Core Components of Touch Display Screens: FPC

This article introduces several common structures of the core component FPC in touch displays, along with their respective advantages and disadvantages for reference when selecting solutions.

FPC stands for Flexible Printed Circuit. It is widely used in various electronic products due to its excellent characteristics such as lightweight, thin thickness, and the ability to bend and fold freely. In the touch display industry, the main role of FPC is to connect and transmit signals between the display, chips, and motherboard.

1. Single-Sided Board

A. Standard Single-Sided Board: A single-sided circuit, usually used as a ribbon cable. The straight pull type circuit and ZIF type FPC function similarly to the same-sided FFC, but with a more flexible shape, circuit transition, and higher reliability compared to FFC. Disadvantage: More expensive than FFC.

B. Single-Sided Hollow Board

Mono LCD or COG products have more applications, while CTP has rarely used this structure. It uses thicker copper, typically above 1OZ.

Advantages: No connectors needed on the PCB, can be pressure welded, low cost.

Disadvantages: The hollow part’s circuit is prone to breakage, and after welding, it has no value for disassembly.

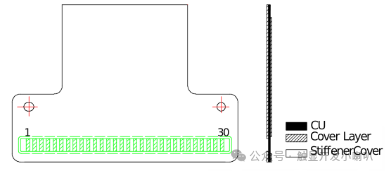

C. Single-Sided Opposite Board (Fake Double-Sided Board)

Single-layer circuit with windows on opposite sides. It can be used as a simple LCD or CTP ribbon cable (plug-in or soldered), and can also be reinforced on both ends for ribbon cable use. To some extent, it functions similarly to the opposite-sided FFC, with similar advantages and disadvantages.

(Pressure contact fingers and pin fingers on two sides)

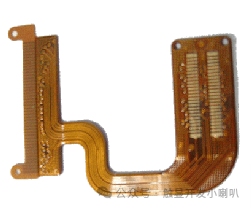

2. Multi-Layer Board

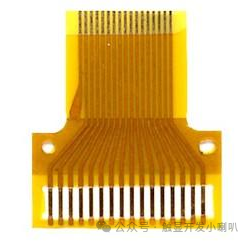

A. Standard Double-Sided Board: Two sides of copper foil, and through the plated through-hole process, the upper and lower layer circuits are connected. SMT can be done on both sides, offering a wider application and more economical cost compared to single-sided and multi-layer boards.

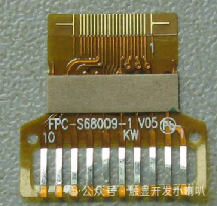

B. Double-Sided Hollow Board: Two sides of copper foil, hollow fingers pressure welded (finger tin plating process) or soldered (finger gold plating process), allowing for more complex circuit transitions.

Advantages and disadvantages are similar to single-sided hollow boards. Rarely used in CTP products.

C. Multi-Layer Board: A multi-layer board (Multilayer) consists of multiple single-sided (or double-sided) boards + pure adhesive + protective film laminated together, with drilled and plated copper connecting the conductive layers; the pure adhesive opening design provides good flexibility.

Advantages: More complex circuits can be designed in limited space, such as high-speed circuit ground layer separation design, etc.

Disadvantages: High cost.

D. Layered Board: Products applied to repeated bending, such as folding phones and laptops.

Only the bending area has layered circuits (removing adhesive layers and substrates), providing better flexibility.

Disadvantages: High cost.

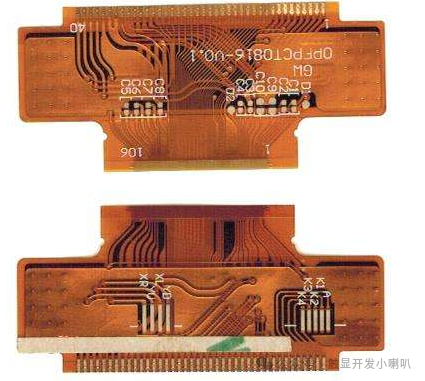

3. Flex-Rigid Board

Refers to a PCB that contains one or more rigid and flexible areas, composed of rigid and flexible boards laminated together through bonding layers.

Advantages: Combines the benefits of both flexible and rigid boards, allowing for three-dimensional assembly under different mounting conditions; features a thinner and smaller design, reducing the assembly size, weight, and wiring errors of electronic products.

Disadvantages: Complex design and manufacturing costs, expensive.

Note: If high-speed signals encounter debugging issues due to structural needs during multiple transitions, consider trying a flex-rigid board.

Follow me for more professional knowledge sharing.