LCD and OLED are common micro-display solutions, with different structures and advantages. According to the different display technologies, displays can be divided into LCD displays made of liquid crystals and self-emissive OLED displays made of organic light-emitting diodes.

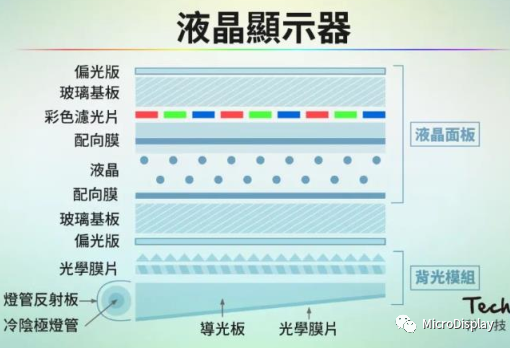

LCD consists of a layer of liquid crystal sandwiched between two glass substrates, where the upper glass substrate is a color filter and the lower glass is embedded with transistors. When current passes through the transistors, the electric field changes the rotational arrangement of the liquid crystal molecules, altering the degree of light rotation passing through and projecting different colors on the color filter.

OLED is made by creating an organic light-emitting layer on indium tin oxide glass, covered by a layer of low work function metal electrodes. Driven by external voltage, holes from the anode combine with electrons from the cathode in the light-emitting layer, generating energy and emitting light, forming the RGB primary colors due to material characteristics.

Without the presence of a liquid crystal layer and always-on backlight, OLED displays are thinner and consume less power; moreover, because OLED can individually control the brightness and on-off state of each sub-pixel, it achieves pixel-level backlighting, resulting in higher contrast. However, organic materials are prone to oxidation, leading to a relatively short lifespan for OLEDs and lower peak brightness. In addition to LCD and LED, there is also DLP digital light processing technology, with developers and major suppliers being German instruments.

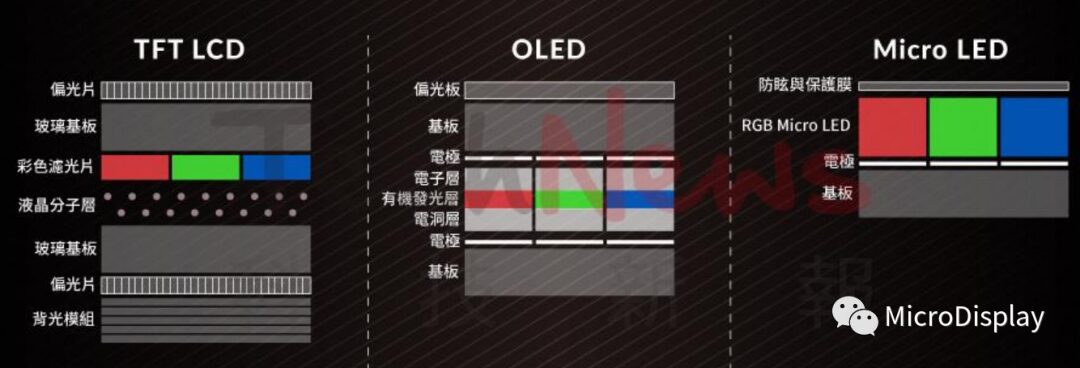

Comparison of the structures of LCD, OLED, and Micro-LED

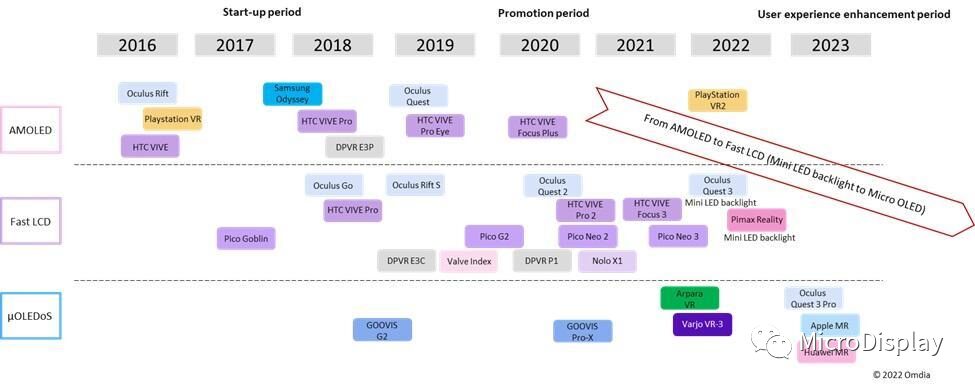

Evolution Direction of XR Display Solutions: AMOLED→Fast LCD→Mini-LED Backlight Fast LCD→Silicon-Based OLED→Micro-LED

Evolution of XR Displays

In XR headsets, Apple’s Vision Pro is the first mainstream product equipped with a silicon-based OLED screen, achieving a resolution of 4K per eye and 8K for both eyes. Assuming its FOV is around 100°, the corresponding PPD is about 40. Currently, mainstream products like PICO4 and Quest2 have display resolutions around 2K, with an FOV of about 100°, corresponding to a PPD of 20, leading to a certain degree of “screen door effect.” The approximately 2 times higher PPD of Apple’s Vision Pro is expected to achieve near “retina” level clarity, significantly reducing pixelation and enhancing the realism of rendered images in real-world scenes, thus providing a seamless virtual-real fusion experience.

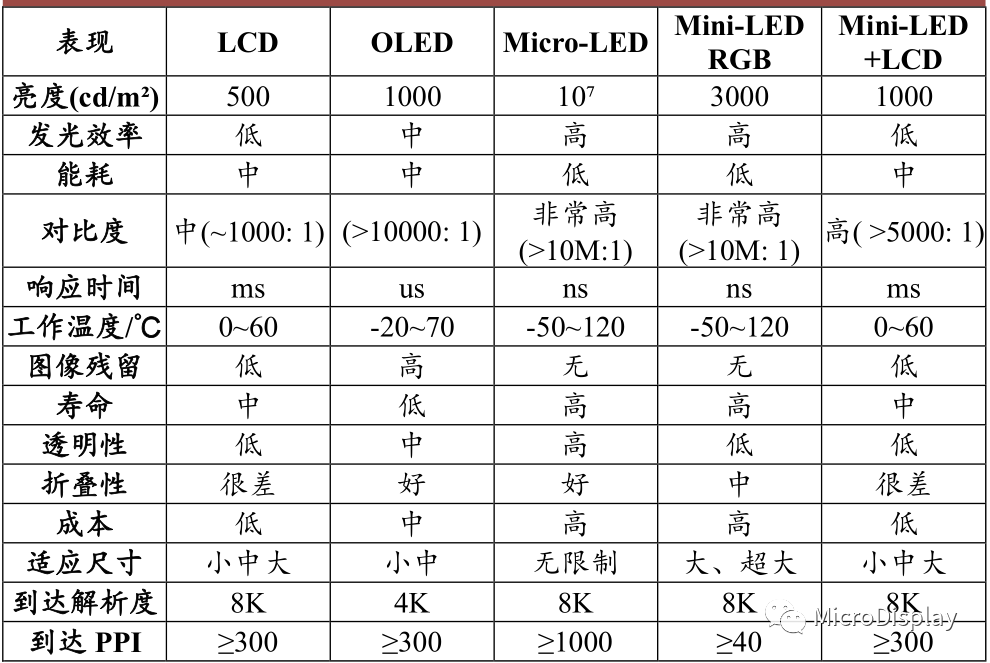

Comparison of Display Technologies

Therefore, Micro-OLED is considered the next generation XR display solution due to its easier realization of small size/high resolution. Traditional LED displays have larger chips with limited arrangement density, making it difficult to achieve higher resolutions.OLED has reduced chip size to some extent while offering better color performance, with early VR products using AMOLED as standard for high-end products.

Traditional LCD has slower electric field response and lower refresh rates. Fast LCD (fast response liquid crystal) combines ultra-fast driving technology with ferroelectric liquid crystal materials, significantly increasing screen refresh rates and being widely used from 2018 to 2021 due to its lower cost.

Mini-LED backlight technology further enhances this by dividing the original backlight panel into several independently controllable brightness zones, improving the contrast between light and dark in the image and making it easier to achieve higher-end HDR display effects. However, Mini-LED backlight requires simultaneous control of the backlight layer and liquid crystal layer, which poses higher technical challenges; and due to the presence of shared backlight points, there is a certain degree of motion blur in the image.

Silicon-based OLED (also known as Micro OLED) uses a CMOS substrate, achieving pixel densities (over 3000 PPI) that ordinary OLEDs find difficult to reach, helping XR products deliver a clearer experience while also being lighter, consuming less power, self-emissive, and having high luminous efficiency. Currently, silicon-based OLED has entered the mass production phase, and before its large-scale commercialization, Mini-LED backlight Fast LCD is expected to become a transitional solution.

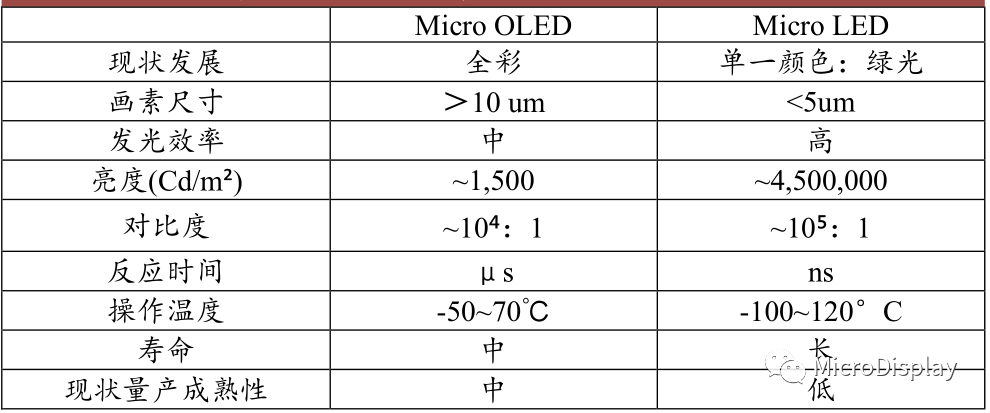

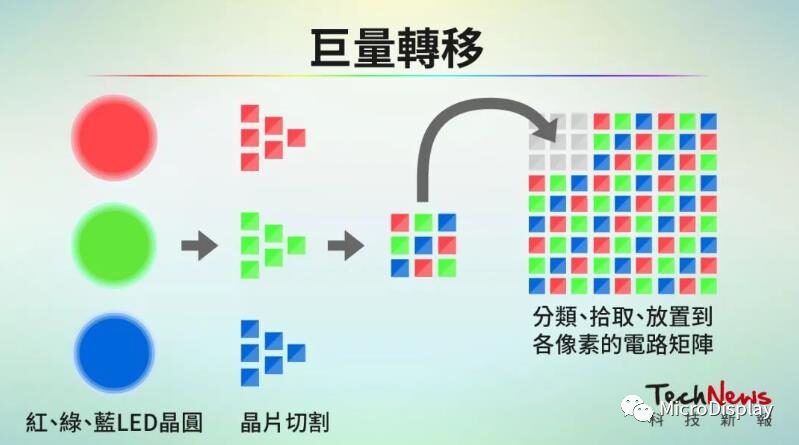

Micro-LED may be the ultimate solution for XR. Micro-LED involves arraying and miniaturizing traditional LEDs and transferring them in bulk to a circuit substrate, forming high-density arrangements and ultra-small spacing LEDs, aiming to individually drive inorganic self-emissive (self-emissive) displays, extending product life.Micro LED displays do not require large substrates for photolithography or evaporation, nor do they require complex processes for color conversion and preventing brightness degradation. In terms of contrast, responsiveness, lifespan, and energy saving, Micro LED significantly outperforms Micro OLED.

Silicon-Based OLED in Early Market Stage

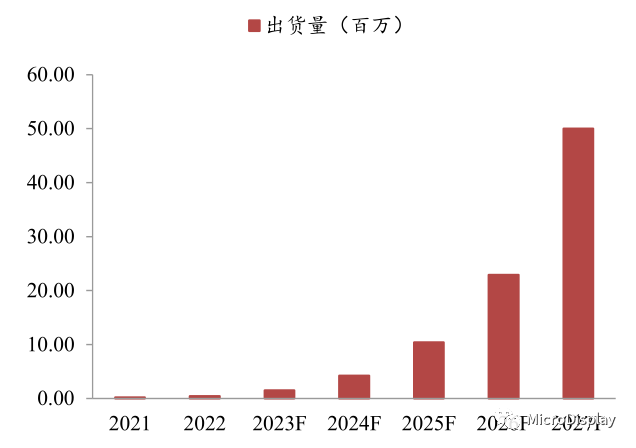

Silicon-based OLED in the XR industry has not yet become mainstream, with a currently small market size and shipment volume, but with great future development potential.

Global shipments of silicon-based OLED for XR headsets

According to Qunzhi Consulting statistics, in 2022, Fast-LCD accounted for as much as 94% of global XR headset panel shipments. Silicon-based OLED accounted for about 4%, mainly for AR glasses with lower size requirements. In 2022, global shipments of silicon-based OLED panels for XR headsets were approximately 430,000 units, doubling year-on-year, mainly driven by shipments in the consumer AR headset market.

In 2023, with Apple set to release MR headsets equipped with silicon-based OLED and the consumer AR headset market continuing to grow, silicon-based OLED shipments are expected to maintain rapid growth. Qunzhi Consulting estimates that global shipments of silicon-based OLED panels for XR headsets are expected to exceed 1.5 million units in 2023, achieving over 2 times growth.

Fast-LCD Remains the Mainstream VR Solution

Among mainstream VR headsets, Fast-LCD remains the most mainstream display technology, such as Pico 4, Pico 4 Pro, Meta Quest Pro, and AjnaXR released in January 2023. The Panasonic VR glasses MaganeX, expected to be released in the second half of 2023, and Apple’s first MR headset are expected to adopt Micro-OLED display technology.

Display technologies of mainstream VR products

Micro-LED May Be the Endgame for XR Display Technology

Micro-LED involves arraying and miniaturizing traditional LEDs and transferring them in bulk to a circuit substrate, forming high-density arrangements and ultra-small spacing LEDs, aiming to individually drive inorganic self-emissive (self-emissive) displays, extending product life.

LED chips have been reduced from the 1000mm level down to the 100mm level for Mini-LED (RGB), and further down to the 10mm level for Micro-LED. Micro LED displays do not require large substrates for photolithography or evaporation, nor do they require complex processes for color conversion and preventing brightness degradation. In terms of contrast, responsiveness, lifespan, and energy saving, Micro LED significantly outperforms Micro OLED.

Considering the limitations of optical waveguide components in transparent AR smart glasses, which result in light efficiency being difficult to break through the 1% limit, Micro LED is an excellent option for micro-display light engine technology in the medium to long term and may become the future development direction for XR displays.

Comparison of Micro OLED and Micro LED Light Engines

However, achieving high yield and low-cost mass transfer is a technical challenge for Micro-LED. TrendForce points out that the key to enhancing Micro LED competitiveness lies in first minimizing chip costs. Compared to the currently mainstream 6-inch production lines, using 8-inch production lines for Micro LED production would make chip costs more economical. Second, solid semiconductor technology is needed as a backing for mass production, providing clients with a complete solution from chip to transfer, then to testing and maintenance.

Shenzhen Longgang Intelligent Audiovisual Research Institute