MH Material Handling’s owners have always focused on innovation, both in production technology and in tools designed to enhance productivity. In this regard, additive manufacturing technology perfectly combines the advantages of both. After conducting some experiments with external suppliers, they decided to acquire a Mark Two™ printer for testing to help the engineering department explore new production opportunities. Positive results quickly became apparent, particularly in the ability to manufacture complex geometrical parts that traditional methods could not produce. Another benefit is the ability to produce parts in a shorter time frame, allowing tools to be put into use more quickly. Among the many developed applications, two are particularly noteworthy: facilitating the twisting of products along the motion axis and manufacturing blower nozzles.

Applications

The twisting system conveys packaged products through a conveyor belt into a specially designed channel, where they are rotated 90° or 180° before being output. Before the advent of 3D printing, these applications were typically achieved using five-axis milling machines to process solid plastic materials or by bending and forming steel rods mounted on custom frames. With the Markforged X7™ printer, MH Material Handling can print the twisting mechanism in two parts, allowing designers to modify the internal slide channel design at a very low cost to meet each customer’s needs. Compared to traditional manufacturing methods, MH Material Handling saves up to 80% in time and material costs using the X7 printer.

“With its continuous fiber-reinforced materials and excellent surface finish, the Markforged® 3D printer enables us to manufacture ready-to-use products with exceptional design flexibility and customization options. Now, the industrial challenges posed by our customers can be addressed more efficiently,” said Francesco Gastroni, Operations Manager at MH Material Handling.

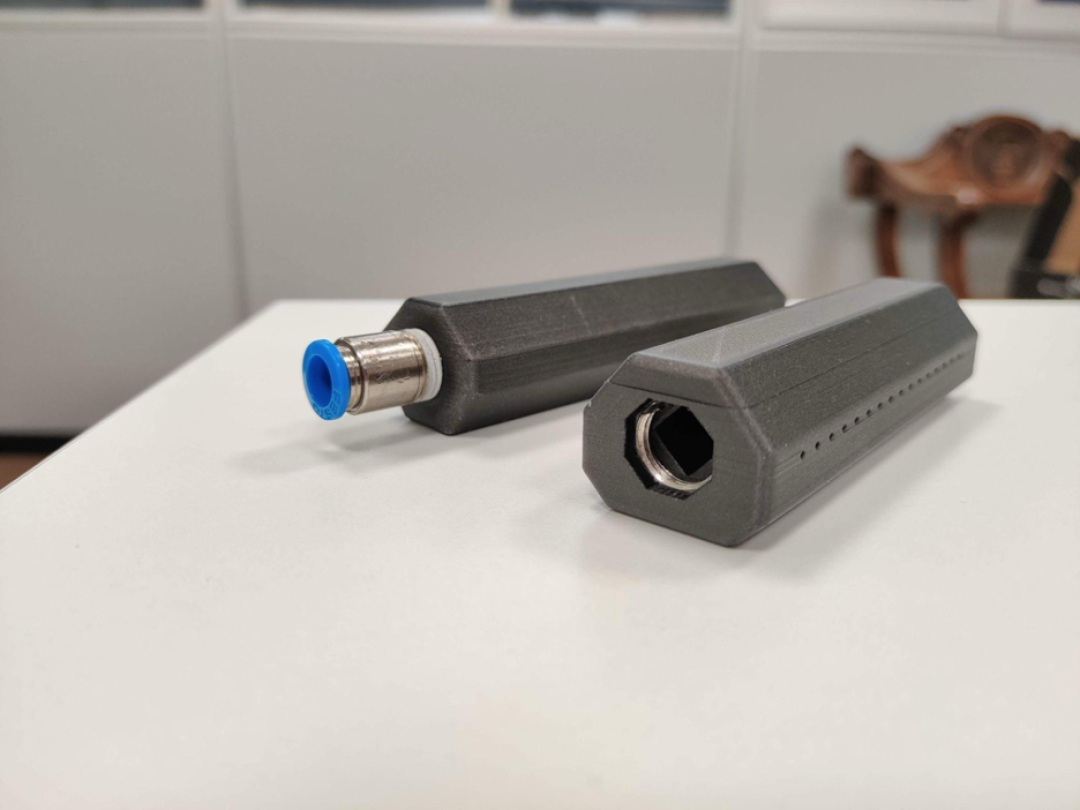

Regarding the blower nozzles, these nozzles typically come from product catalogs. “For customers with specific flow and pressure requirements, it is often difficult to find the exact size suitable for their application,” Francesco Gastroni explained. “Therefore, we use Digital Forge to optimize designs, enhancing the adaptability of components to perfectly configure them to meet the specific needs of the factory. In this case, the cost savings primarily come from time and the convenience of design, as there is no need to customize parts to fit the application.”

3DP FSS 3D Printing Full-Service Provider

Consultation Hotline|400-8626-086

Official Website|www.3dpways.com