of today, infrared touch screens have developed to the fifth generation, with significantly improved resolution and resistance to strong light interference, making them usable in direct sunlight. More importantly, there has been a substantial leap in product lifespan and maintenance-free performance. Following the guiding principle of redundant distribution of probabilistic function devices, the lifespan under working conditions exceeds 7 years, pushing the application of touch screens to a new level. However, the operational mode of infrared touch screens also leads to some unavoidable application defects, such as susceptibility to strong light and dust interference, and low resolution. Currently, the development of infrared touch screen technology mainly revolves around two directions: one is using new sensors to achieve touch screen functionality, and the other is improving existing touch screen technology defects and enhancing application functions. The development of infrared touch screens is mainly focused on improving resolution and enhancing anti-interference performance while expanding application functions such as multi-touch, which brings richer functionalities to touch screens.

Currently, the infrared touch screens available in the domestic market are mainly medium to large sizes (over 15 inches). Due to the limitations of optical technology design, algorithms, and infrared lamp sizes, infrared optical touch screens smaller than 10 inches are costly, technically unstable, and easily affected by infrared light and dust interference. To fully leverage the advantages of infrared touch screen technology and meet certain industry application needs, mature small-sized infrared optical touch products are highly anticipated in the industry.

Introduction to Domestic Small-Sized Infrared Touch Technology

Unlike the mainstream large-sized traditional infrared optical touch screens in China, the author has discovered a small-sized optical infrared touch screen solution—Lierda 7-inch optical infrared touch screen LSD1TP-1R70N1D3 (hereinafter referred to as LSD1TP).

This optical infrared touch screen overcomes the disadvantages of traditional small-sized infrared touch screens, such as high costs, technical instability, and susceptibility to strong light and dust interference, through unique optical structure design and algorithms. Compared to resistive/capacitive touch screens, it has advantages such as high light transmittance, support for glove operation, strong anti-interference capability, and long lifespan, making it suitable for use in automotive navigation, industrial control, medical human-computer interaction, and other harsh working environments. It completely transforms the original application market of infrared touch screens.

Principle of LSD1TP

The LSD1TP infrared optical touch screen consists of a set of infrared emitters and detectors, optical guiding components, control circuits, and control software. The emitters emit pulsed infrared light that passes through the guiding plate and the touch surface, and the changes in light intensity detected by the detectors indicate a touch by an object. The touch position and the size of the object are calculated from the combined measurements of multiple detectors (infrared receiving tubes PD). The outputs from multiple sensors can be used to identify gestures and scanning operations.

1. Optical Structure

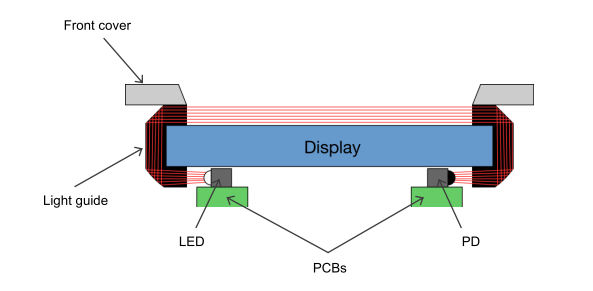

The guiding component of the LSD1TP infrared optical touch screen is a key part of the touch system. It directs infrared light from the LEDs towards the optical touch area and disperses the infrared light beam over the display area. On the opposite side, it guides the collected light from the optical touch area towards the PD devices. (Figure 1).

Figure 1: Basic Structure of the Guiding Plate

The guiding component is an injection-molded part made of optical-grade polycarbonate, which is a key component that differentiates it from traditional infrared screens. Its main functions are:

Unlike traditional infrared touch screens, where the infrared emitters and receivers are directly placed around the TFT display screen, resulting in excessive height of the surrounding protrusions, the guiding layer’s structural design limits the height of the surrounding protrusions to within 1.8mm.

The guiding layer employs an arc-shaped protrusion design, allowing each LED emitter to correspond to two infrared receiving tubes (PD) for differential infrared scanning, achieving extremely high resolution for the optical infrared touch screen and effectively overcoming dust and infrared, strong light interference.

2. Differential Infrared Scanning

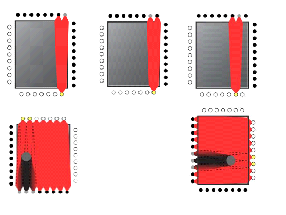

Traditional infrared touch screens can only achieve one-to-one correspondence between infrared emitters and receivers, with the label value of the infrared receiving tube (PD) being either 0 or 1, relying on the number and density of infrared emitters and receivers to marginally improve the accuracy and resolution of infrared touch. The LSD1TP infrared optical touch screen adopts a differential infrared scanning method, where a total of 28 pairs of infrared emitters and receivers are used, with each LED emitter corresponding to two infrared receiving tubes (PD) as shown in Figure 2.

Each infrared receiving tube PD can be classified into 16 different levels based on the strength of the received infrared light, with label values ranging from 0-15, thereby achieving a touch resolution of over 1024*600 with 28 pairs of infrared emitters and receivers, with a DPI of 500. Additionally, this differential infrared scanning combined with software algorithms can effectively overcome the dust, infrared, and strong light interference issues that traditional infrared touch screens cannot resolve, with a signal-to-noise ratio > 10:1, ensuring high reliability and strong anti-interference capability. The maximum infrared scanning frequency reaches 400Hz, with millisecond-level high-speed response, making handwriting smooth and fluid.

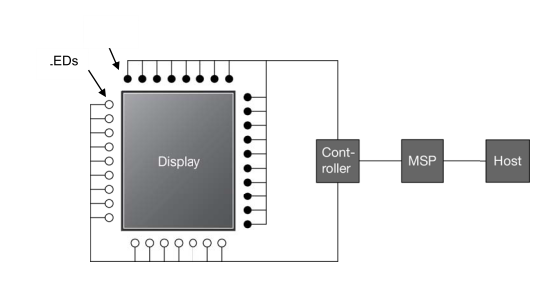

The hardware circuit scheme is shown below.

PDs

LEDs: Infrared emitters

PDs: Measure the infrared light emitted by the LEDs.

Multi-touch controller: All control hardware including LED drivers, amplifiers, multipliers, voltage regulators, and filters are integrated into the controller.

Microprocessor (MSP): Executes the control software part, controls the multi-touch controller, and sends the touch point information to the host via I2C.

Applications of Small-Sized Infrared Touch Screens:

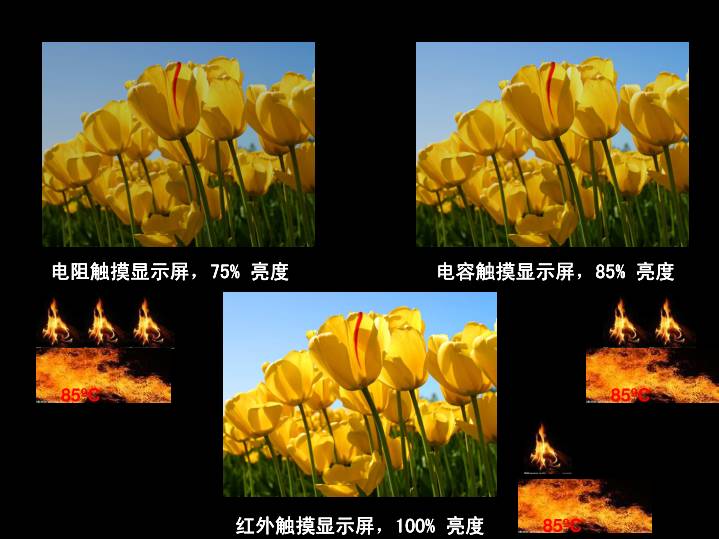

Compared to resistive/capacitive touch screens, the LSD1TP optical infrared touch screen has high light transmittance, and compared to displays equipped with capacitive and resistive touch screens, the color saturation and contrast of the display are better, enhancing user visual comfort.

This performance characteristic is fully demonstrated in e-books, with infrared touch products available from Sony and Amazon.

Furthermore, the LSD1TP infrared optical touch screen does not require touch pressure and can be operated freely even while wearing gloves. The two-point touch capability is sufficient for general operational needs, allowing touch with any object. The visibility in sunlight during the day is very high, with low power consumption and moderate pricing, providing excellent cost performance compared to capacitive and resistive screens.

As we know, a disadvantage of capacitive screens is drift: changes in environmental temperature and humidity can alter the environmental electric field, causing drift in capacitive screens and leading to inaccuracies. Therefore, in environments with strict requirements for operating and storage temperatures, such as automotive and industrial control environments, as well as in extremely cold or hot regions, infrared screens allow for smooth user control, with fast and accurate responses, providing a fluid and rapid on-site experience, significantly outperforming resistive and capacitive screens.

The LSD1TP infrared optical touch screen employs differential infrared scanning principles and software algorithms that effectively address the disadvantages of traditional infrared touch screens, including low touch accuracy, low resolution, and susceptibility to dust and infrared interference.

The author has conducted several tests on dust, waterproofing, etc.:

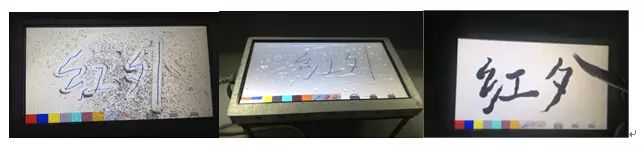

Test 1: The author sprinkled dirt (<0.6mm) on the infrared screen, and the touch function worked normally.

Test 2: Water was sprinkled on the surface of this infrared screen, and after simple wiping, the touch function worked normally.

Test 3: Writing with a brush was smooth and fluid.

In summary, the LSD1TP optical infrared touch screen has unparalleled advantages in industrial and automotive environments. It is an excellent choice for automotive multimedia, industrial human-computer interface operations, medical devices, and smart home human-computer interaction technologies.

For instance, the recently released Volvo XC90 uses this infrared touch technology for its central multimedia navigation screen. The chief touch screen engineer, Jens Henriksson, commented on infrared touch technology: “The screen can sense your finger without applying pressure, allowing you to operate the touch screen while wearing gloves. If you have experienced a Nordic winter, you will find this very practical. Because we use infrared touch technology, this becomes feasible. There is an infrared light module directly in front of the screen, and when your finger enters this area, the screen can automatically sense the touch.”