Siemens All-in-One + TIA Portal + EPLAN Electrical Design Video Recordings for Sale at Low Prices!

Chuangkong Education Siemens All-in-One Course Introduction

1. Touch Screen Controls Inverter via PLC

1. Currently, in general situations, controlling an inverter typically requires communication between the PLC and the inverter to read the inverter’s information. The touch screen then communicates with the PLC to control the inverter’s start, stop, and monitor its operating frequency, current, voltage, and other functions.

2. The method of controlling the inverter via PLC with a touch screen: Connect the touch screen to the PLC’s programming port, then expand a 485 interface on the PLC, allowing communication between the PLC and the inverter via 485. These two communications can operate independently, and corresponding programs should be written as needed to allow the touch screen to change the inverter’s frequency through the PLC.

2. Direct Control of Inverter by Touch Screen without PLC

To operate the inverter, two conditions must be met: a start signal and a frequency signal. Therefore, the essence of controlling the inverter with a touch screen is to implement the start signal and frequency signal for the inverter on the touch screen.

The communication connection between the touch screen and the inverter means that the touch screen acts as the master station while the inverter is the slave station to establish a connection.

Inverters are equipped with RS485 interfaces that support the MODBUS protocol. Thus, we only need to establish a MODBUS slave in the touch screen. Below, we will demonstrate a practical case of how to directly control the inverter with the touch screen, including methods and steps.

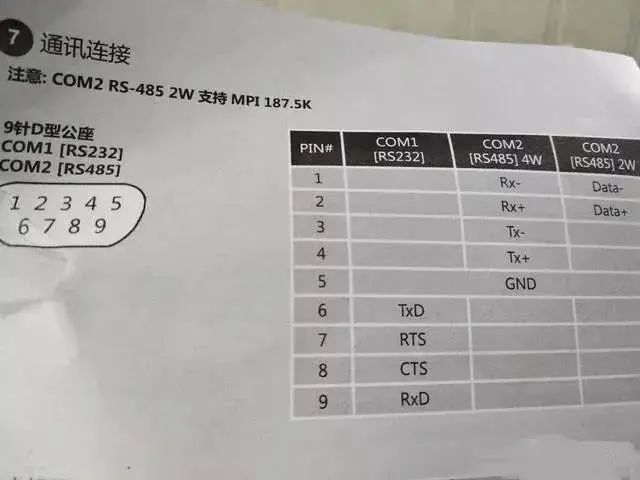

3. Communication Ports Between Touch Screen and Inverter

1. Delta Inverter’s RS485 Communication Port

2. Wecon Touch Screen’s Communication Port

3. Here we need to connect the RS485 terminals of the touch screen and the inverter with wires.

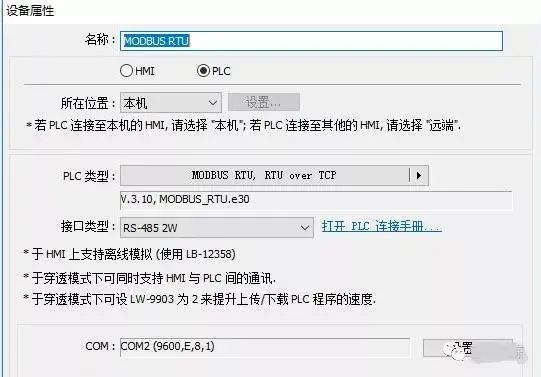

4. Communication Settings for Touch Screen and Inverter Control

1. Set the inverter’s operation command and frequency command to use MODBUS communication, with the communication address set to 1, baud rate at 9600, and data parity set to (E, 8, 1) even parity for RTU.

2. Set the touch screen’s communication parameters to: MODBUS RTU format, 9600, E, 8, 1.

5. Steps to Directly Control Inverter with Touch Screen

1. Create a communication cable to connect the touch screen and the inverter.

2. Set the communication parameters for the inverter.

3. Set the communication parameters for the touch screen.

4. Create the operation interface on the touch screen.

5. Wiring and debugging of the master station controlling the slave station.

(Content sourced from the internet, copyright belongs to the original author)

Disclaimer: If there are copyright issues, please contact for deletion!Neither individuals nor organizations bear related legal responsibilities.

Siemens All-in-One + TIA Portal + EPLAN Electrical Design Video Recordings for Sale at Low Prices!

Chuangkong Education Siemens All-in-One Course Introduction