Industrial control systems generally refer to a variety of control systems, including Supervisory Control and Data Acquisition (SCADA) systems, Distributed Control Systems (DCS), and Programmable Logic Controllers (PLC), among others.

01

Five-Layer Architecture

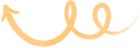

The classic hierarchical model of industrial control systems in the international standard IEC62264-1 divides typical industrial control systems into five levels based on functionality, which are: Enterprise Resource Level (Decision Management Level), Production Management Level (Operational Management Level), Process Monitoring Level, Field Control Level, and Field Device Level (Physical Device Level).

The five-layer architecture is as follows:

-

L0 Physical Device Level: Consists of actuators, sensors, smart instruments, motors, and actuating devices, primarily responsible for converting various physical variables and electrical signals during the production process, collecting on-site production data, and executing control commands, forming the basis for digitalization in “smart manufacturing”.

-

L1 Field Control Level: Composed of DCS controllers, PLCs, and other devices with logical control functions, it receives data from the physical device level (such as sensors, transmitters, or smart instruments), calculates the required control quantities according to specific control strategies, and sends them back to the on-site actuators (such as valves and motors). The operator and engineer stations at the field control level can simultaneously perform continuous control, sequential control, or logical control functions, achieving monitoring and control of on-site equipment.

-

L2 Process Monitoring Level: Mainly consists of operator stations, engineer stations, OPC servers, SCADA systems, and DCS systems, focusing on centralized monitoring of the production site and production status, providing an overall grasp of the enterprise’s production conditions.

-

L3 Production Operation Level: Mainly composed of MES, MIS systems, production command, operational scheduling, and office terminals, primarily achieving execution management of the production process (manufacturing data management, planning and scheduling management, production scheduling management, inventory management, quality management, work center/device management, tool and fixture management, material management, production board management, production process control, lower-level data integration analysis, upper-level data integration decomposition), recording data processing, and production command scheduling.

-

L4 Decision Management Level: Mainly consists of ERP, CRM, procurement, portals, OA, Email, and office terminals, covering various information systems and information support systems of the enterprise, integrating various resources, and analyzing summarized data from multiple dimensions to provide management decision support for the group headquarters and subordinate enterprises.

Next, let’s introduce industrial control systems. What is an industrial control system? It refers to an automatic control system composed of computers and industrial process control components, consisting of controllers, sensors, transmitters, actuators, and input/output interfaces. These components are connected through industrial communication lines according to specific communication protocols, forming an industrial production or processing system with automatic control capabilities.

It generally refers to several types of control systems, including SCADA systems, DCS, PLCs, and other control systems.

02

PLC

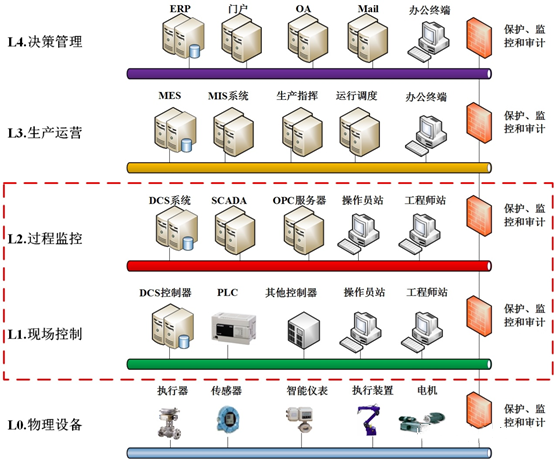

PLC is an electronic device designed for digital operation in industrial environments, using programmable storage to internally store instructions for executing logical operations, sequential operations, timing, counting, and arithmetic operations, directly controlling the operation and production of various types of production equipment. It is fundamental to achieving industrial automation, digitalization, and networking, playing a crucial role in the production field and is widely used in production enterprises across various industries, as shown in the deployment structure below.

Coal Industry: In coal enterprises, the PLCs used are mainly from brands such as Siemens, AB, Mitsubishi, and Hualisi, primarily applied in transportation systems, coal selection systems, and mining systems.

Power Industry: In thermal power enterprises, PLC devices are predominantly from Siemens, Rockwell, and Schneider, mainly applied in auxiliary control facilities of thermal power; in wind power enterprises, the PLCs used are mainly from Beifu, ABB, and Bachmann, primarily applied in the control of wind power motors.

Rail Transit Industry: In railway enterprises, the integration of industrial control systems is entirely undertaken by domestic manufacturers, and the main control systems are also primarily developed independently by domestic manufacturers, with relevant vendors including Casco, Tonghao Institute, Jiaoda Weilian, Lanzhou Dacheng, and Tieke Institute, mainly applied in centralized scheduling and traction power supply systems in railways.

Port Industry: In port enterprises, the PLC devices used are from the Rockwell brand, mainly applied in tipping, transportation belts, stacker-reclaimers, and loading operations.

Shipping Industry: In shipping enterprises, the controllers used are mainly from Kongsberg and SAM, applied in ship automation control systems.

Coal Chemical Industry: In coal chemical enterprises, the PLC devices used are primarily from Honeywell, Siemens, AB, GE, and Schneider, applied in auxiliary control systems of coal chemical processes, such as coal selection, coal preparation, desulfurization, and wastewater treatment.

03

DCS System

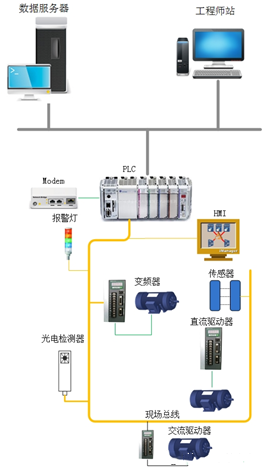

DCS (Distributed Control System) implements real-time control of all devices, alarm management, historical data and event collection and storage, report generation and storage, and process operations, mainly monitoring the DCS controllers and on-site processes in the production area (factory or workshop scope). The signals from on-site instruments are transmitted to the on-site cabinet room and central control room, with data transmission commonly using cables or optical fibers. The DCS system processes this data uniformly, performing all control, monitoring, alarm, and reporting operations in the central control room, as shown in the figure:

DCS systems are mainly used for continuous reaction process control, such as in power generation, chemical, and pharmaceutical industries. Foreign DCS products are mainly provided by manufacturers such as FOXBORO, ABB, Emerson, Siemens, Honeywell, and Yokogawa, while domestic DCS products are mainly provided by Shanghai Xinhua, Hualisi, Zhejiang University Control, Guodian Zhishen, and Zhejiang Weisheng.

Power Industry: Mainly used for the control of main and auxiliary machines in thermal power enterprises, with major brands including Siemens, ABB, Emerson, and domestic brands such as Guodian Zhishen and Xinhua.

Coal Chemical Industry: Mainly applied in process control of coal chemical processes, with major brands including Honeywell, Hualisi, and GE Xinhua.

04

SCADA System

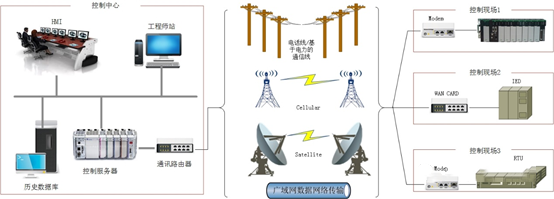

SCADA (Supervisory Control And Data Acquisition) system, which is a data acquisition and monitoring control system, has functions similar to DCS, but SCADA systems mainly monitor a relatively wide range (cross-plant or cross-region) of production equipment. The data transmission methods are diverse, and the delay requirements for data are not as strict as DCS, emphasizing centralized data collection, monitoring, and trend analysis, as shown in the figure below.

Coal Industry: SCADA systems in the coal mining sector are mainly used for comprehensive automation monitoring, primarily using WinCC, IFix, Intouch, PSI, pSpace, etc., while also centrally monitoring systems such as power supply, transportation, ventilation, drainage, and coal selection.

Power Industry: In wind power enterprises, it is mainly used for one-way collection of data from the central monitoring layer of wind farms for statistical analysis; as a major subsystem of the Energy Management System (EMS), it has advantages such as complete information, improved efficiency, accurate grasp of system operating status, accelerated decision-making, and rapid diagnosis of system fault states. The main SCADA system integrators are Huari Wind Power, Xinjiang Goldwind Technology, Guodian Nanzi, Siemens, Nari Technology, and Su Si Lan Energy. Thermal power enterprises also have similar SCADA monitoring systems, such as the NCS system for power plant substations, with main system integrators being Guodian Nari and Sifang Technology.

Rail Transit Industry: The traction power supply SCADA system is mainly used for remote monitoring of traction power supply equipment, with the main brand being Chengdu Jiaoda Guangming Co., Ltd. Other systems such as decentralized autonomous scheduling centralized systems and vehicle operation monitoring systems have similar functions and attributes to SCADA systems. The production and integration of related systems are mainly undertaken by domestic manufacturers.

Port Industry: The central control system of ports functions similarly to SCADA systems, mainly used for overall monitoring of port automation systems, involving monitoring and control of the status of transportation belts and other individual machines.

Shipping Industry: In shipping enterprises, the ship engine room automation system is similar to SCADA systems, including engine room monitoring and alarm systems, main engine remote control systems, and ship power station systems, with centralized monitoring of the engine room, main engine, and power station from the control room.

Coal Chemical Industry: SCADA systems are mainly applied in monitoring the power supply and distribution systems in coal chemical enterprises.

This article is sourced from: Intelligent Manufacturing Home

(All rights to the images and text belong to the original author, if there is any infringement, please inform us for deletion) Contact Us

Phone

:400-069-0308

: 601454066

: Shanxi Jinlu Tongchuang Information Technology Co., Ltd.

Address: Shanxi Jinlu Tongchuang Information Technology Co., Ltd.

Official Website

:http://sxjltc.com

Recommended Reading

Today’s Share—”Decoding Intelligent Manufacturing”【Holiday Notice】 Happy Labor Day!【New Arrival】 Millisecond Intelligent Control, Flexible and Efficient~ Modular Controller AMAX-5570E Launched!【Essentials】 What to Do When the Mainboard is Out of Power?

Since you’re here, please give us a thumbs up before you go~~~