In recent years, with the rapid development and popularization of electronic technology products, various display technologies have shone brightly in different application scenarios. Among them, LCD technology has gained market favor due to its strong color performance, high brightness, long lifespan, and cost-effectiveness, becoming the dominant display technology.

It is estimated that by 2025, mainland China will account for about 72% of the global LCD panel production capacity. The new type of display photoresist, which plays a key role in driving product upgrades and performance improvements, is expected to reach a global market size of $2.115 billion by 2030, with a compound annual growth rate (CAGR) of 3.77% (according to QY Research statistics and forecasts).

According to information from Founder Securities, in the components of LCDs, color filters are key devices that enable color display, accounting for about 14-16% of the total cost of LCD panels. Colored/black photoresist is a core material, making up about 27% of the cost of color filters. However, over 70% of the market is still dominated by foreign photoresist manufacturers, and the road ahead remains challenging.

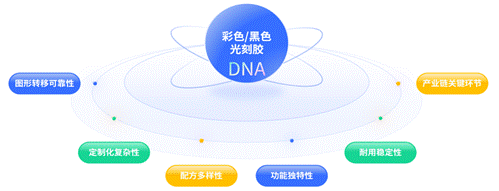

Colored/black photoresist, the DNA of new display panel performance

On October 2, 1925, “the father of television” Baird successfully manufactured the first mechanical television capable of transmitting images. Since then, in the century-long development process, the evolution of display panels has undergone continuous technological iteration. On one hand, the pursuit of display performance has evolved from the initial “capable of imaging” to high standards of “color display, high definition,” and even “true image restoration”; on the other hand, technological advancements have made displays ubiquitous as interactive windows, needing to meet diverse application requirements.

It is the emergence of high-resolution, high-contrast, and high-transmittance colored/black display photoresists that allows LCD display devices to provide better visual enjoyment, meet diverse application needs, and subsequently promote the development of new-generation display technologies such as OLED and quantum dot displays.

The role of colored/black photoresist in display panel manufacturing is not just as a simple material; its quality, like DNA in biological organisms, determines the final performance of the display panel, directly tracing back to depict the panel’s “life blueprint” throughout the manufacturing process.

Colored/black photoresist determines key performance of LCD panels like DNA:

In terms of color performance,colored photoresist has excellent color performance, with only RGB three colors; by adjusting the brightness of each color from 0 to 255, it can achieve approximately 16 million possible color combinations; the high transmittance of colored photoresist can enhance the brightness and energy efficiency of the display panel, making the images more vibrant and displaying a colorful world; different display panels require different performance photoresists to meet specific manufacturing requirements, exhibiting highly customizable characteristics.

In terms of high precision and high contrast,the high precision of black photoresist directly determines the size and spacing of pixels on the display panel, improving resolution; a high OD value can enhance contrast. With the continuous advancement of display technology, the performance requirements for photoresists are also constantly increasing. High-resolution display panels require high-resolution photoresists to achieve finer pattern transfers.

Colored/black photoresist ensures the consistency and stability of “genetic” information like DNA:

In terms of pattern transfer,colored/black photoresist must accurately transfer the fine graphics from the mask onto the substrate during the photolithography process to ensure consistency and reliability. This imposes high demands on key characteristics such as photosensitivity, resolution, contrast, adhesion, and chemical stability of colored/black photoresist.

In terms of durability,colored/black photoresist remains as functional material within the display devices, needing to maintain specific optical characteristics while accompanying the panel’s lifecycle. Therefore, it has stringent requirements for resistance to chemical corrosion, high and low temperatures, light exposure, and drops, necessitating robust parameter specifications to meet usage standards.

It can be said that colored/black photoresist, as the DNA of new display panels, plays a crucial role in the key performance of display panels. Additionally, colored/black photoresist is one of the key factors influencing the price and competitiveness of new display panels, making it an indispensable “gem on the crown” of the new display industry.

New display photoresist, urgent industrial demand

With the new display industry shifting to mainland China, total investment in the domestic display industry has reached trillions of yuan. Companies such as BOE, TCL Huaxing Optoelectronics, and HKC are becoming dominant players in the global panel market, with significant achievements in the domestication of new display panels and a prosperous development landscape. Meanwhile, there is an urgent demand from the industry and panel manufacturers for stable supply and technological improvements of upstream materials.

According to Hu Chunming, Executive Deputy Secretary-General of the LCD Branch of the China Optical Optoelectronic Industry Association, the development of China’s display panel industry is rapid, with most related raw materials now domestically supplied, but the domestication rate of colored/black photoresist remains very low. The overall market size for photoresists for new displays is less than 10 billion, yet it is tightly linked to the industrial development with over a trillion total investment.

Distribution map of panel production lines in mainland China (Image source: LCD Network)

As photoresists are industries intensive in capital, technology, and talent, and as colored/black photoresist in China has only just started in the past decade compared to decades of development abroad, the industry as a whole still faces multiple challenges. These highly customizable products not only have high technical barriers but also face many pain points in industry development. According to Lu Jin, Executive Deputy Secretary-General of the China Electronic Materials Industry Association, industry statistics show that domestic photoresist manufacturers generally have small revenue scales and high R&D investment; multiple links such as supporting raw materials and equipment are still highly dependent on imports; the collaboration verification cycle between upstream and downstream is long and costly; there is a notable shortage of high-end R&D and management personnel, and the cost of cultivating talent independently is high and lengthy, all of which are difficulties that photoresist companies find hard to overcome in a short time. However, despite this, a number of excellent domestic display photoresist manufacturers have emerged in recent years, such as Xinyi New Materials and Yake Technology (which has acquired foreign companies) achieving good results in black/colored photoresists.

China is advancing with unprecedented determination and strength to promote the vigorous development of new productive forces, striving to gain an edge in global technological competition, with the new materials industry being strategic, foundational, and pioneering. Since the 12th Five-Year Plan, China has introduced several policy documents to comprehensively deploy in the materials field, and during the 13th and 14th Five-Year Plans, national policies and guidelines have been issued, with new display photoresists receiving significant attention and support from various levels of government, encouraging development and innovation in the photoresist industry. The Ministry of Industry and Information Technology and the Ministry of Finance have issued policies such as the “National New Materials Industry Resource Sharing Platform Construction Plan” and “Guiding Opinions on Expanding Strategic Emerging Industry Investment to Cultivate and Strengthen New Growth Points and Growth Poles,” requiring breakthroughs in fields such as photoresists, thus providing a clear and broad market outlook for the development of the new display photoresist industry.

Against this backdrop, colored/black photoresist, as a key material as important as DNA in display panel manufacturing, is accelerating its domestication process, not only to meet the urgent needs of the rapidly developing domestic industry but also to build a secure and controllable supply chain system.